Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

197 results about "Toluenediamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toluenediamine may refer to these isomeric organic compounds with the formula C₆H₃(NH₂)₂: 2,4-Diaminotoluene, precursor to toluene diisocyanate and azo dye. 2,6-Diaminotoluene, a common impurity in 2,4-diaminotoluene 2,5-Diaminotoluene, precursor to hair dyes.

Polyimide film, and method for production thereof

InactiveUS20090197068A1Increase production capacityImprove productivitySynthetic resin layered productsPrinted circuit aspectsToluenediamineCarboxylic acid

Disclosed is a polyimide film prepared from an aromatic tetracarboxylic acid component consisting essentially of 3,3′,4,4′-biphenyltetracarboxylic dianhydride and an aromatic diamine component consisting essentially of not less than 65 mol phenylenediamine % but less than 97 mol % of p-phenylenediamine and not less than 3 mol % but less than 35 mol % of 2,4-toluenediamine.

Owner:UBE IND LTD

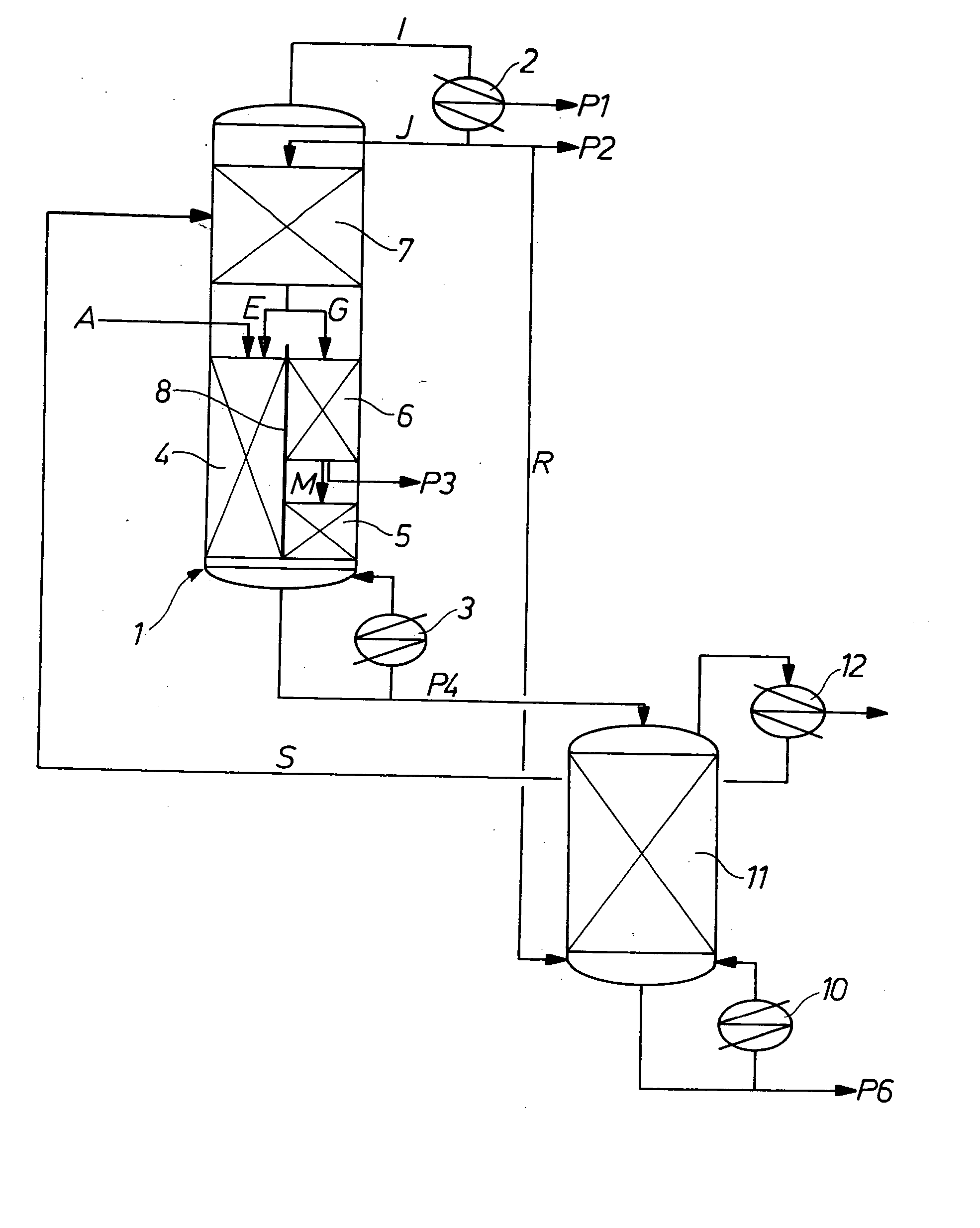

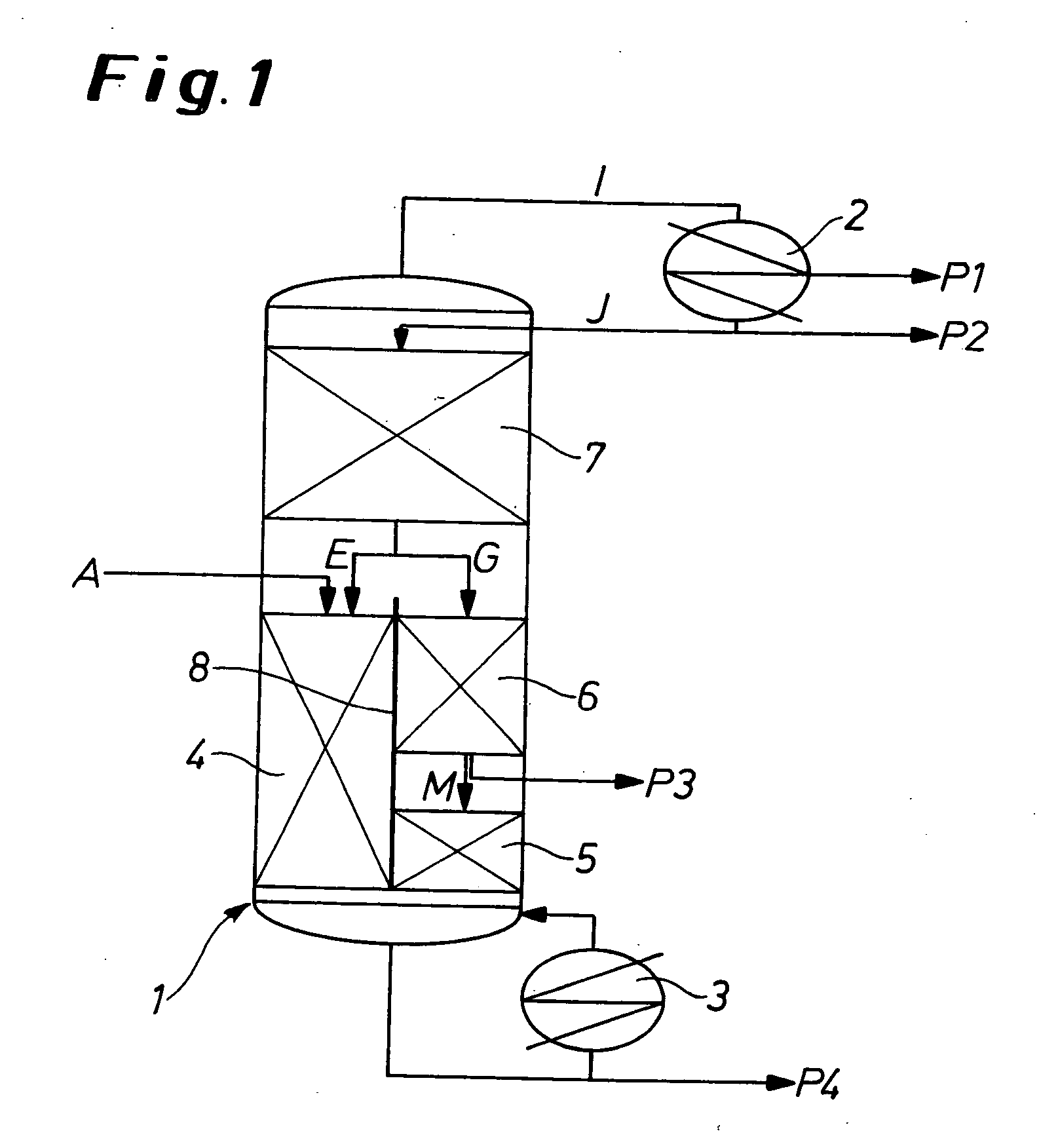

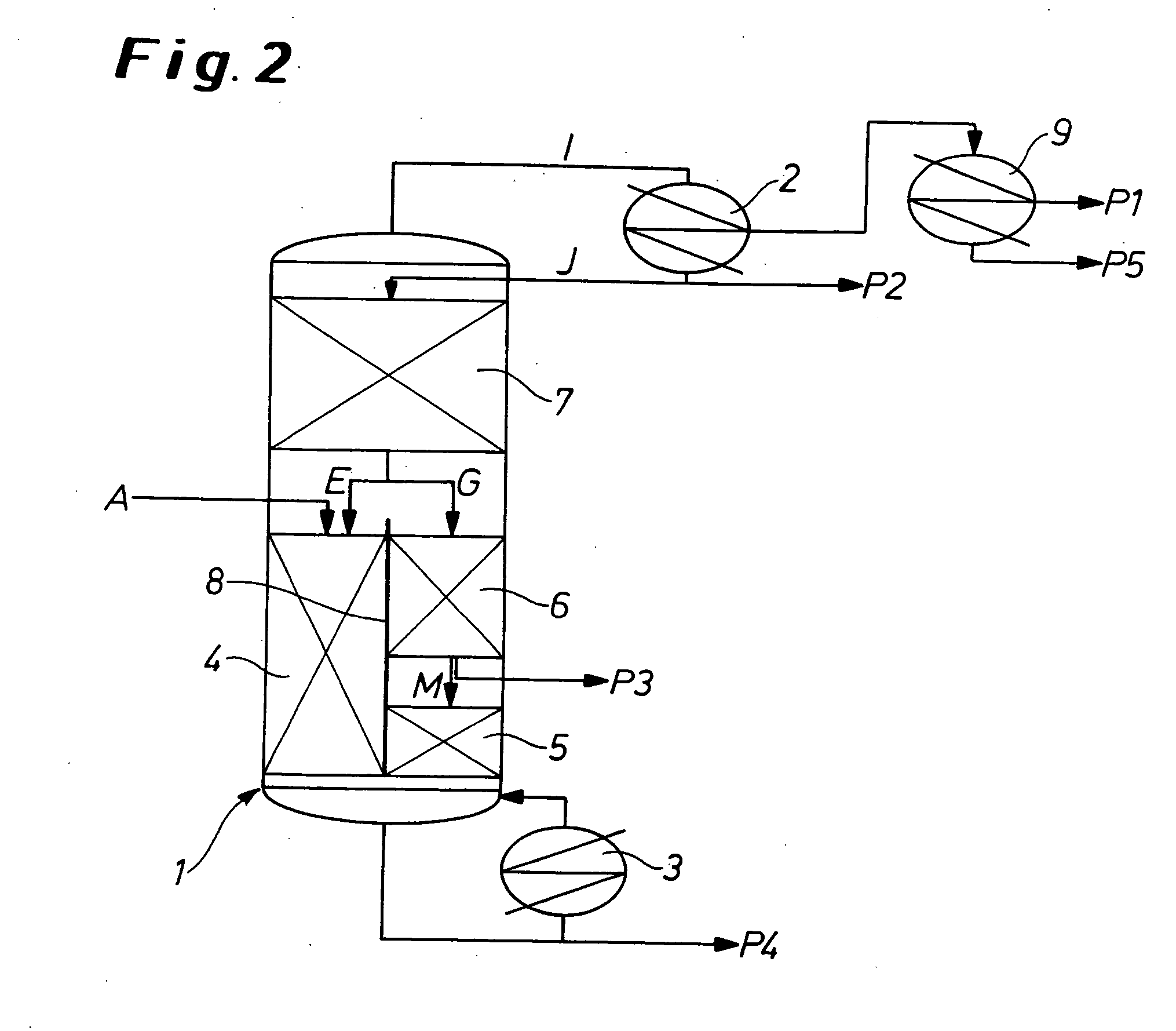

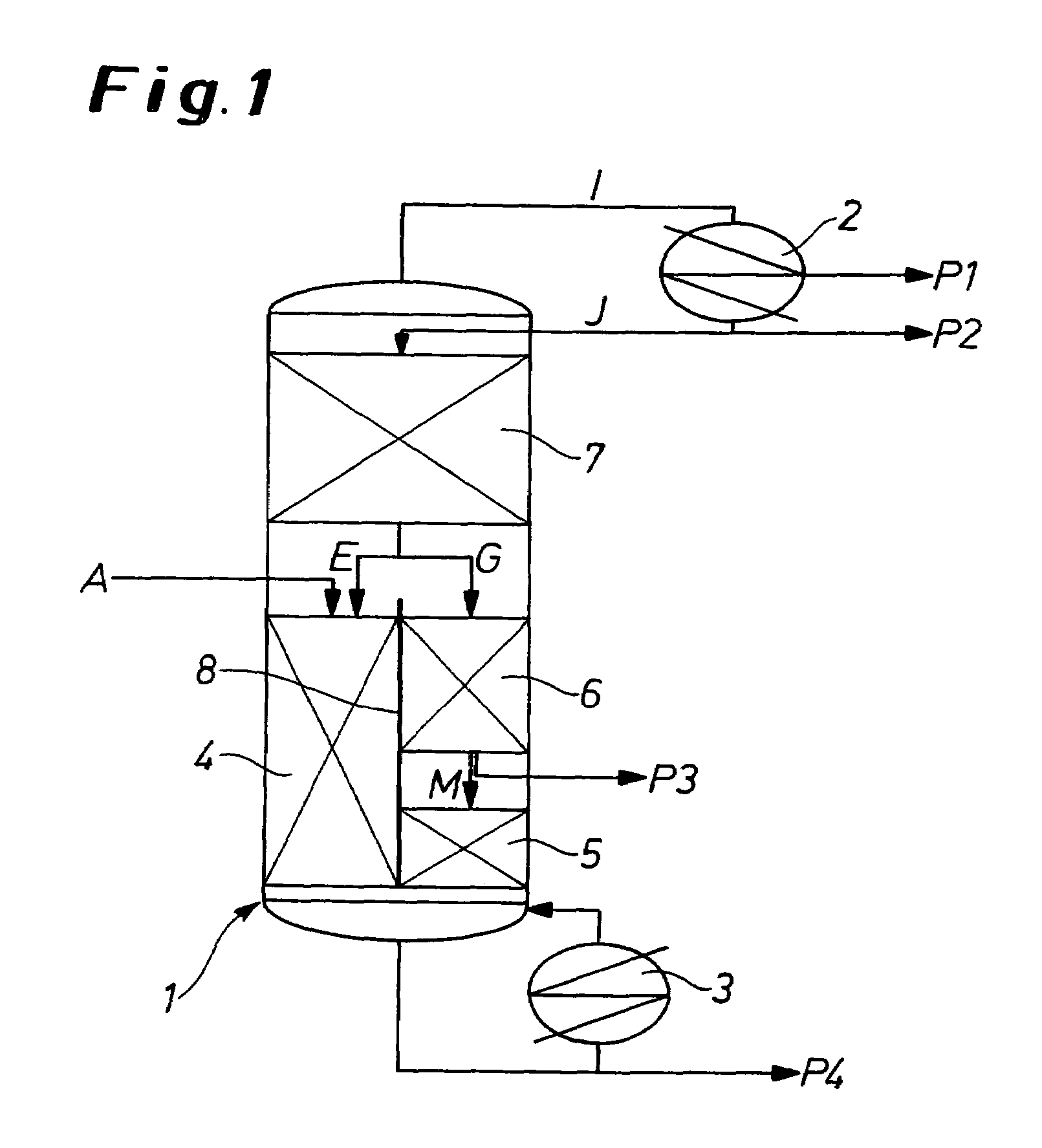

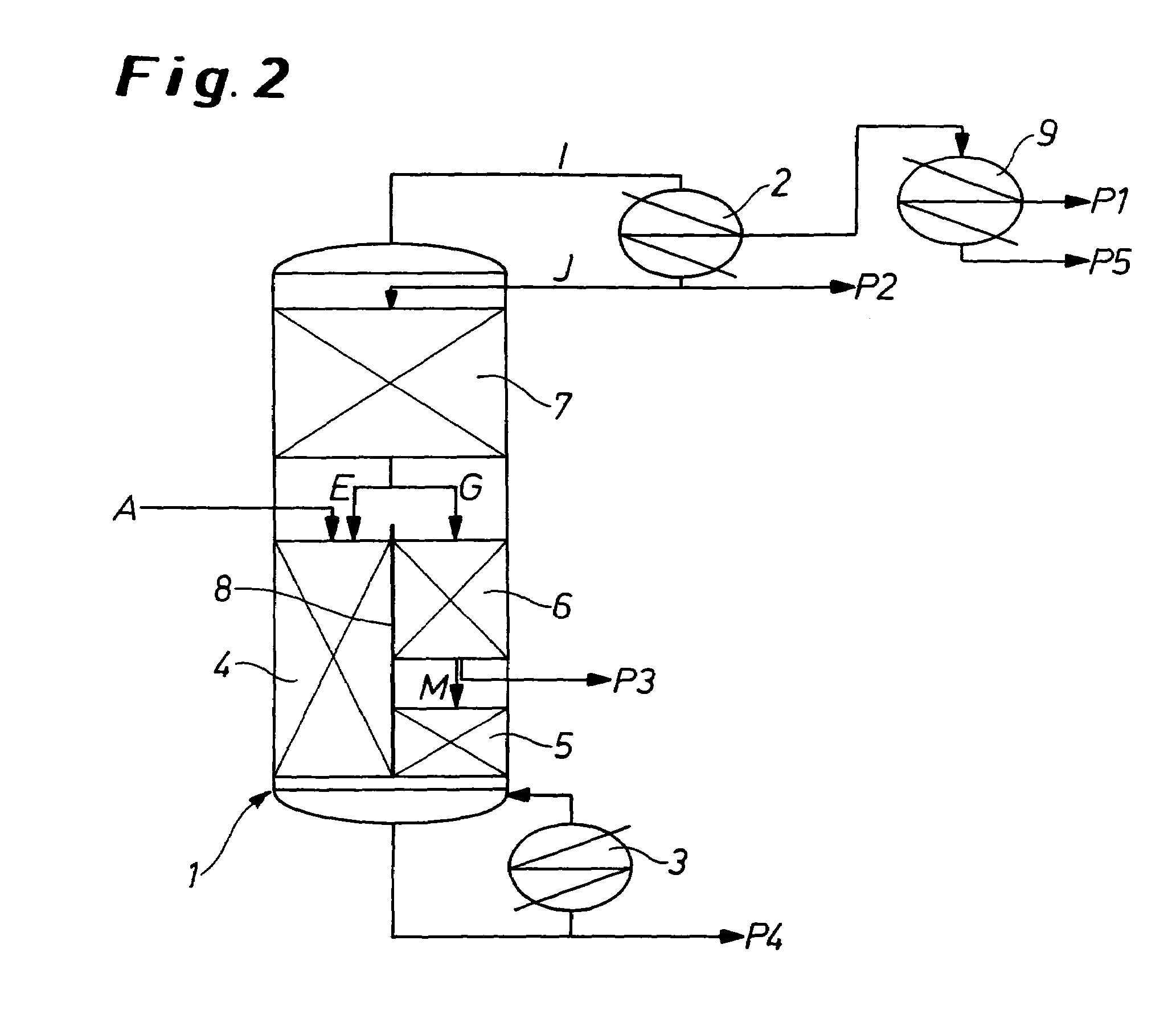

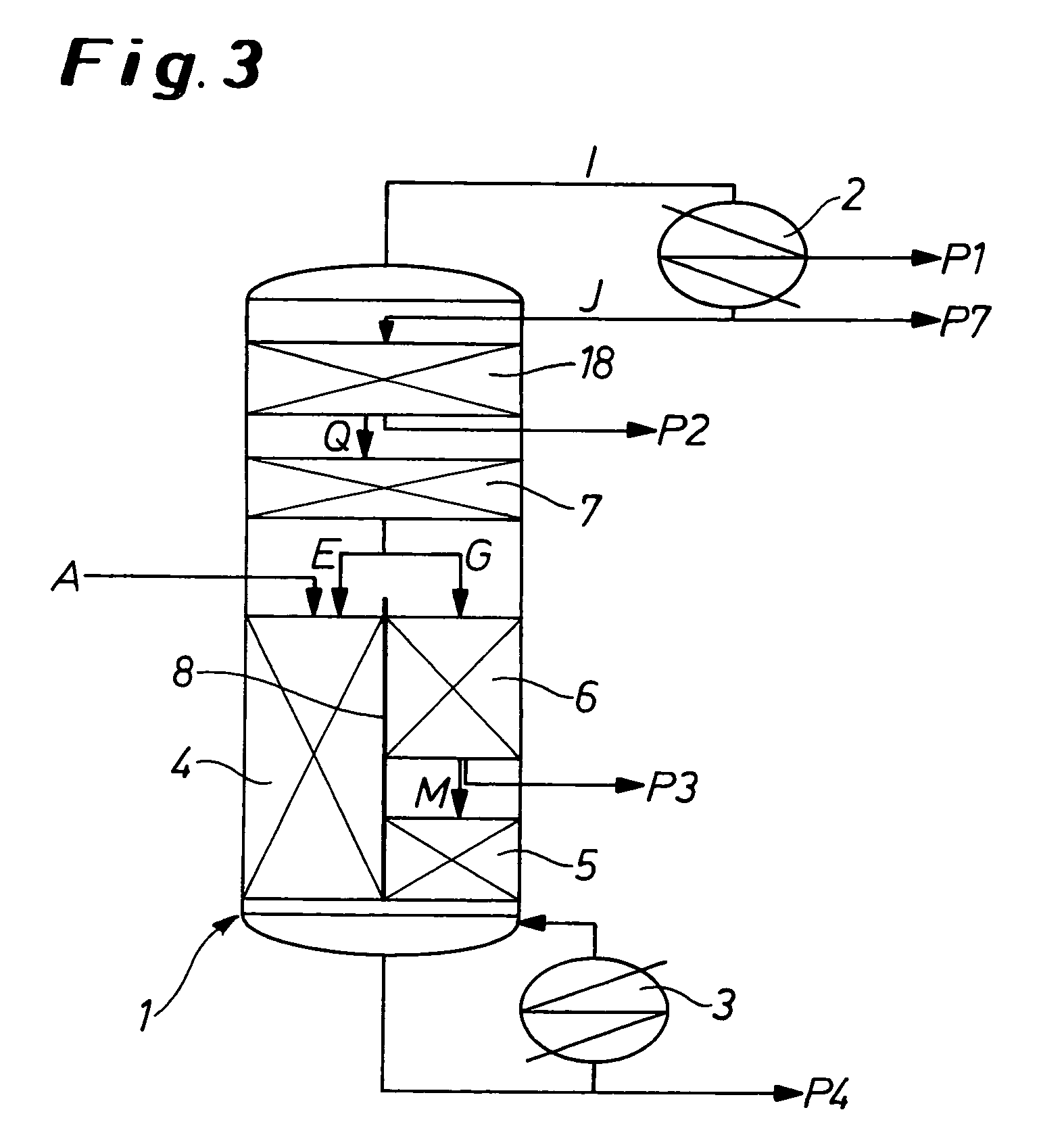

Process for the preparation of toluenediamine

