Hexastyle supporting type coal mining and filling hydraulic bracket

A hydraulic support and support technology, which is applied in the direction of filling, mine roof support, mining equipment, etc., can solve problems such as environmental threats, and achieve the effect of good filling effect, compact structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

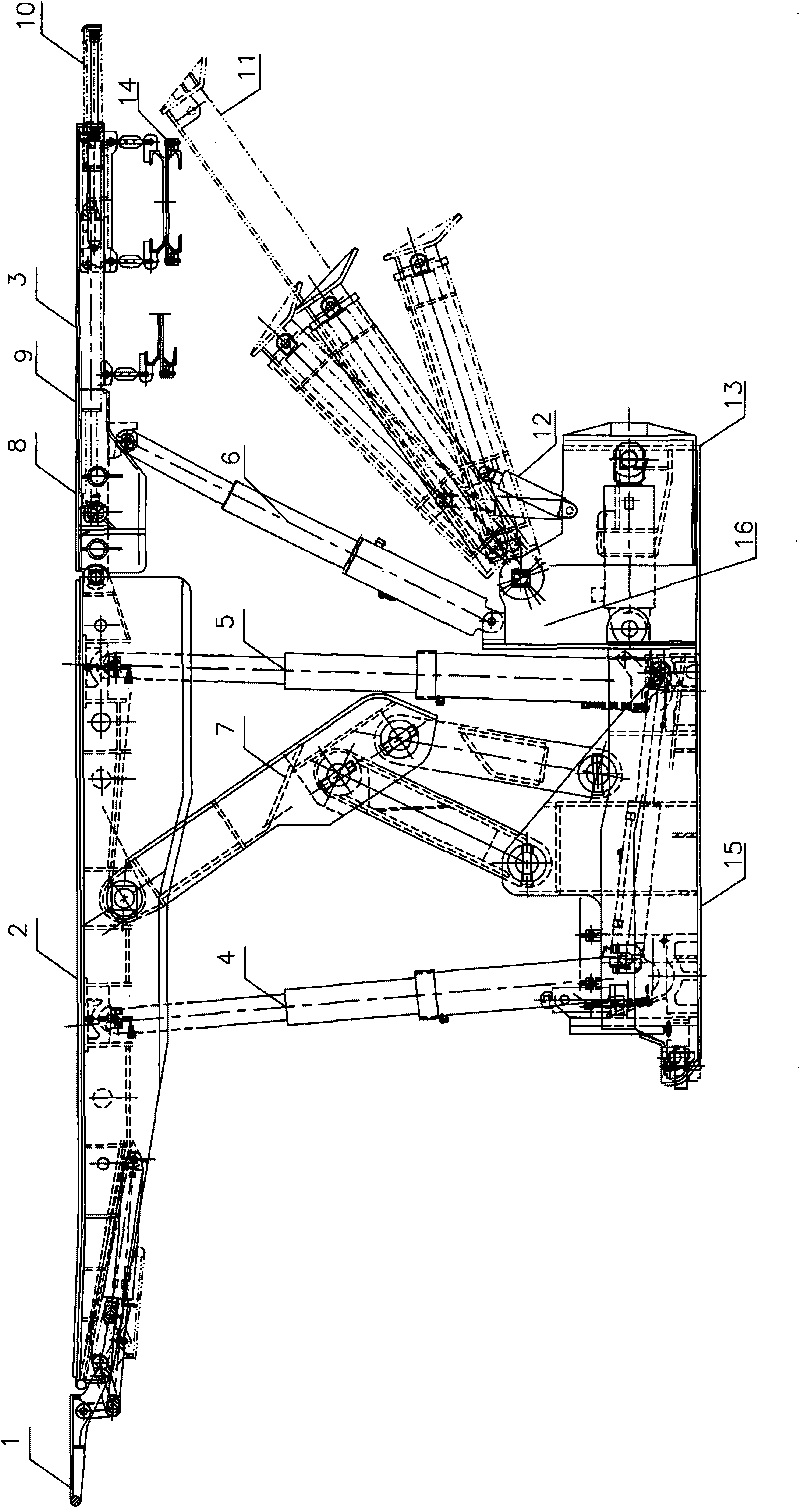

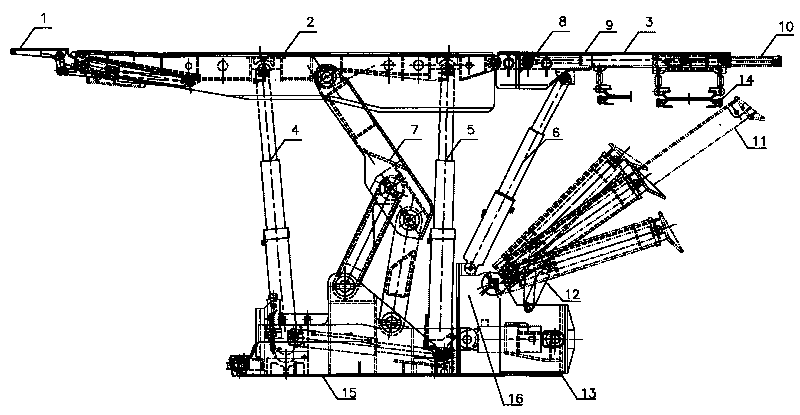

[0009] The present invention will be further described below in conjunction with the example in the accompanying drawings:

[0010] As shown in the accompanying drawings, the six-column supporting coal mining filling hydraulic support is mainly composed of a telescopic beam 1, a front top beam 2, a rear top beam 3, a front column 4, a middle column 5, a rear column 6, a four-bar linkage mechanism 7, a rear insertion Type roof protection device 10, middle and upper compacting mechanism 11, height-adjusting jack 12, lower box type compacting mechanism 13, filling and mining conveyor 14, base 15 and support 16 constitute. The telescopic beam 1 is located at the front portion of the front roof beam 2, and completes the telescopic action by being located at the telescopic oil cylinder under the front roof beam 2. The rear portion of the front roof beam 2 is connected to the rear roof beam 3, and the back roof beam 3 is hung with a filling and mining conveyor 14 by an anchor chain. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com