Enclosed composite member forming tool and application method thereof

A composite material component and forming tooling technology, applied in the application, household components, household appliances and other directions, can solve the problems of difficult processing of split forming tooling, affecting the appearance quality of the parts, reducing the service life and other problems, so as to shorten the demoulding time. , the effect of improving service life and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

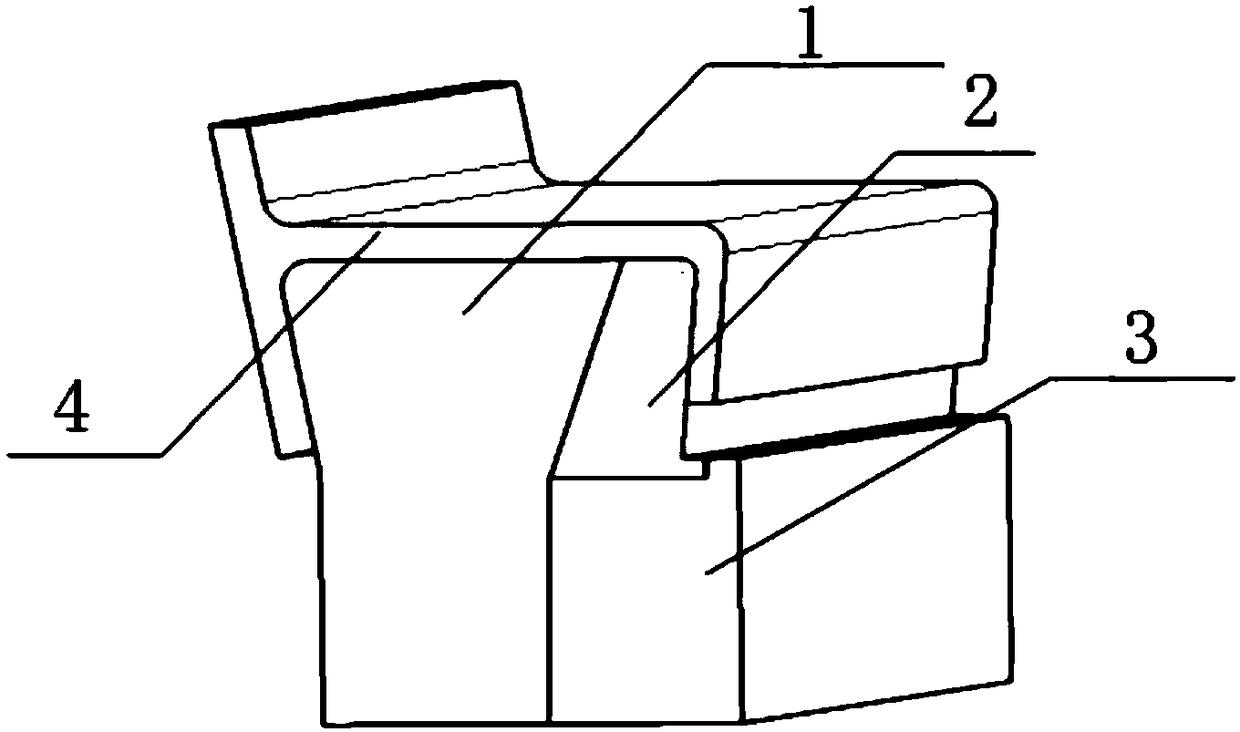

[0022] For the "J" type composite beam, the length is 11.8 meters, the angle between the edge strip and the web in the non-open area is 84.5°, there is a large closure, and it is difficult to demould. Adopt the forming frock design scheme of the present invention, the closed area is split, and the split angle is 60°, which ensures that the split frock 2 is open and can be pulled out from the mold (see attached figure 2 ). After the mold is cleaned first, the split tooling 2 is placed on the bottom bracket 3, and the bottom bracket 3 is placed close to the split tooling 1, and then the prepreg is laid up. After the parts are solidified, demoulding is carried out, and the bottom support 3 is removed from the mold in a horizontal direction, so that the split tooling 2 is in a suspended state. Then slide the split tooling 2 downwards out of the inner cavity of the part, gently tap the composite material part to separate it from the split tooling 1, and remove the part to complet...