InactiveUS20070015940A1Minimizing m-TDA lossAdd equipmentIsocyanic acid derivatives preparationOrganic compound preparationDistillationHydrogenation reaction

Toluenediamine is produced and separated from by-products of the reaction by: a) hydrogenating dinitrotoluene in the presence of a catalyst, b) separating the catalyst, water and optionally solvent from the hydrogenation reaction mixture to give crude toluenediamine, and c) separating by distillation the crude toluenediamine in a separating wall column into at least four product streams P1, P2, P3 and P4. The product stream P1 is a stream containing low boilers. The product stream P2 is a stream containing o-toluenediamine. The product stream P3 is a stream containing m-toluenediamine. The product stream P4 is a stream containing high boilers and m-toluenediamine.

Owner:COVESTRO DEUTSCHLAND AG

Semi-rigid polyurethane foams and processes for their production and use

InactiveUS20130209778A1Improve propertiesReduced compressive strengthLayered productsThin material handlingPolyolToluenediamine

Semi-rigid polyurethane foams having a density of 90 to 180 kg / m3 and a compressive strength of 20 to 95 kPa are produced by reacting a polyisocyanate with an isocyanate-reactive component that includes an o-toluenediamine initiated polyether polyol. These foams are particularly useful as composites for automotive interior components.

