Air bag die and method for machining air bag by adopting same

An airbag and mold technology, applied in the field of molds, can solve the problems of high labor intensity for mold users, lower airbag production efficiency, and increased labor intensity for operators, so as to improve appearance and quality, increase manufacturing yield, and reduce procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

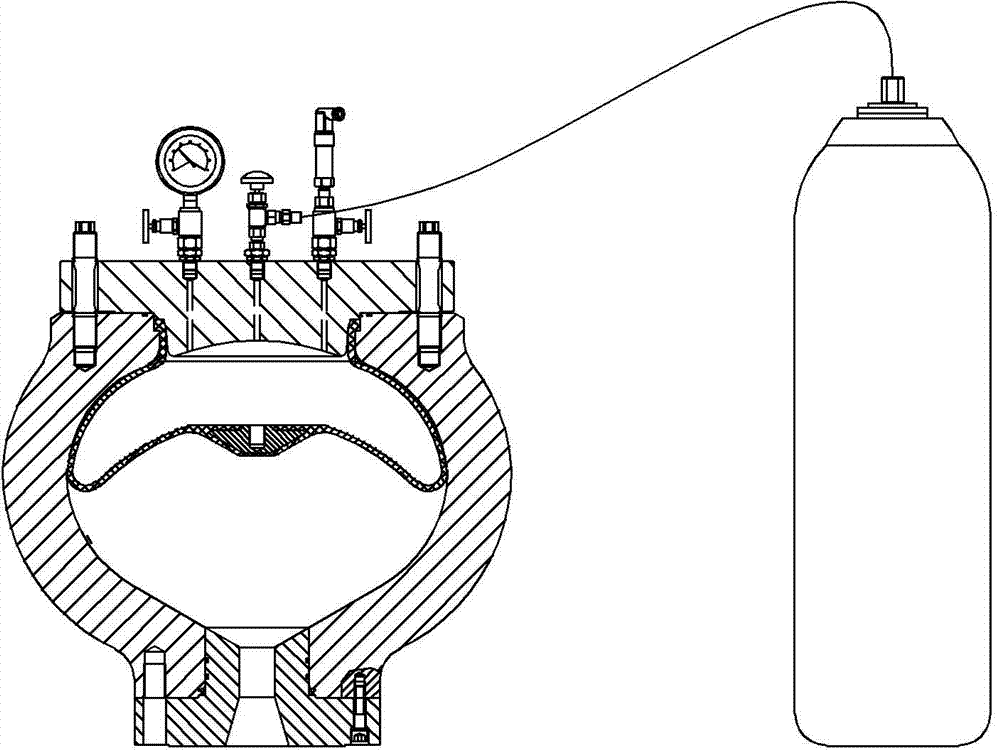

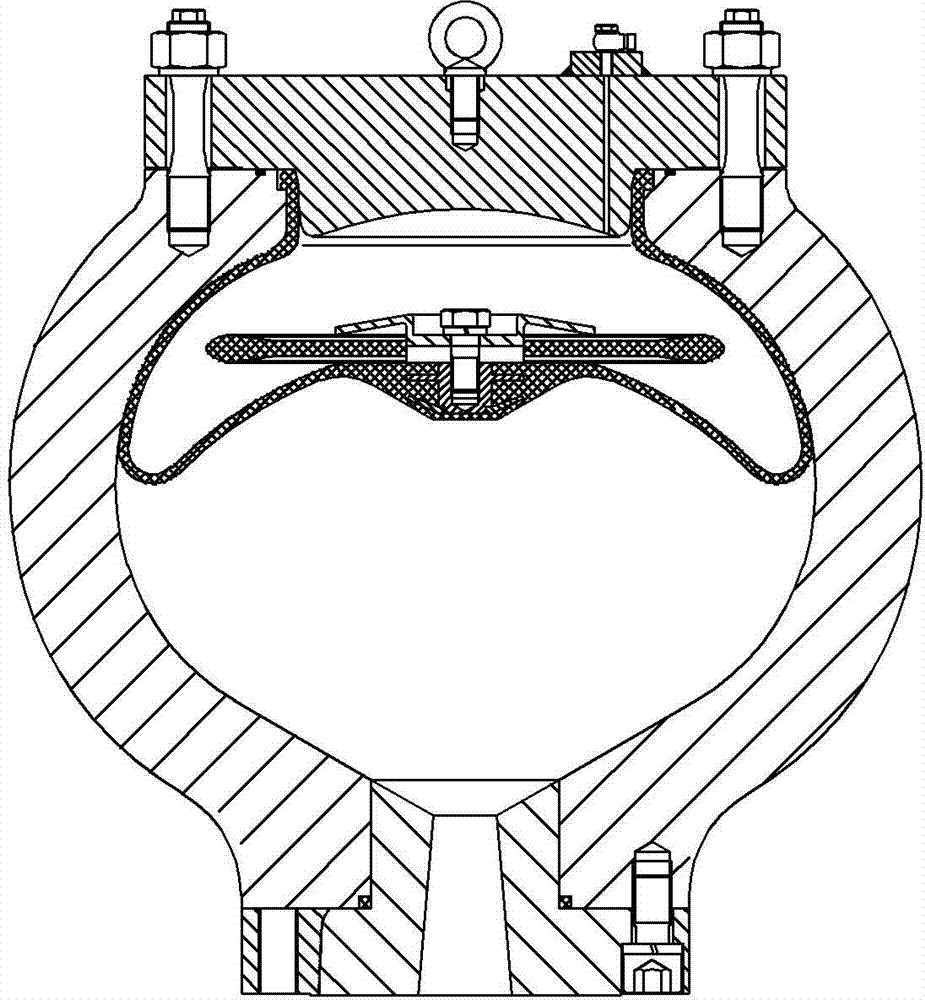

[0058] The airbag mold of the present invention will be described in further detail below in conjunction with the accompanying drawings.

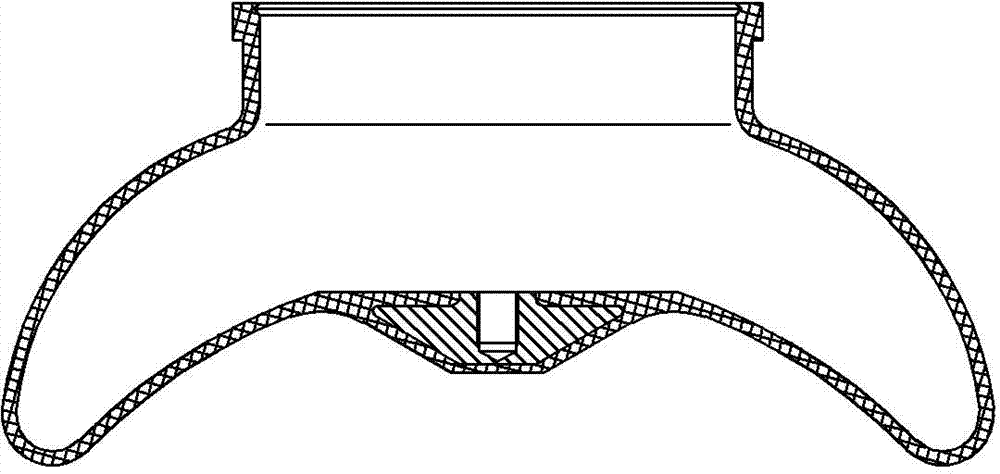

[0059] like Figure 6 and Figure 9 Shown are the structural schematic diagram of the airbag mold of the present invention, and the split view of each part of the airbag mold. The lower mold 12 is located at the bottom of the entire mold, and the middle part of the lower mold 12 has a conical protrusion 13 (arc surface), and a concave center 17 is formed at the top center of the conical protrusion 13. The shape of 16 is corresponding, and airbag iron core 16 is a trapezoidal platform; The wall height of the outer edge of lower mold 12 is slightly lower than the top of circular truncated protrusion 13, and the outer wall top of lower mold 12 has glue flow groove 1.

[0060] The top of the lower mold 12 is the central core 10, and the central core 10 is buckled upside down on the lower mold 12 like a "bowl". The center core 10 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com