Method for acquiring activated regenerated paracetamol pharmaceutical waste activated carbon through microwave heating

A technology of paracetamol and microwave heating, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problem of secondary pollution of drugs, achieve low cost, simple production process, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The method for regenerating paracetamol pharmaceutical waste activated carbon by microwave heating, its specific steps are as follows: first, 20g of paracetamol pharmaceutical waste activated carbon is placed in a microwave heating furnace with a power of 40kW, and the temperature is raised to After heat preservation at 500°C for 8 minutes, the paracetamol medicinal waste activated carbon after microwave heating was dried at 105°C for 24 hours, and the activated and regenerated paracetamol medicinal activated carbon could be prepared after cooling; the paracetamol medicinal waste activated carbon had a particle size of 200 mesh and a moisture content of is 40%, and the methylene blue value is 48mg / g.

[0018] The methylene blue adsorption value of the activated and regenerated acetaminophen medicinal activated carbon prepared through the above steps was 165.0 mg / g, and the activation and regeneration yield was 94.38%.

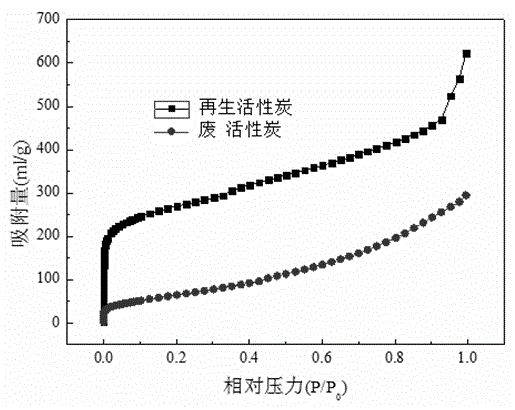

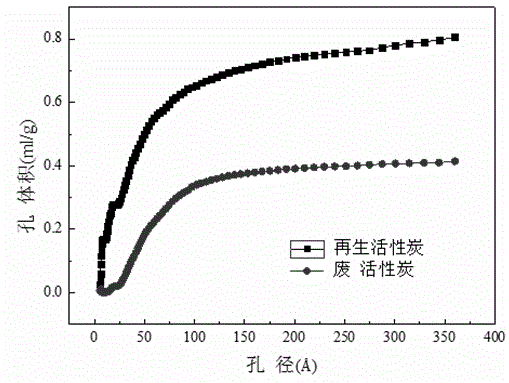

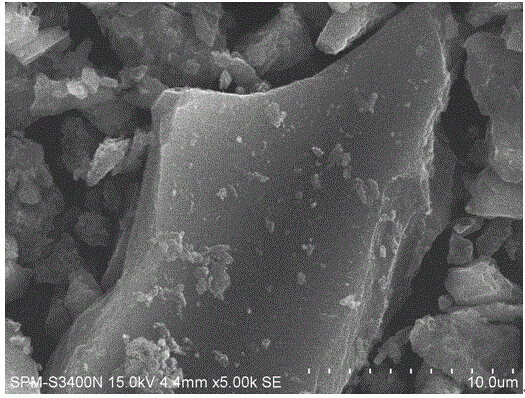

[0019] The nitrogen adsorption curve at 77K of the...

Embodiment 2

[0021] The method for regenerating paracetamol pharmaceutical waste activated carbon by microwave heating, its specific steps are as follows: first, place paracetamol pharmaceutical waste activated carbon in a microwave heating furnace with a power of 40 kW, and raise the temperature to 600 °C at a heating rate of 150-170 °C / min. After heat preservation at 10°C for 10 minutes, dry the paracetamol pharmaceutical waste activated carbon after microwave heating at 115°C for 48 hours, and then prepare activated and regenerated paracetamol pharmaceutical activated carbon after cooling; the particle size of the paracetamol pharmaceutical waste activated carbon is 200 mesh, and the water content is 36%, and the methylene blue value is 50mg / g.

[0022] The methylene blue adsorption value of the activated and regenerated acetaminophen medicinal activated carbon prepared through the above steps was 187.5 mg / g, and the activation and regeneration yield was 90.23%.

Embodiment 3

[0024] The method for regenerating paracetamol pharmaceutical waste activated carbon by microwave heating, its specific steps are as follows: first, place paracetamol pharmaceutical waste activated carbon in a microwave heating furnace with a power of 1 kW, and raise the temperature to 700 °C at a heating rate of 145-150 °C / min. After heating at 8°C for 8 minutes, the paracetamol medicinal waste activated carbon after microwave heating was dried at 110°C for 36 hours, and after cooling, the activated and regenerated paracetamol medicinal activated carbon could be prepared; the paracetamol medicinal waste activated carbon had a particle size of 200 mesh and a water content of 34%, methylene blue value is 40mg / g.

[0025] The methylene blue adsorption value of the activated and regenerated acetaminophen medicinal activated carbon prepared through the above steps was 172.5 mg / g, and the activation and regeneration yield was 90.54%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com