Owner:COVESTRO DEUTSCHLAND AG

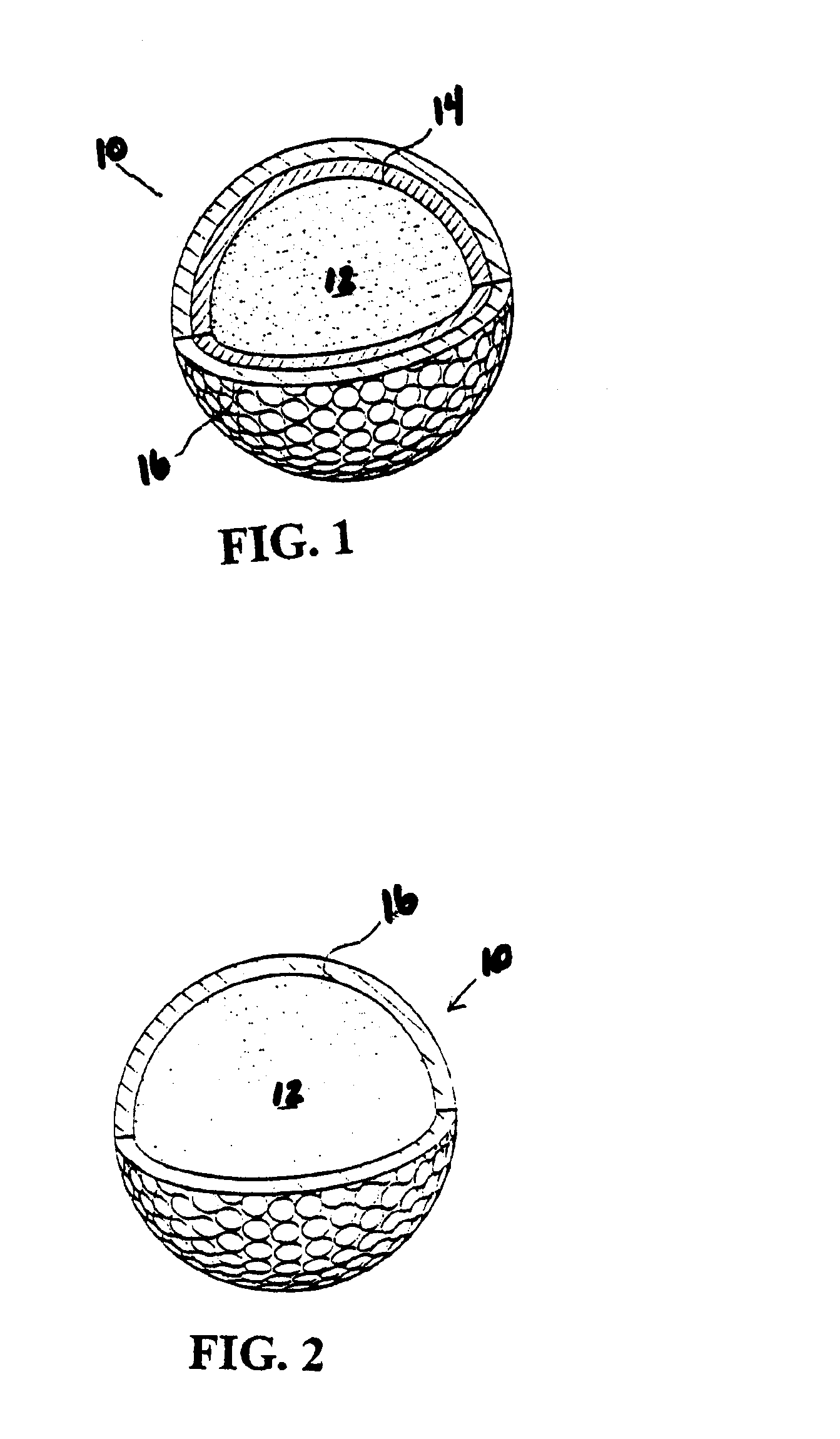

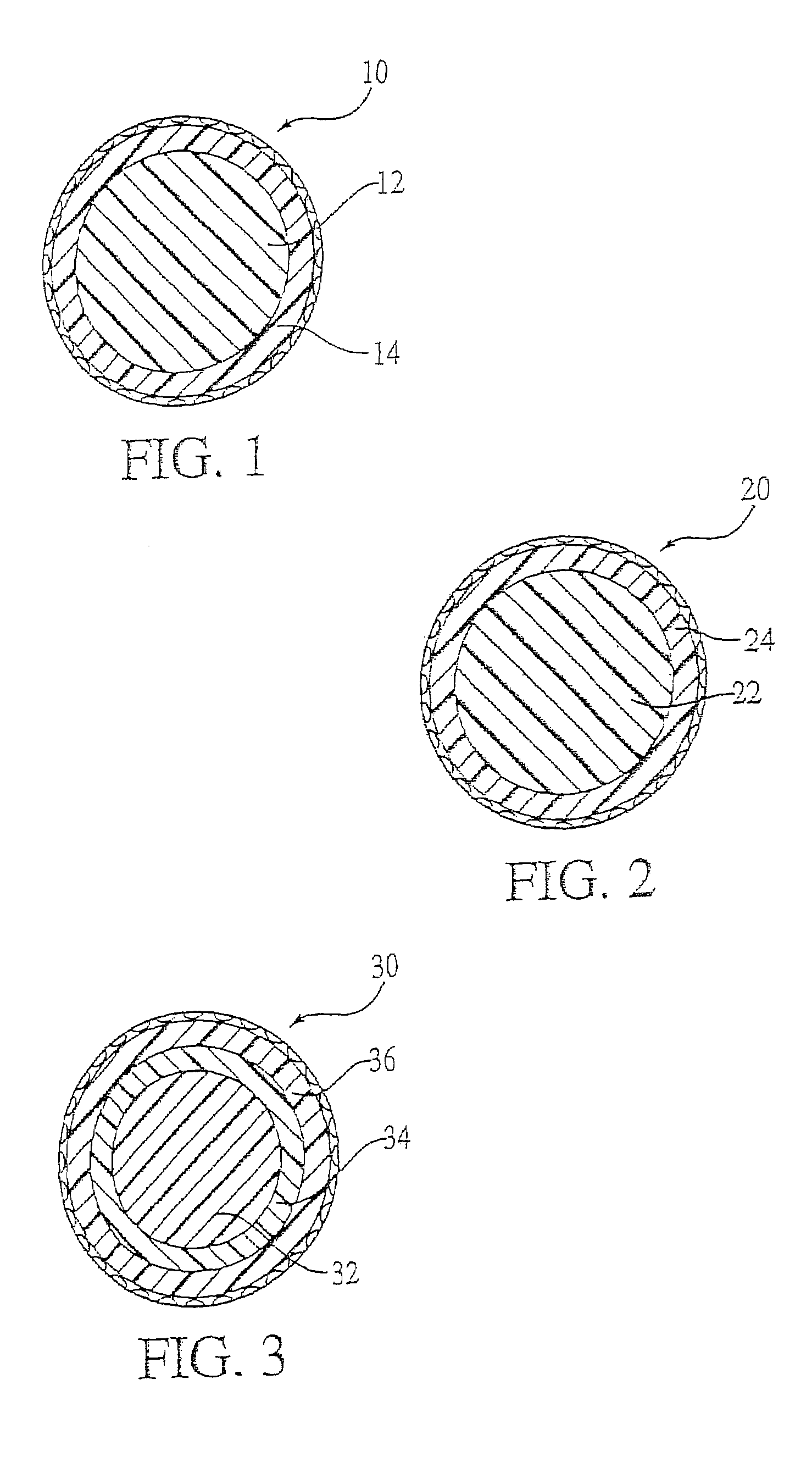

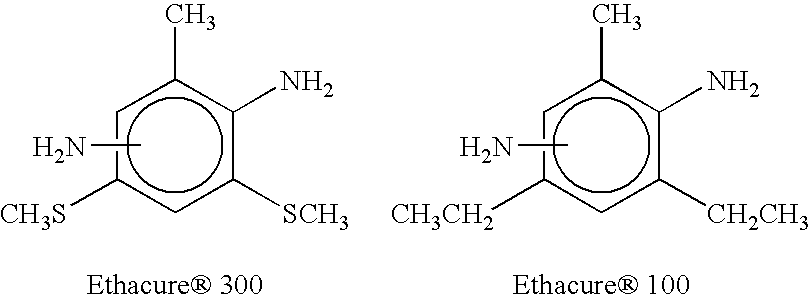

Golf ball having a polyurethane cover

A golf ball with a cover composed of a thermosetting polyurethane that has increased resistance to yellowing is disclosed herein. The golf ball of the present invention is able to accomplish this by providing a cover composed of a thermosetting polyurethane material formed from a polyurethane prepolymer and a curative composed of 20 to 40 parts 4,4′-methylenebis-(3-chloro,2,6-diethyl)-aniline and 80 to 60 parts diethyl 2,4-toluenediamine. The cover is preferably formed over a core and boundary layer.

Owner:CALLAWAY GOLF CO

Reaction injection material for a golf ball

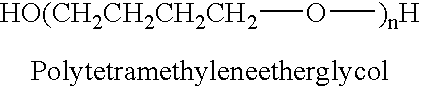

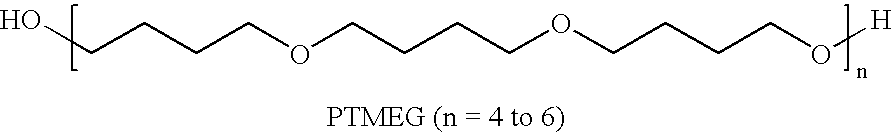

A golf ball having a layer composed of a polyurethane / polyurea material formed from reaction injection molding a polyol component and an isocyanate component. The polyol component preferably comprises a polytetramethylene ether glycol having a molecular weight of approximately 1000 and a 3,5-diethyl-2,4 toluenediamine. The layer is preferably a cover layer having a thickness ranging from 0.010 inch to 0.025 inch.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Zeolitic adsorbents, their process of preparation and their uses

The present invention relates to zeolitic adsorbents based on small agglomerated crystals of zeolite X comprising barium, combining optimum properties in terms of selectivity and of mechanical strength.These adsorbents have applications in the separation of fractions of aromatic C8 isomers and in particular xylenes, in the separation of substituted toluene isomers, such as nitrotoluene, diethyltoluene or toluenediamine, in the separation of cresols and in the separation of polyhydric alcohols, such as sugars.

Owner:ARKEMA FRANCE SA +1

Hard polyurethane foam composite, foam preparation method and thermal insulation component

The invention relates to a hard polyurethane foam composite which comprises the following components: (a) a polyhydric alcohol composite comprising a polyether polyol polymerized from sucrose and oxidized olefin, a polyether polyol polymerized from sorbitol, glycerinum and oxidized olefin, an amine polyether polyol polymerized from toluenediamine and the oxidized olefin, a polyether polyol polymerized from glycerinum and the oxidized olefin, and a polyether polyol polymerized from MDA (methylene diphenylamine) and the oxidized olefin; (b) a foam stabilizer; (c) a composite catalyst comprising a foaming catalyst, a gel catalyst and a polymerization catalyst at the weight ratio of (0-4):(0.2-10):1; (d) a foaming agent; (e) water; and (f) an organic isocyanate. The invention further relates to a hard polyurethane foam preparation method and a thermal insulation component comprising the hard polyurethane foam.

Owner:HEFEI HUALING CO LTD

Process for the preparation of toluenediamine

InactiveUS7307190B2Isocyanic acid derivatives preparationOrganic compound preparationPtru catalystHydrogenation reaction

Owner:COVESTRO DEUTSCHLAND AG

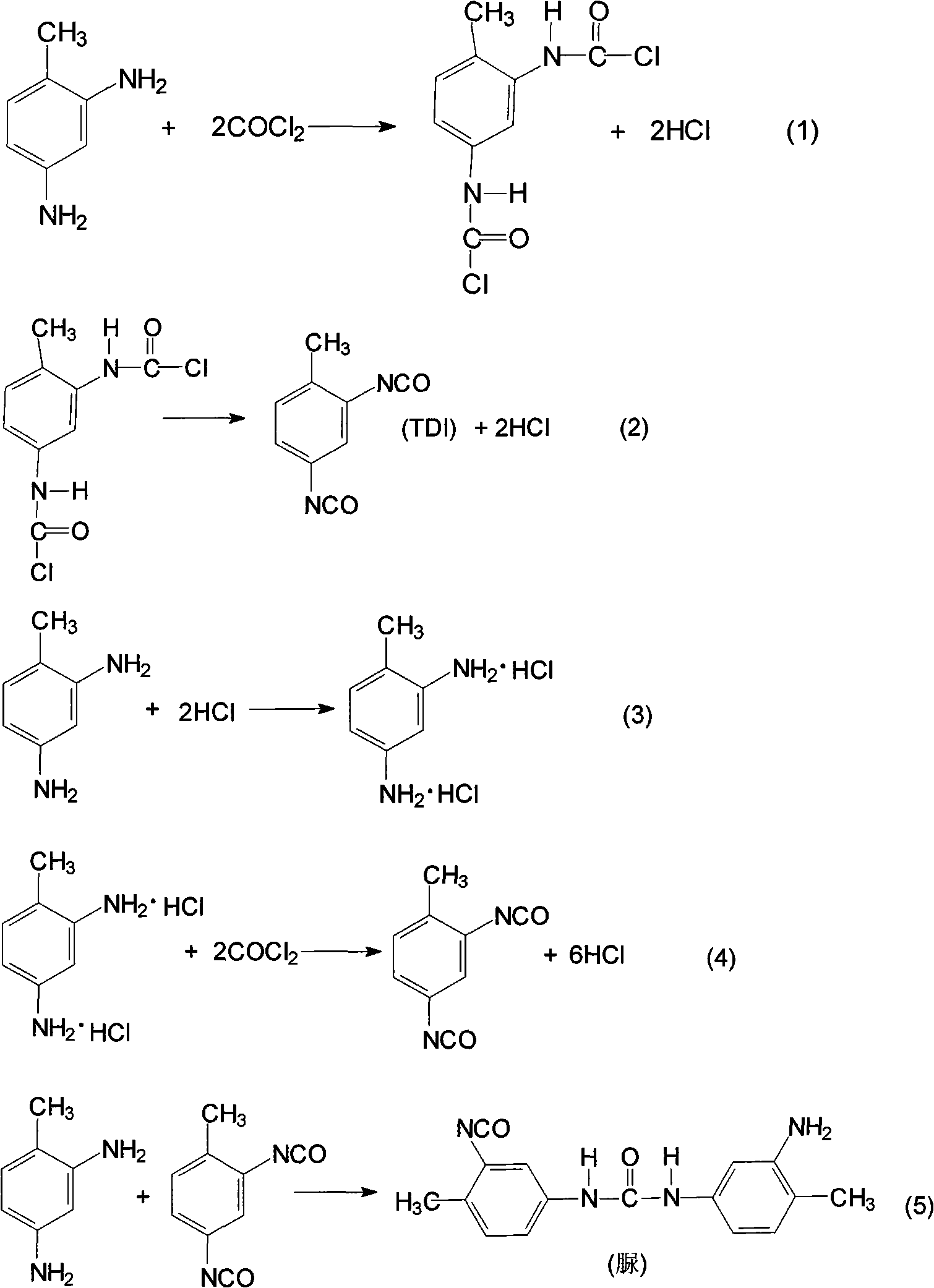

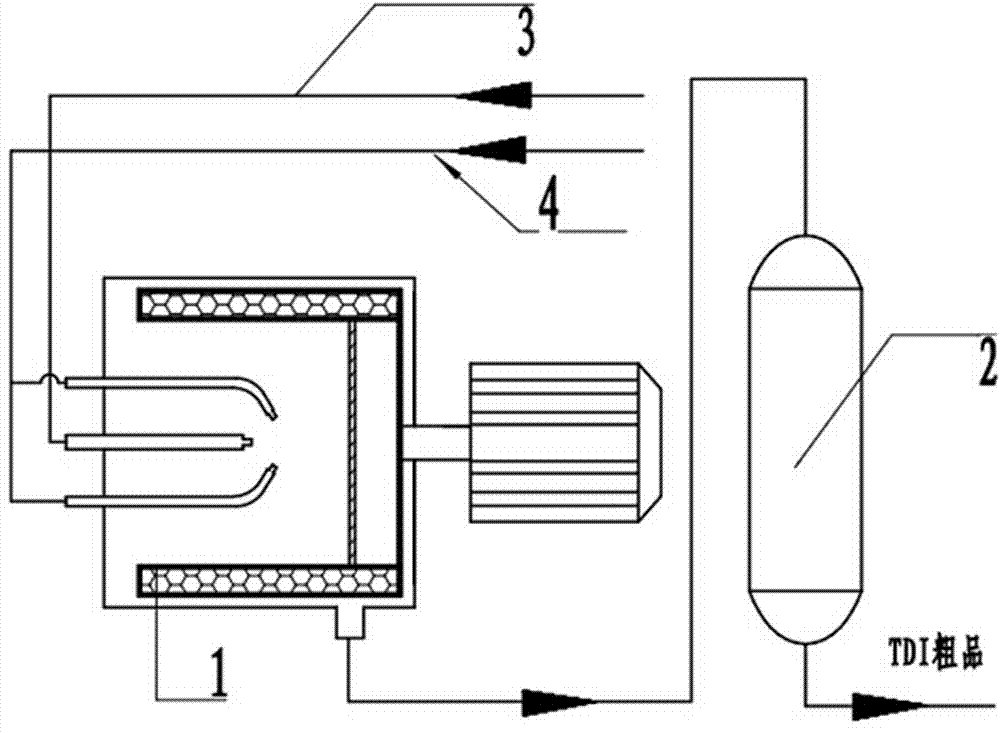

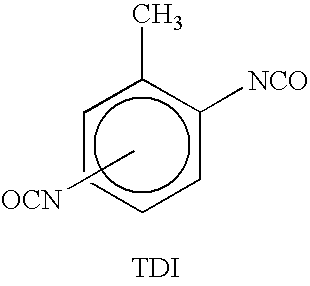

Method for continuously manufacturing toluene di-isocyanate

InactiveCN101671275AHigh energy consumptionReduce generationPreparation from carbamatesHydrogenToluenediamine

The invention discloses a method for continuously manufacturing toluene di-dsocyanate, comprising the following steps: (1) premixing a toluenediamine inert solvent solution with a phosgene inert solvent solution containing a hydrogen chloride with a mass fraction lower than 0.1 percent by a premixer and generating reaction; (2) importing the reacted mixture into a high shear reactor and refillingthe phosgene inert solvent solution containing the hydrogen chloride with the mass fraction lower than 0.5 percent to continue mixing and generating reaction; (3) leading materials in an outlet of thehigh shear reactor into detention equipment, continuing reacting at a temperature of 90-200 DEG C and an absolute pressure of 0.3-1.8 MPa until the solution turns transparent and a crude toluene di-isocyanatel is generated. The method for continuously manufacturing toluene di-dsocyanate is realized by mixing the phosgene with hydrogen chlorides in different contents with the toluenediamine step by step, thereby reducing the generation amount of low amine hydrochloride, improving the yield of the product toluene di-isocyanate and avoiding the addition of the energy consumption in refining phosgene recovering.

