III-shaped hypergravity device and technology for continuous preparation of toluene diisocyanate

A toluene diisocyanate, hypergravity technology, applied in the preparation of isocyanic acid derivatives, the preparation of organic compounds, chemical/physical/physical-chemical nozzle reactors, etc., can solve the problem of poor reaction selectivity, reaction device failure, Problems such as declining conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

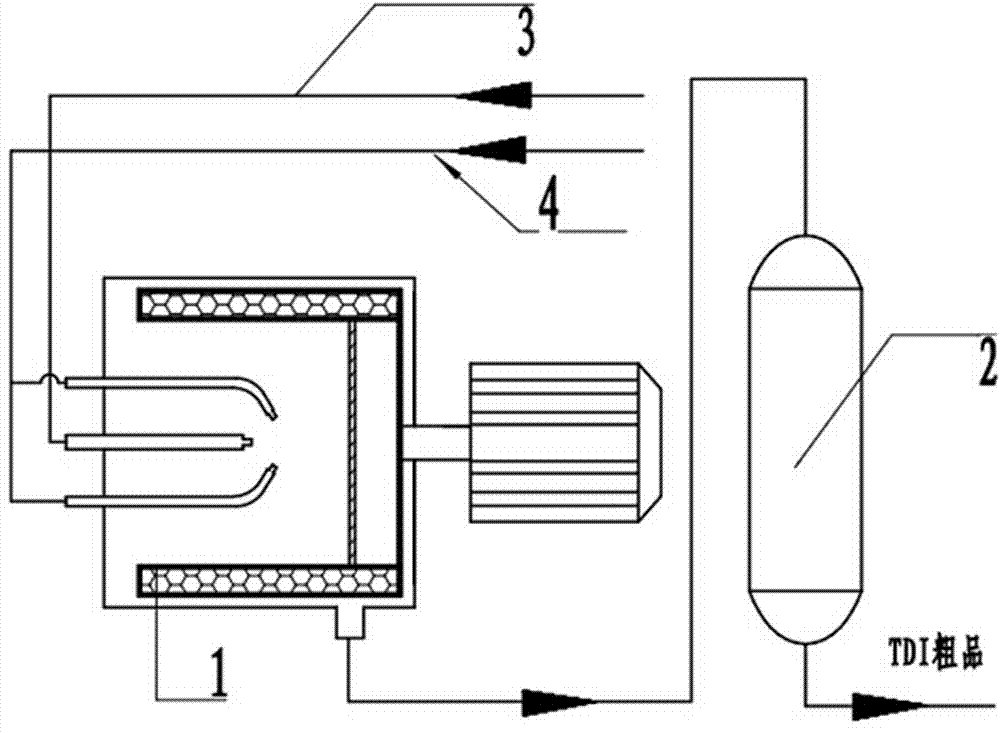

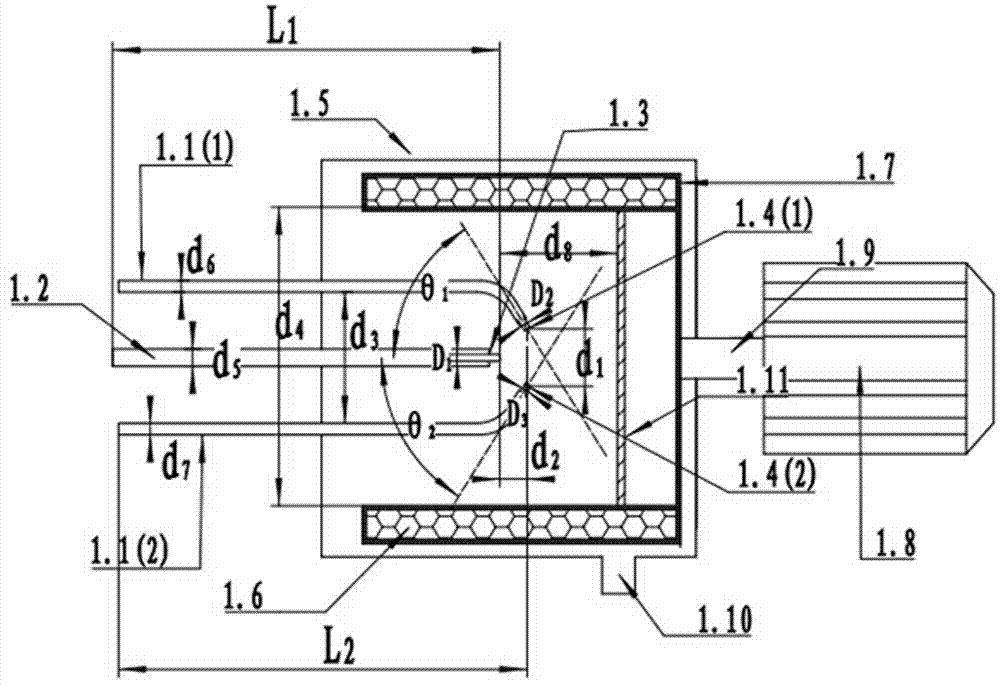

[0073] In a TDI manufacturer, the process and device of the present invention were used to carry out a pilot test. The details are as follows: o-dichlorobenzene light solvent is used as the inert solvent, the temperature of the toluene diamine inert solvent solution is 110°C, the mass fraction is 40%, and the mass flow rate The temperature of the phosgene inert solvent solution is 70℃, the mass fraction concentration of phosgene is 20%, the mass flow rate is 15240kg / h, and the volume flow ratio of phosgene to toluene diamine inert solution is approximately 15:1. The reactor is reacting with a rotating packed bed supergravity structure, and the filler is wire mesh packing; the diameter of the main feed pipe of the cold reactor is d 5 100mm, the main feed pipe diameter d 5 And main feed nozzle diameter D 1 The ratio range is 50, the main feed pipe nozzle diameter D 1 2mm; the ratio of the diameter of the secondary feed pipe to the diameter of the main feed pipe is in the range ...

Embodiment 2

