Hard polyurethane foam composite, foam preparation method and thermal insulation component

A technology of rigid polyurethane and composition, which is applied in the field of rigid polyurethane foam composition, can solve the problems of no clear demolding time, unsuitable door body rapid demoulding and foaming, etc., so as to improve the post-curing performance and shorten the demoulding time. Mold time, the effect of improving dimensional stability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

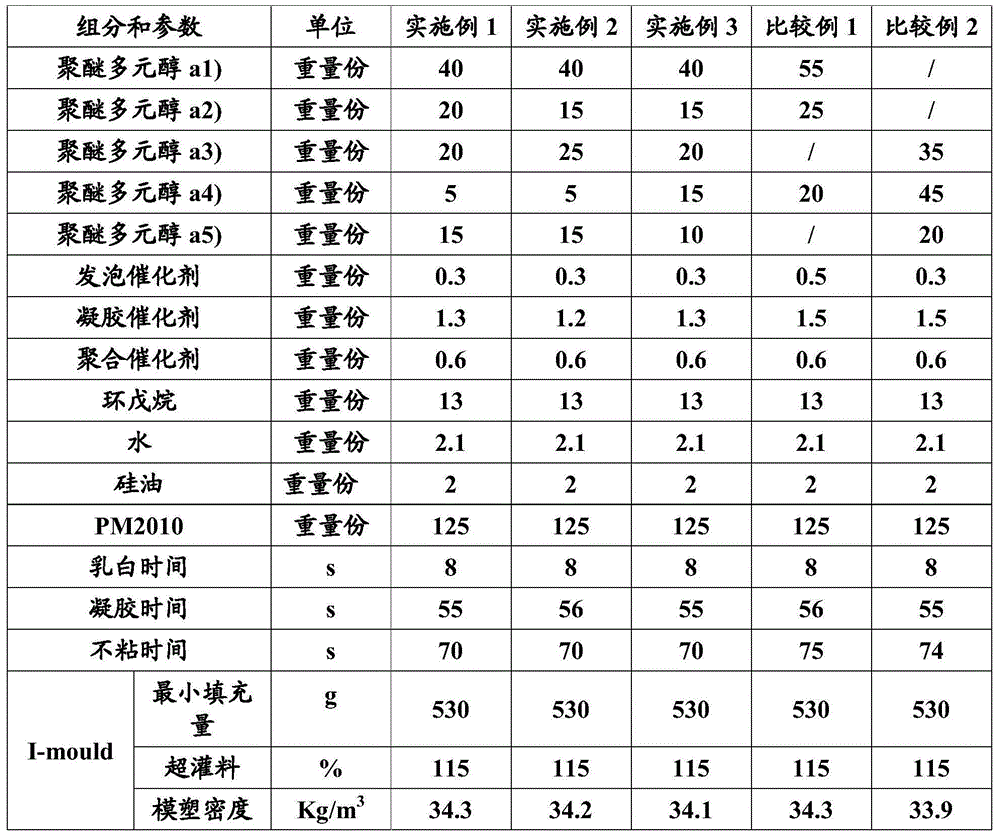

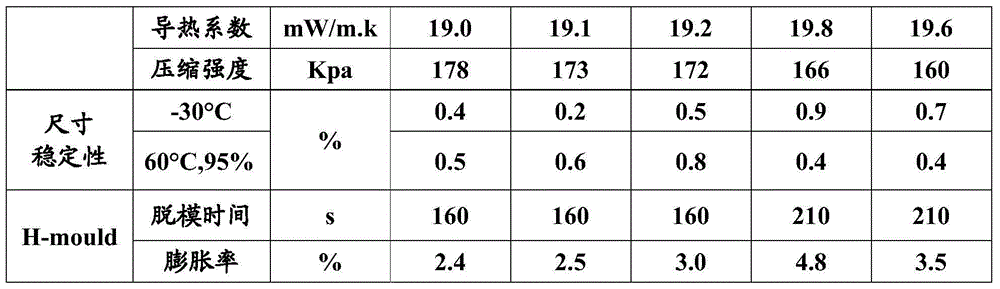

[0127] In Example 1-3, changing the ratio of polyol components (a1) to (a5) and the ratio of each component in the composite catalyst can prepare polyurethane foam with short demoulding time, high strength and good dimensional stability, See Table 1 for details. Among them, the polyol composition of Comparative Example 1 did not include the polyol components (a3) and (a5), and the polyol composition of Comparative Example 2 did not include the polyol compositions (a1) and (a2).

[0128] Table 1

[0129]

[0130]

[0131] As can be seen from Examples 1, 2 and 3 in Table 1 above, high-functionality polyether and aromatic amine polyether polyol compositions can be used to produce polyurethane foams with high strength and good mold release properties, and the foams Has good dimensional stability.

[0132] As can be seen from Table 1 above, Comparative Example 1 does not contain polyol components (a3), (a5), foam expansion rate and thermal conductivity increase significan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com