Sand filling device for flood control sandbags used in geological disasters

A technology of geological disasters and sandbags, applied in dikes, water conservancy projects, sea area projects, etc., can solve the problems of low hand safety, slow filling speed, time-consuming and labor-intensive problems of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

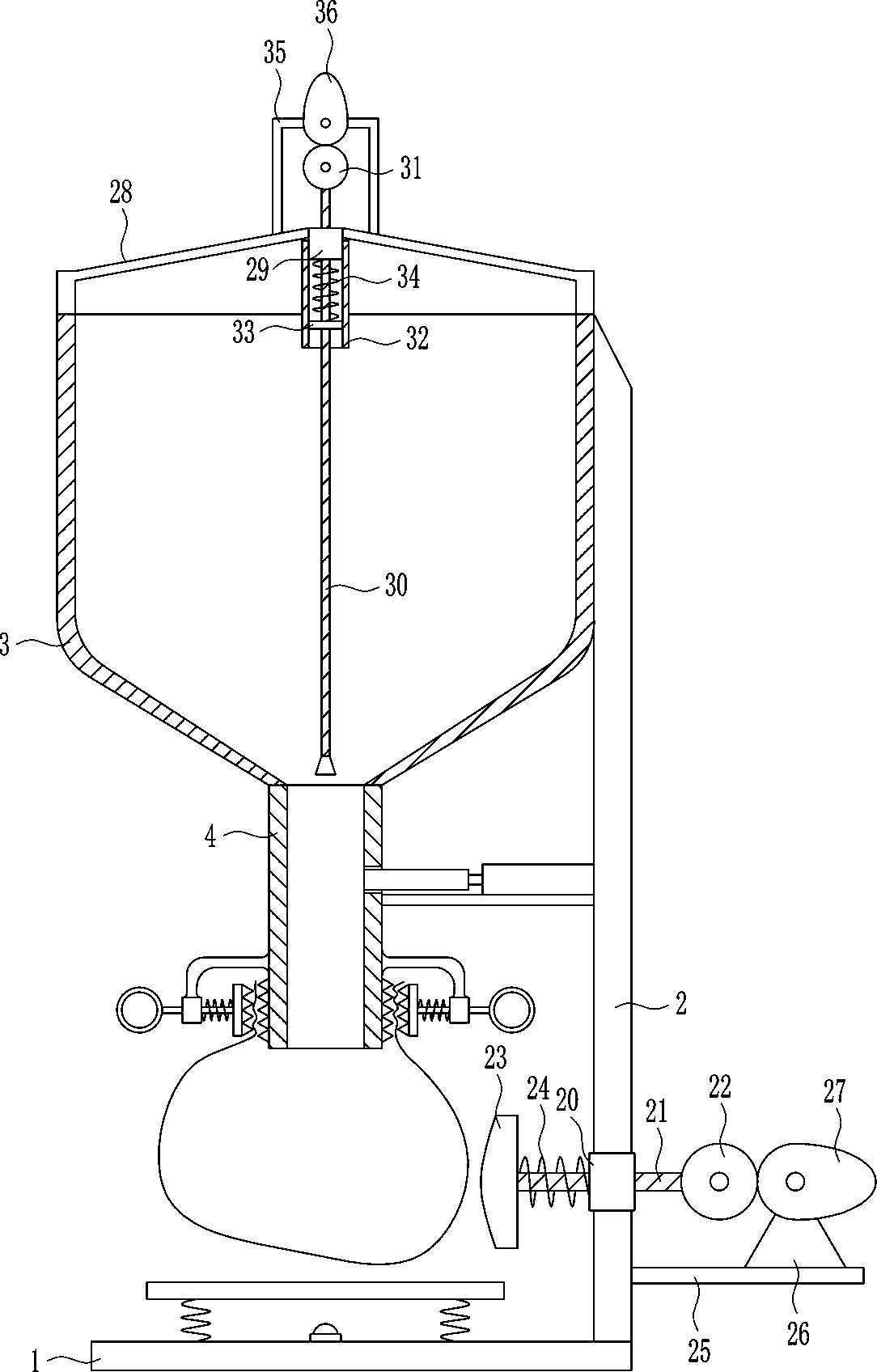

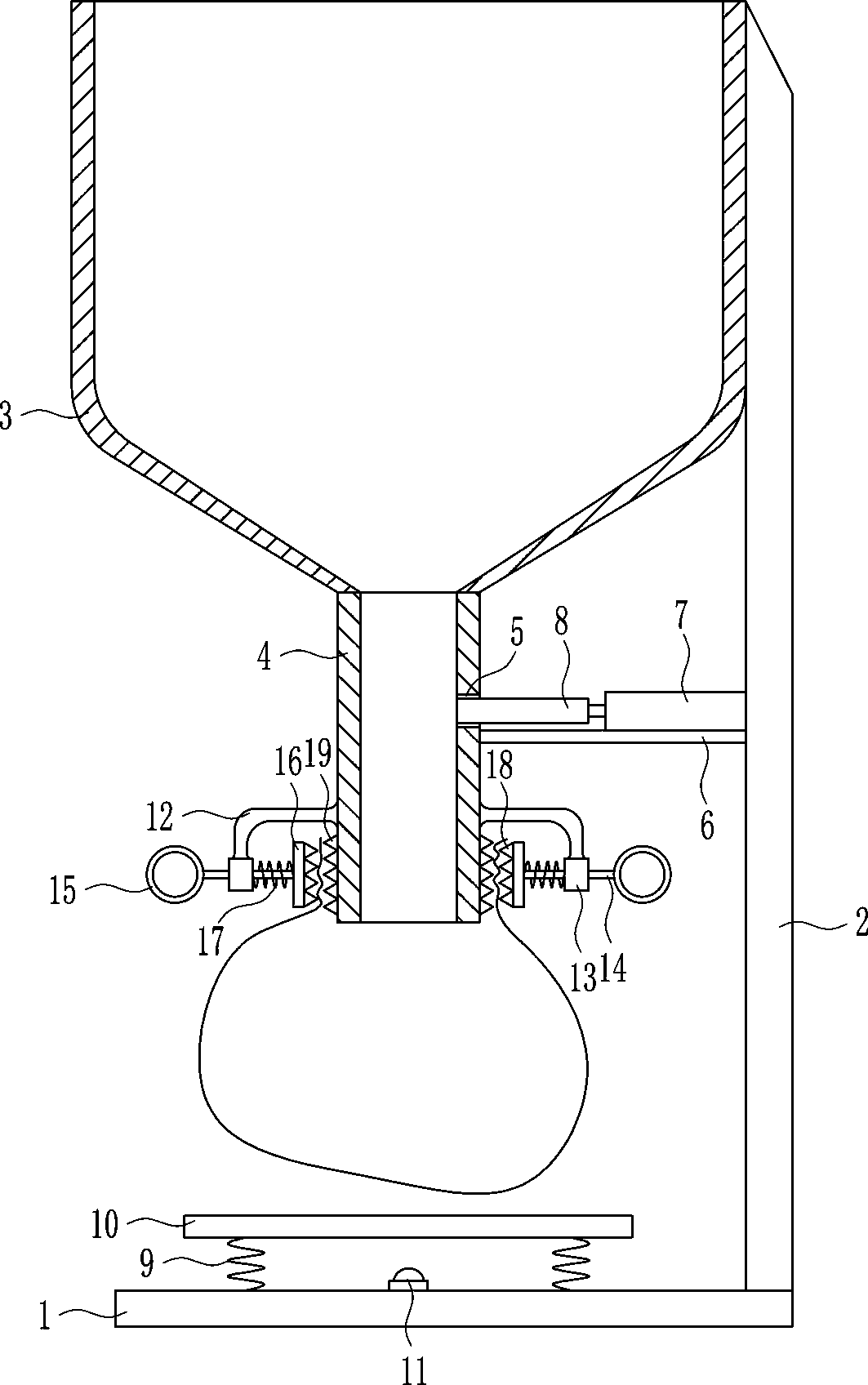

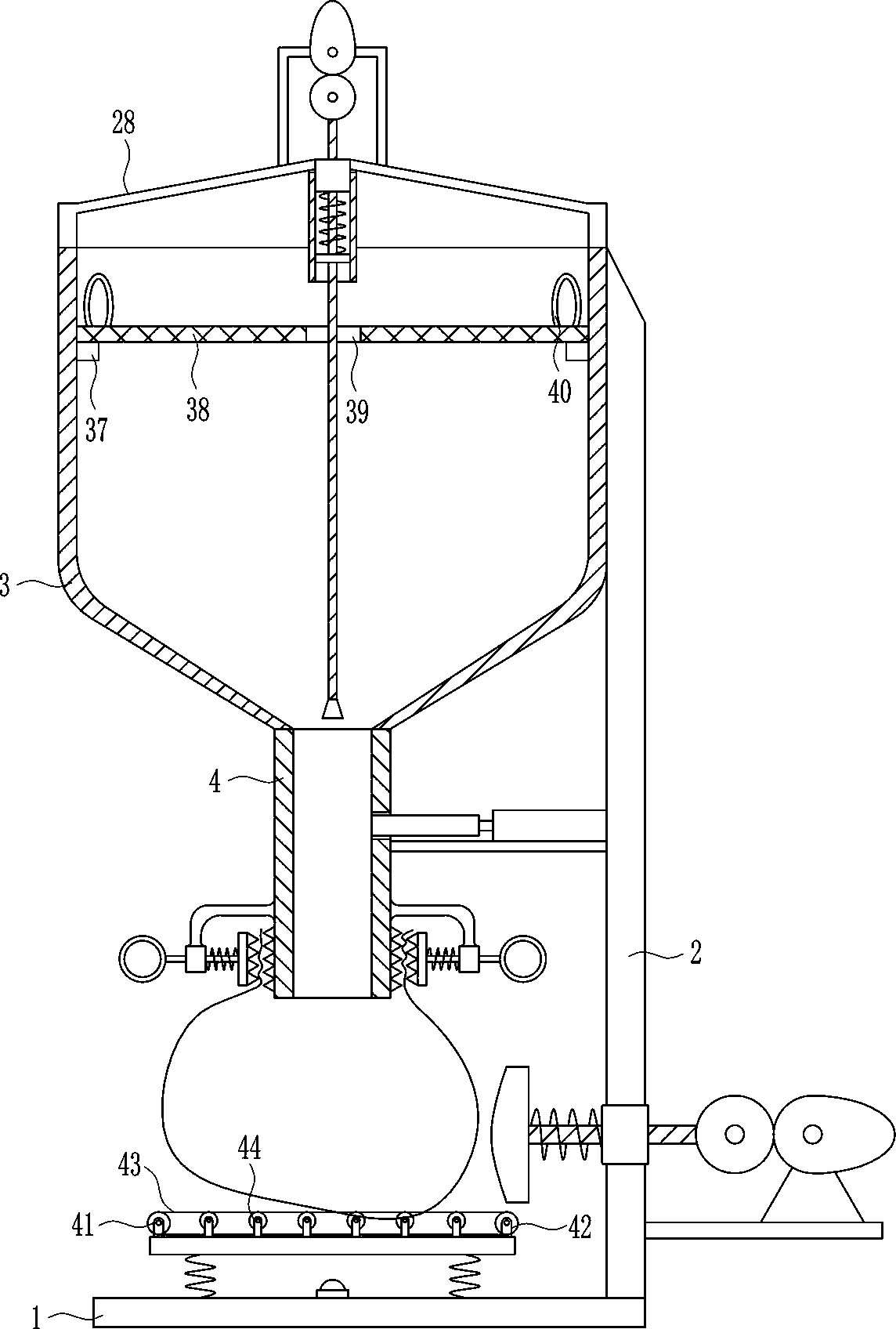

[0022] A flood control sandbag filling sand device for geological disasters, such as Figure 1-3 As shown, it includes a base plate 1, a support plate 2, a material storage box 3, a feeding pipe 4, a horizontal plate 6, a cylinder 7, a baffle plate 8, a first spring 9, a pressure plate 10, a contact switch 11, and a first connecting rod 12 , the first guide sleeve 13, the first guide rod 14, the pull ring 15, the pressure block 16, the second spring 17, the first tooth plate 18 and the second tooth plate 19, the top right side of the bottom plate 1 is provided with a support plate 2, the support The upper left side of the plate 2 is provided with a material storage box 3, the middle of