Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Evenly attached" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

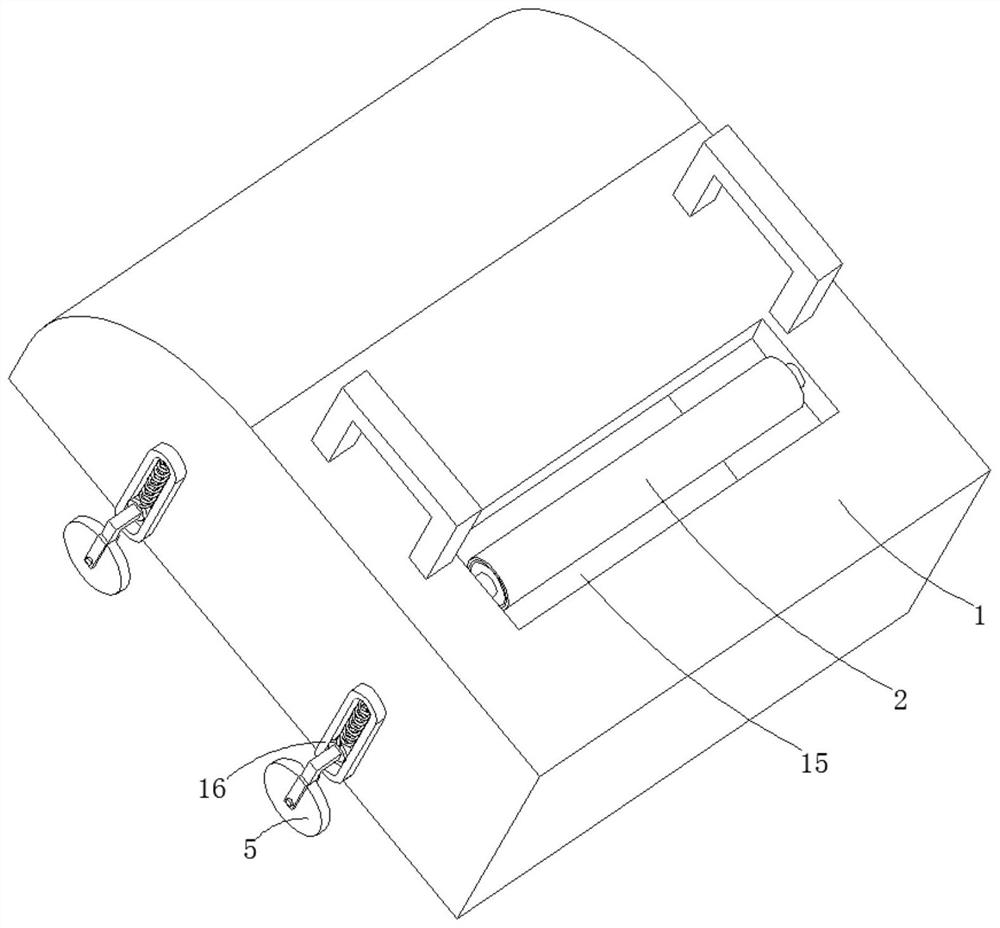

Injection-moulding mould for in-mould transfer printing

ActiveCN102198721AEvenly attachedReduce wrinklesCoatingsInjection mouldingElectrical and Electronics engineering

The invention discloses an injection-moulding mould for in-mould transfer printing. The injection-moulding mould comprises a female mould, a laminated plate, a male mould and a gas exhausting device, wherein a transfer printing film can be accommodated between the laminated plate and the male mould; the laminated plate can press the transfer printing film; the female mould and the male mould form a cavity; when the cavity is filled with plastic to form a plastic component, ornamental patterns on the transfer printing film can be transferred to the plastic component; a gas exhausting hole which is communicated with the cavity is formed on the female mould; a gas exhausting component is fixedly arranged in the gas exhausting hole; a gas pumping hole which is communicated with the cavity and the gas exhausting hole is formed on the gas exhausting component; and the gas exhausting device is connected with the gas exhausting hole and is used for pumping out the gas in the cavity so as to attract the transfer printing film towards the surface of the female mould. The injection-moulding mould can reduce the creases of the transfer printing film and make the transfer printing film adhere to the surface of the female mould uniformly.

Owner:汕头市澄海区雄城塑胶玩具有限公司

Fast-infiltration breathable absorption object and preparation method thereof

InactiveCN108309578APromote absorptionImprove absorption ratePersonal careLaminationNonwoven fabricPlant sap

The invention relates to the field of disposable sanitary products, in particular to a fast-infiltration breathable absorption object and a preparation method thereof, and mainly solves the problems that an absorption object in the prior art is slow in infiltration and poor in breathability. The fast-infiltration breathable absorption object comprises an absorption core and is characterized in that the absorption core comprises bulky nonwoven fabric, a first sap layer and a second sap layer are respectively arranged on the upper surface and the lower surface of the bulky nonwoven fabric, firstdust-free paper is compositely adhered to the first sap layer, second dust-free paper is compositely adhered to the second sap layer, the first sap layer is provided with at least one first through groove, the second sap layer is provided with at least one second through groove, and the width of each first through groove and each second through groove is 0.1-40mm.

Owner:美佳爽(中国)有限公司

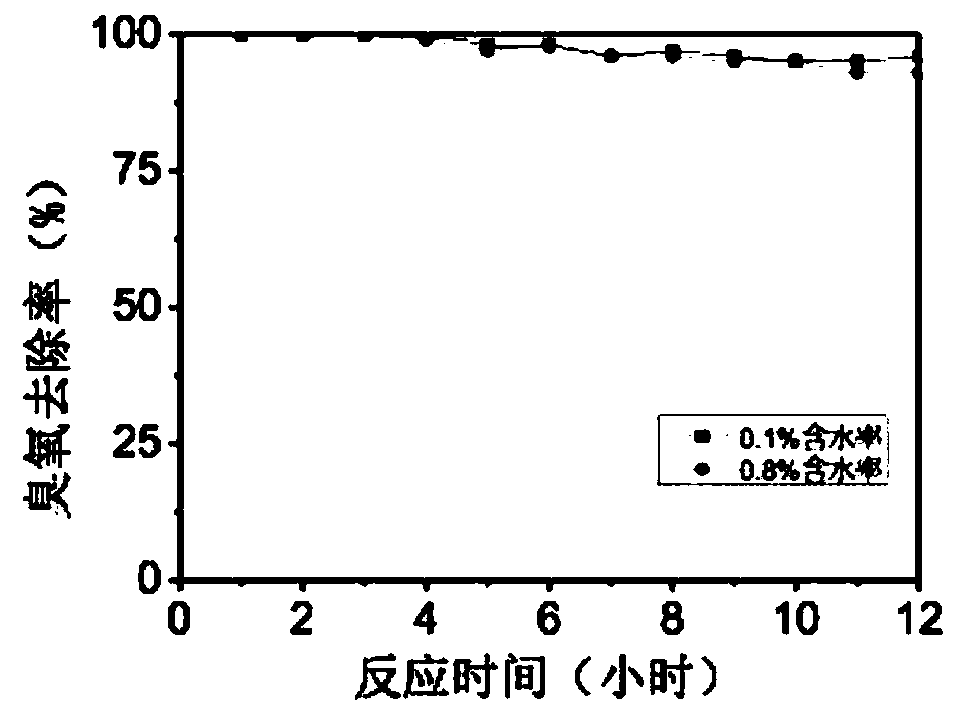

Preparation of copper and cobalt codoped manganese-based catalyst and application of catalyst to low-concentration ozonolysis

InactiveCN109261164AHigh catalytic activityEasy to useDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseCopper nitrate

The invention discloses preparation of a copper and cobalt codoped manganese-based catalyst with high stability and water-resistant capability and application of the catalyst to low-concentration ozonolysis, and belongs to the technical field of ozone purification catalysts. An efficient water-resistant ozonolysis catalyst is prepared by using copper, cobalt and manganese as active ingredients bya hydro-thermal method. In the preparation process, a certain quantity of potassium permanganate and manganese acetate are respectively dissolved in de-ionized water to form a uniform solution; then,a manganese acetate solution is slowly added into the potassium permanganate solution; uniform stirring is performed to form a uniform solution; copper nitrate solid and cobalt nitrate solid are addedinto the uniform solution; ultrasonic uniform stirring is performed; then, the solution is transferred into a hydrothermal reaction kettle; the temperature is regulated to be 150 DEG C; reaction is performed for 2h; after the reaction is finished, natural cooling is performed; after centrifugal washing and acid treatment drying are performed, the final material is obtained. The preparation methodis simple and convenient; the materials can be easily obtained; the problem of poor water resistant capability of a catalyst in the existing process is solved; the preparation process is simple; thematerials can be easily obtained; good industrial application prospects are realized.

Owner:GUANGDONG POLYTECHNIC OF ENVIRONMENTAL PROTECTION ENG

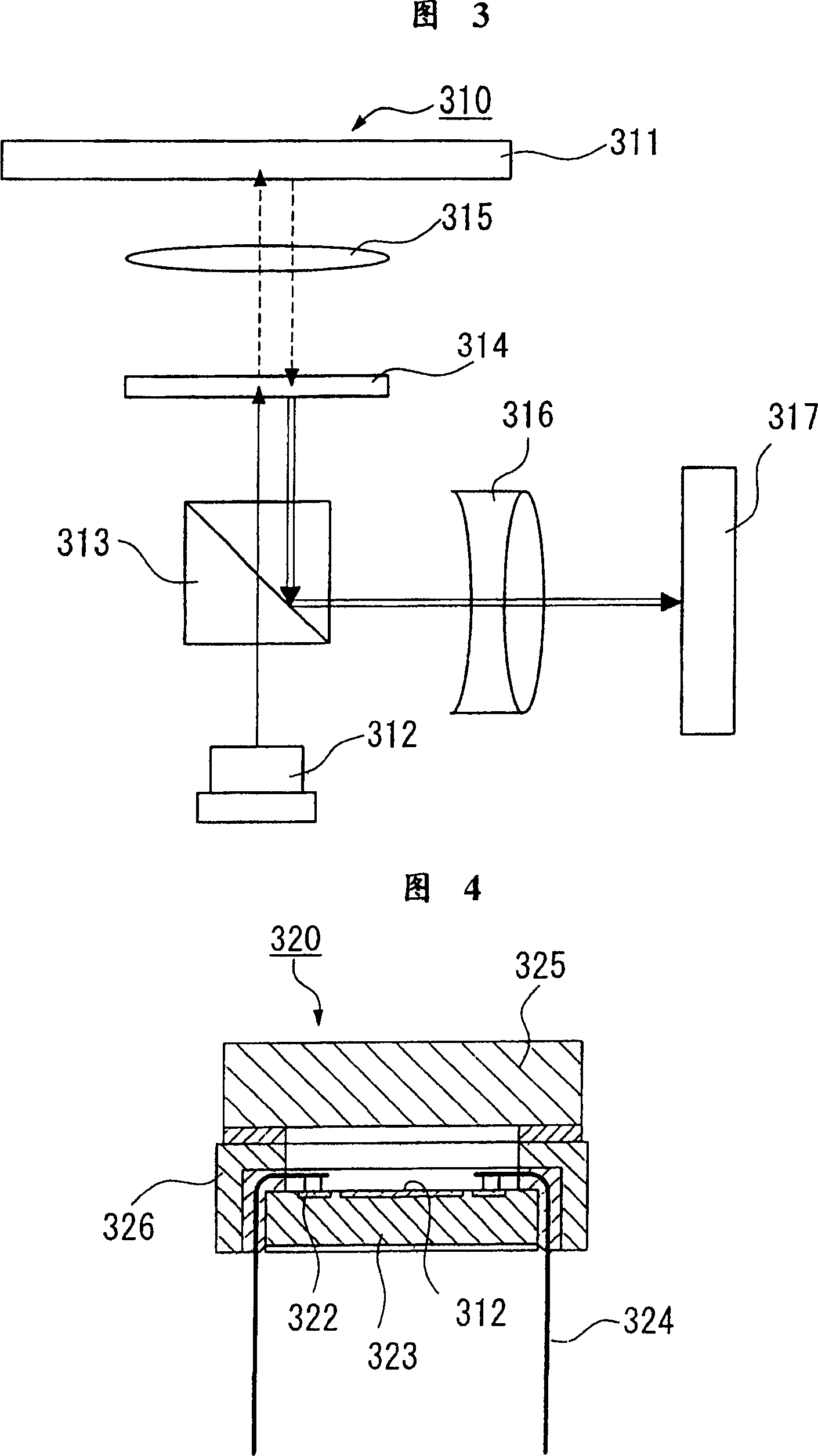

Sample cup and multi-channel optical test system containing same

InactiveCN102507445AAccuracy is not affectedAvoid affecting measurement accuracyMaterial analysis by optical meansOptical testEngineering

The invention provides a sample cup and a multi-channel optical test system containing the same. The sample cup comprises a sealing cover, a flexible connection plate, a cup body and a sample container patch, wherein a sample containing cavity is arranged at the lower part of the cup body and is used for containing a sample; a vertical sample injection inlet part, a main sample injection channel and an air exhaust channel are arranged at the upper part of the cup body; a boundary surface between the sample injection inlet part and the cup body below the sample injection inlet part is an inclined plane; the upper ports of the main sample injection channel and the air exhaust channel are positioned at the upper and lower sides of the inclined plane; the upper port of the air exhaust channel is positioned above the inclined plane and is higher than that of the main sample injection channel; the upper part of the air exhaust channel vertically extend downward from the upper port and is roughly parallel to the sample injection inlet part and the main sample injection channel; the lower parts of the air exhaust channel and the main sample injection channel are inward bent; the lower ports of the air exhaust channel and the main sample injection channel are converged at the highest point of the sample containing cavity; and the cross-sectional area of the sample injection inlet part is equal to the sum of the cross-sectional areas of the main sample injection channel and the air exhaust channel. Through arranging the air exhaust channel, air bubbles generated in a sample injection process or an experiment process can be smoothly discharged to be above the sample, thereby not influencing the measurement precision at all.