Owner:SEDIN ENG +1

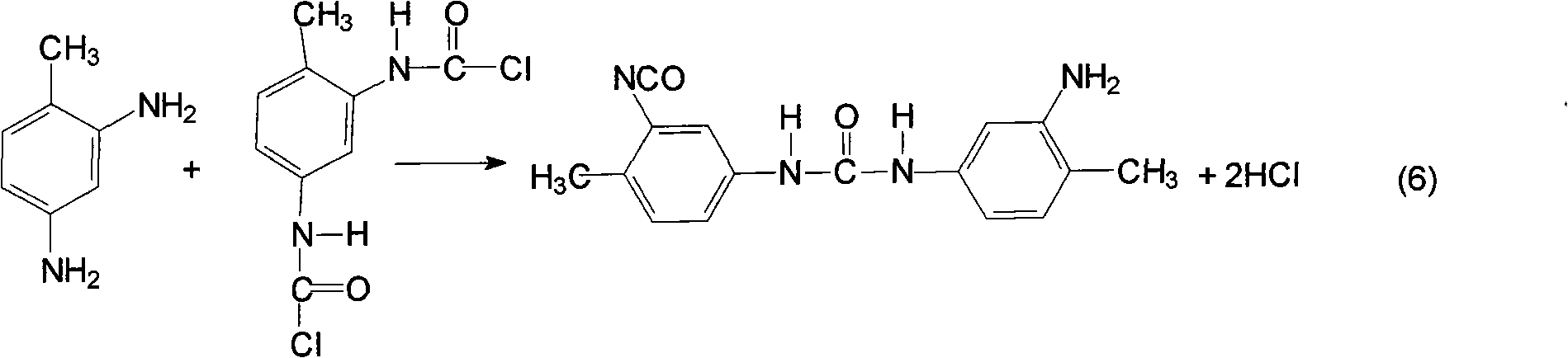

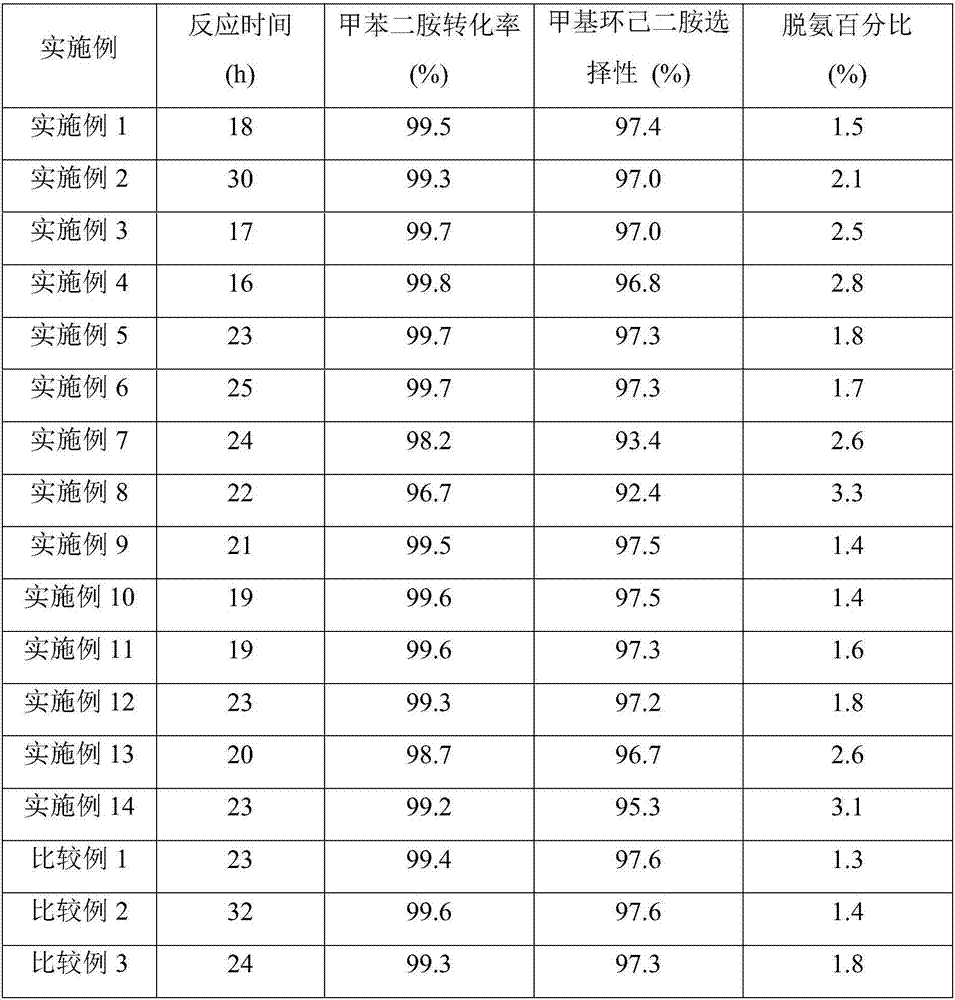

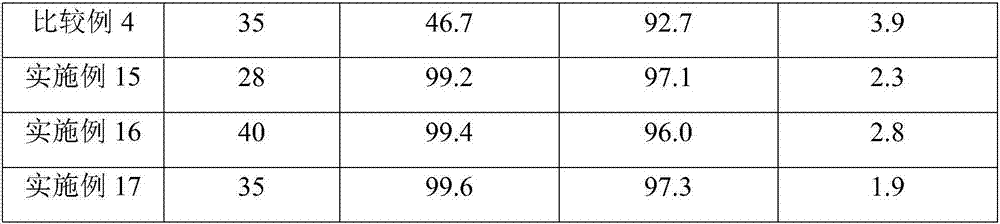

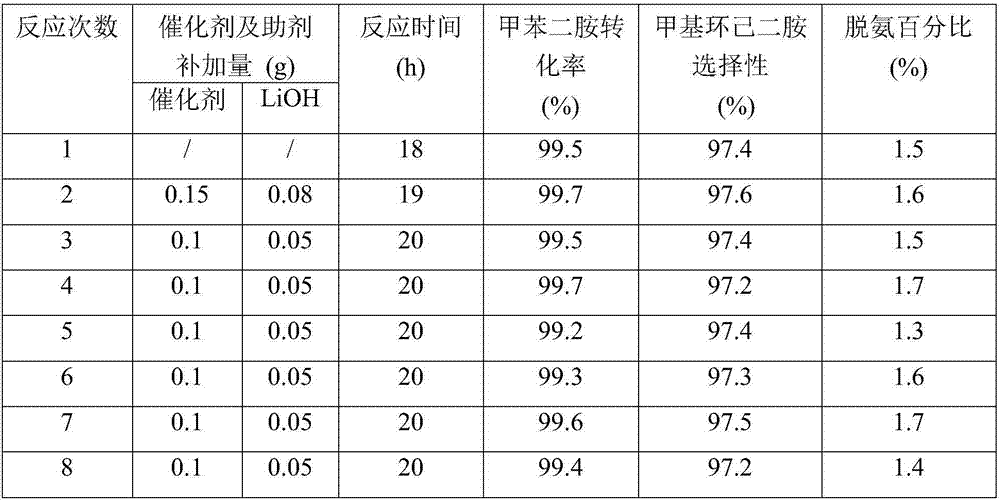

Method for preparation of methyl cyclohexanediamine by selective hydrogenation of toluenediamine and catalyst

ActiveCN106994344AHigh reactivityHigh selectivityOrganic compound preparationAmino compound preparationPolyethylene glycolCerium

The invention provides a catalyst for preparation of methyl cyclohexanediamine by selective hydrogenation of toluenediamine. The catalyst comprises an active component and an additive, wherein the active component is ruthenium; the additive is prepared from one or several of cerium, manganese, barium, calcium, magnesium and lanthanum. The catalyst is prepared by a method with the following steps of dissolving the active component, the additive and a dispersant into a solvent, so as to obtain impregnating liquid; soaking a carrier into the impregnating liquid for impregnating; drying, roasting and reducing the impregnated carrier, so as to obtain the catalyst, wherein the dispersant is prepared from one or several of polyethylene glycol, sodium lauryl sulfate, polyvinylpyrrolidone and sodium dodecyl benzene sulfonate. The catalyst has the advantages that the activity is high, the selectivity is good, and the stability is good; the catalyst is mixed to react to complete the preparation of the methyl cyclohexanediamine by selective hydrogenation of the toluenediamine, the conversion rate of the toluenediamine is high, the selectivity of the methyl cyclohexanediamine is good, and the catalyst can be continuously used for 20 times or more.

