Magnetic alloy powder for permanent magnet and mfg. method thereof

A technology of permanent magnets and magnetic alloys, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of flattening the shape of magnetic powder, reducing the molding efficiency, and deteriorating the fluidity of magnetic powder, achieving excellent atmospheric corrosion resistance, high temperature The effect of small change and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

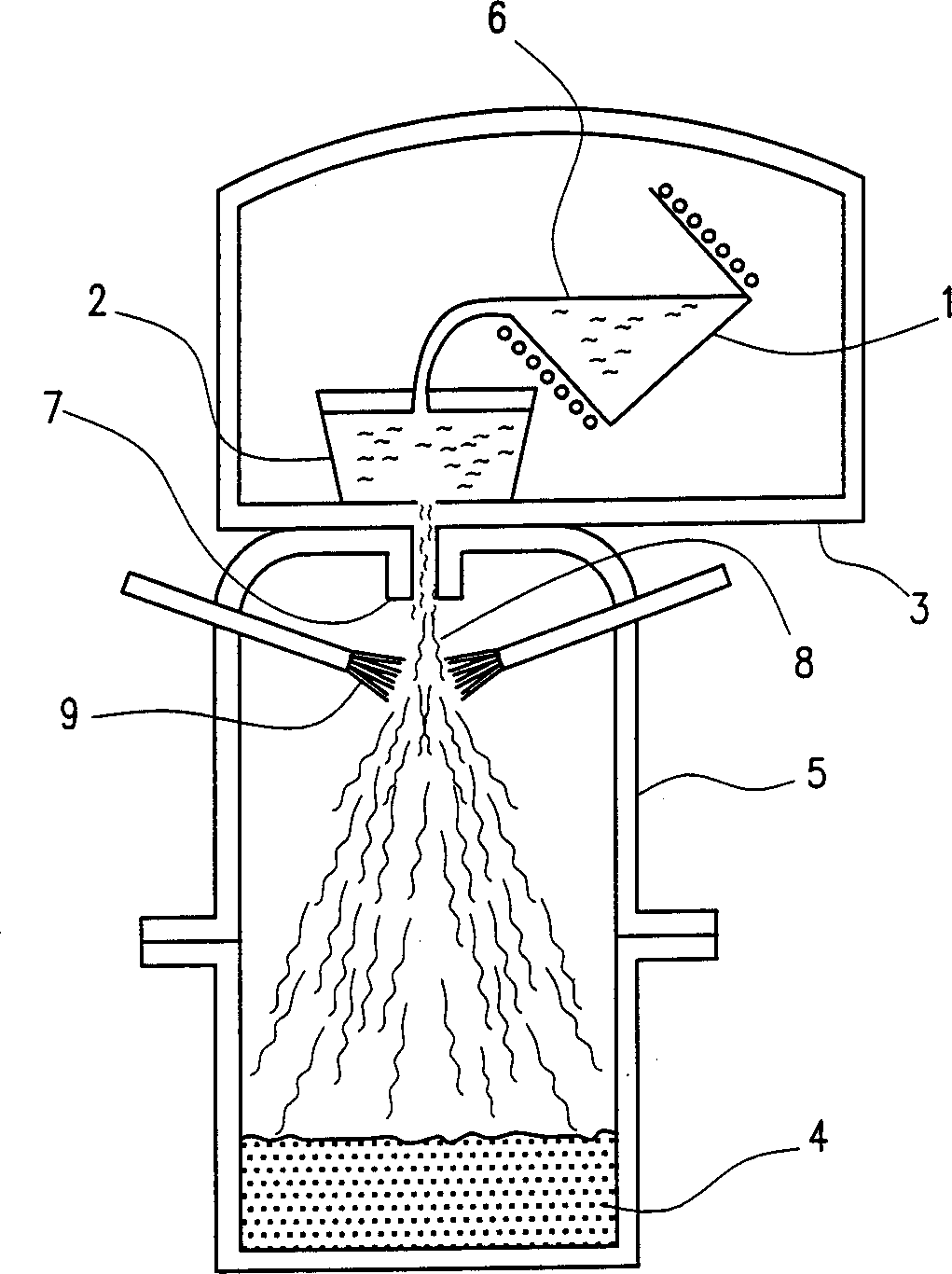

Method used

Image

Examples

Embodiment 1

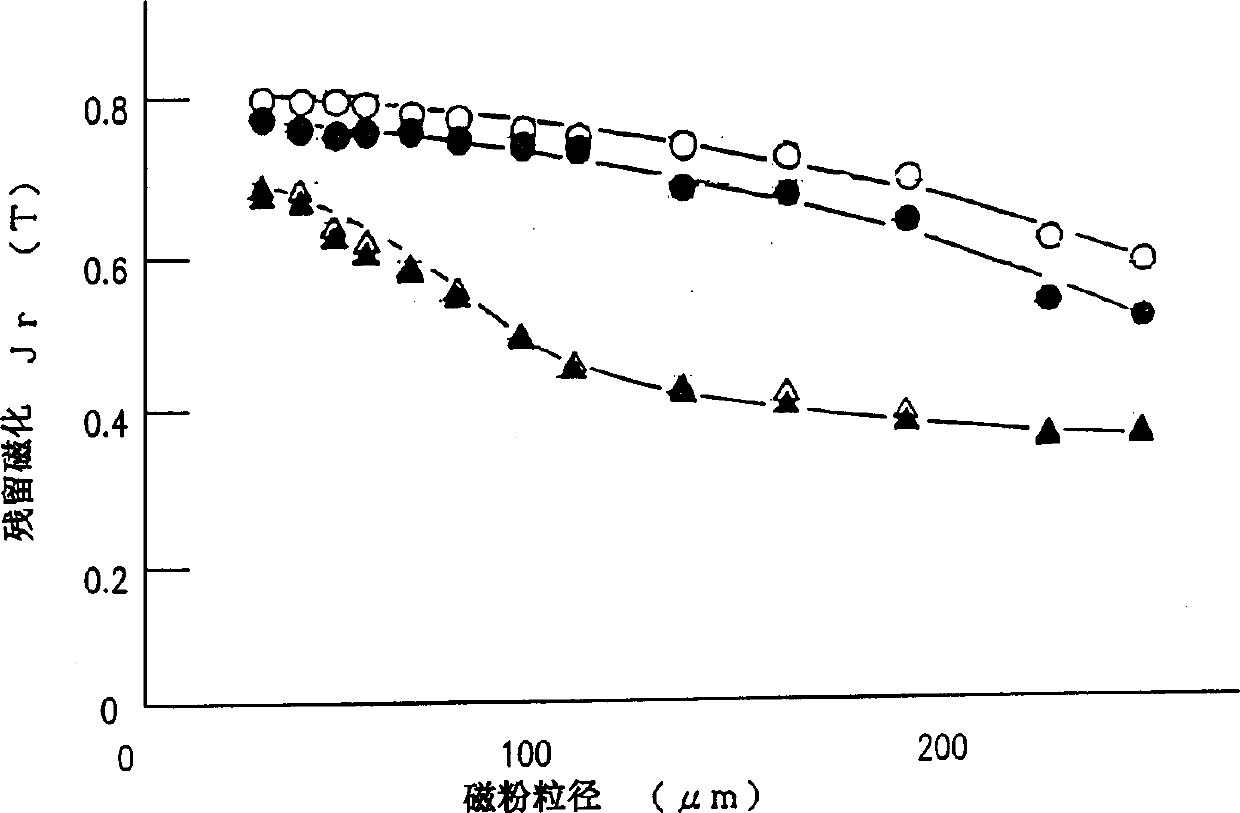

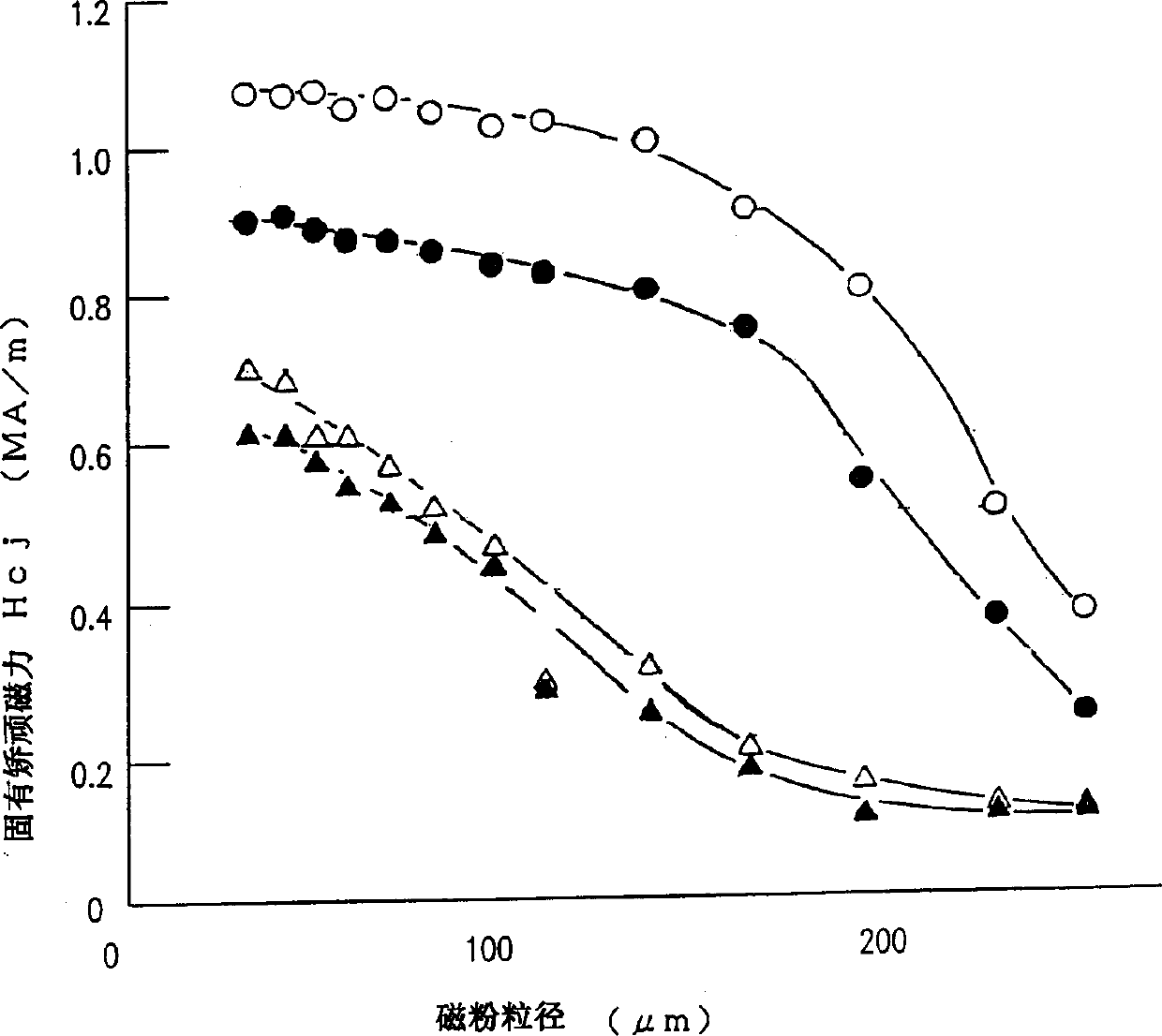

[0059] In this example, using master alloys having various compositions shown in Table 1 below, alloy melts were sprayed in an argon atmosphere to produce powders composed of spherical particles. The temperature of the alloy melt during spraying is about 1400-1500°C, and the temperature of the argon atmosphere is about 30°C.