Owner:BEIJING GENOME BIOTECH

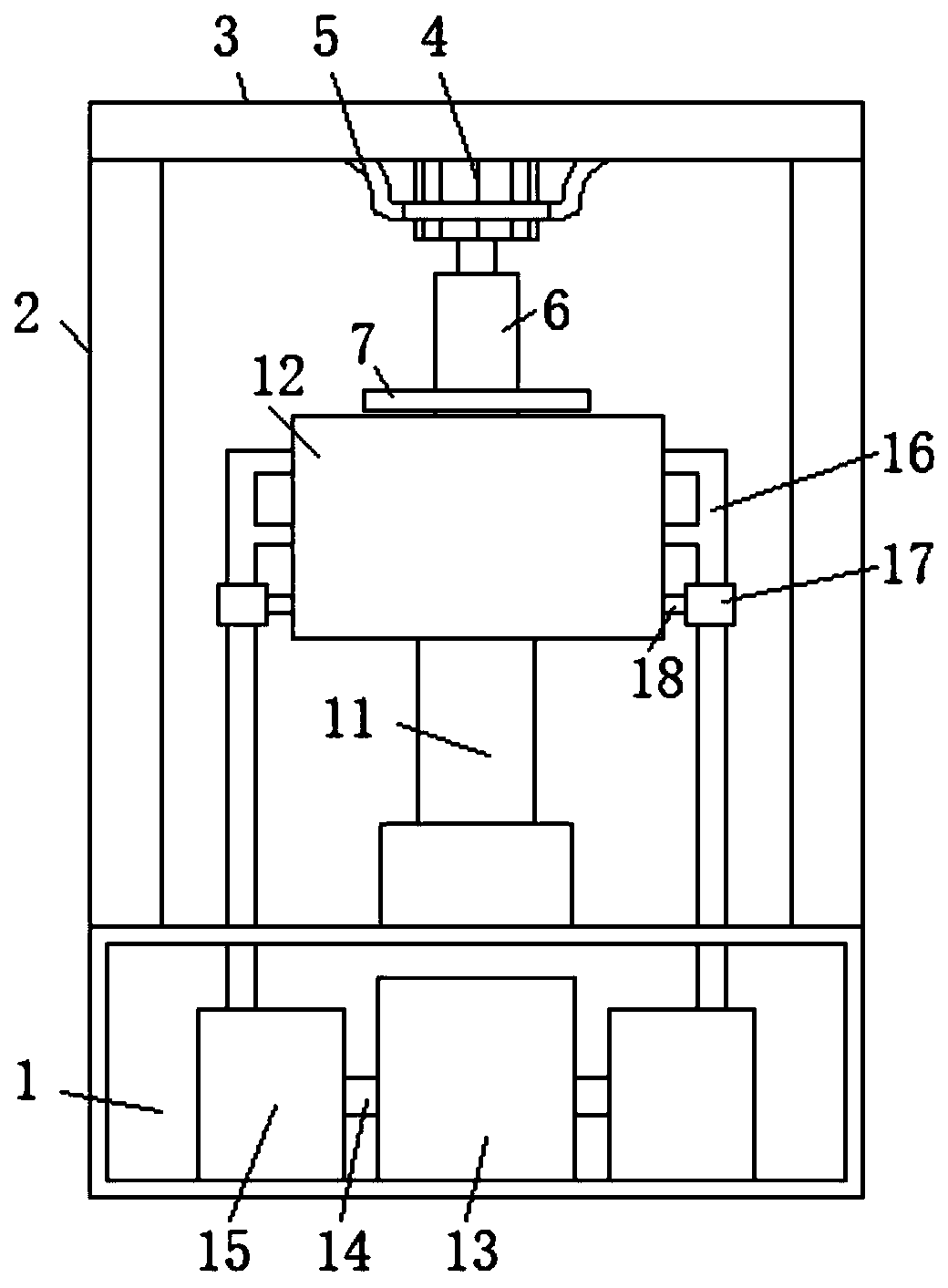

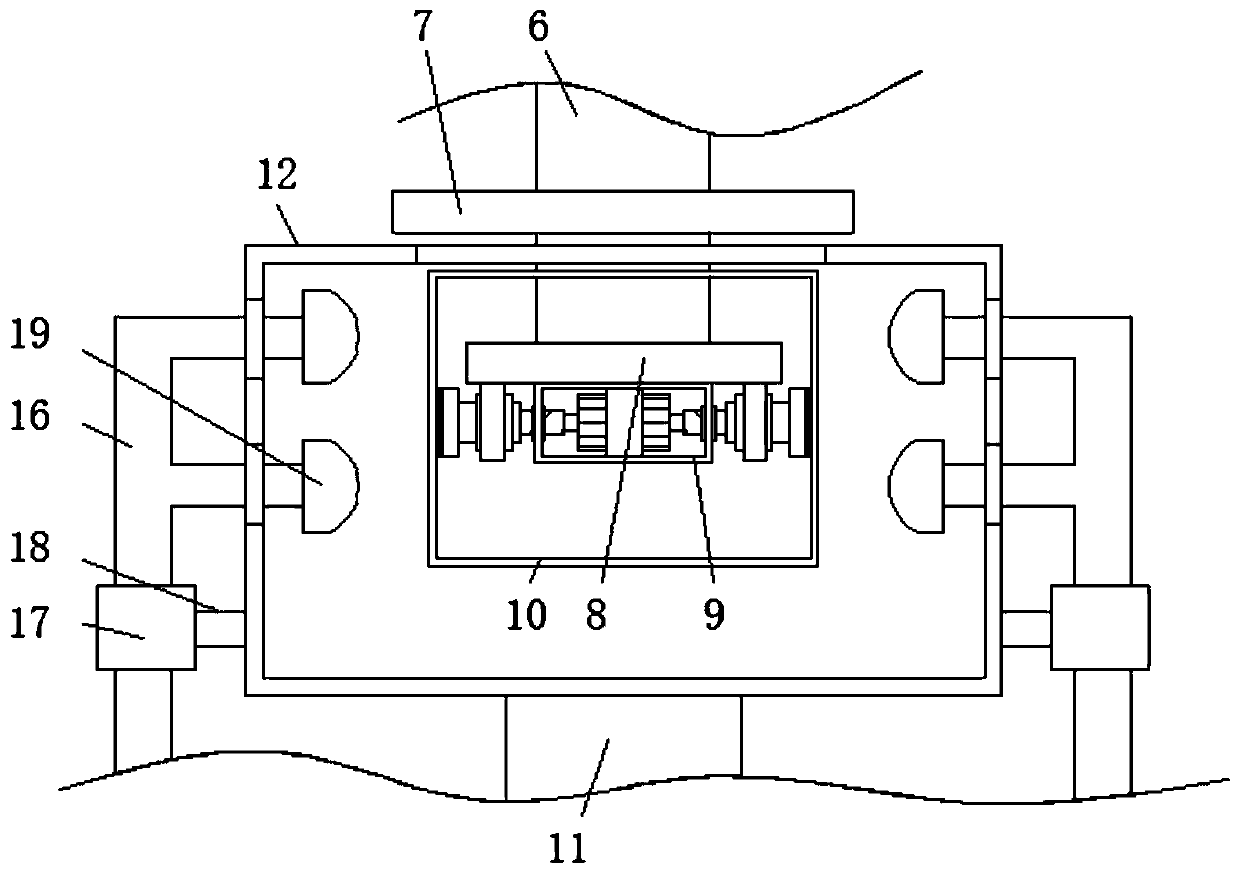

Anti-splashing equipment for paint spraying of aluminum alloy motor shell

ActiveCN110237978AImprove efficiencyImprove uniformityLiquid spraying apparatusSpray boothsEngineeringAlloy

The invention relates to the technical field of paint spraying of motor shells, in particular to anti-splashing equipment for paint spraying of an aluminum alloy motor shell. The anti-splashing equipment comprises a storage box, wherein the top of the storage box is fixedly connected with a fixing plate through a supporting frame, the top of the fixing plate is movably connected with a rotary motor through a rotating rod, the bottom of the rotating rod penetrates through the anti-splashing plate and is fixedly connected with the anti-splashing plate, the bottom of the rotating rod is fixedly connected with a position limiting mechanism through a connecting plate, the position limiting mechanism is movably connected with a machine shell, the bottom of the inner cavity of the storage box is fixedly connected with a paint storage tank, the side surface of the paint storage tank fixedly communicates with a paint pumping pump through a paint pumping pipe, a paint spraying pipe fixedly communicates with the top of the paint pumping pump, and an atomizing nozzle is fixedly connected to one end, located in a protective box, of the paint spraying pipe. According to the anti-splashing equipment, compared with a handheld paint spraying device, the anti-splashing equipment has the advantage that the labor intensity is reduced, sprayed paint is prevented from being diffused into the air and falls onto the skin of a paint sprayer and the discomfort of a body is caused in the nose.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

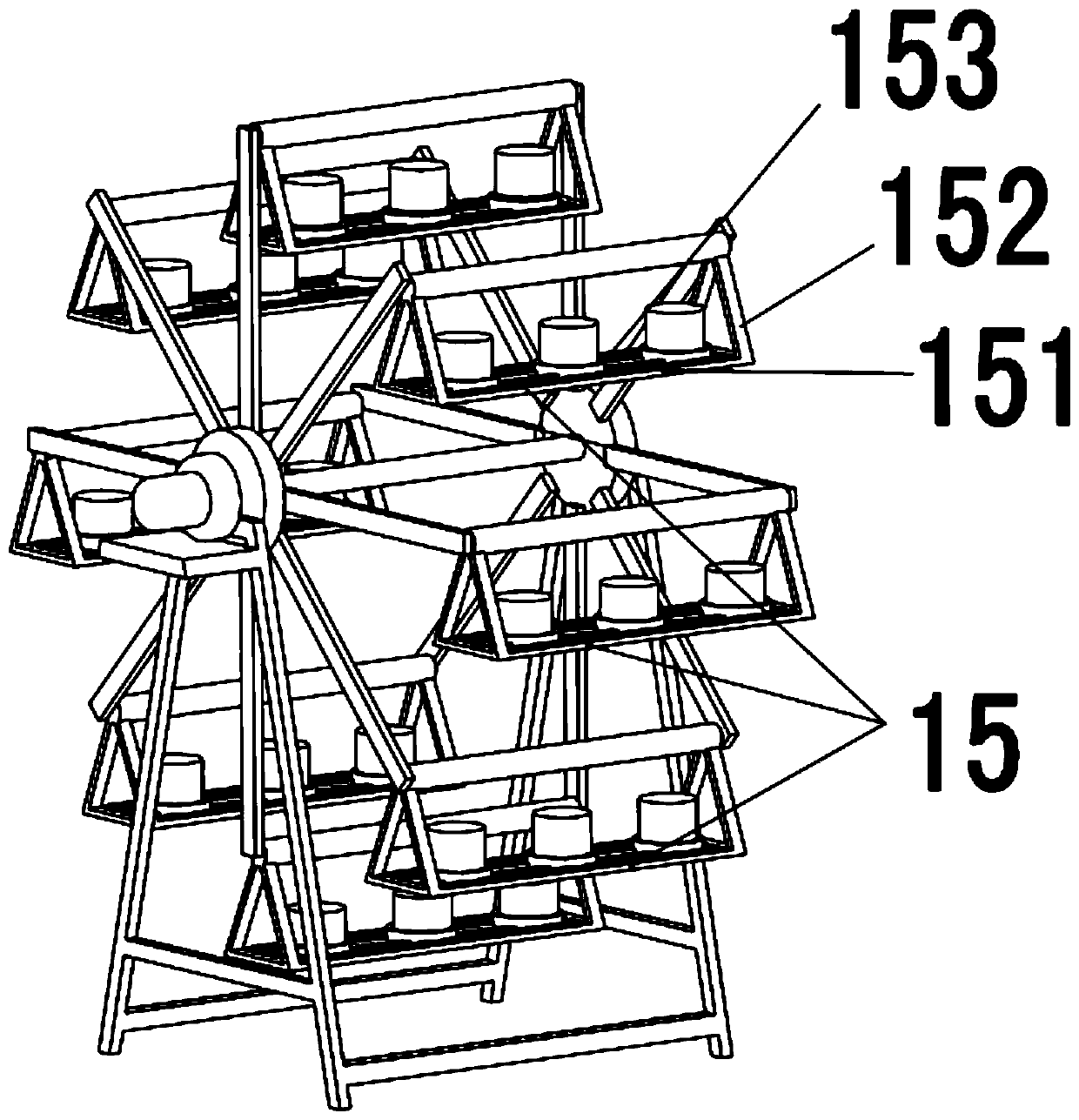

Ceramic rotary slurry spraying forming method

ActiveCN110126078ASimple structureReduce uneven sprayingFeeding arrangmentsAuxillary shaping apparatusCeramicNozzle

The invention discloses a ceramic rotary slurry spraying forming method. The ceramic rotary slurry spraying forming method is characterized by comprising the following steps that (1) mold arrangementis conducted, specifically, molds needing to be machined are arranged on a rotary mold conveying device; (2) mold transporting is conducted specifically, the molds needing to be machined are transported to slurry spraying stations; (3) slurry spraying is conducted, specifically, after the molds are transported to the slurry spraying stations, nozzles located below the stations are made to stretchinto the molds through a lifting device, the nozzles rotatably spray the slurry onto the inner walls of the molds uniformly, and blank bodies are formed; (4) mold blank transporting is conducted, specifically, the blank bodies are transported to blank taking stations; and (5) blank taking is conducted, specifically, the bank bodies are taken down after being transported to the blank taking stations. According to the ceramic forming method, through the mode that the nozzles spray the slurry rotationally, the slurry can be sprayed onto the interiors of the molds more uniformly, the probability that pores occur to the blank bodies due to traditional slurry injection can be reduced, and the phenomenon that the slurry is not sprayed uniformly is decreased.