Owner:JIANGSU QINGQUAN CHEM CO LTD

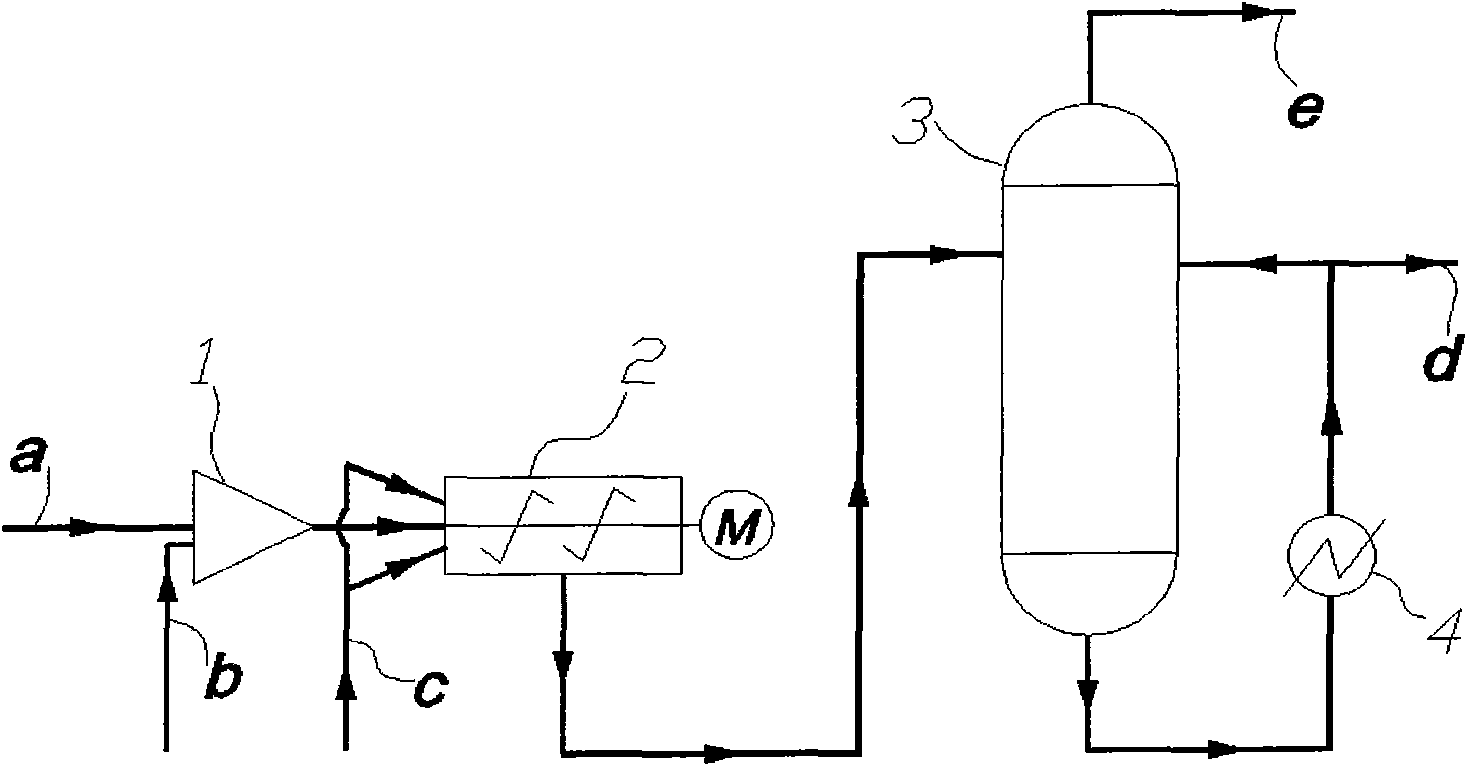

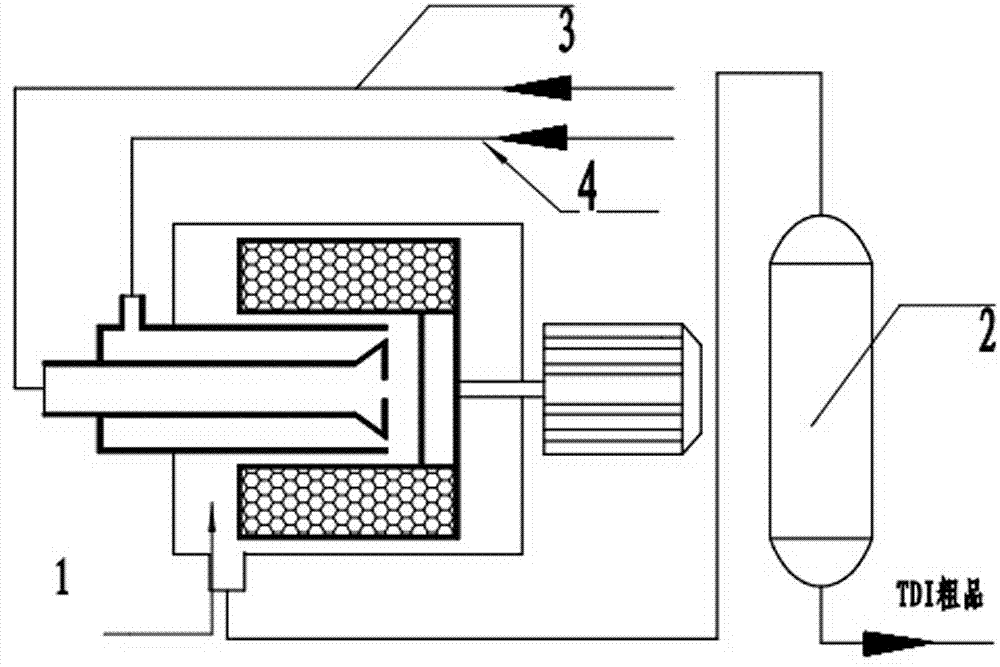

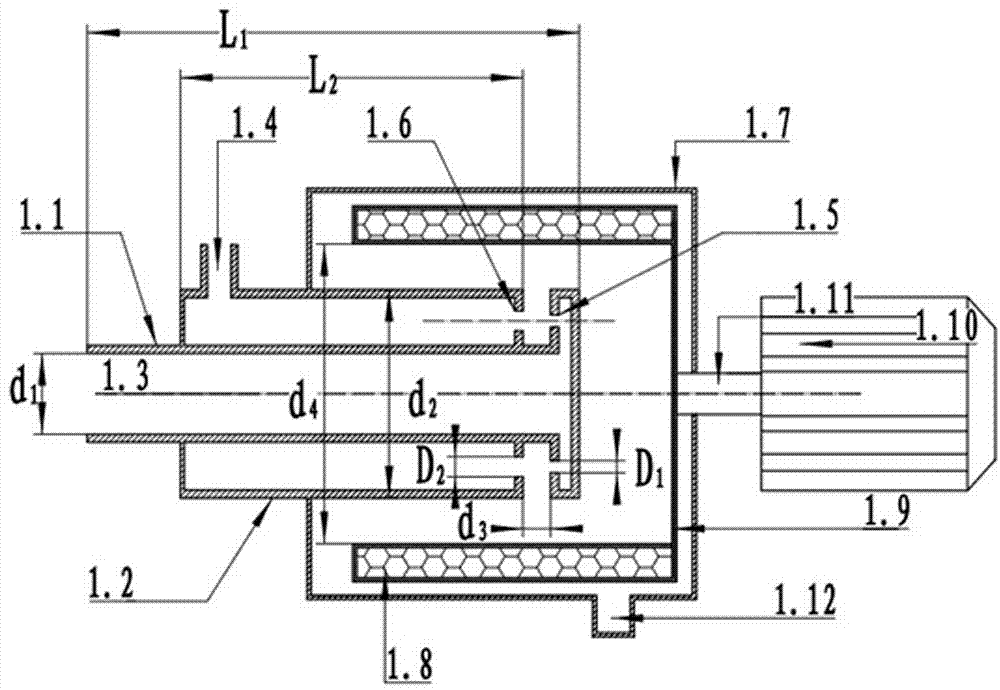

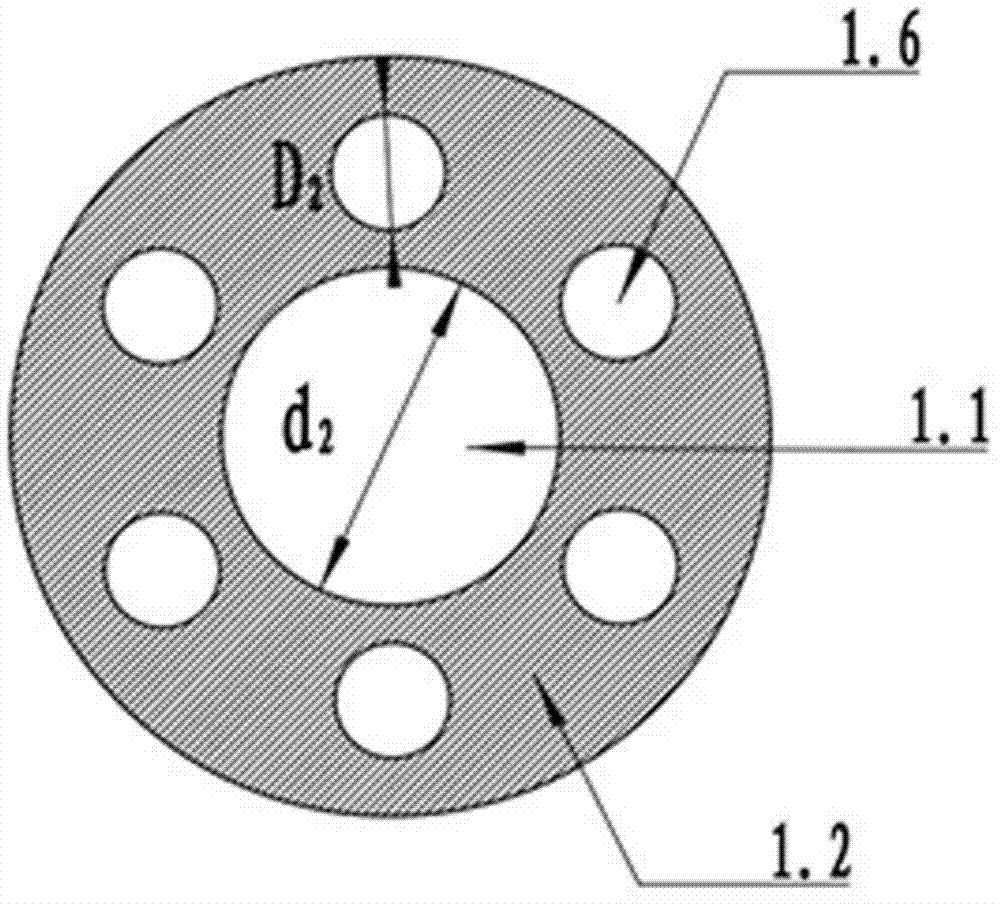

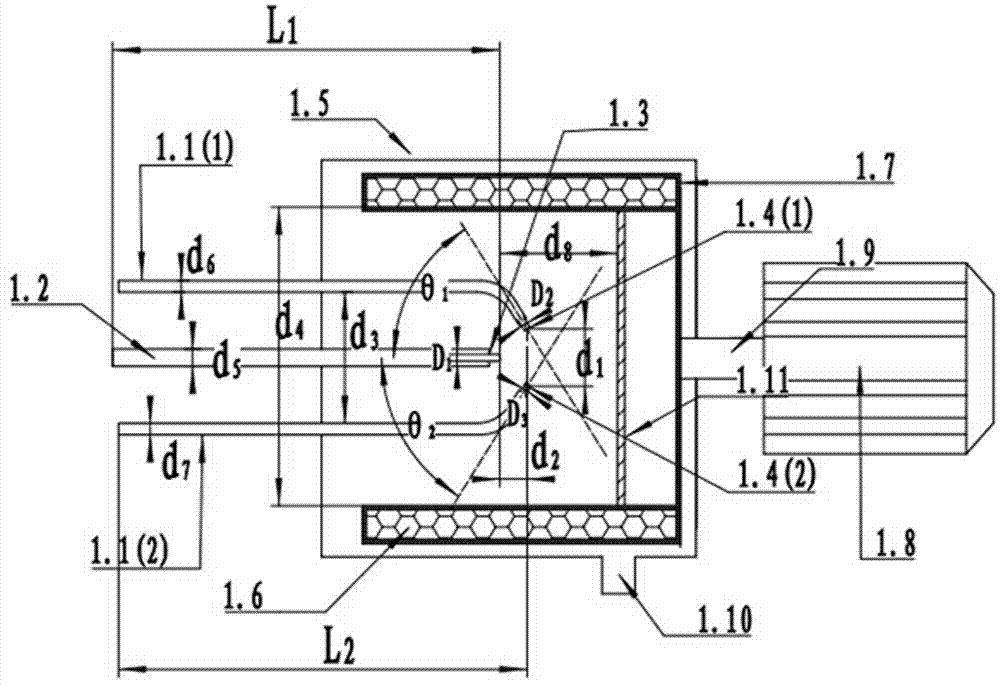

Device and technology for continuous preparation of toluene diisocyanate

ActiveCN104496851AThe result is obviousNo significant decrease in admixtureIsocyanic acid derivatives preparationOrganic compound preparationToluene diisocyanateToluenediamine

The invention belongs to the technical field of toluene diisocyanate production and discloses a device and technology for continuous preparation of toluene diisocyanate. The device and technology solves the problem that the existing toluene diisocyanate production technology has large difference of a material volume flow ratio, poor reaction selectivity, a low conversion rate and can cause reaction device fault. The device comprises a cold reactor and a heat reactor. The cold reactor comprises an unlimited impinging stream structure and a hypergravity structure. The unlimited impinging stream structure comprises a main material feeding pipe and a sleeve pipe, and the pipes have different diameters. The technology comprises that a phosgene inert solvent and a toluenediamine inert solvent solution are oppositely collided by the unlimited impinging stream structure so that macroscopic mixing and preliminary microscopic mixing are fast finished, and the mixture is fed into a rotating filler, stays for some time, then is fed into the heat reactor and undergoes a reaction to produce a toluene diisocyanate TDI crude product. The device and technology realize basically complete toluene diisocyanate reaction, prevent urea substance generation, effectively prevent pipe and reactor blocking and improve toluene diisocyanate production efficiency.

Owner:ZHONGBEI UNIV +2

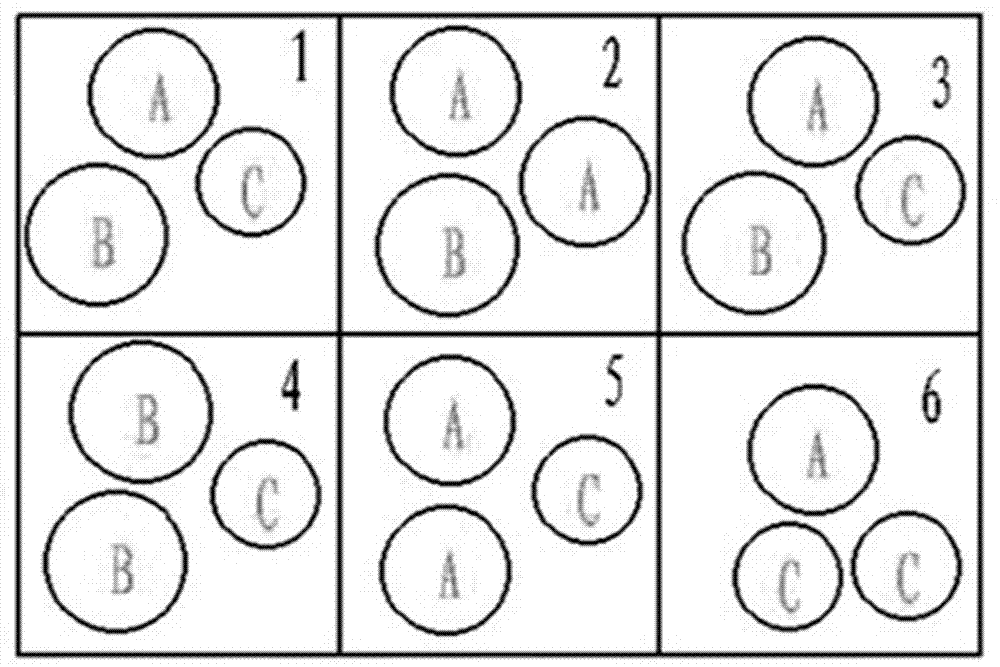

III-shaped hypergravity device and technology for continuous preparation of toluene diisocyanate

ActiveCN104496852AThe result is obviousMixed declineIsocyanic acid derivatives preparationOrganic compound preparationHypergravityToluene diisocyanate

The invention belongs to the technical field of toluene diisocyanate production and discloses an III-shaped hypergravity device and technology for continuous preparation of toluene diisocyanate. The device and technology solves the problem that the existing toluene diisocyanate production technology has poor reaction selectivity and a low conversion rate because of large difference of a material volume flow ratio thereby causing reaction device fault. The hypergravity device comprises a cold reactor and a heat reactor. The cold reactor comprises an unlimited impinging stream structure and a hypergravity structure. The unlimited impinging stream structure comprises a main material feeding pipe, an auxiliary material feeding pipe I and an auxiliary material feeding pipe II. The technology comprises that a phosgene inert solution and a toluenediamine inert solution are collided by the unlimited impinging stream structure, and the mixture is fed into a rotating filler, then is fed into the heat reactor and undergoes a reaction to produce a toluene diisocyanate TDI crude product. The device and technology realize basically complete toluene diisocyanate reaction, prevent urea substance generation, effectively prevent pipe and reactor blocking and improve toluene diisocyanate production efficiency.

Owner:ZHONGBEI UNIV +2

Polyurethane rigid foam with low density and low thermal conductivity

the invention discloses a low-density low-conductive polyurethane rigid foam, which comprises the following parts: (a) 30-60 wt% polyether, which adopts sucrose as initiator to addition with oxidized olefin; 10-30wt% polyether, which adopts toluenediamine as initiator to addition with oxidized olefin; 20-50wt% polyether, which adopts pentaerythrite and methylglucoside as initiator to addition with oxidized olefin; 5-20wt% polyether, which adopts glycerin as initiator to addition with oxidized olefin; (b) 1.5-3.5 wt% compound catalyst; (c) 7-17wt% foamer; (d) 1.5-2.8wt% water; (e) 1.4-4.0wt% foam stabilizer; (f) polyisocyanates, which adopts compound as datum polyether and water with index at 0.95- 1.50.