[0060] Next, the thus-produced powder was classified with a sieve to obtain a powder with a particle diameter of 38 μm to 63 μm, and then the magnetic properties of the powder (residual magnetic flux density B r and coercive force H cJ ). Table 1 shows the evaluation results for sample Nos. 1 to 20. The values shown in Table 1 are values measured with a vibrating sample type magnetometer.

[0061] No.

Composition (mass%)

magnetic properties

Br(T)

h cJ (MA / m)

1

30.0Nd-69.0Fe-0.5B-0.5C

0.778

0.850

2

28.0Nd-69.0Fe-2.0Co-0.5B-0.5C

0.804

0.814

3

22.0Nd-8.0Pr-69.0Fe-...

Embodiment 2

[0078] In this embodiment, B is essential, and in addition to B, C, S, P, or Si is added. In this example, the melt of an alloy containing Q (Q is an element including B, C, S, P and / or Si) in an amount of 0.5% by mass to 2.0% by mass is rapidly cooled by a spraying method, thereby forming a powder change. The content ratio of B to the total content of Q is 0.10 or more and less than 0.95.

[0079] As can be seen from Table 3, excellent magnetic properties can be obtained according to this embodiment.

Embodiment 3

[0081] Powder particles with a particle size of 63 μm or less

[0082] As can be seen from Table 4, the recoveries of samples Nos. 1, 3, 21, 22 and 24 were 70% or more, which was much higher than the recoveries of samples Nos. 17 and 18 of the comparative example. This means that the addition of C, S, P and / or Si helps to make the particle size of the spray powder smaller. The main reason for the particle size reduction is that the viscosity of the alloy melt during spraying is reduced by adding an appropriate amount of elements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com