Owner:福建省德化县豪鹏机械有限公司

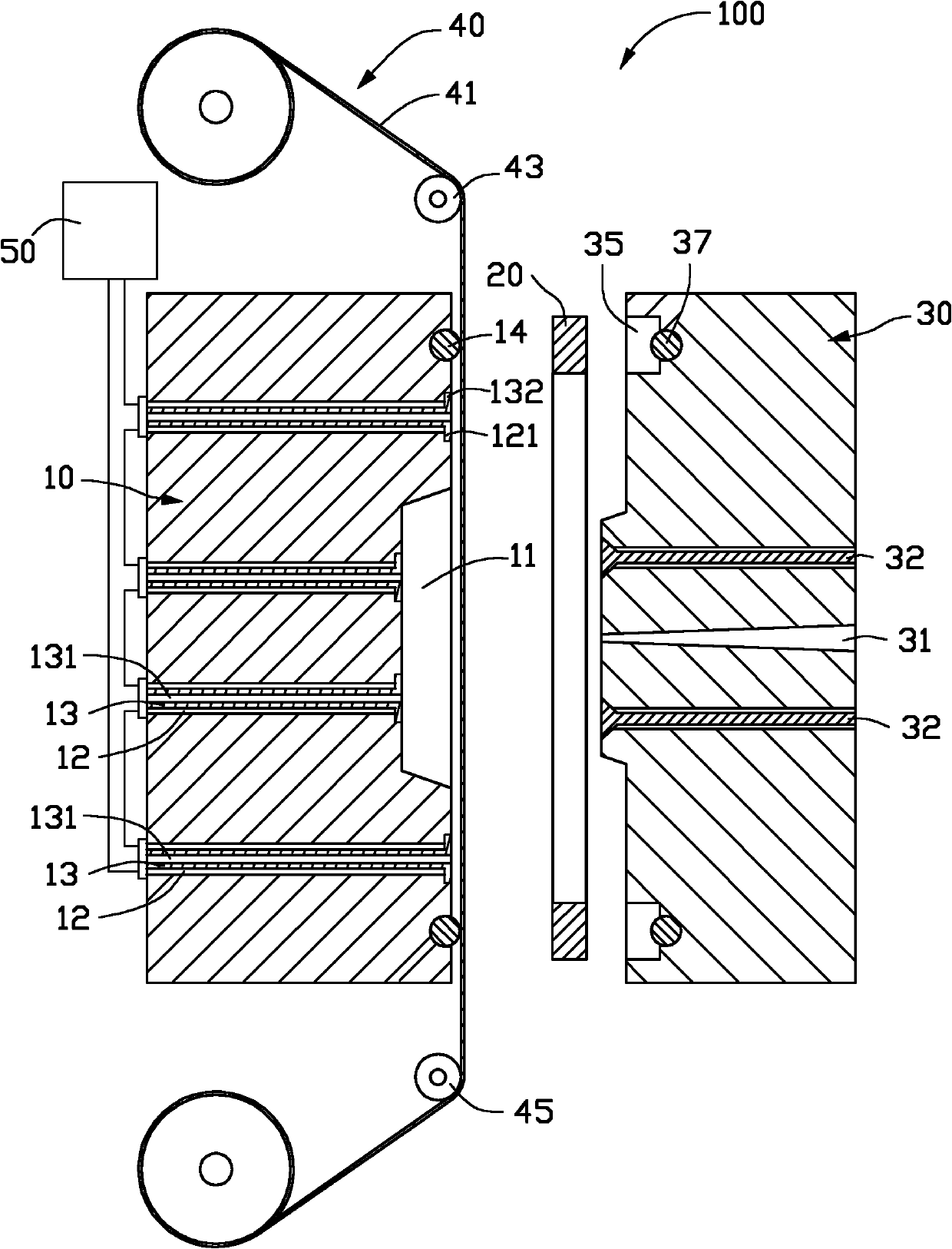

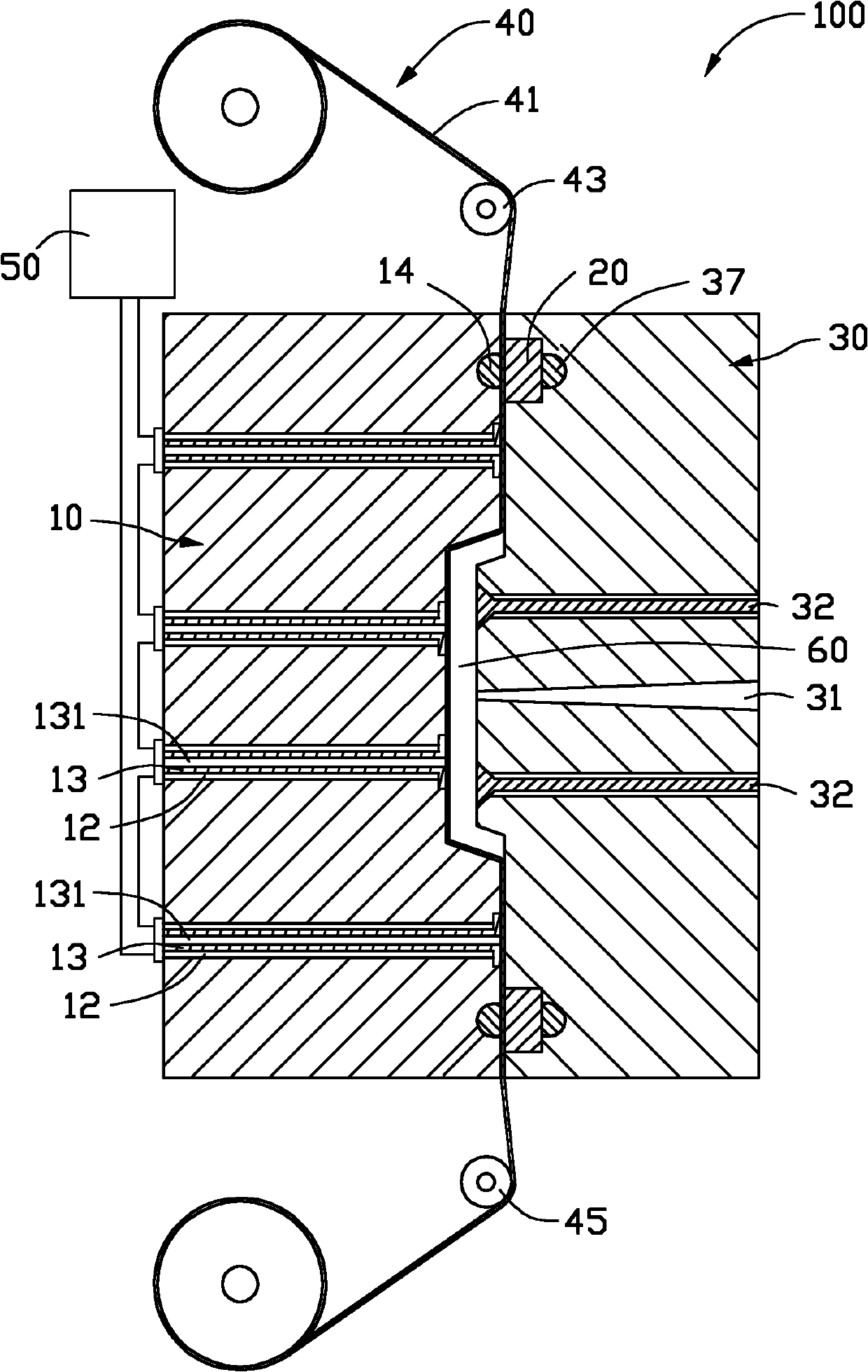

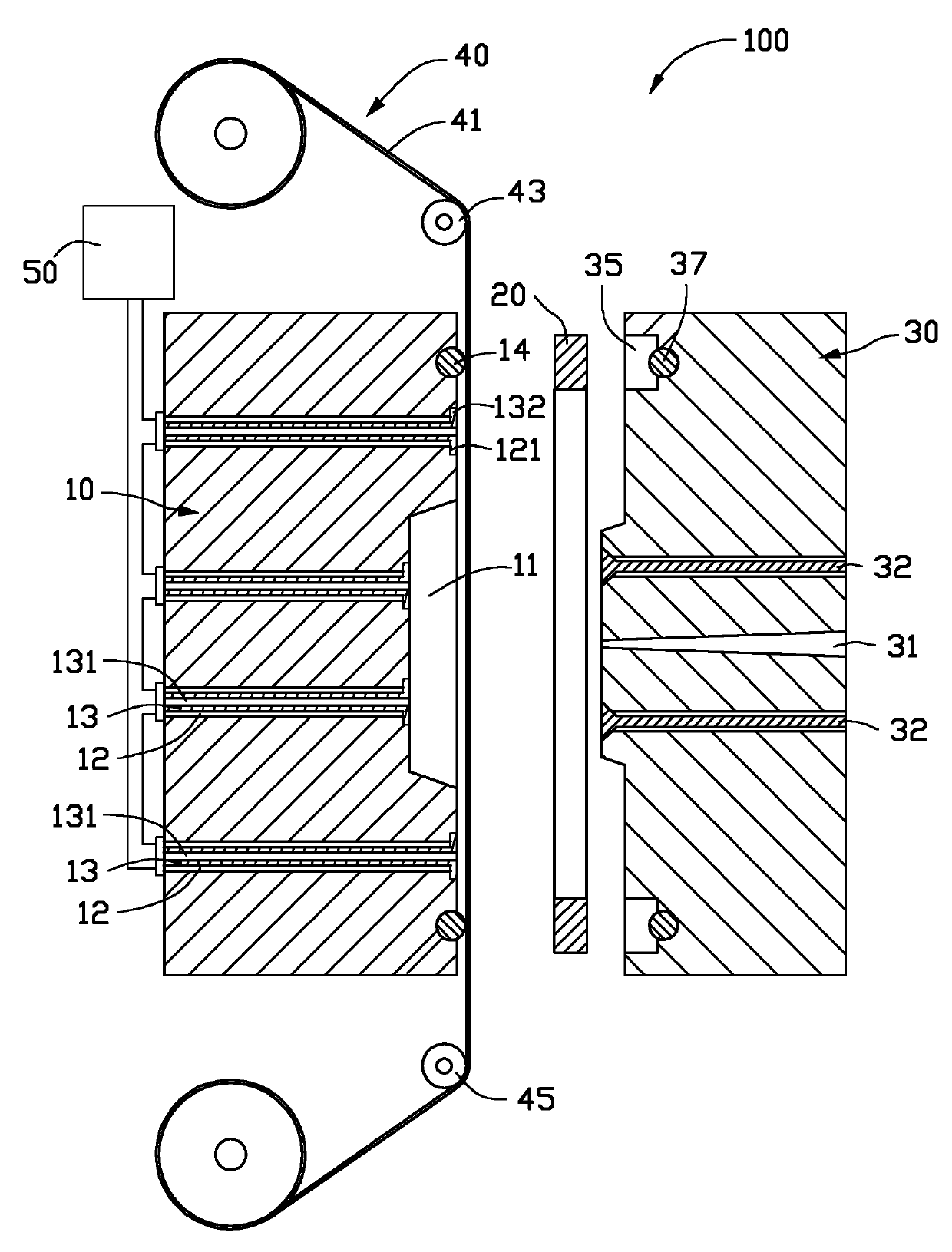

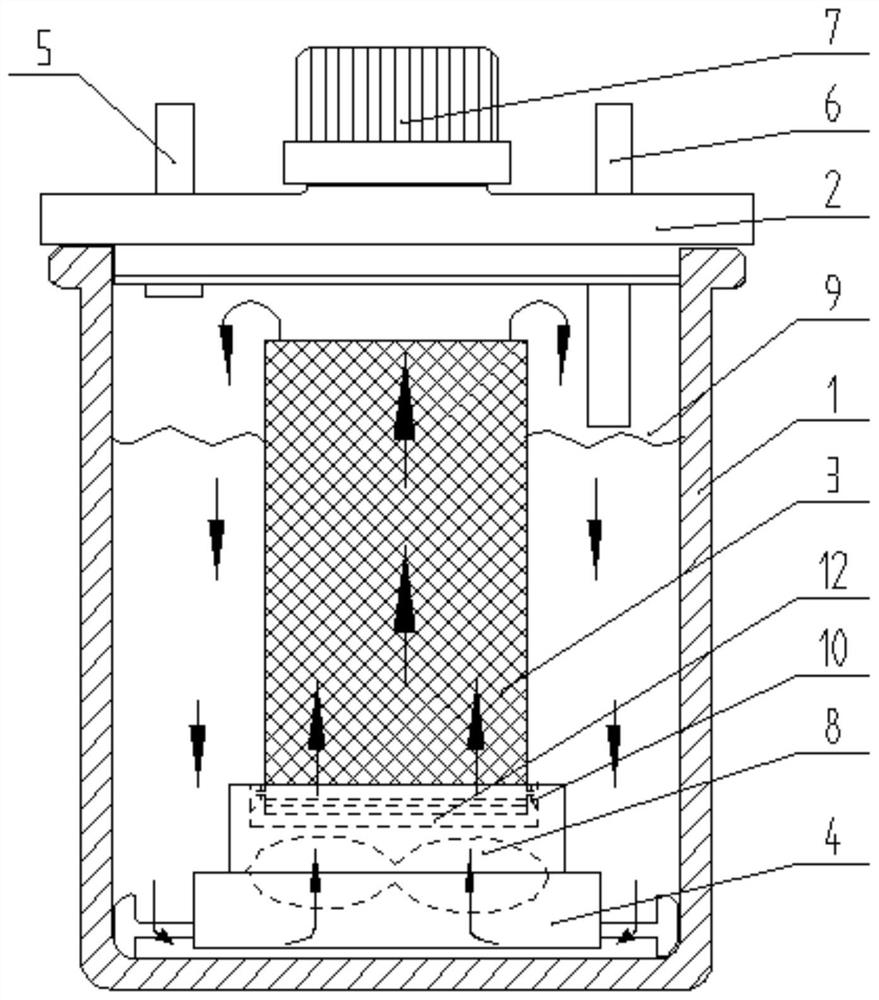

Fixed bed type bioreactor

PendingCN112708562ASolve the problem of excessive shear forceSolve the problem of uneven adhesionBioreactor/fermenter combinationsBiological substance pretreatmentsFixed bedPhysical chemistry

The invention relates to the technical field of bioreactors for culturing adherent cells and suspension cells with low shear force, in particular to a fixed bed type bioreactor. The fixed bed type bioreactor comprises a tank body and a carrier column, wherein the upper part of the tank body is hermetically connected with a tank cover; a magnetic stirring base is arranged at the lower part in the tank body; a drainage hole is formed in the bottom of the magnetic stirring base; a magnetic stirrer for rotationally stirring water is installed in the magnetic stirring base; the carrier column is detachably installed above the magnetic stirring base; and the carrier column is filled with a plurality of fibrous carrier sheets. The magnetic stirrer drives a culture medium to flow in from the drainage hole in the bottom, pass through the carrier sheets in the carrier column, finally flow out from the top of the carrier column and return to the tank body through rotary stirring to form a circulating liquid flow direction in the culture medium. Aiming at the defects in the prior art, the problems that part of cells difficultly grow in the bioreactor and part of suspension cells produce toxin in a common STR reactor or the protein expression quantity is low are solved.

Owner:昆明柏特生物科技有限公司

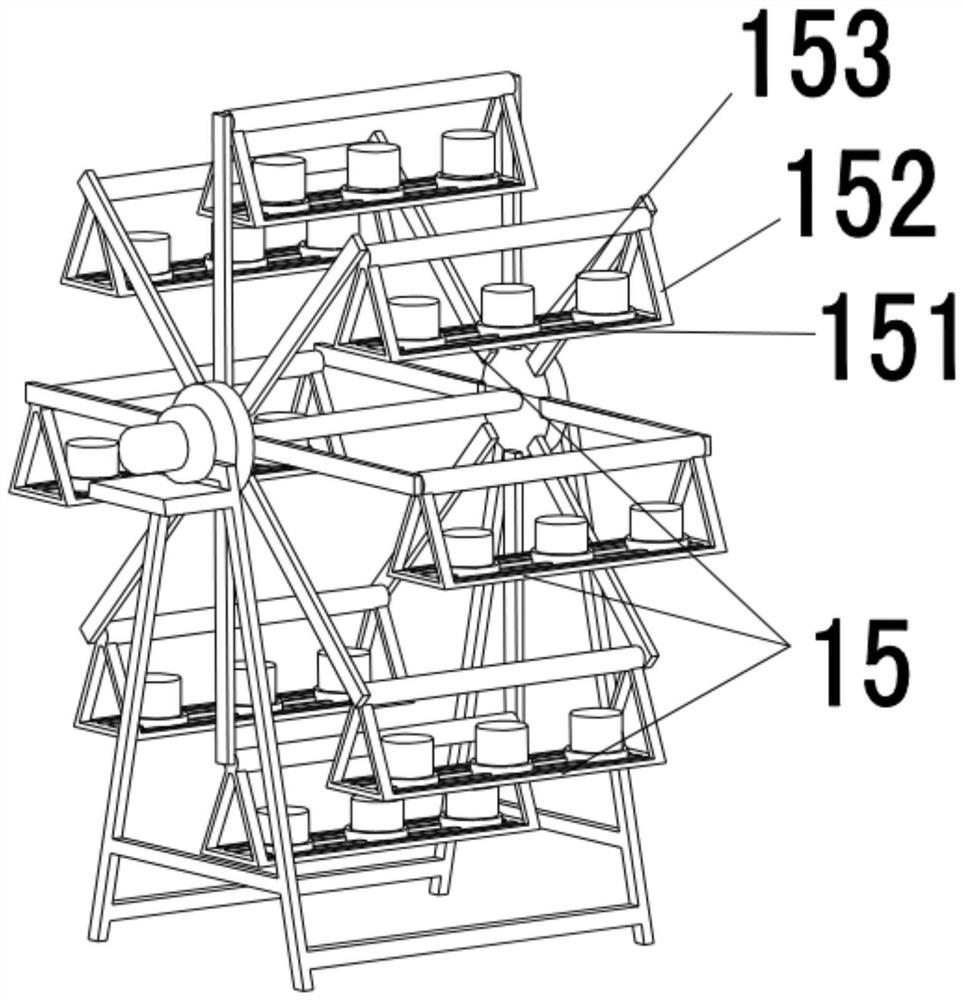

Uniform external stain coating device for food processing

The invention relates to the field of food processing, in particular to a uniform external stain coating device for food processing. The device structurally comprises a rectangular cavity, an externalstain discharge and recovery device connected with the cavity in an up-to down sealing manner, and a rotation shaft transmission device attached to and connected with the cavity. Through the uniformexternal stain coating device for food processing, processing is carried out in a closed engine body, so that automatic processing is completed, cleanliness and sanitation are provided, and the processed external stains can be uniformly attached to the surfaces of food; through a recovery device for stains, an automatic cleaning effect can be achieved during recycling.