the bottom of the material storage box 3 is provided with a feeding pipe 4, the upper part of the right wall of the feeding pipe 4 has an opening 5, and the left middle part of the support plate 2 is provided with a horizontal plate 6. The left end of the plate 6 is in contact with the middle pa...

Embodiment 2

[0024] A flood control sandbag filling sand device for geological disasters, such as Figure 1-3 As shown, it includes a base plate 1, a support plate 2, a material storage box 3, a feeding pipe 4, a horizontal plate 6, a cylinder 7, a baffle plate 8, a first spring 9, a pressure plate 10, a contact switch 11, and a first connecting rod 12 , the first guide sleeve 13, the first guide rod 14, the pull ring 15, the pressure block 16, the second spring 17, the first tooth plate 18 and the second tooth plate 19, the top right side of the bottom plate 1 is provided with a support plate 2, the support The upper left side of the plate 2 is provided with a material storage box 3, the middle of the bottom of the material storage box 3 is provided with a feeding pipe 4, the upper part of the right wall of the feeding pipe 4 has an opening 5, and the left middle part of the support plate 2 is provided with a horizontal plate 6. The left end of the plate 6 is in contact with the middle pa...

Embodiment 3

[0027] A flood control sandbag filling sand device for geological disasters, such as Figure 1-3 As shown, it includes a base plate 1, a support plate 2, a material storage box 3, a feeding pipe 4, a horizontal plate 6, a cylinder 7, a baffle plate 8, a first spring 9, a pressure plate 10, a contact switch 11, and a first connecting rod 12 , the first guide sleeve 13, the first guide rod 14, the pull ring 15, the pressure block 16, the second spring 17, the first tooth plate 18 and the second tooth plate 19, the top right side of the bottom plate 1 is provided with a support plate 2, the support The upper left side of the plate 2 is provided with a material storage box 3, the middle of the bottom of the material storage box 3 is provided with a feeding pipe 4, the upper part of the right wall of the feeding pipe 4 has an opening 5, and the left middle part of the support plate 2 is provided with a horizontal plate 6. The left end of the plate 6 is in contact with the middle pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com