Owner:红宝丽集团泰兴化学有限公司 +1

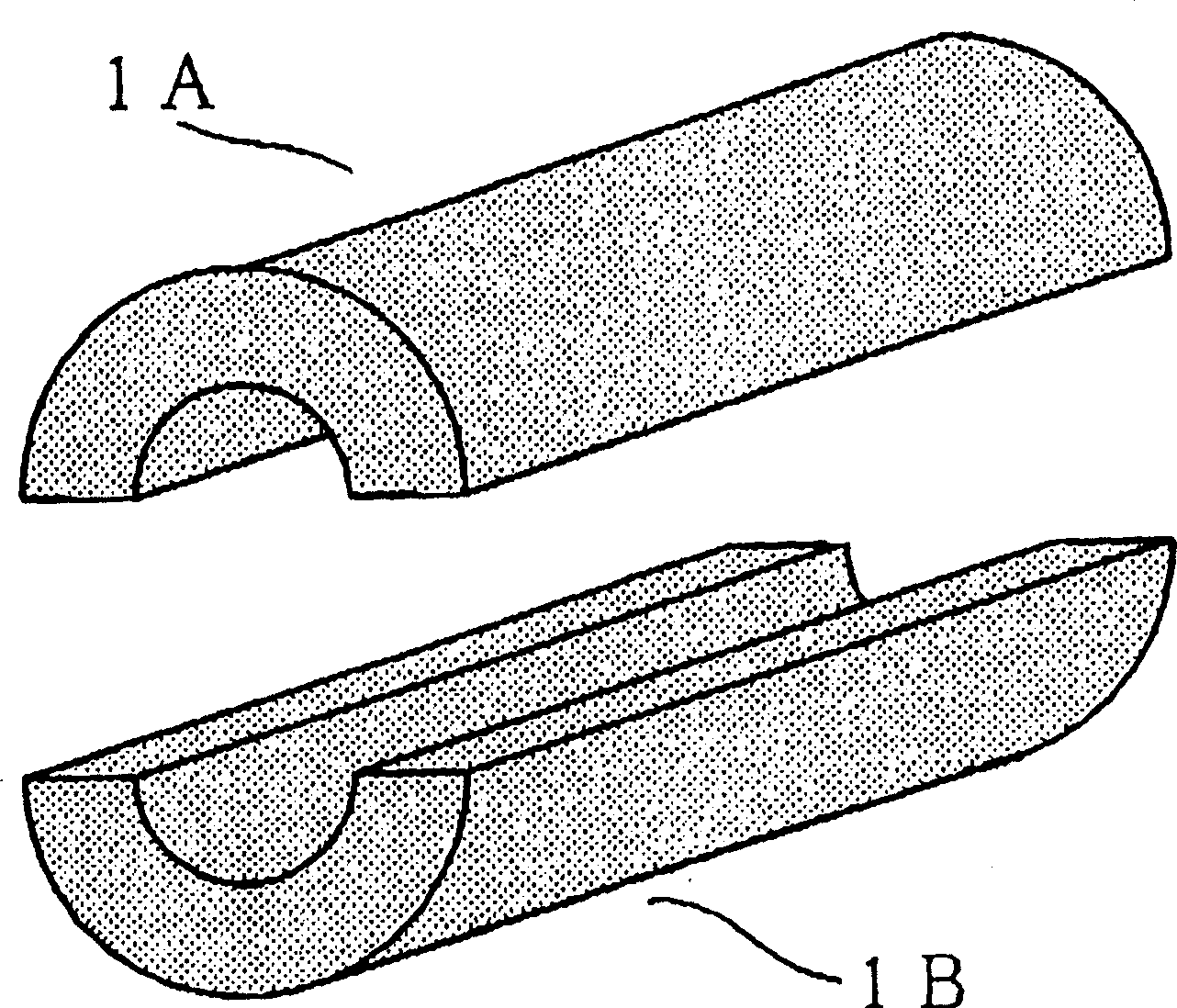

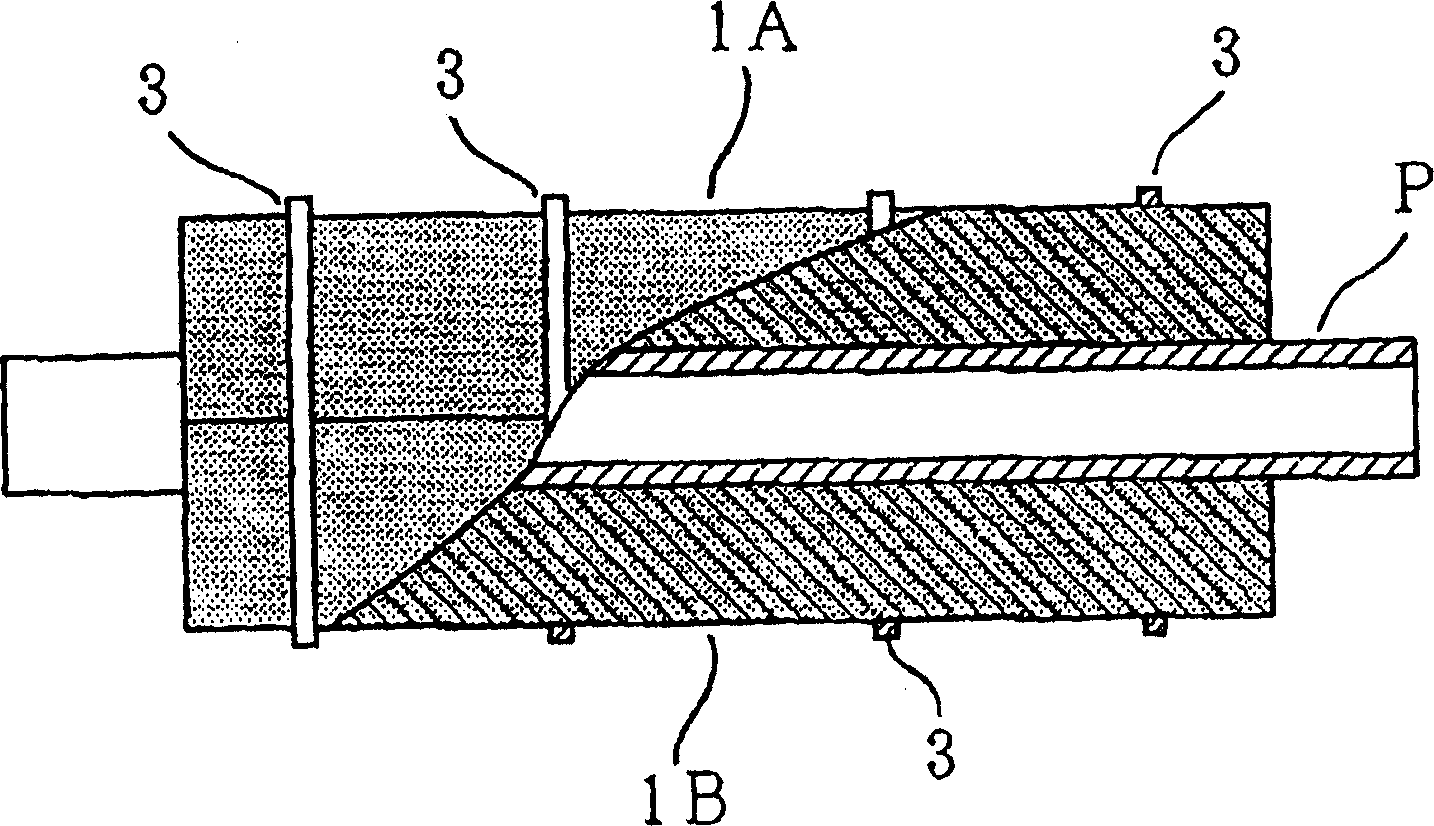

Method for manufacturing hard polyurethane slabby foam and heat-insulating material for piping

InactiveCN1840561ABurning does not occurLow thermal conductivityThermal insulationBuilding componentsPolyolFoaming agent

The present invention provides a method for producing a rigid polyurethane slab foam having low heat conductivity and excellent incombustibility without generating scorch inside.(A) A modified polyisocyanate having NCO content of 25-28% which is obtained by modifying at least a part of polymeric diphenylmethane diisocyanate (MDI) containing MDI in a ratio of 30-80 mass% using a modifier comprising a polyether polyol with 2-4 functional groups and a hydroxy value of 100-900 mgKOH / g, (B) a polyol component containing a polyether polyol (B1) in a ratio of 50 mass% or more which is obtained by adding ethylene oxide and / or propylene oxide to toluenediamine, and (C) a foam forming composition containing a foaming agent comprising water are reacted.

Owner:NIPPON POLYURETHANE IND CO LTD

Polyurethane material for two and three piece golf balls and method

InactiveUS20030166819A1Easy to manufactureIncreased durabilityHollow inflatable ballsHollow non-inflatable ballsIonomerPolyol

A novel composition useful for golf ball covers that comprises a blend of a dilsocyanate / polyol polyurethane prepolymer with a curing agent comprising a blend of slow-reacting diamine with a fast-reacting diamine such as dimethylthio 2,4-toluenediamine and diethyl 2,4-toluenediamine, respectively. A golf ball cover made with this composition exhibits the characteristic feel and playability of a balata cover with superior durability characteristics (cut and shear resistance) which exceed those of a balata or ionomer cover.

Owner:TAYLOR MADE GOLF

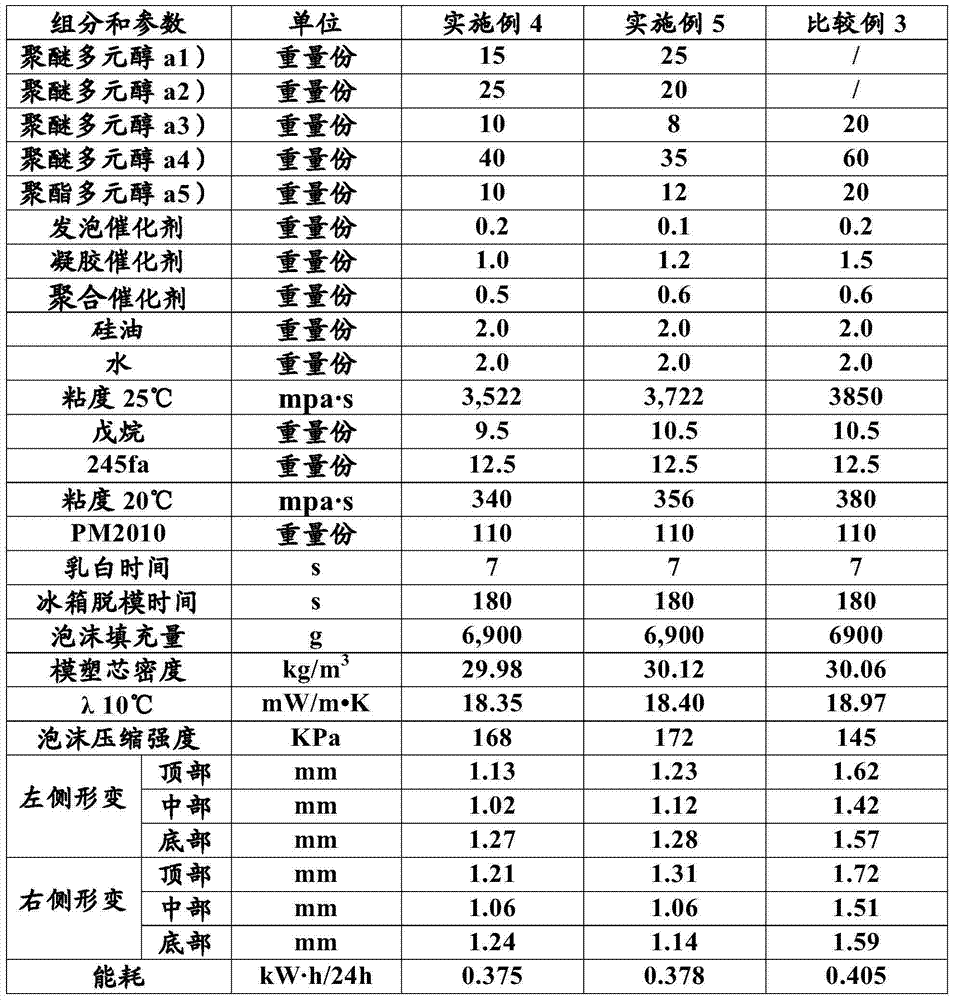

Process for the preparation of toluenediamines by catalytic hydrogenation of dinitrotoluenes

The present invention relates to a process for the preparation of toluenediamine, in which dinitrotoluene is reacted with hydrogen in the presence of a catalyst. The dinitrotoluene required by this process has a content of carbon dioxide, in either physically dissolved or chemically bonded form, of not more than 0.175 mol %, based on the molar amount of the dinitrotoluene.

Owner:COVESTRO DEUTSCHLAND AG

Solid desulfurization agent preparation method

The present invention relates to a desulfurization agent preparation method, particular to a solid desulfurization agent preparation method, which comprises: 1, taking main components such as 20% by weight of triethanolamine, 10% by weight of calcium carbonate, 10% by weight of ferric hydroxide, 20% by weight of ammonium carbonate, 20% by weight of aniline carbonate, and 20% by weight of 2-ethyl toluenediamine; 2, mixing the effective component taken in the step 1 and alumina according to a ratio of 1:1; 3, adding an adhesive during the mixing process in the step 2, and adding an appropriate amount of isopentane; and 4, under an anaerobic condition, at a temperature of 180 DEG C, heating the obtained mixture for 30 min. According to the present invention, the solid desulfurization agent has characteristics of high product yield, good desulfurization effect, good product appearance, simple operation, no waste, and environmental protection.