Owner:靖江市盛讯信息科技有限公司

Composite factor anti-aging moisturizing cosmetic

InactiveCN112089662AEliminate wrinklesAnti-agingCosmetic preparationsToilet preparationsFacial skinBiomedical engineering

The invention belongs to the technical field of cosmetic production and application, and particularly relates to a composite factor anti-aging moisturizing cosmetic. A maintenance device used in the application process of the cosmetic comprises a device box, a connecting pipe and a mask; a water tank and a steam box are fixedly connected to the interior of the device box, and the water tank and the steam box are communicated with each other; a supporting rod is rotatably connected to the upper surface of the device box; the connecting pipe is fixedly connected to the portion, close to the right end face of the supporting rod, of the lower surface of the supporting rod; and the mask is fixedly connected to the lower end face of the connecting pipe. By means of the composite factor anti-aging moisturizing cosmetic, water evaporation of the face of a person is effectively achieved, the skin of the face is heated, blood flow in the skin of the face is accelerated, pores are promoted to beopened, and water absorption is improved; and meanwhile, rapid absorption of ingredients of the cosmetic can be effectively promoted, by means of atomization treatment of the diluted cosmetic, the cosmetic can uniformly fall on the face, manual assistance smearing is not needed, and the cosmetic is convenient and easy to use.