[0077] In a TDI manufacturer, the process and device of the present invention are used for pilot experiments. The details are as follows: o-dichlorobenzene light solvent is used as the inert solvent, the temperature of the toluene diamine inert solvent solution is 150℃, the mass fraction is 40%, and the mass flow rate 9000Kg / h; the temperature of the phosgene inert solvent solution is 110℃, the phosgene mass fraction concentration is 50%, the mass flow rate is 37800kg / h, the volume flow ratio of phosgene to toluene diamine inert solution is approximately 4:1, enter The cold reactor is used for reaction, adopts a stator-rotor type supergravity structure, and the filler is metal foam filler; the diameter of the main feed pipe of the cold reactor is d 5 100mm, the main feed pipe diameter d 5 And main feed nozzle diameter D 1 The ratio range is 1, the main feed pipe nozzle diameter D 1 100mm; the ratio of the diameter of the secondary feed pipe to the diameter of the main feed pipe i...

Embodiment 3

[0081] In a TDI manufacturer using the process and device of the present invention to carry out a pilot test, the details are as follows: o-dichlorobenzene light solvent is used as the inert solvent, the temperature of the toluene diamine inert solvent solution is 120°C, the mass fraction is 30%, and the mass flow rate 10500Kg / h; the temperature of the phosgene inert solvent solution is 90℃, the phosgene mass fraction concentration is 20%, the mass flow rate is 11300kg / h, and the volume flow ratio of phosgene to toluene diamine inert solution is approximately 1:1. The reactor is used for reaction and adopts spiral channel type supergravity structure. The diameter of the main feed pipe of the cold reactor is d 5 100mm, the main feed pipe diameter d 5 And main feed nozzle diameter D 1 The ratio range is 10, the main feed pipe nozzle diameter D 1 10mm; the ratio of the diameter of the secondary feed pipe to the main feed pipe is 0.5, and the diameter of the secondary feed pipe d 6 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com