Embodiment 2

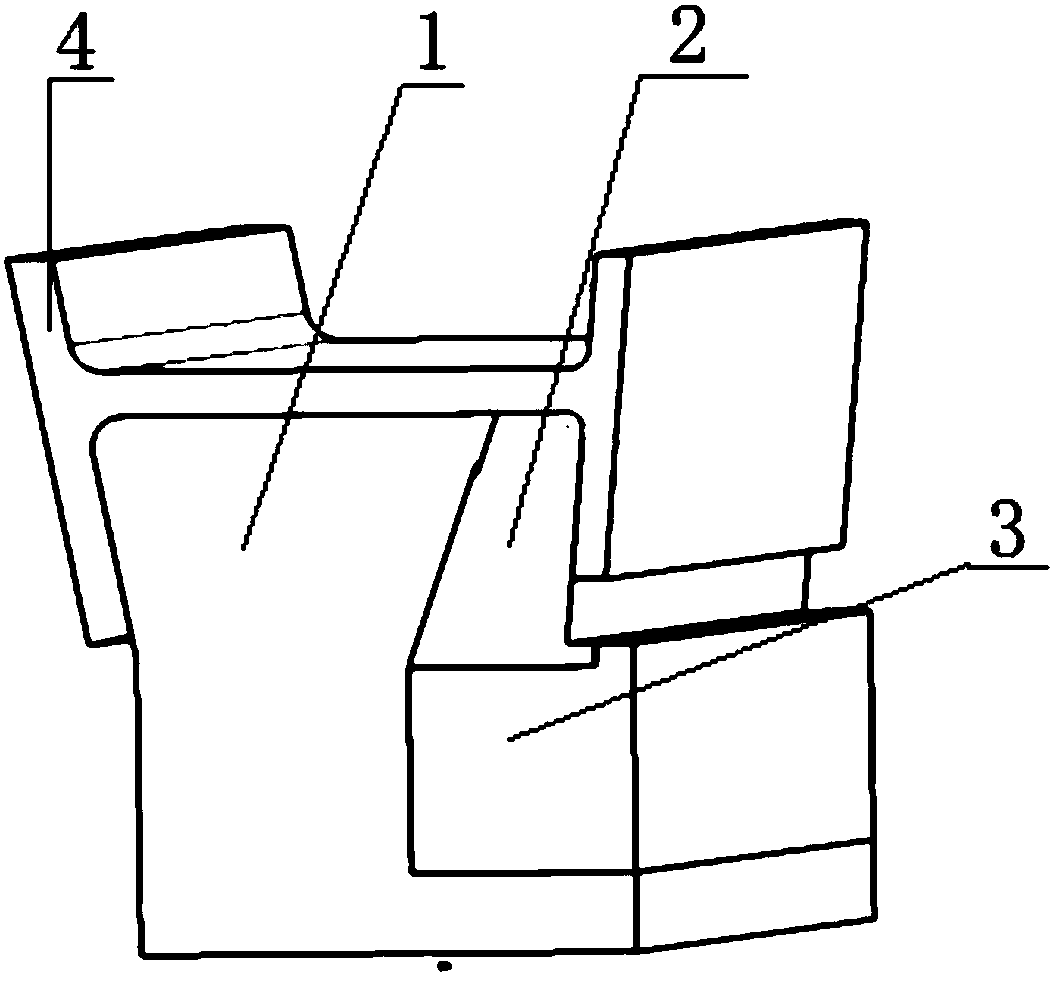

[0024] For the "I" type composite rib, the angle between the edge strip and the web in the non-open area is 83.3°, there is a large closure, and it is difficult to demould. Adopt the mold design of the present invention, the closing area is carried out split body, guarantee that the split frock 2 is open, can deviate from the mould (see attached image 3 ). After the mold is cleaned first, the split tooling 2 is placed on the bottom bracket 3, and the bottom bracket 3 is placed close to the split tooling 1, and then the prepreg is laid up. After the parts are solidified, demoulding is carried out, and the bottom support 3 is removed from the mold in a horizontal direction, so that the split tooling 2 is in a suspended state. Then slide the split tooling 2 down from the inner cavity of the part, gently tap the composite material part to separate it from the split tooling 1, and then take the part out of the main tooling to complete the part manufacturing