Owner:绍兴上虞锦色化妆品有限公司

Wall cloth attaching device capable of preventing wrinkles

Owner:河南省同宇建筑工程有限公司

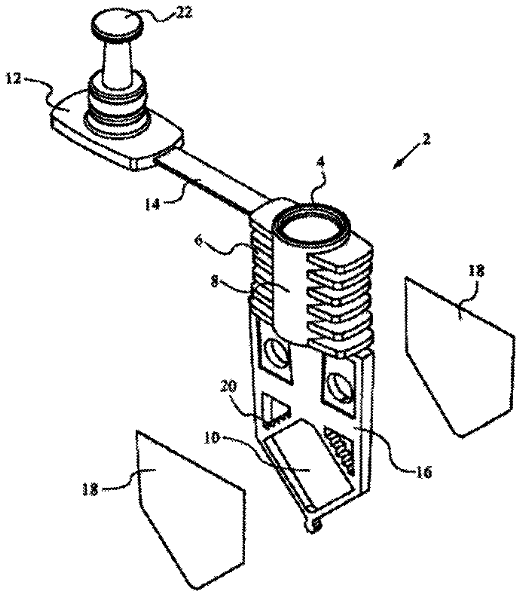

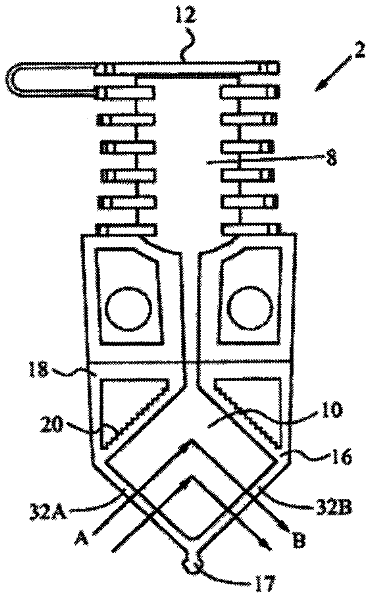

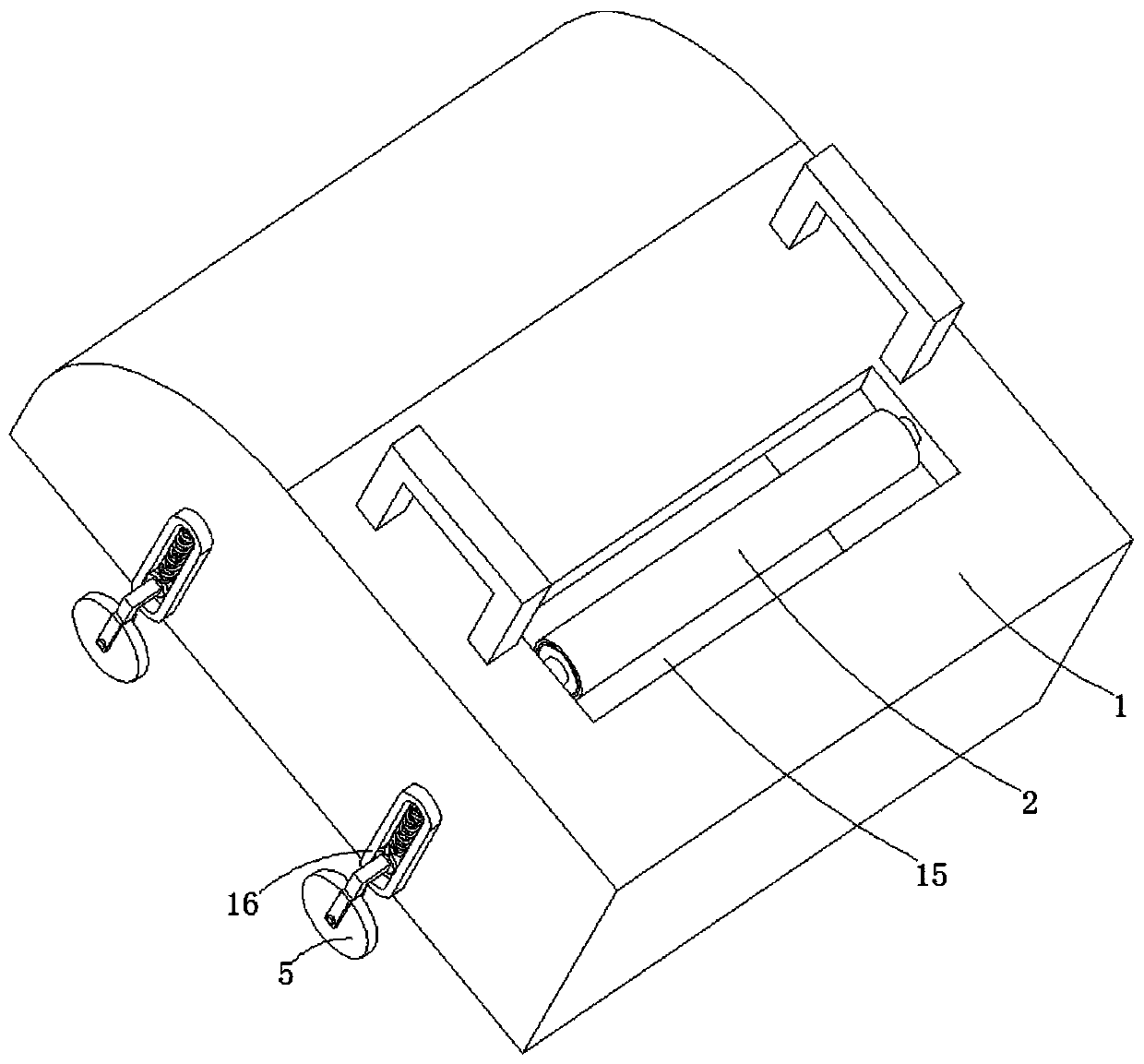

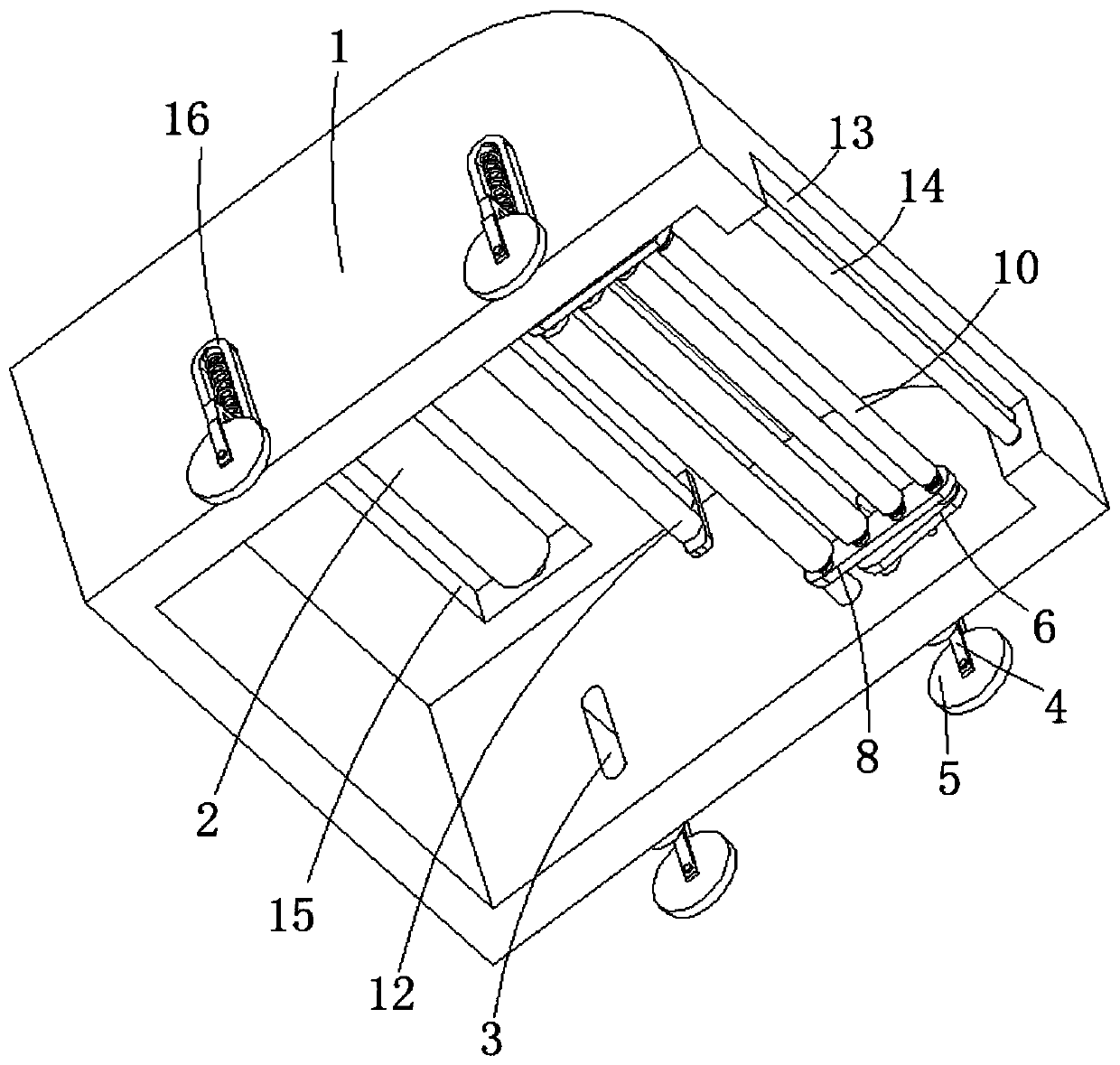

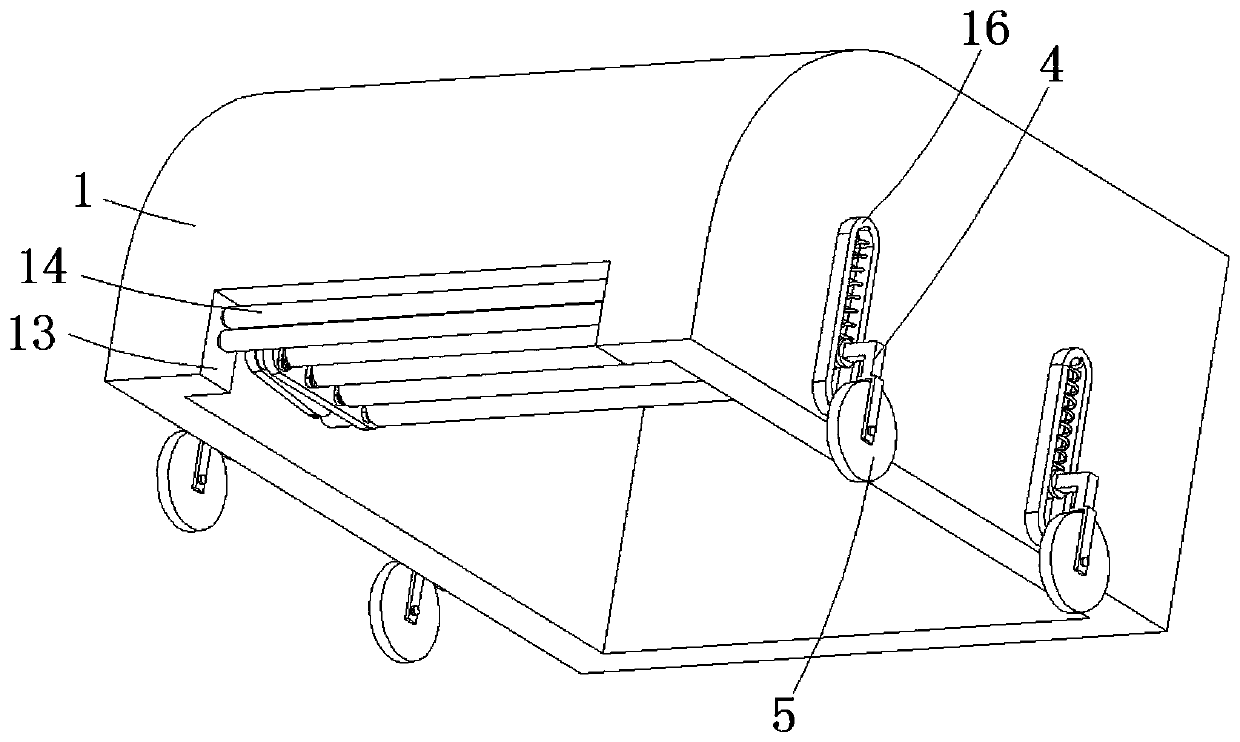

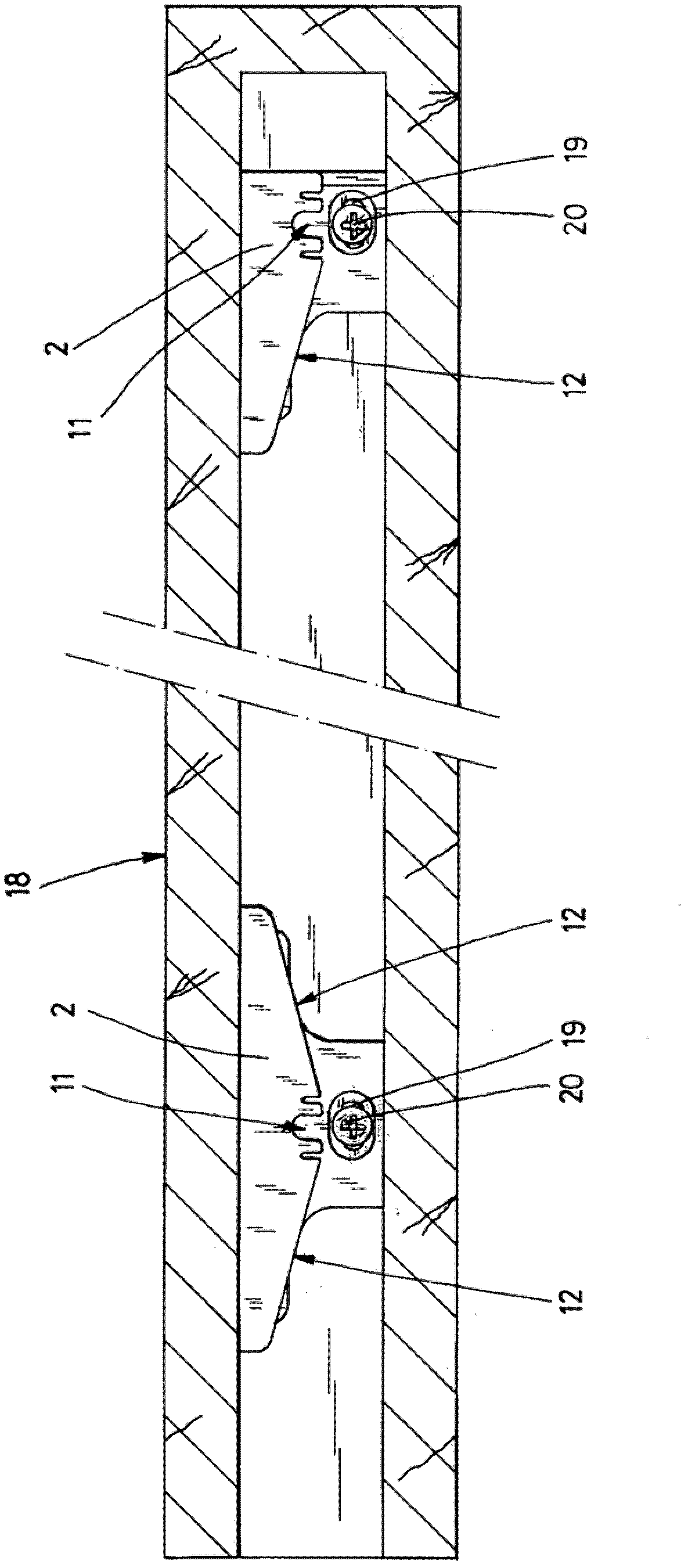

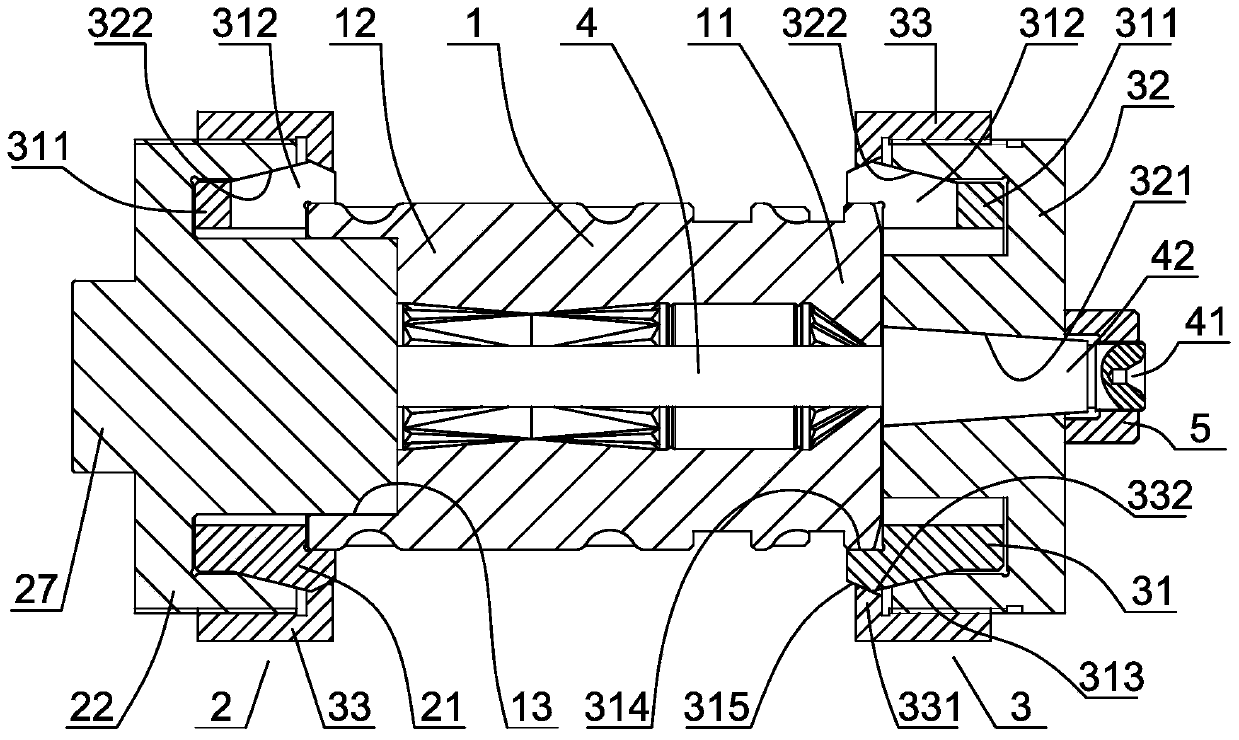

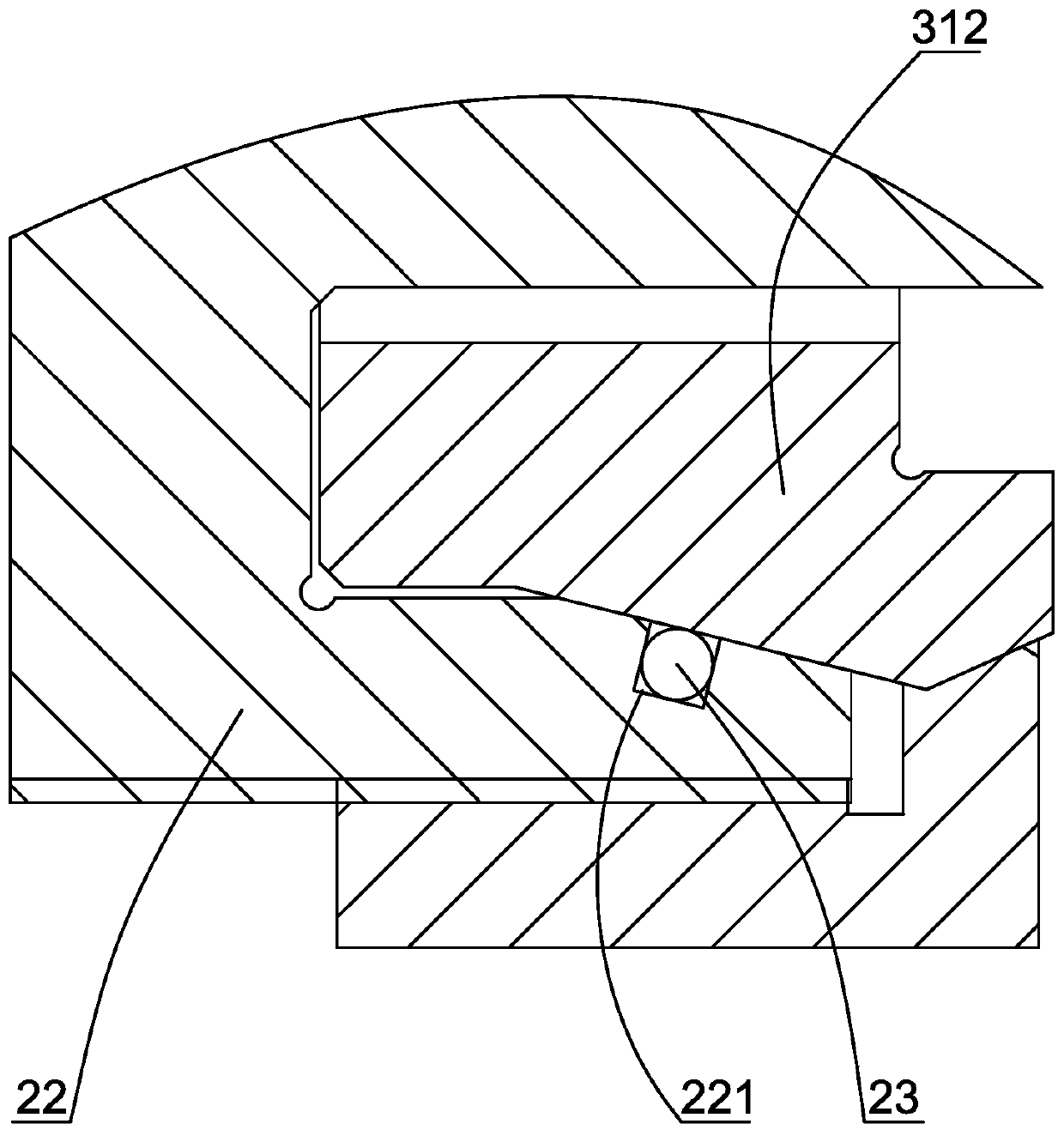

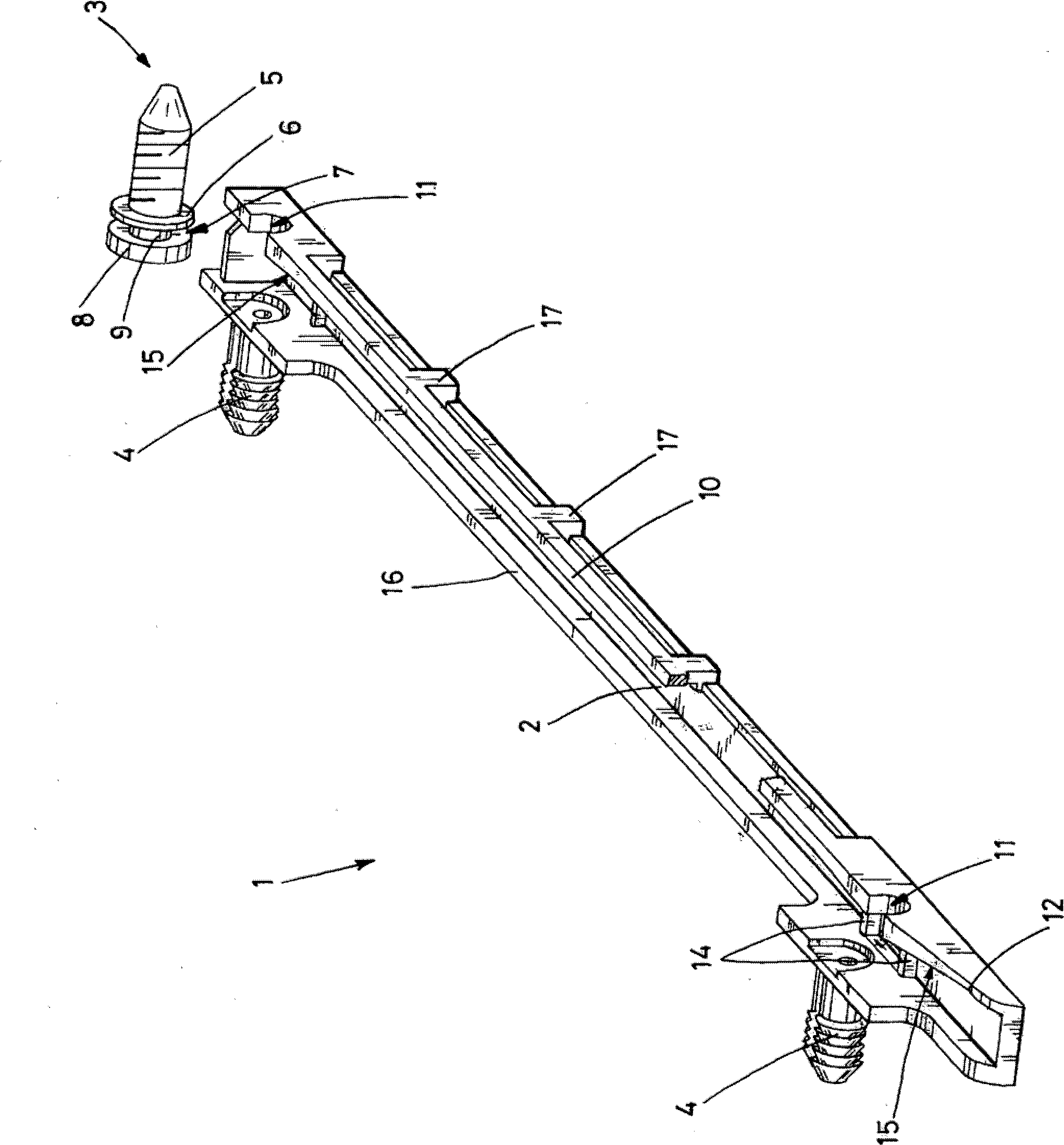

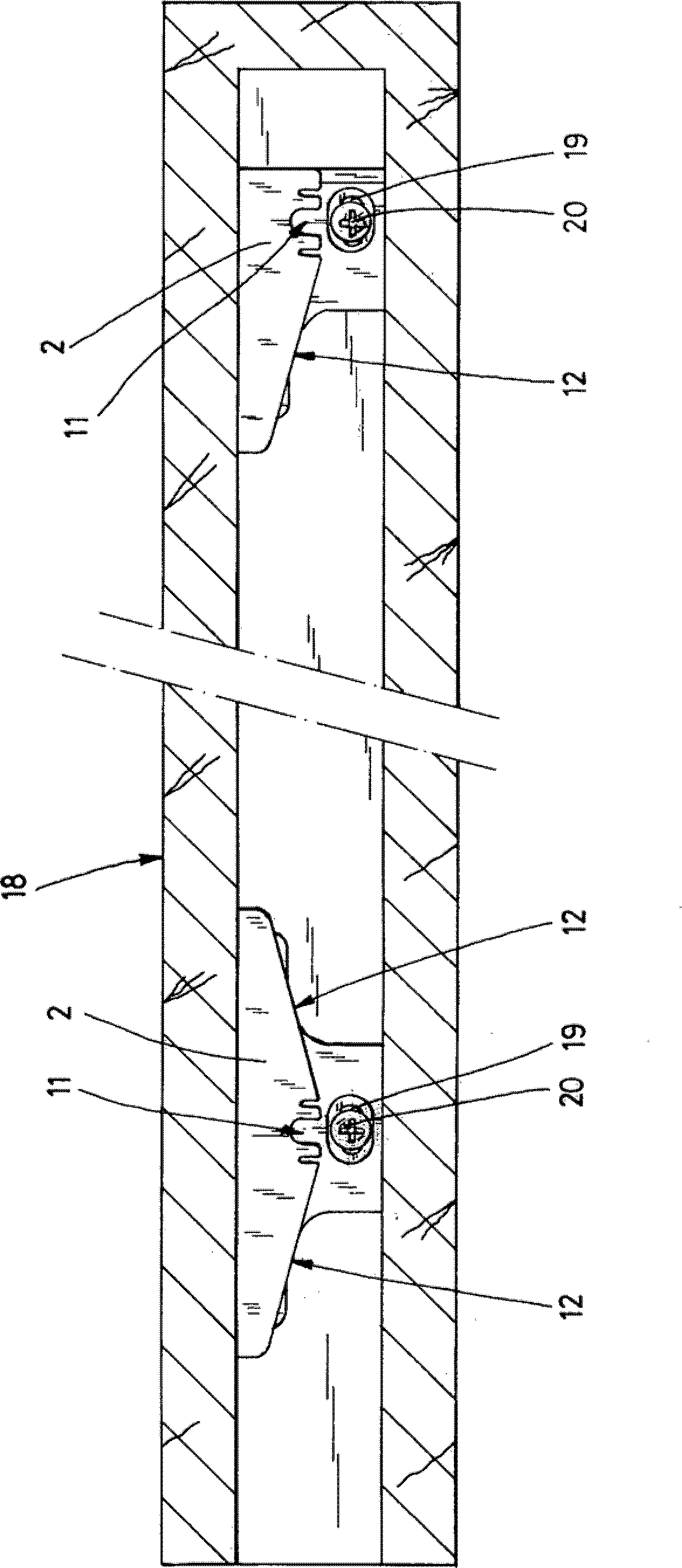

Furniture fitting

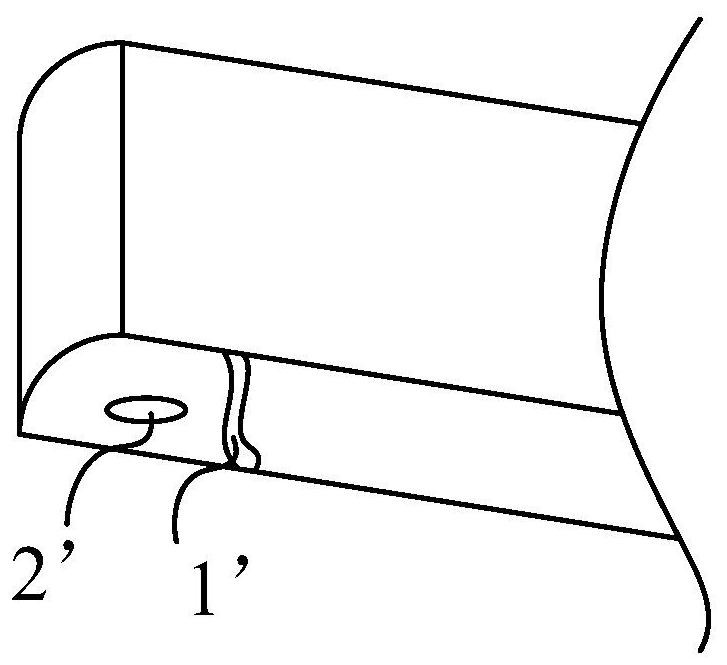

InactiveCN102575701AEasy to connect correctlyConducive to manipulationSheet joiningFurniture joiningEngineeringMechanical engineering

The invention relates to a furniture fitting (1) for connecting two furniture parts that are brought together in a horizontal longitudinal motion, comprising at least two fitting parts (2, 3), of which a first fitting part (1) is provided on a first of the two furniture parts and a second fitting part (3) is provided on a second furniture part, the first fitting part being designated as a guide part (2), and the second fitting part being designated as a locking part (3) and being movable on the guide part (2)until the second fitting part reaches a locking position, in which the two furniture parts are connected to each other, the two fitting parts (2, 3) engaging one behind the other and thus securing the two furniture parts in their connected arrangement. According to the invention, the two fitting parts have complementary insertion surfaces, which form a guide bevel (12) that lifts the locking part when the locking part is placed against the guide part, and the two fitting parts have complementary transverse guide surfaces (15) such that, when the two fitting parts are brought together horizontally, the two furniture parts thus connected are automatically brought together in a transverse direction, which is likewise horizontal but extends transversely to the prior longitudinal direction of motion, and thus the distance between the furniture parts is reduced, and the locking part (3) can be locked to the guide part (2) in a downward motion.

