Sauce and juice dual-purpose pour-in valve

A filling valve, dual-purpose technology, used in packaging, bottle filling, liquid bottling, etc., can solve the problems of thermal deformation of valve body components, poor fluidity, inability to meet production requirements, etc., to achieve the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

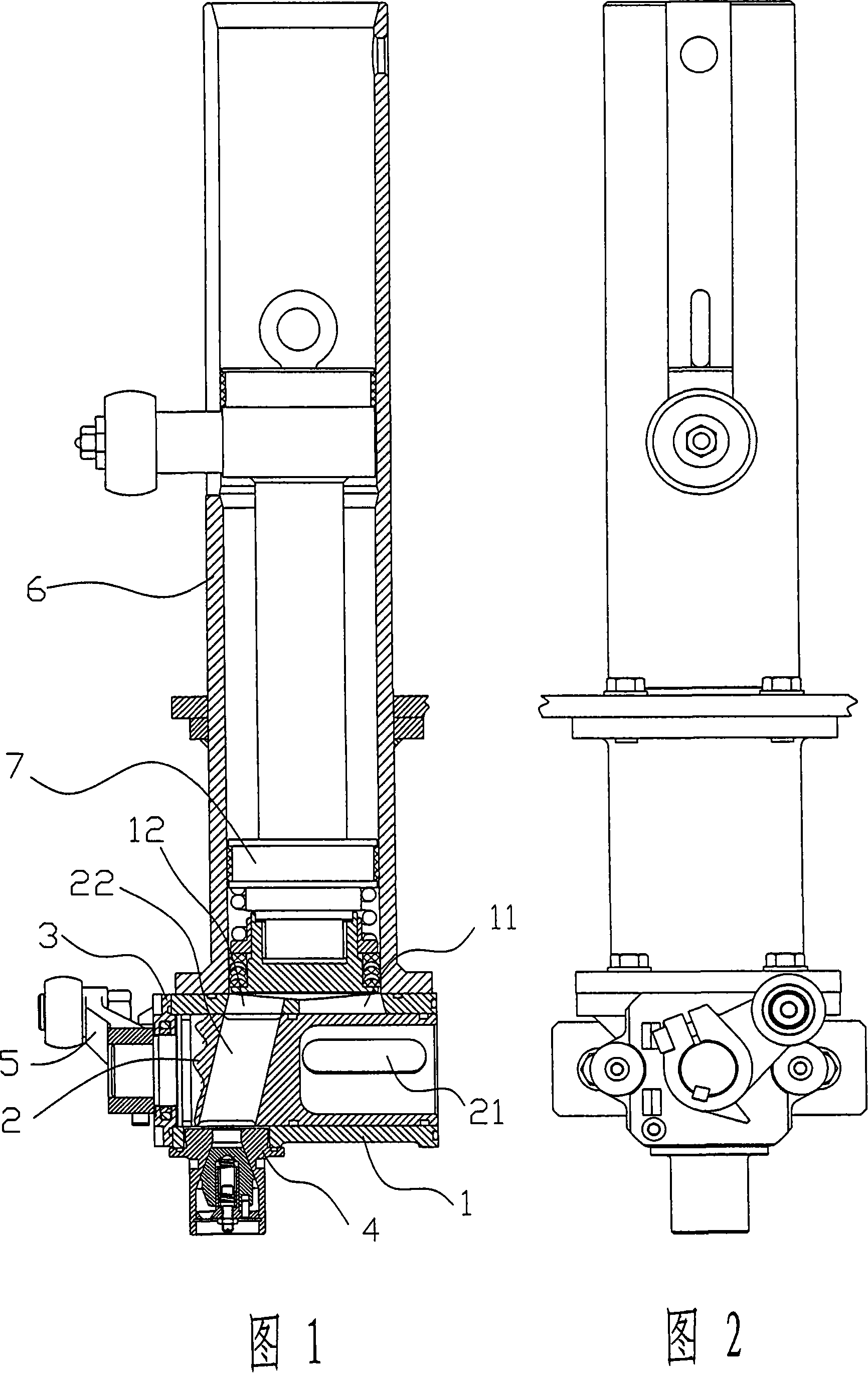

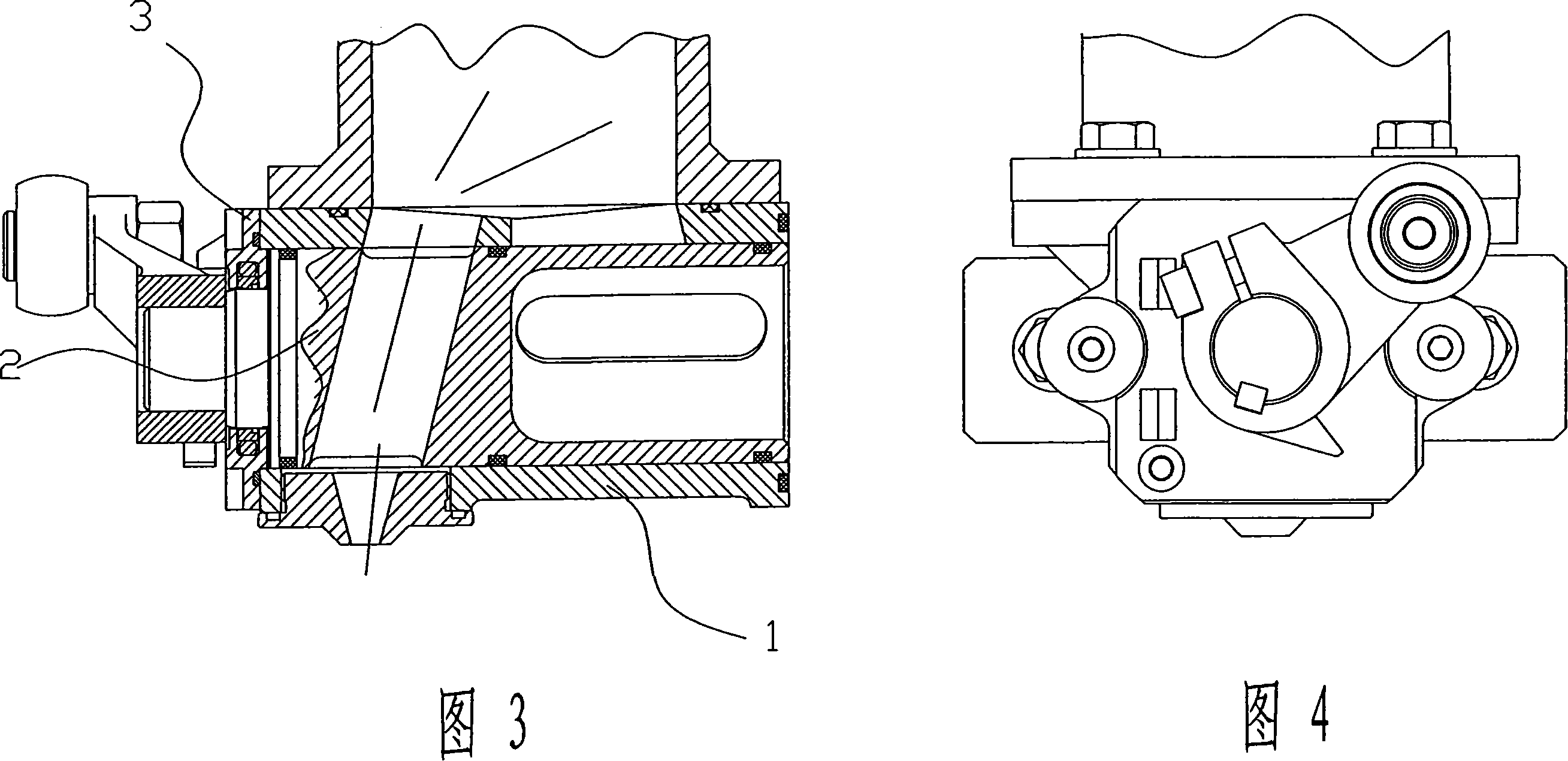

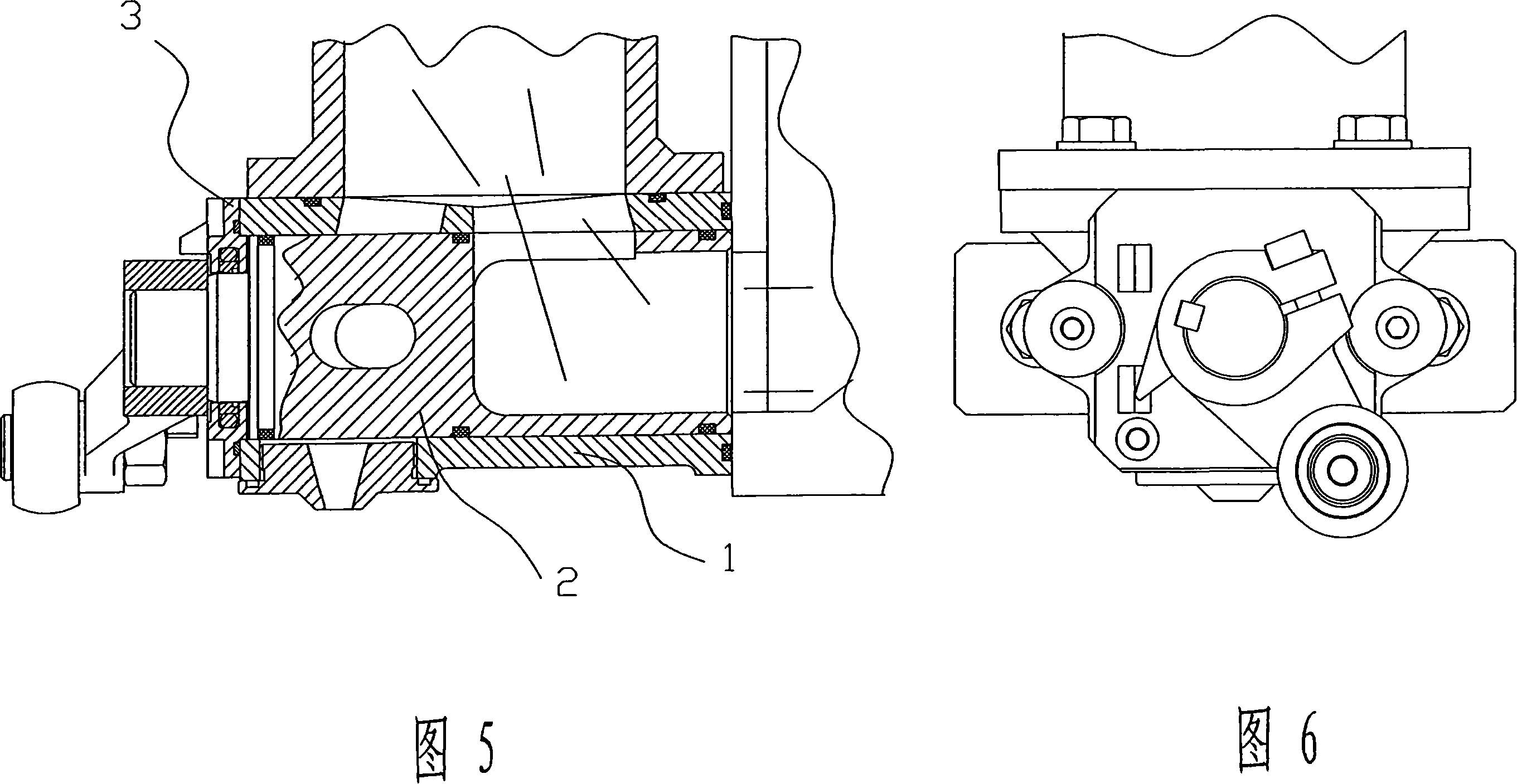

[0020] Shown in Figures 1, 2, 3, 4, 5, 6, 7 and 8, the dual-purpose filling valve for sauce and juice of the present invention includes a main valve body 1 and a cylinder that can rotate relative to it in the main valve body 1 Shaped main valve core 2, the inner surface of the main valve body 1 and the outer surface of the main valve core 2 are liquid-tight fit, and the part where the main valve core 2 protrudes from the main valve body 1 is provided with a sealing cover 3, and the sealing cover 3 is in contact with the main valve core 2. The main valve body 1 is fixedly connected, and a combination seal is used between the main valve core 2 and the sealing cover 3. The upper part of the main valve body is equipped with a quantitative piston cylinder 6, a suction and discharge piston 7, and a sauce filling valve at the lower part of the main valve body. There is a connecting body around the feed port, and a juice filling valve is conveniently connected to the connecting body. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com