Low cost polyurethane material for safe tyre internal filling and using method thereof

A technology of polyurethane material and safety tire, applied in the field of tire inner filling material, can solve the problems of high cost, large amount of polyether, high viscosity, etc., and achieve the effects of simple operation, low raw material cost and fast filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

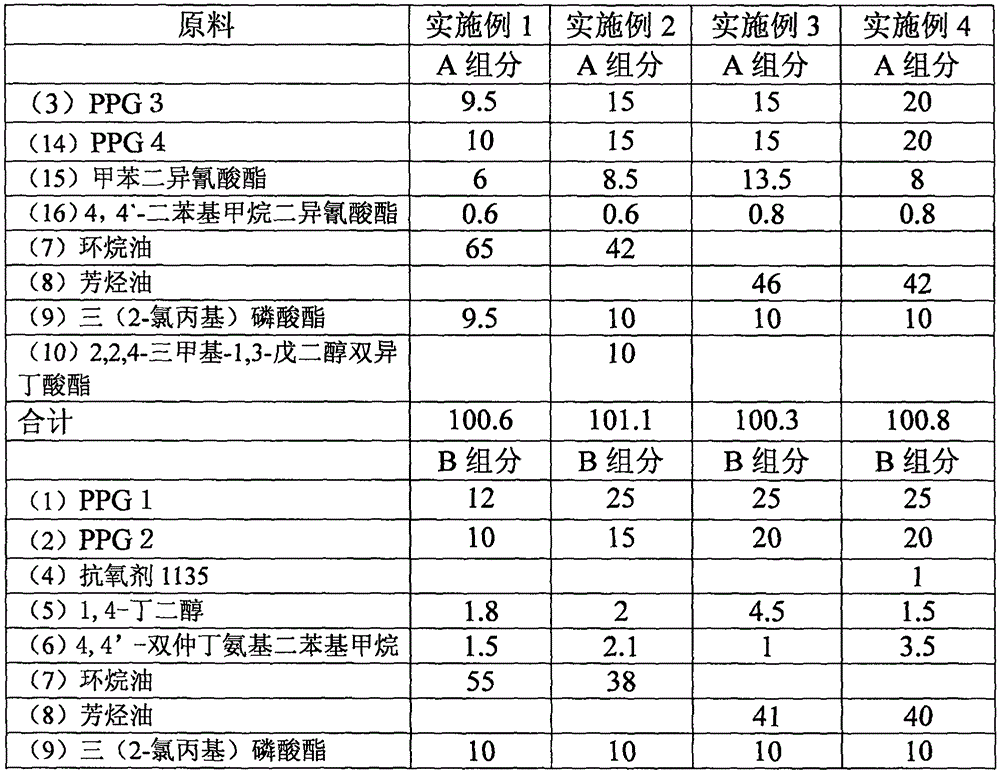

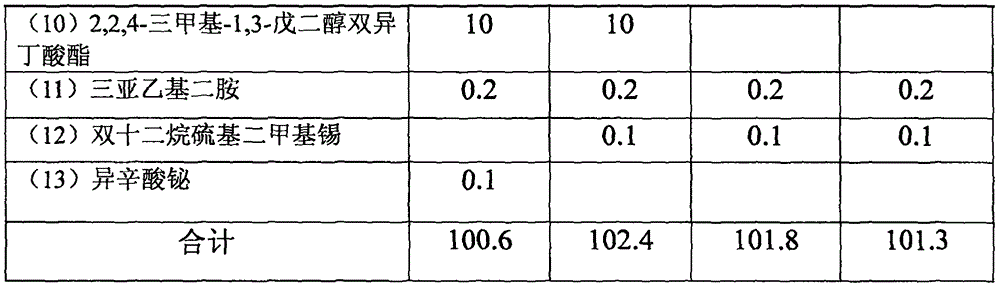

[0021] The present invention is described in detail below in conjunction with embodiment. The used raw material of embodiment formula:

[0022] (1) PPG 1 uses glycerin as the initiator of ethylene oxide and propylene oxide block polyols, with a functionality of 3 and a hydroxyl value of 36.

[0023] (2) PPG 2 uses glycerol as the initiator of ethylene oxide and propylene oxide block polyols, with a functionality of 3 and a hydroxyl value of 24.

[0024] (3) PPG 3 uses glycerin as the initiator of ethylene oxide and propylene oxide block polyols, with a functionality of 3 and a hydroxyl value of 28.

[0025] (4) PPG 4 uses ethylene glycol as the initiator of ethylene oxide and propylene oxide block polyols, with a functionality of 2 and a hydroxyl value of 28.

[0026] Embodiment 1-4 raw material parts by weight are shown in Table 1, raw materials (15), (16) and (3), (14) were stirred and reacted rapidly at 90 DEG C for 2 hours, and prepolymer was made, and (7)( 8) (9) (10) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com