Owner:欧仕达家俱制造商

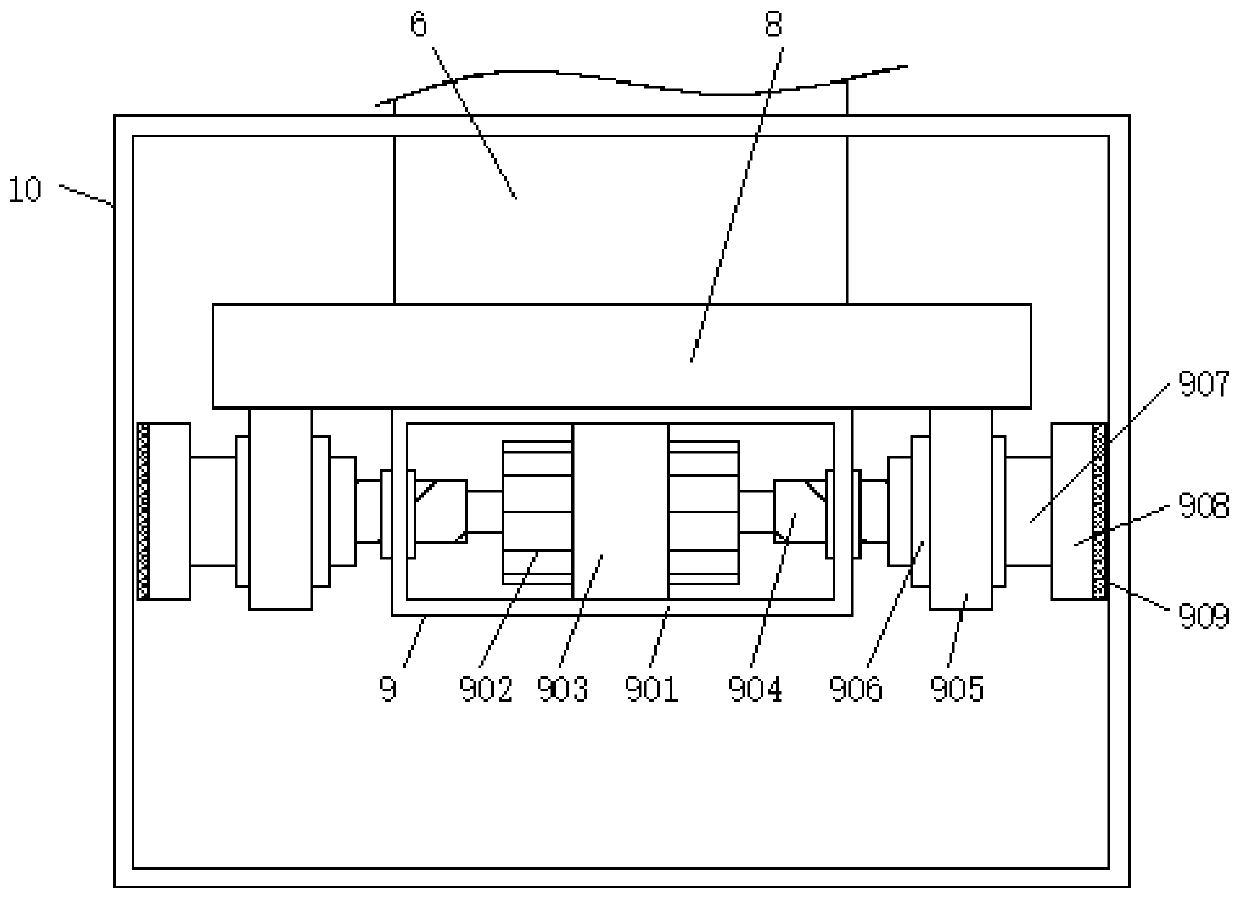

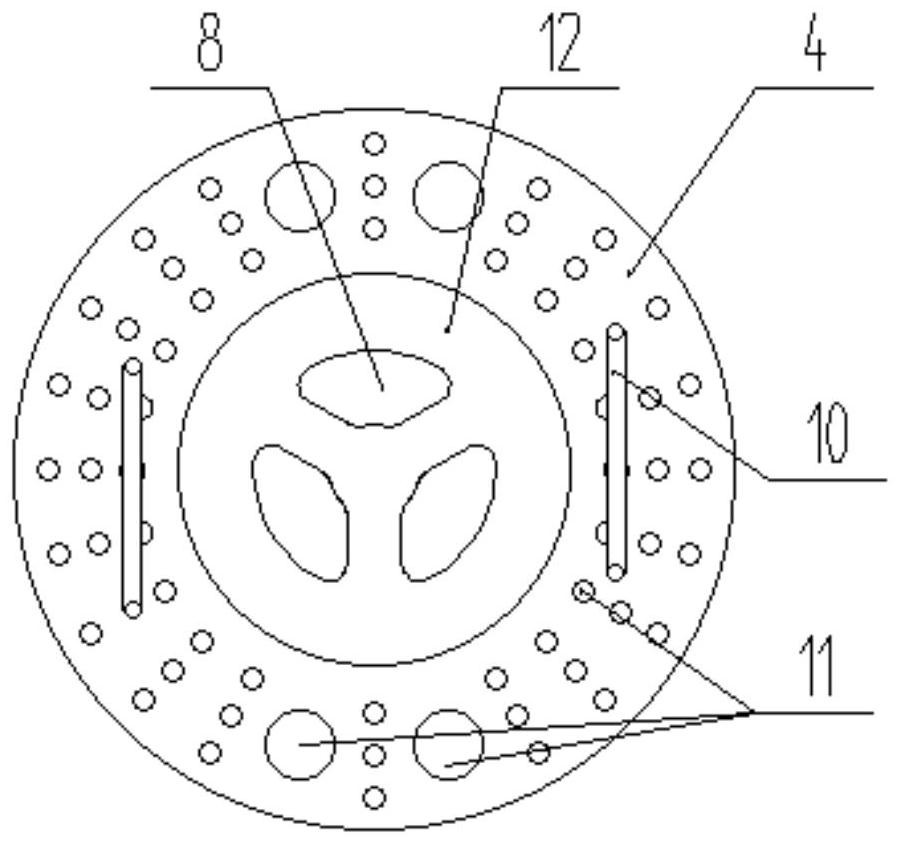

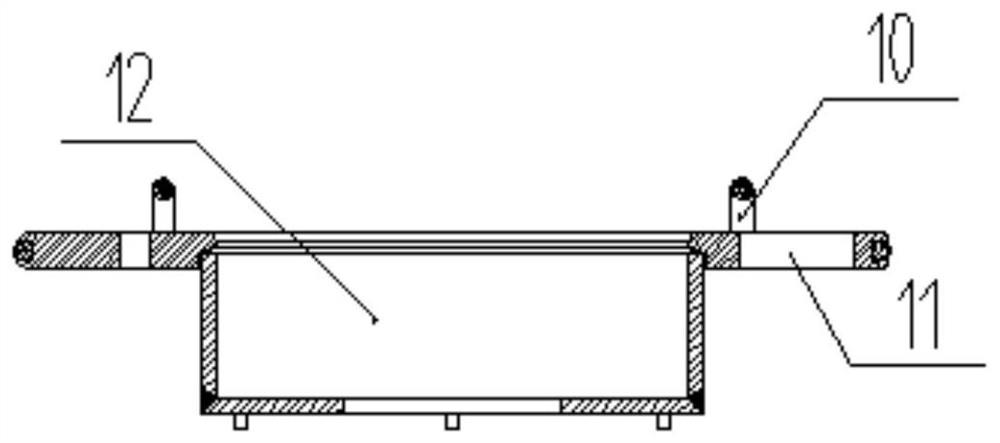

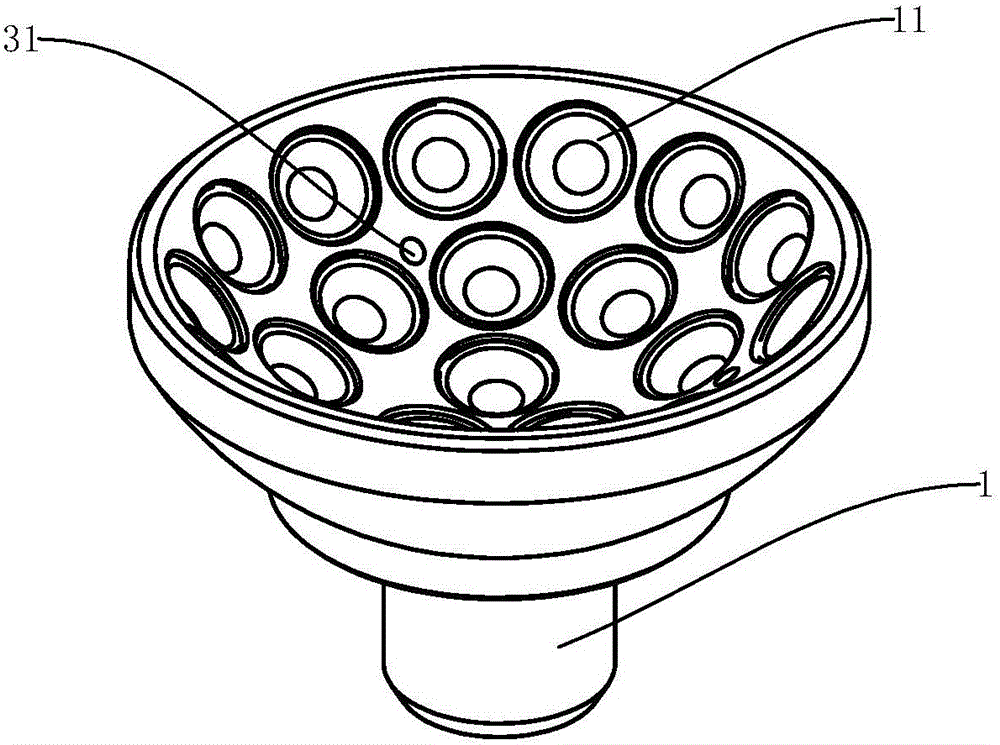

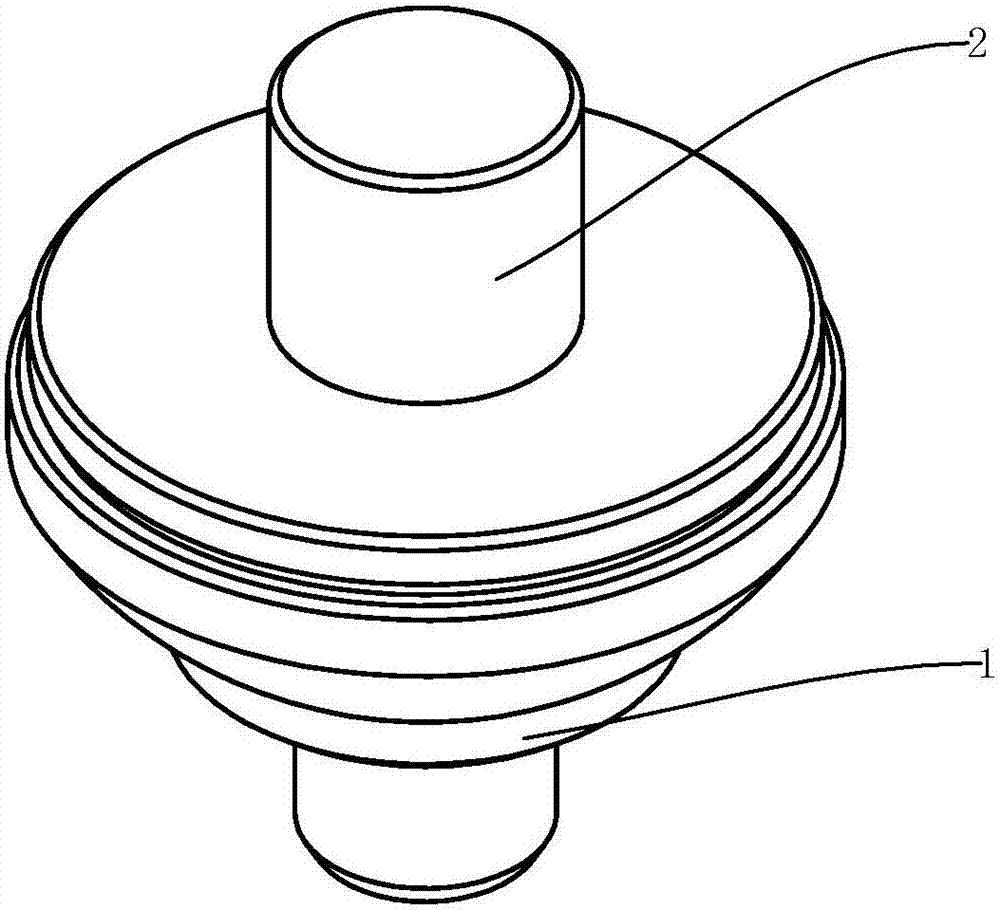

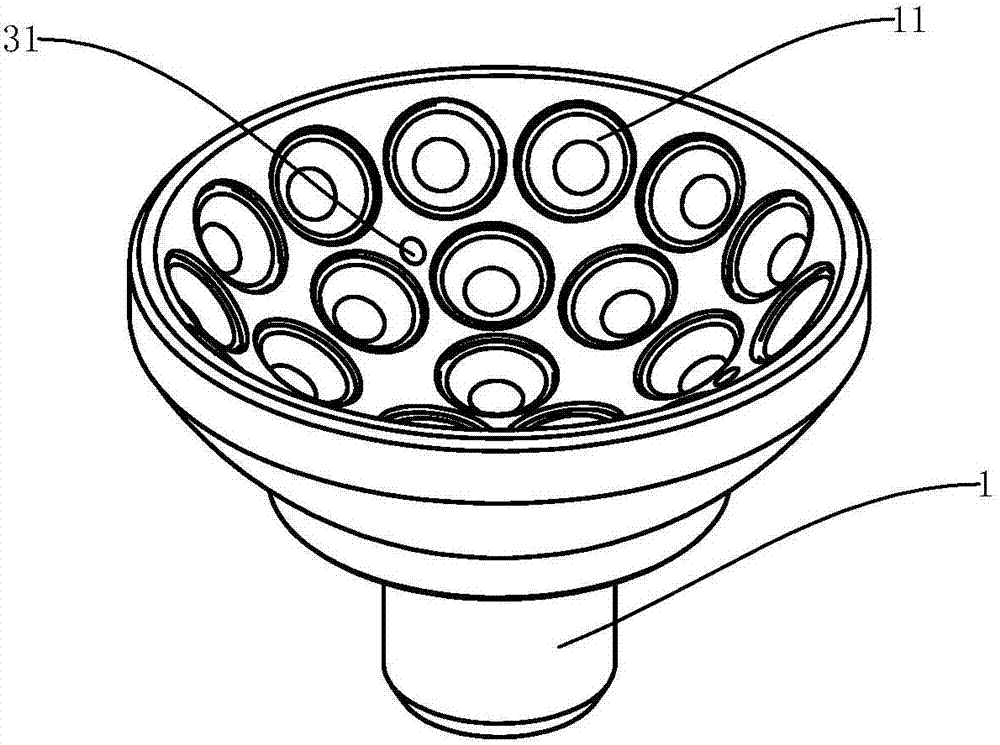

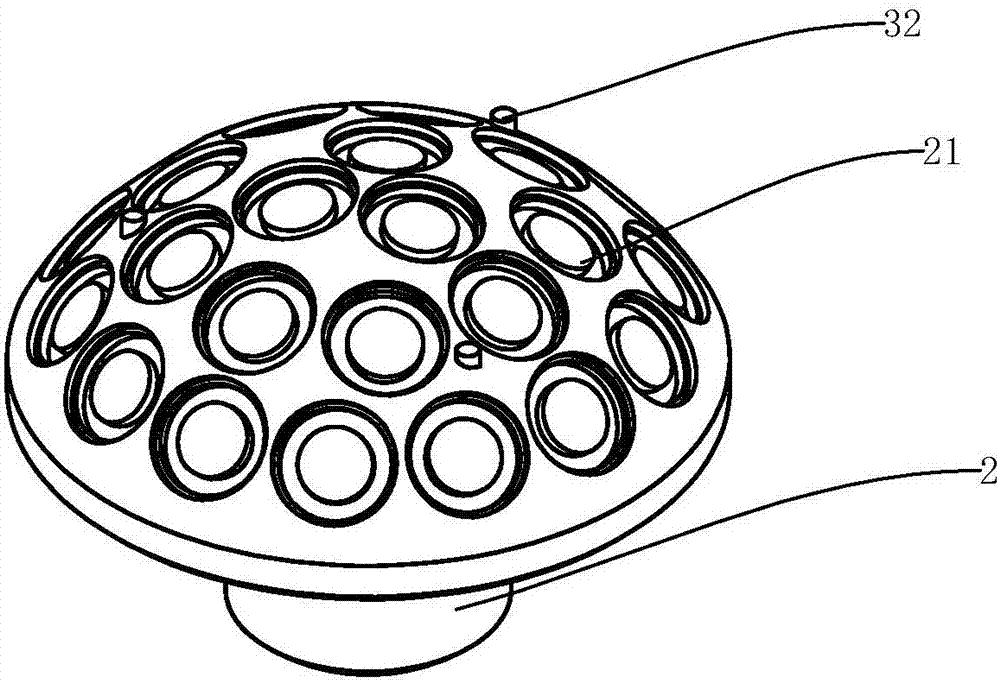

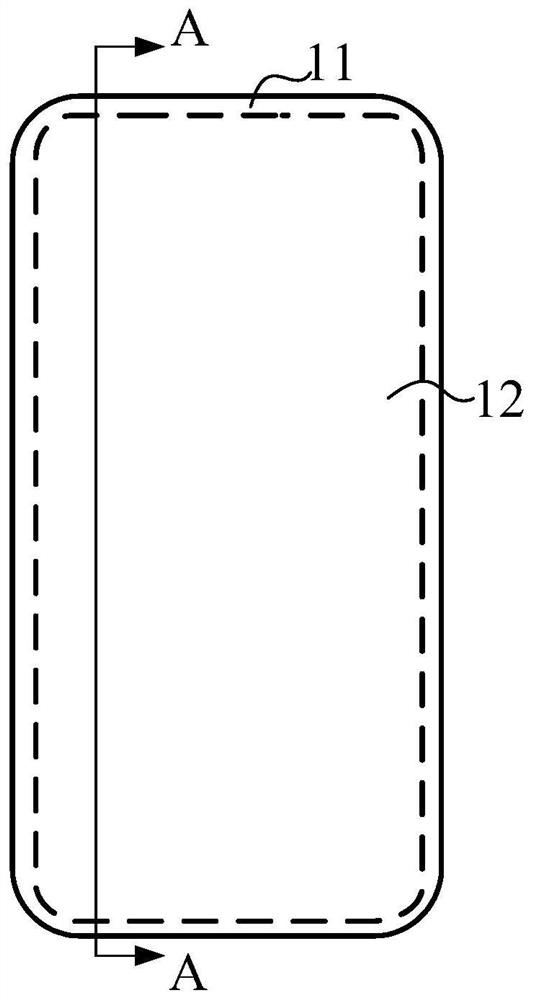

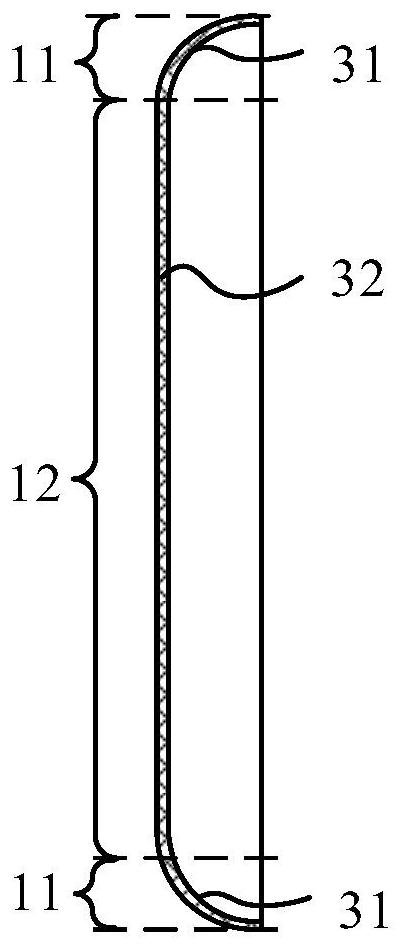

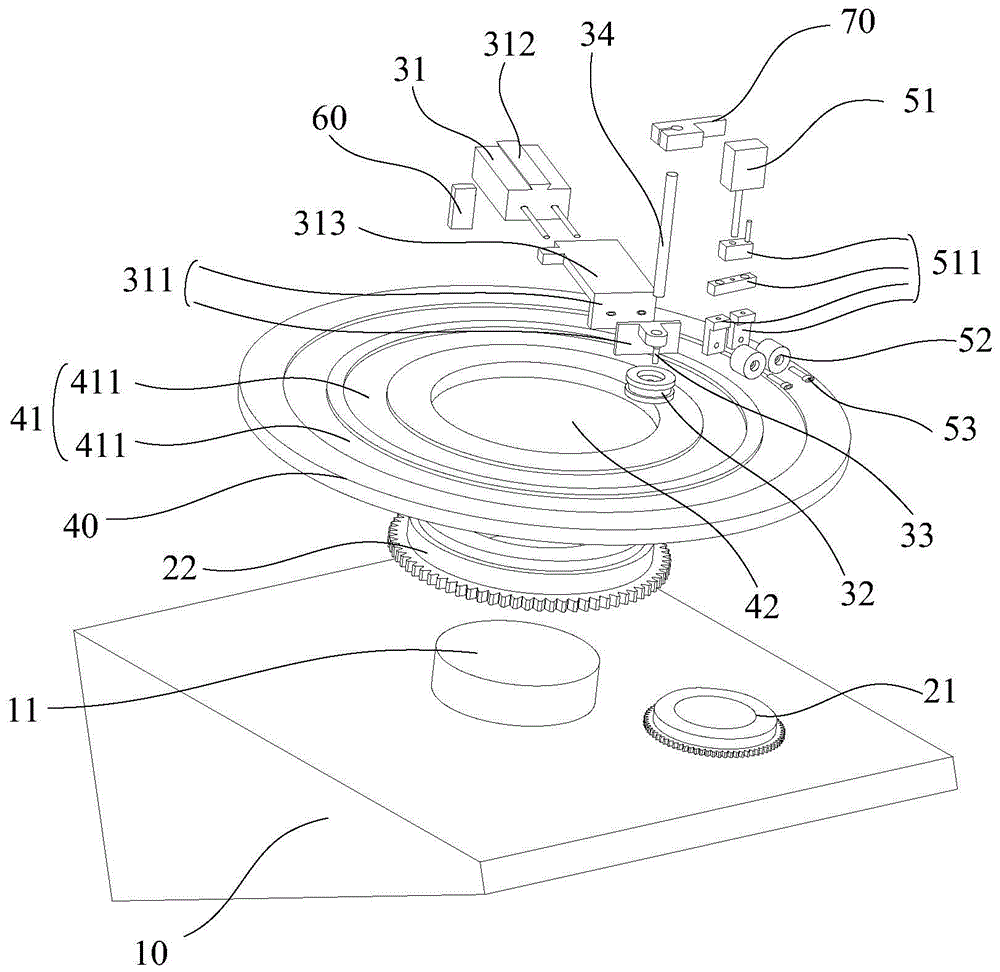

Light strip attaching apparatus

ActiveCN105499975AShorten the timeEvenly attachedMaterial gluingMetal working apparatusEngineeringLED lamp

The invention discloses a light strip attaching apparatus for attaching LED light strips to a lamp which has an inner circular wall used for attaching the light strips. The light strip attaching apparatus comprises a base as well as a turntable and a compression mechanism disposed on the base; the base comprises a rotation drive mechanism which is in transmission connection with the turntable to drive the turntable to rotate; the side of the turntable opposite to the base is provided with a mounting site for mounting the lamp; a presser mechanism is located on the inner side of the mounting site and used for abutting LED light strips to the inner circular wall of the lamp. The technical scheme may improve the attaching efficiency of LED light strips and reducing rework cost of LED lamps.

Owner:SHENZHEN SKYWORTH LIGHTING ELECTRIC +1

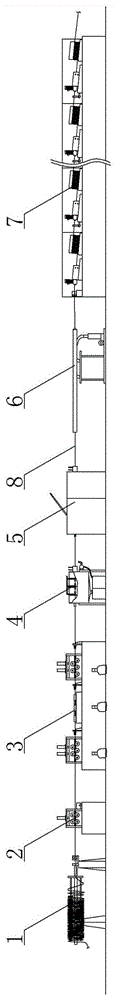

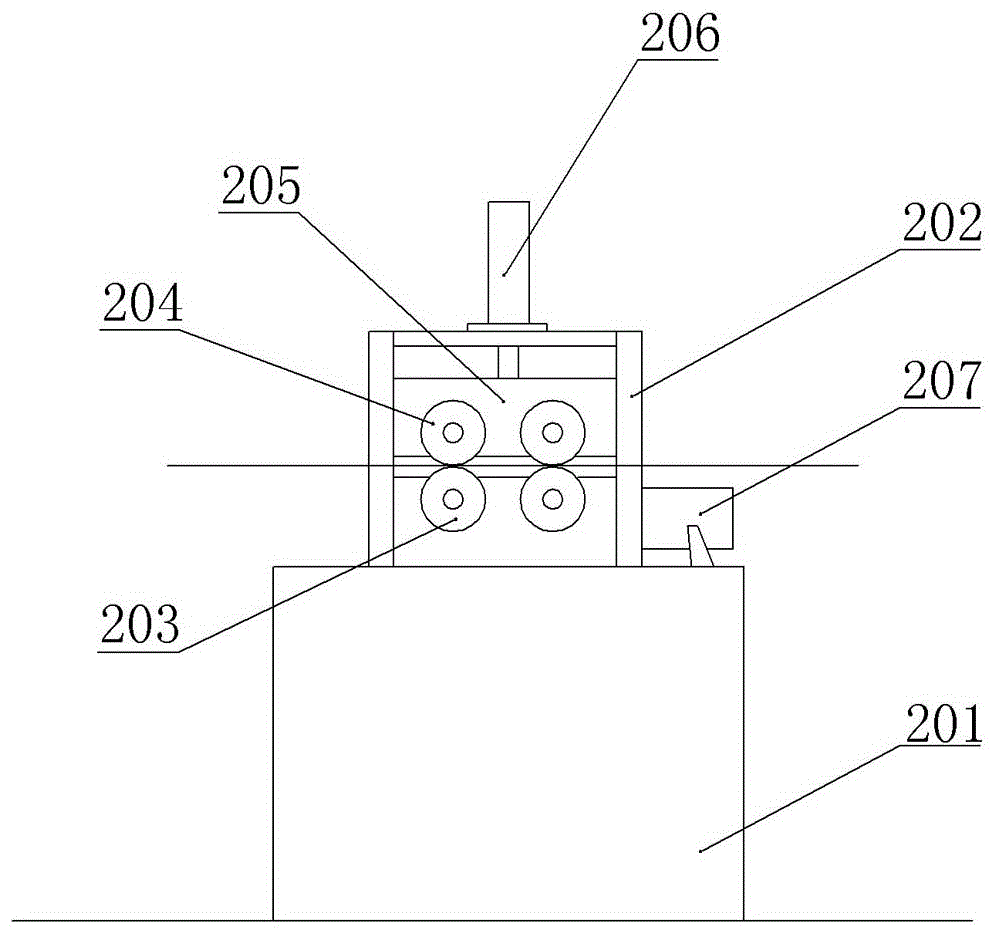

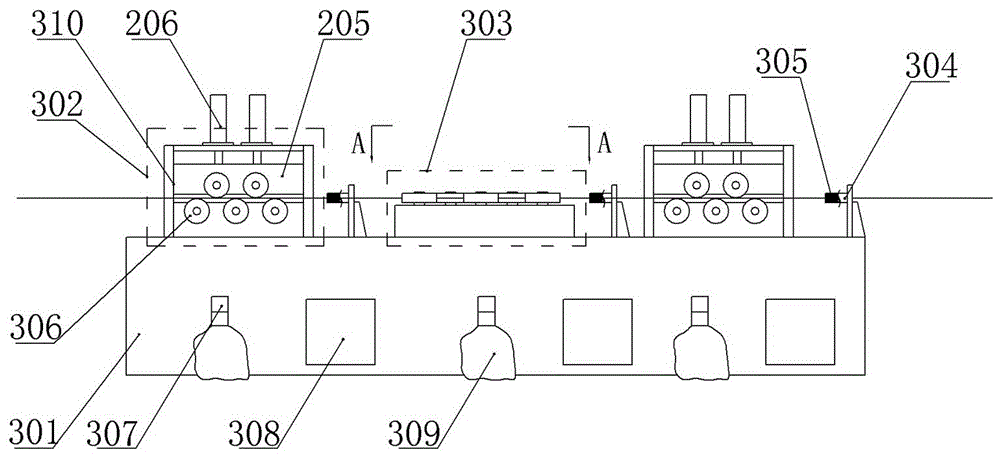

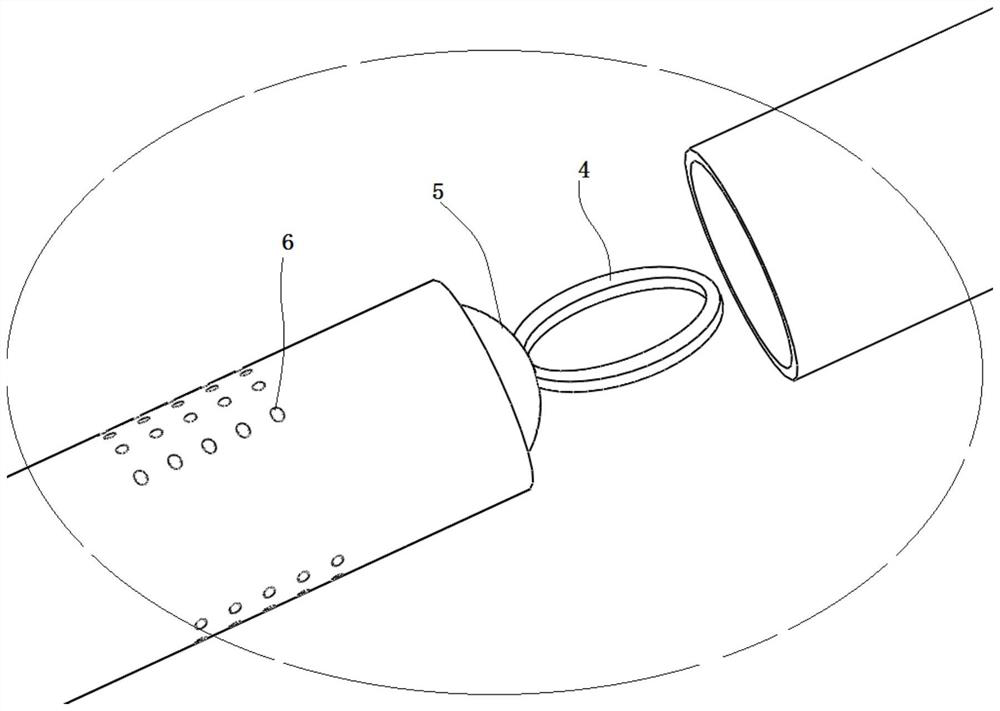

Prestressed steel strand without pickling, non-phosphating drawing equipment and production process