Owner:濮阳市联众兴业化工有限公司

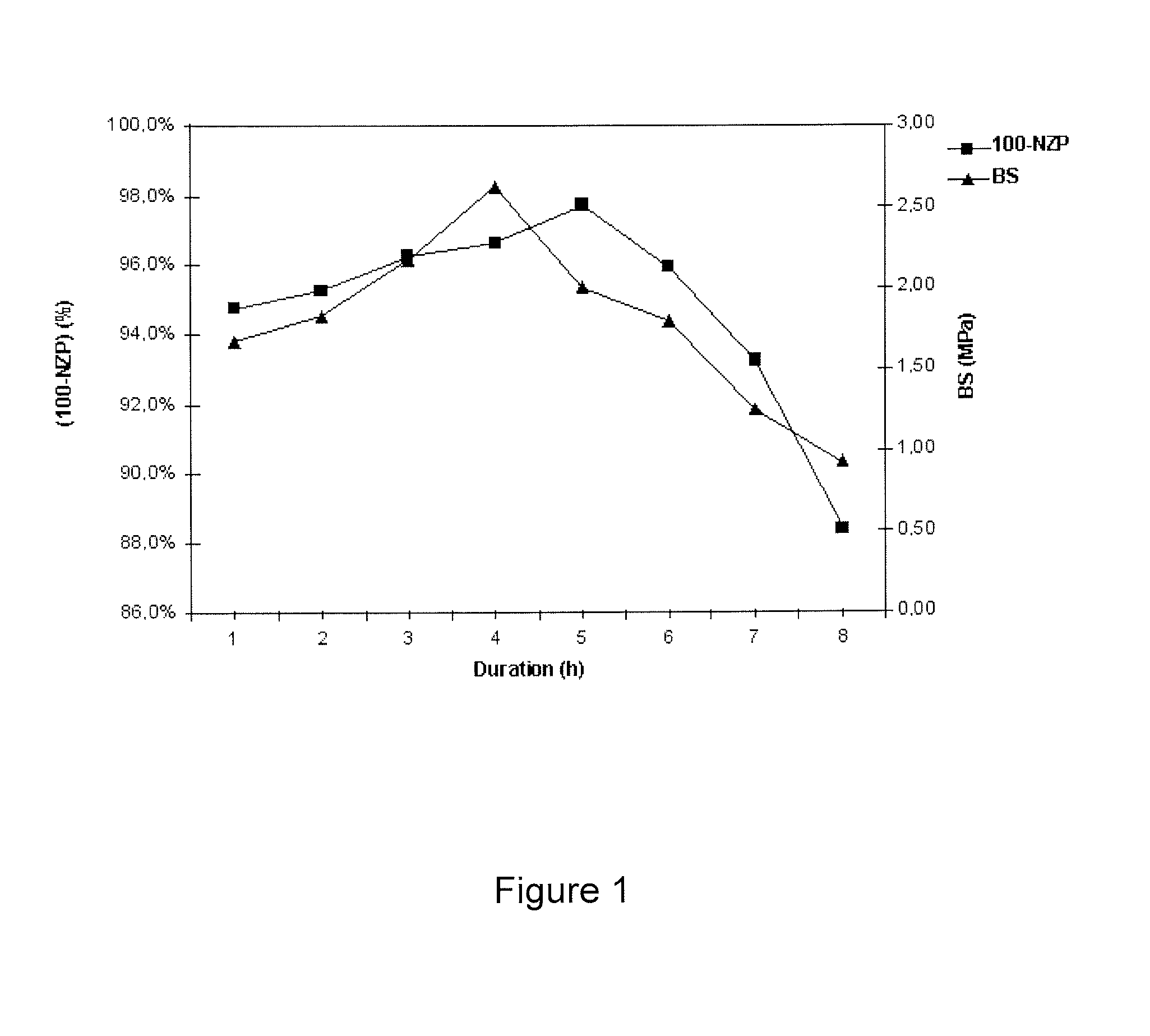

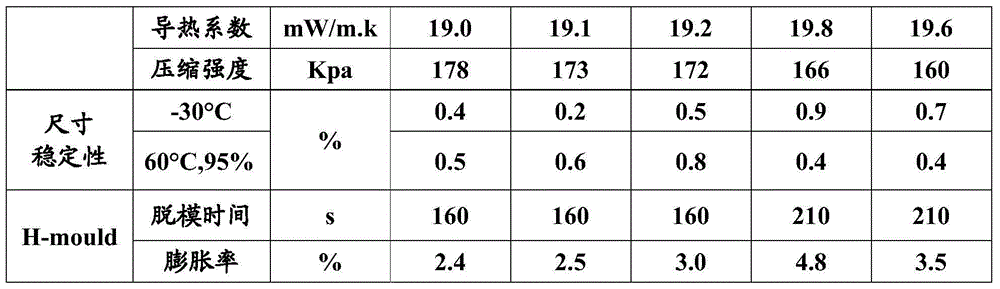

Hard polyurethane composition with low thermal conductivity and rapid demoulding property as well as its preparation method

InactiveCN102432794ADamage index 0Excellent quick release performanceChemical industryFoaming agentThermal insulation

The invention relates to a hard polyurethane composition with low thermal conductivity and rapid demoulding property. The composition comprises: 1) 100 parts of composite polyethers composed of 40-70 parts of polyethers with cane sugar as a starting agent, 10-50 parts of polyethers with ortho toluenediamine as a starting agent, 3-20 parts of polyethers with glycerin as a starting agent, and 3-20 parts of composite polyethers with a composite starting agent composed of cane sugar and glycerin; 2) 1.0-3.0 parts of a composite catalyst; 3) 10-20 parts of a foaming agent cyclopentane; 4) 1.5-3.0 parts of water; 5) 1.0-3.5 parts of a foam stabilizer; and 6) 130-150 parts of isocyanate with an index of 100-130. The hard polyurethane composition of the invention has demoulding time short to 170 seconds, low thermal conductivity and excellent thermal insulation performance, and can meet the demands for energy saving, environmental protection and production efficiency improvement when used in refrigerator production.

Owner:可利亚多元醇(南京)有限公司

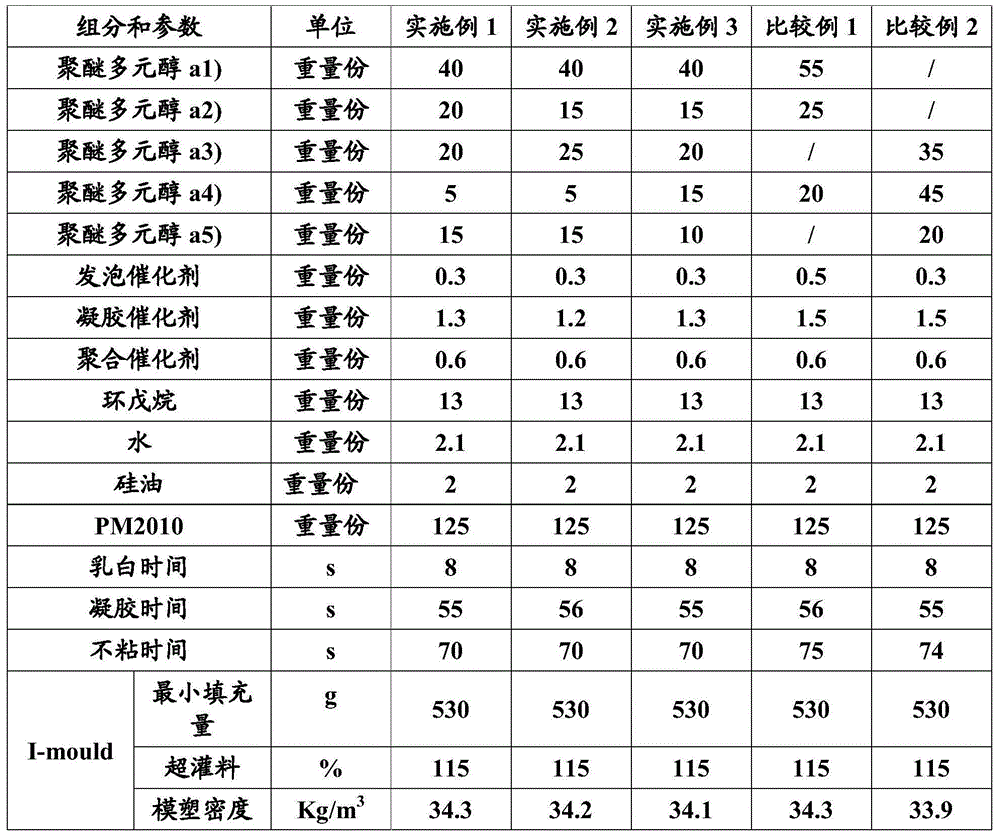

Polyalcohol composition, application thereof and rigid polyurethane foam prepared from polyalcohol composition

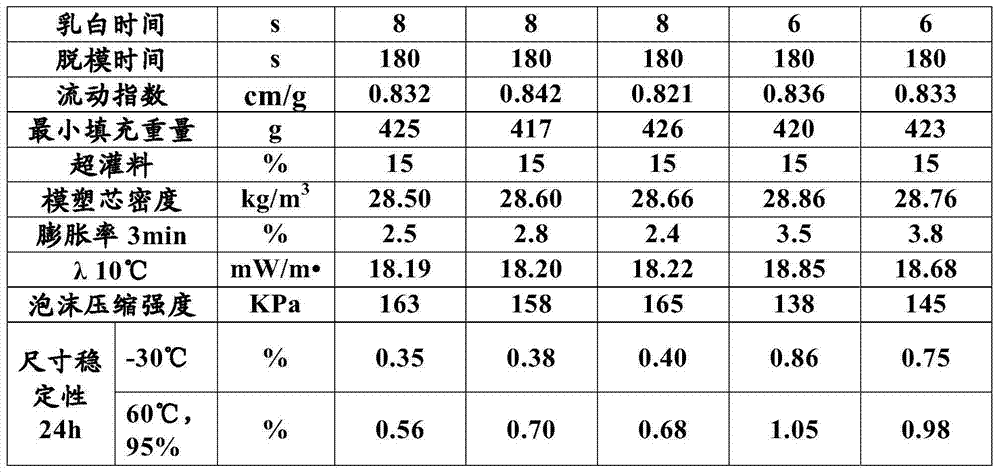

The invention relates to a polyalcohol composition containing the following components in parts by weight: 5-45 parts of polyether polyol (a1) formed by toluenediamine and oxyalkylene polymerization, 7-50 parts of polyether polyol (a2) formed by toluenediamine, triethanolamine and oxyalkylene polymerization, 3-25 parts of polyether polyol (a3) formed by glycerin and oxyalkylene polymerization, 15-65 parts of polyether polyol (a4) formed by saccharose and oxyalkylene polymerization and 3-20 parts of polyether polyol (a5), wherein the total weight part of the components from (a1) to (a5) is 100. The invention also relates to an application of the polyalcohol composition to the preparation of rigid polyurethane foam and rigid polyurethane foam prepared from the polyalcohol composition.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Process for synthesis of toluenediamine by low pressure hydrogenation of dinitrotoluene, catalyst and preparation method of catalyst

InactiveCN104045569AHigh strengthImprove stabilityOrganic compound preparationChemical recyclingHydrogenGas phase

A process for synthesis of toluenediamine (TDA) by low pressure hydrogenation of dinitrotoluene (DNT) is as follows: preparing a fresh Raney nickel catalyst and DNT into fresh catalyst slurry, adding the fresh catalyst slurry into a hydrogenation reactor; respectively adding raw material DNT and hydrogen into the hydrogenation reactor for reaction, leading a liquid reaction product into a catalyst separator I for separation, sending an upper clear liquid to a catalyst separator II, sending a gas phase into a purge gas separator, and returning settled catalyst slurry to the hydrogenation reactor; and filtering a clear liquid in the central part of the catalyst separator II with a filter to obtain a crude TDA product. The process has the advantages of low equipment investment, low energy consumption, and synthesis of the toluenediamine (TDA) by hydrogenation of the dinitrotoluene in the absence of an externally added solvent and under the low pressure condition of 1MPa.

Owner:SEDIN ENG

Method for continuously purifying and refining ortho toludiamine

ActiveCN102757351AContinuous separationAmino compound purification/separationProcess engineeringToluenediamine

The invention relates to method for continuously purifying and refining ortho toludiamine. The method comprises the steps of: carrying out rectification by two towers connected in series, removing a front fraction of an ortho toludiamine crude product through a light component removing tower, and rectifying and separating out ortho toludiamine and meta-toluenediamine through a product tower. The method has the advantages that rectification is carried out by the two towers connected in series; and the ortho toludiamine, the meta-toluenediamine, monamine and other impurities can be continuously separated, and the purity of the ortho toludiamine can be up to over 99.5%.

Owner:NANTONG BOTAO CHEM

Polyurea elastomer construction engineering waterproof material

InactiveCN101037587ANot affected by ambient temperatureNot affected by ambient humidityOther chemical processesBuilding insulationsAlkaneElastomer

The invention relates to a polyurea elastic body architectural engineering water-proofing material, which is constituted of component A and component B of equal weight ratio. The component A is isocyanate, component B includes raw materials (by weight ratio of component B) of: amido end-sealing epoxy alkane compound of 55-70%, diethyl toluenediamine of 8-10%, 3,3'-diethyl-4,4'-diaminodiphenylmethane of 3-5%, phosphite triester of 5-7%, dihexandiol ester of 3-5%, N,N'-dialkyldiamine of 5-8%, N,N'-dialkylmethanediamine of 2-4%, and titanium dioxide of 4-6%. Advantages of the invention are: high strength, plant puncture resistant, aging resistant, energy-saving, environmental protection, long using lifetime of more than 30 years, and changeable colors.

Owner:山东斯泰普力高新建材有限公司

Catalyst for producing diethyltoluene diamine and preparation method and application of catalyst

ActiveCN107999089AHigh activityHigh selectivityAmino preparation from aminesCatalyst activation/preparationAlkyl transferActive component

The invention discloses a supported catalyst for producing diethyltoluene diamine. The supported catalyst for producing diethyltoluene diamine comprises a modified carrier and a supported active component, wherein the modified carrier contains SiO2 and B2O3 obtained by decomposing a soluble silicon-containing compound and a boron-containing compound through drying and roasting after introducing the soluble silicon-containing compound and the boron-containing compound into the carrier. The invention further discloses a preparation method and application of the catalyst. The catalyst disclosed by the invention is suitable for the alkylation of aromatic amines, especially has extremely high activity and selectivity for continuous production of diethyltoluene diamine with toluenediamine alkylation. The catalyst has a simple preparation process, high economy and better application prospects.

Owner:WANHUA CHEM GRP CO LTD

Method for recovering toluenediamine from waste slag emitted from production of toluene diisocyanate

InactiveCN103804198AHigh yieldFast hydrolysisAmino compound purification/separationOrganic compound preparationDistillationSlag

The invention relates to a method for recovering toluenediamine (TDA) from waste slag emitted from production of toluene diisocyanate (TDI). The method comprises the steps: with triethylenetetramine as a reaction medium, performing catalysis hydrolysis on crushed TDI residue at a normal pressure by using a strong base, and completing the reaction within 3 hours; and salting out a hydrolysis product by using a saturated sodium chloride solution after filtering, extracting by using dichloromethane, and finally performing reduced pressure distillation on an extract to obtain the TDA, wherein the yield is capable of reaching above 75 percent and the purity is capable of reaching above 95 percent. According to the method, a high-pressure reactor and distillation or fractionation equipment with high cost are not needed, the reaction time consumption is short, the product yield is high, and the large-scale production of preparing the TDA through recovering of the residue of the TDI is favorably promoted.

Owner:UNIV OF JINAN

Recovery of toluene diamine from tar waste residue discharged from synthesis process of toluene diisocyanate

ActiveUS20130041182A1Increase speedEfficient recyclingOrganic compound preparationChemical recyclingToluene diisocyanateSlurry

The recovery of toluene diamine from tar waste residues discharged from the synthesis process of toluene diisocyanate comprising steps of: a) grinding the tar waste residues into particles; b) dispersing the particles of tar waste residues into a phase transfer catalyst, alkali and water to obtain a slurry, said phase transfer catalyst being selected from the group consisting of higher alcohols, polyols, polyether compounds and combinations thereof having a boiling point ranging from 120 to 280° C.; c) under the protection of a protective gas, subjecting the slurry to a hydrolysis reaction at a temperature of 120-180° C. under a meter-measured pressure of 0-0.95 MPa to produce toluene diamine; and d) recovering toluene diamine from the hydrolysis reaction solution. The present invention achieves highly efficient recovery of toluene diamine (the recovery rate of TDA is up to 60%) under mild conditions such as 120-180° C. and 0-0.95 MPa (meter-measured pressure), and has a significant economic benefit and friendliness to the environment by recycling the phase transfer catalyst (its recovery rate is up to 99.6%) and water.

