Beam shaping system for metal SLM printing

A beam shaping, metal technology, applied in the direction of optics, optical components, process efficiency improvement, etc., can solve problems such as not being well elucidated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the specific embodiments and accompanying drawings are not intended to limit the scope of rights of the present invention.

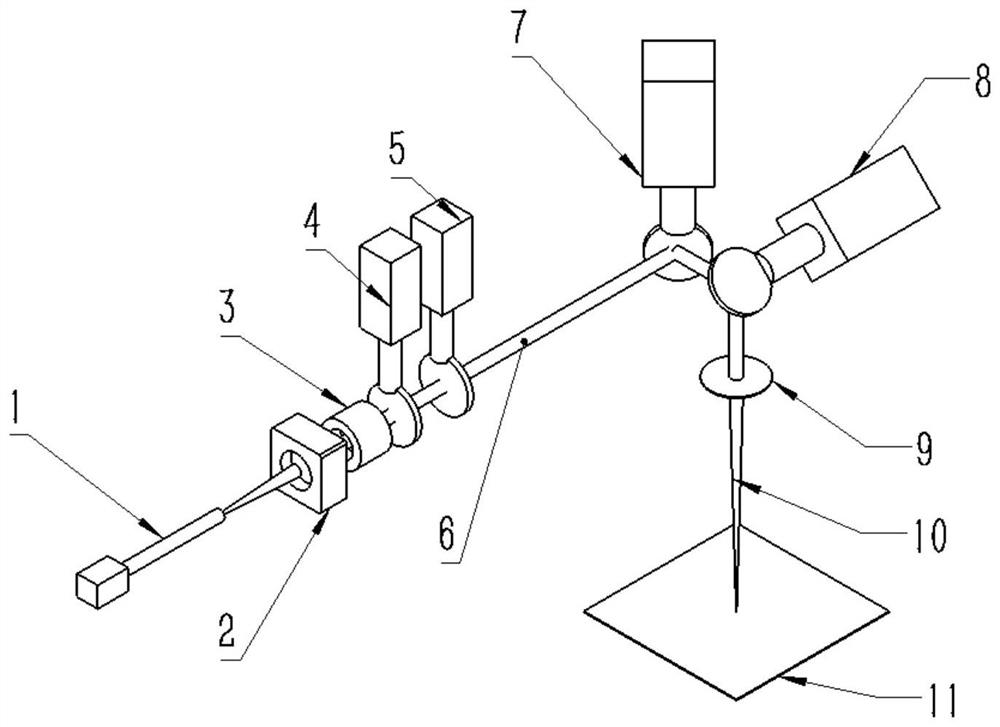

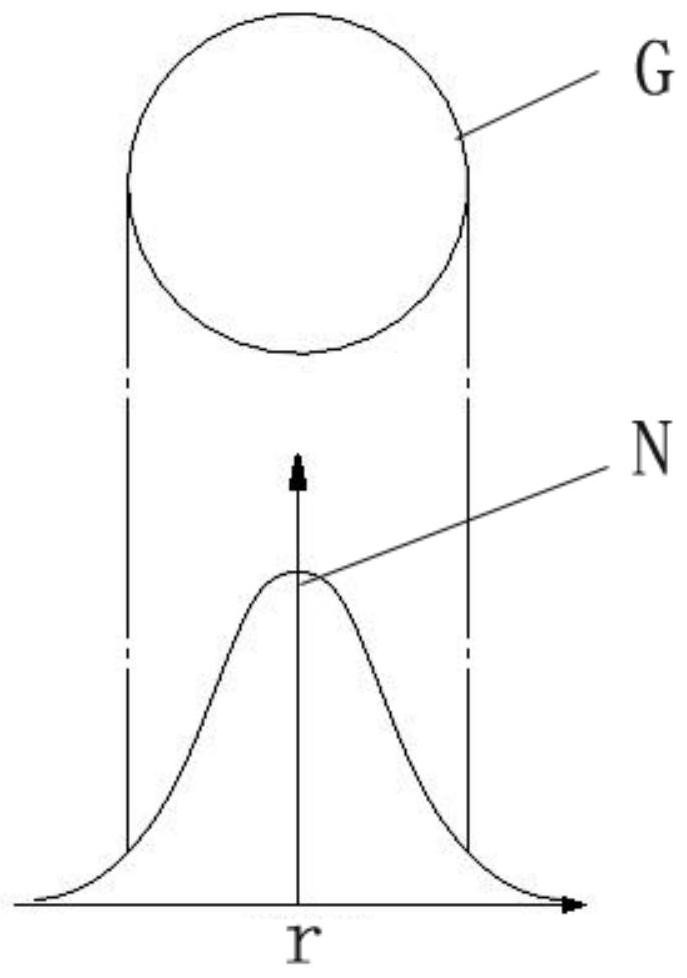

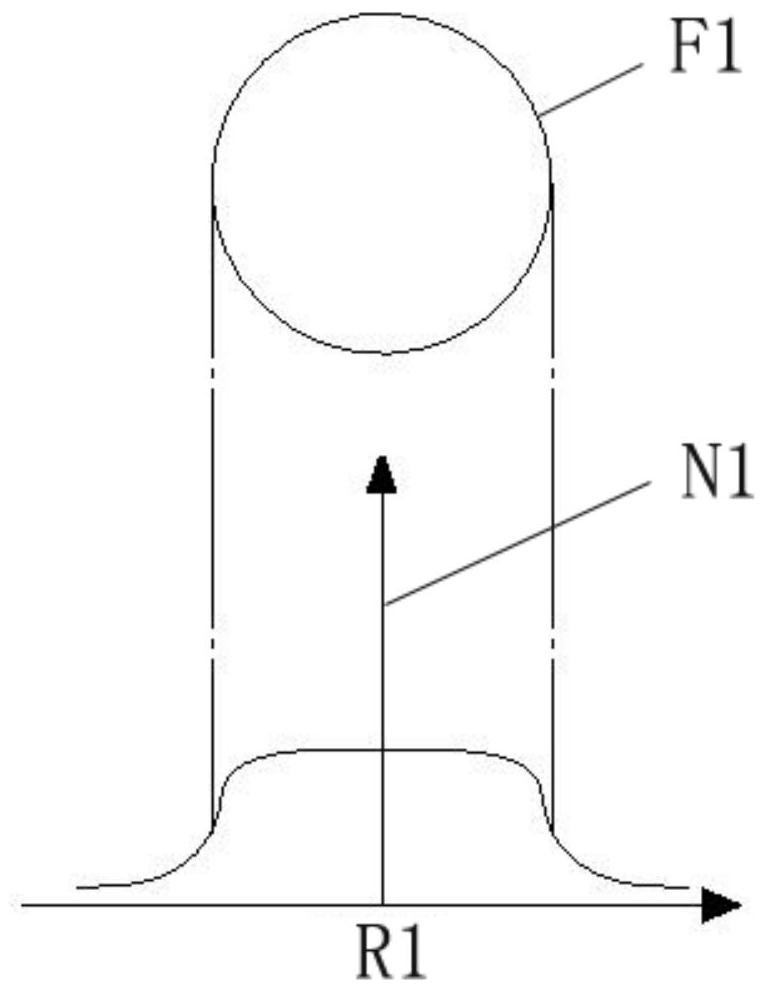

[0024] Such as Figure 1 to Figure 6 As shown, this embodiment provides a beam shaping system for metal SLM printing, including a laser 1, a collimator 2 arranged in sequence along the propagation direction of the laser beam emitted by the laser 1, a variable magnification beam expander 3, and a beam Shaping mechanism, galvanometer system and working platform 11, laser 1 is connected to collimator 2 with fiber interface through optical fiber, collimator 2 is connected to variable magnification beam expander 3, and variable magnification beam expander 3 is connected to beam shaping mechanism , the laser beam emitted by the laser 1 is collimated by the collimator 2, and the collimated beam em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com