Embodiment 3

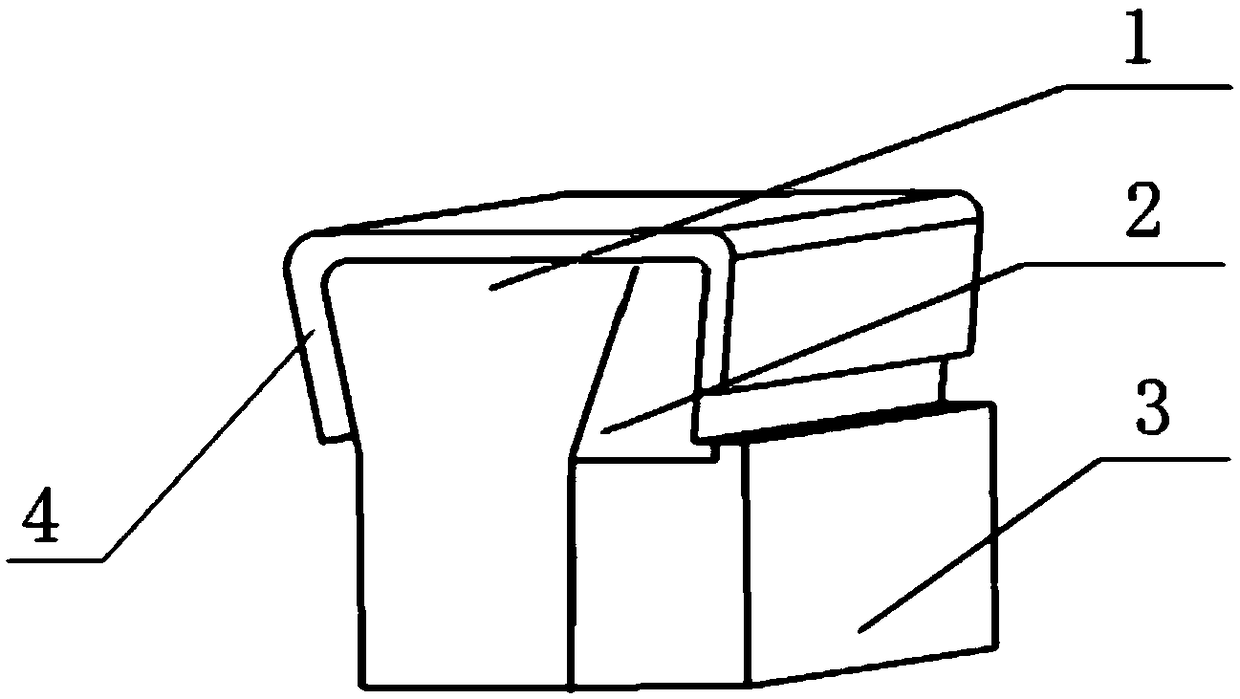

[0026] For the "C" type composite beam, the length is 6.2 meters, and the angle between the edge strip and the web in the non-open area is 81.5°, there is a large closure, and it is difficult to demould. Adopt the mold design of the present invention, the closed area is split, and the split angle is 63 °, which ensures that the split frock 2 is open and can be released from the mold (see attached figure 1 ). After the mold is cleaned first, the split tooling 2 is placed on the bottom bracket 3, and the bottom bracket 3 is placed close to the split tooling 1, and then the prepreg is laid up. After the parts are cured, demoulding is carried out. First, the bottom bracket 3 is removed from the molding tool along the direction perpendicular to the length of the part, so that the split tooling 2 is in a suspended state. Then the split tooling 2 is slid downwards out of the inner cavity of the part, and the composite material part is gently tapped to separate it from the split tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com