Owner:CANGZHOU FENGYUAN ENVIRONMENTAL PROTECTION SCI & TECH

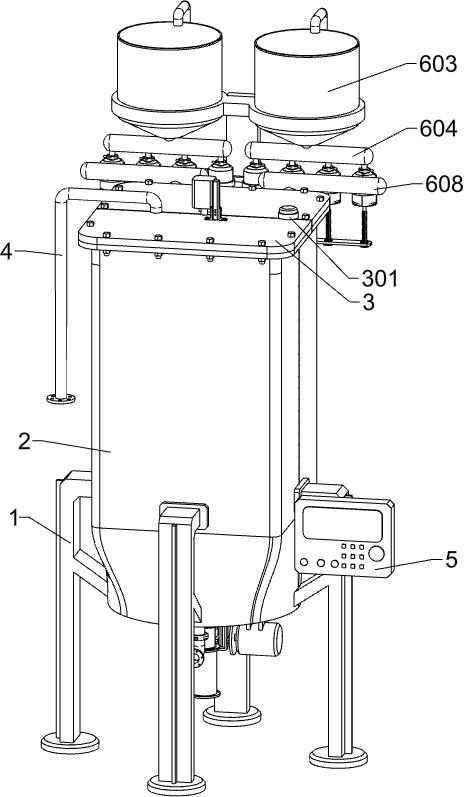

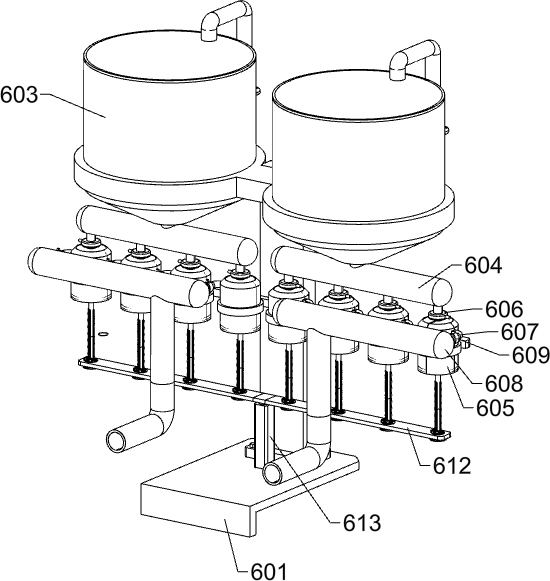

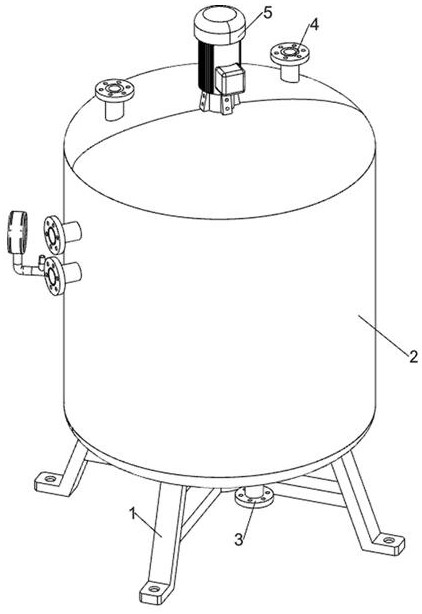

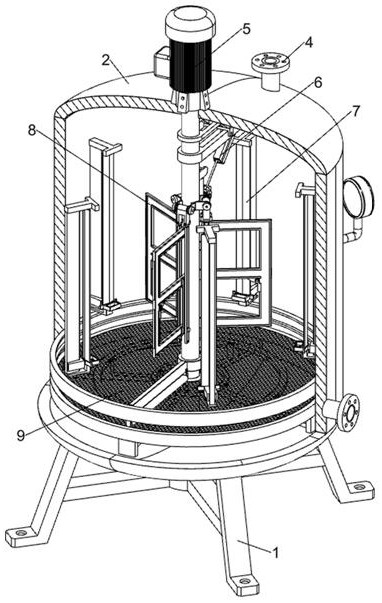

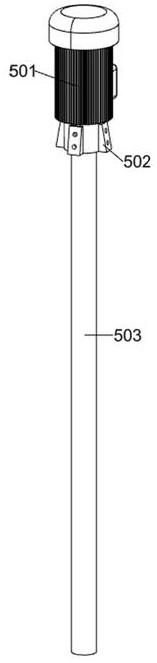

Diethyltoluenediamine production device with accurate material proportioning function

ActiveCN114797636AAvoid stickingQuality improvementAmino compound purification/separationOrganic compound preparationBLENDER/MIXERStructural engineering

The invention aims to provide a diethyltoluenediamine production device with an accurate material proportioning function, and relates to the field of diethyltoluenediamine production devices.The diethyltoluenediamine production device comprises a first supporting frame, a mixing cabin is fixedly connected to the first supporting frame, a quantitative proportioning mechanism is arranged on the first supporting frame, the quantitative proportioning mechanism communicates with the mixing cabin, and the mixing cabin communicates with the quantitative proportioning mechanism; a stirring mechanism is arranged in the mixing cabin, and an inner wall cleaning mechanism is arranged in the mixing cabin. The quantitative proportioning mechanism is arranged, so that the influence of the bottom pressure of the material box on feeding is avoided, and meanwhile, the situation that the production quality of a diethyl toluenediamine product is reduced due to inaccurate proportioning of two liquid materials caused by different feeding amounts of the two liquid materials is avoided; the stirring mechanism is arranged, so that the stirring time of two liquid materials is shortened, and the production efficiency of diethyltoluenediamine is improved; the inner wall cleaning mechanism is arranged, so that the influence of impurities on the inner wall of the mixing cabin on the next preparation of the diethyltoluenediamine is avoided, and the quality of the diethyltoluenediamine is improved.

Owner:东营海瑞宝新材料有限公司

Process for the production of toluene diisocyanate

ActiveUS20070287857A1Less coloringReduce colorAmino compound purification/separationOrganic compound preparationToluene diisocyanateToluenediamine

The invention relates to a process for the production of toluene diisocyanate, in which the crude toluenediamine obtained from the hydrogenation is purified and then phosgenated. The purification step reduces the total amount of cyclic ketones to less than 0.1% by weight, based on 100% by weight of the toluenediamine.

Owner:COVESTRO DEUTSCHLAND AG

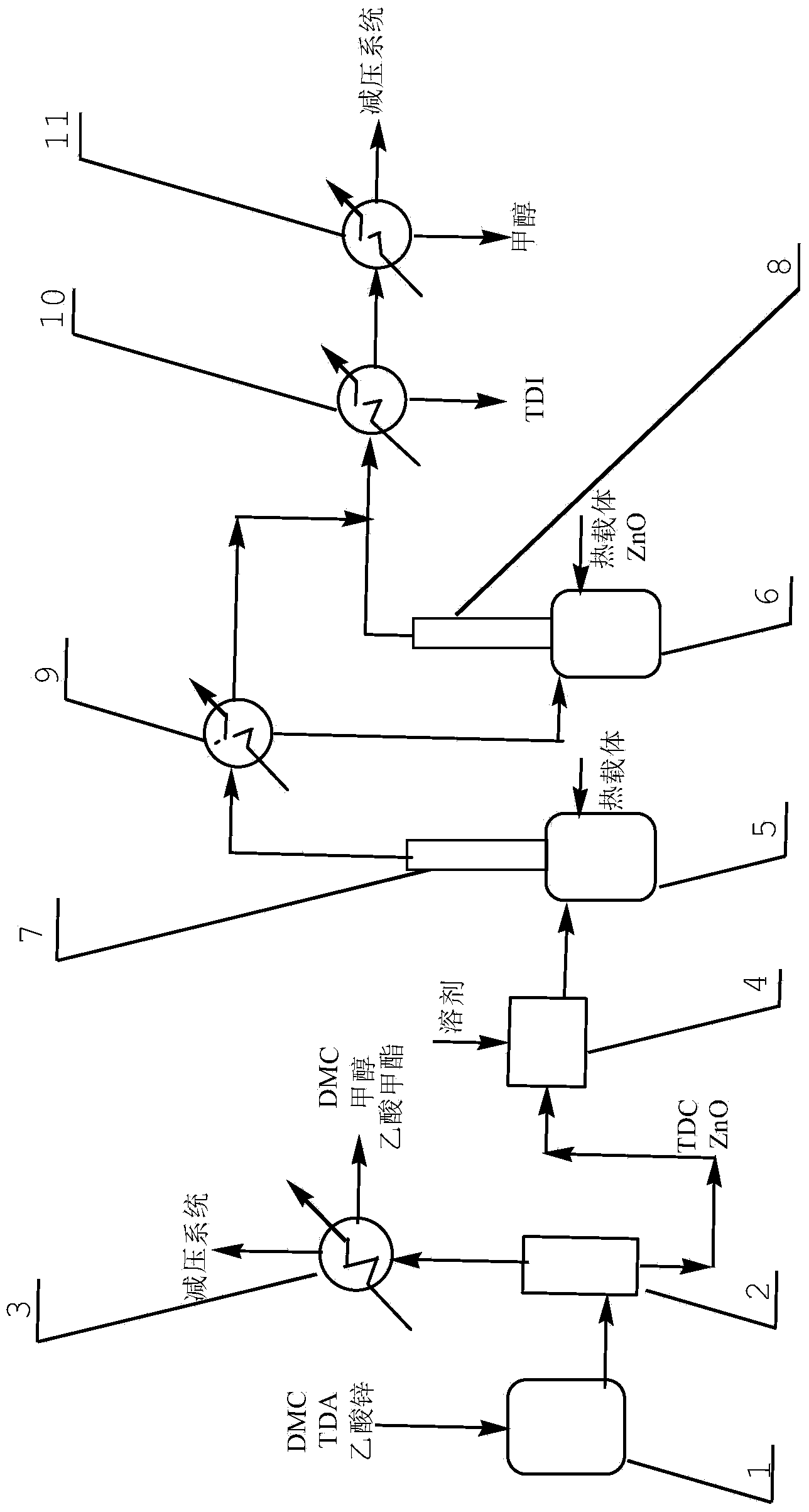

Process for preparing toluene diisocyanate (TDI) by using toluenediamine and dimethyl carbonate

ActiveCN103936623ASimple processHigh yieldPreparation from carbamatesToluene diisocyanateReaction temperature

The invention relates to a process for preparing toluene diisocyanate (TDI) by using toluenediamine and dimethyl carbonate. According to the process, a deactivation catalyst, namely zinc oxide (ZnO), of a reaction, which is used for synthesizing toluene dicarbamate (TDC) through catalyzing toluenediamine and dimethyl carbonate by zinc acetate, is used as a catalyst of a reaction for TDC decomposed TDI preparation, the deactivation catalyst, namely ZnO, of the reaction is not required to be separated from the product TDC and is directly applied to the reaction for TDC decomposition catalyzed TDI preparation, and a TDC decomposed TDI preparation process adopts that decomposition reactors of two stages are in series connection and a fractional condenser is arranged between the decomposition reactors of two stages. According to the process, TDC is synthesized through catalyzing toluenediamine and dimethyl carbonate by zinc acetate, and the deactivation catalyst, namely ZnO, of TDC synthesis is selected as an efficient catalyst for TDC decomposition reaction, so that the catalysis effect is good, and the yield of TDI is high; and the temperature of the TDC decomposition reaction is low, so that the total production cost can be greatly reduced.

Owner:HEBEI UNIV OF TECH

Zeolite adsorbents comprising zeolite EMT, process for preparing the same and uses thereof

The present invention relates to zeolite adsorbents based on agglomerated crystals of zeolite EMT comprising barium and / or potassium. These adsorbents find applications in the separation of aromatic C8 isomer fractions, especially of xylenes, in the separation of substituted toluene isomers, such as nitrotoluene, diethyltoluene and toluenediamine, and in the separation of cresols, and in the separation of polyhydric alcohols, such as sugars.

Owner:ARKEMA FRANCE SA

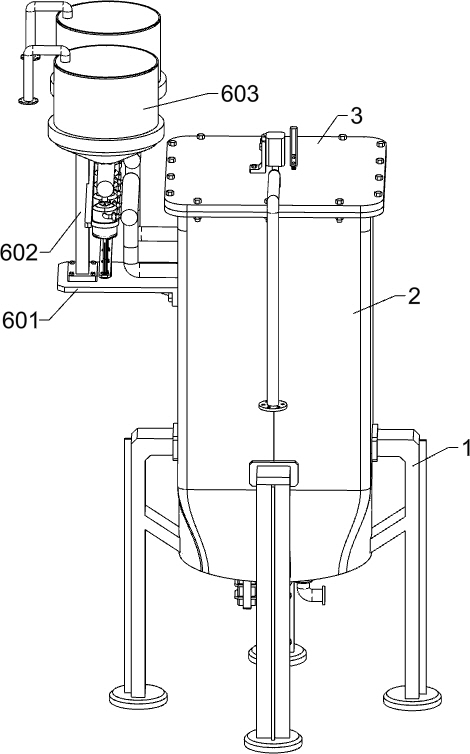

Self-cleaning type diethyltoluenediamine reaction kettle

ActiveCN113559813AStir wellWell mixedOrganic compound preparationRotary stirring mixersChemical reactionPhysical chemistry

The invention relates to the technical field of chemical reaction kettles, in particular to a self-cleaning type diethyltoluenediamine reaction kettle. The technical problem is that a wall plate and a machine head stirring blade of a diethyl toluenediamine reaction kettle are difficult to clean. According to the technical scheme, the self-cleaning type diethyltoluenediamine reaction kettle comprises a bottom supporting frame, a reaction kettle body, a liquid discharge valve, a liquid feeding valve, a stirring machine head assembly, a lifting control system, a wall plate cleaning system, a machine head cleaning system and a fragmentation system; the reaction kettle body is welded to the top of the bottom supporting frame. The inner side of the reaction kettle is automatically cleaned, cleaning liquid is added after the reaction kettle is used, the surfaces of the two sides of each wall plate of the reaction kettle and gaps in the connecting positions of the wall plates and the kettle body are sequentially and automatically cleaned, automatic cleaning of the machine head is achieved, and the surfaces of stirring blades of the machine head are prevented from being wrapped by impurities.

Owner:东营海瑞宝新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com