ActiveCN104841706BGood effectReasonable structural designExtrusion cleaning devicesPre stressPre stressing

The invention belongs to the technical field of prestressed steel strand drawing and discloses pre-stressed steel strand pickling-free and phosphating-free drawing equipment and a production process. The equipment comprises a pay-off rack, a straightening traction device, a shelling device, a high-pressure washing device, a boronizing device, a drying device, a steel strand drawing device and a take-up rack which are sequentially arranged. The pre-stressed steel strand pickling-free and phosphating-free drawing equipment provided by the invention is reasonable in structural design, through the design of multiple shelling wheel sets, the drawing equipment can be matched with a pre-stressed steel strand for physical shelling, and then through the design of a rust removal casing and steel wire balls, rust attached to the pre-stressed steel strand after shelling can be further cleared, so that the overall effect of the pre-stressed steel strand after shelling is good, compared with a conventional acid method, the shelling efficiency is greatly improved, and the degree of automation is high. The adjustment of the corresponding shelling wheels can also be carried out for pre-stressed steel strands with different diameters and pre-stressed steel strands with different degrees of oxidation, so that the application range is wide.

Owner:河南恒星钢缆股份有限公司

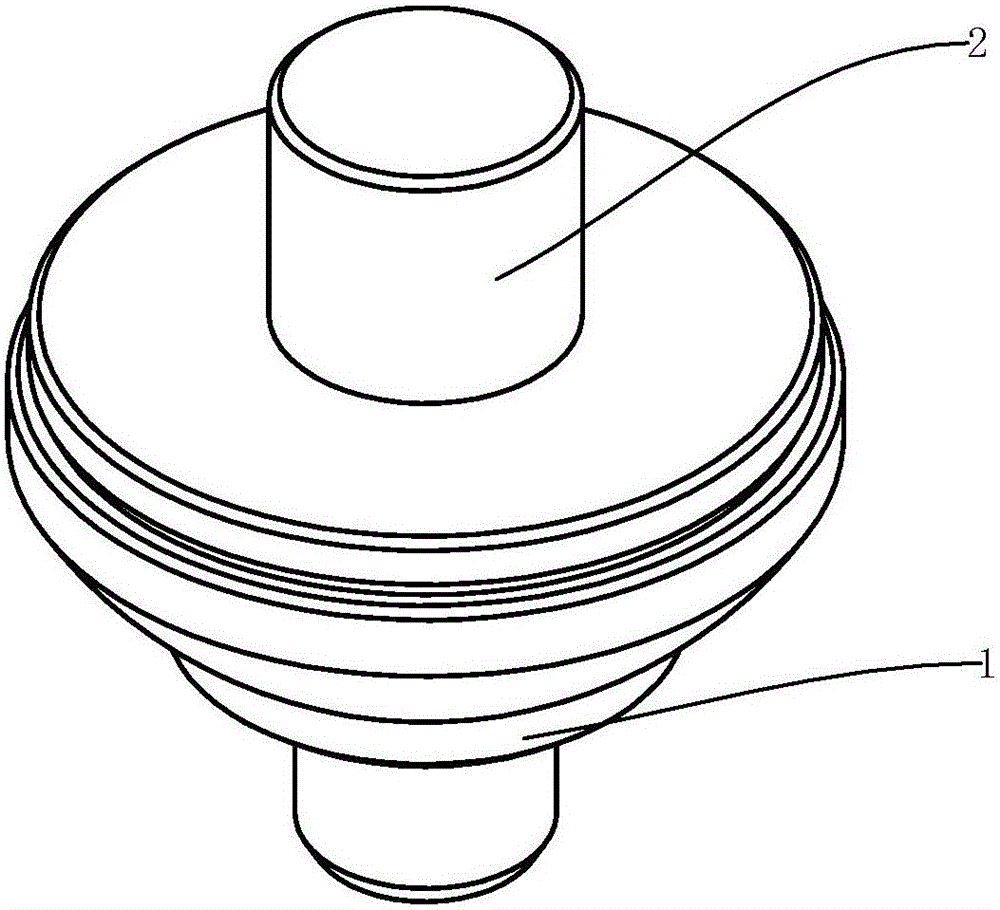

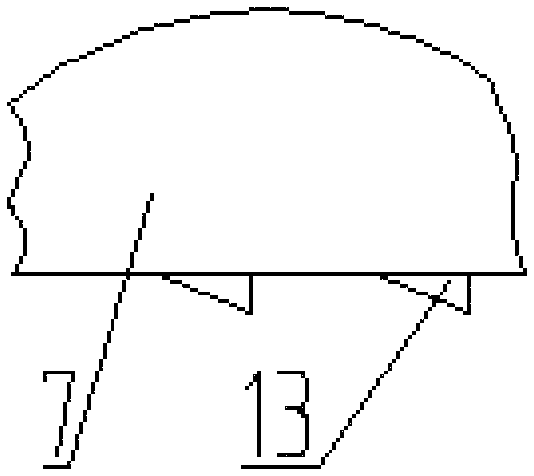

Drilling vessel assembly for edge-thinned lens

ActiveCN105773853AEvenly attachedAvoid offsetWorking accessoriesStone-like material working toolsMarine engineeringLens plate

The invention discloses a drilling vessel assembly for an edge-thinned lens. The drilling vessel assembly comprises a drilling vessel, and the drilling vessel is provided with at least one drilling vessel counter bore used for fixing the lens. The drilling vessel assembly further comprises an upper disc vessel which is matched with the drilling vessel and used for compressing the lens to be processed. The upper disc vessel is provided with upper disc vessel counter bores matched with the drilling vessel counter bores. The upper disc vessel is connected with the drilling vessel through a locating piece. The upper disc vessel counter bores are provided with annular grooves, and silica gel sealing rings used for supporting the to-be-processed surface of the lens are arranged in the annular grooves. According to the drilling vessel assembly, when the lens is subjected to drilling vessel processing, the to-be-processed lens can be accurately positioned through the upper disc vessel and the drilling vessel, and the phenomena that the lens deflects on the drilling vessel and cannot be compressed completely due to thickness difference, and 'deflection' and non-uniform thickness happen to the processed lens can be avoided.

Owner:GUANGDONG KINGDING OPTICAL TECH CO LTD

Thin edge lens drilling dish assembly

ActiveCN105773853BEvenly attachedAvoid offsetWorking accessoriesStone-like material working toolsSide dishMarine engineering

Owner:GUANGDONG KINGDING OPTICAL TECH CO LTD

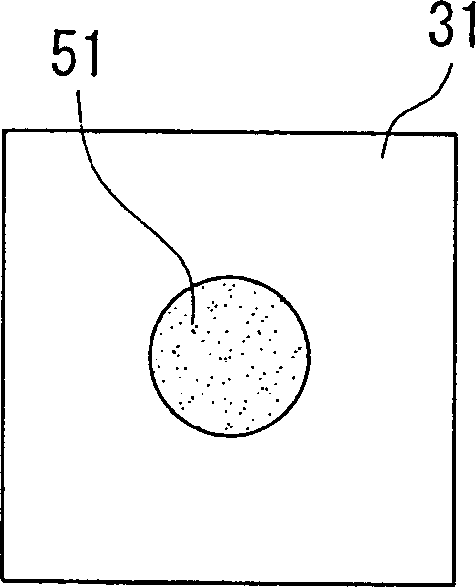

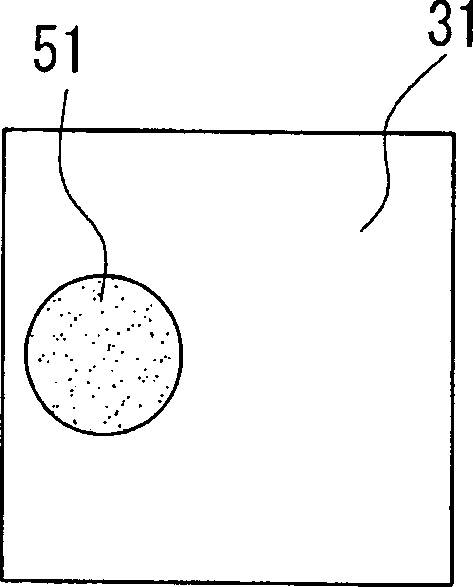

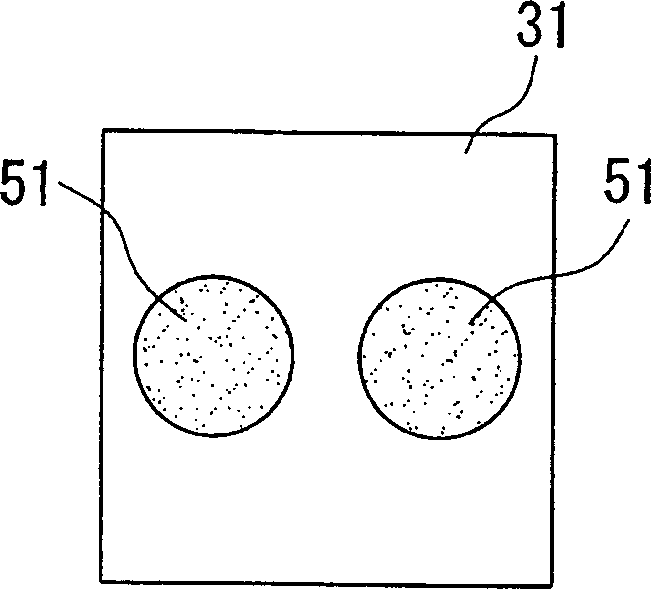

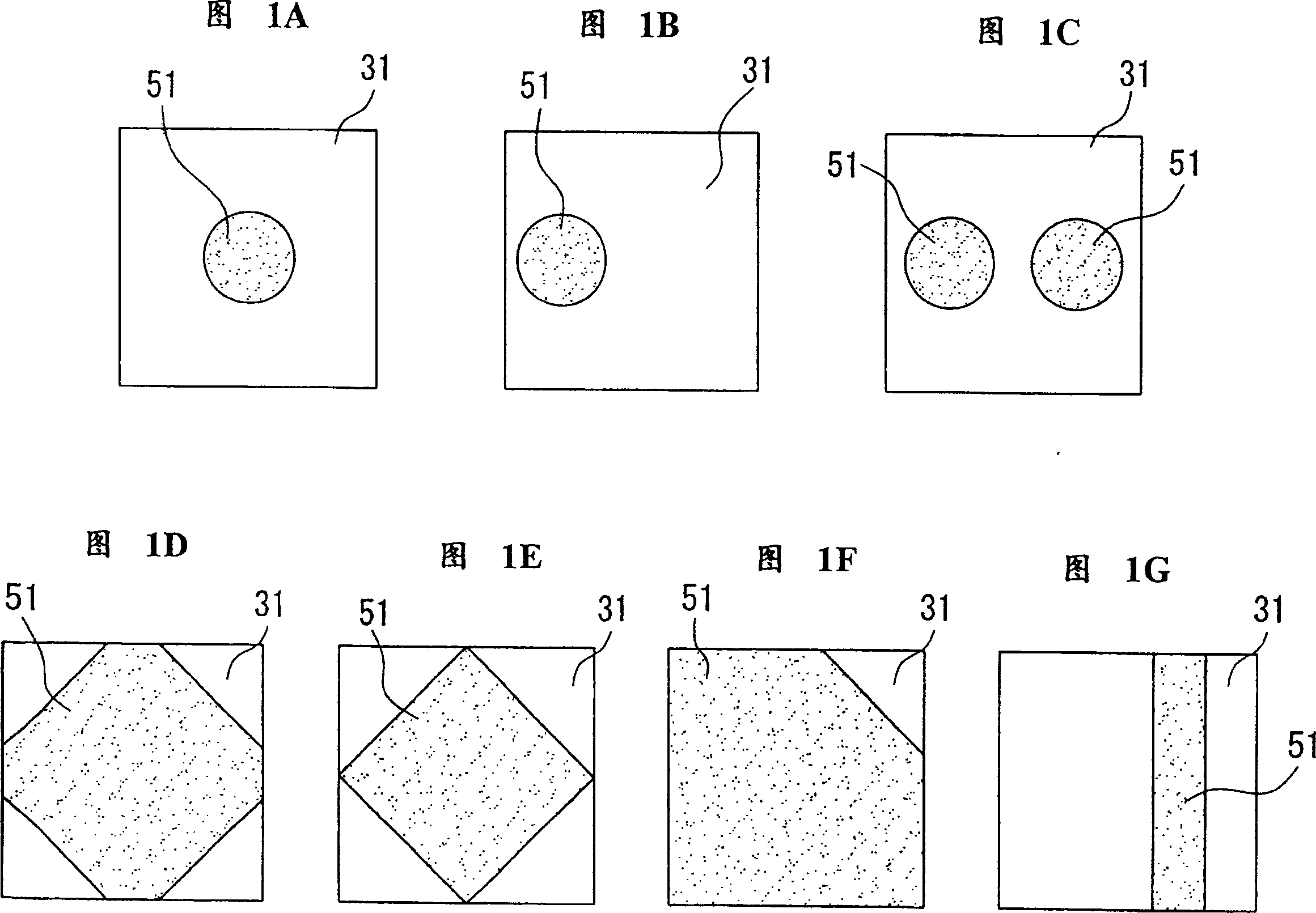

Optical element, optical element chip, and corresponding producing method

InactiveCN1469139ALow costShorten the cutting processLayered productsIntegrated optical head arrangementsWaferingOptical thin film

Provided is an optical element wafer on which a plurality of optical elements are formed altogether, whose cost can be reduced and in which an optical film is prevented from partly peeling and floating when stuck to a package main body. The optical element wafer 10 comprises a base material preform 30, and a holding material 40 stuck to one of the sides of the base material preform 30. The base material preform 30 has a plurality of base materials 31 formed by dividing the base material preform 30. The optical film 51 is partially stuck to each base material 31.

Owner:TOMOEGAWA PAPER CO LTD

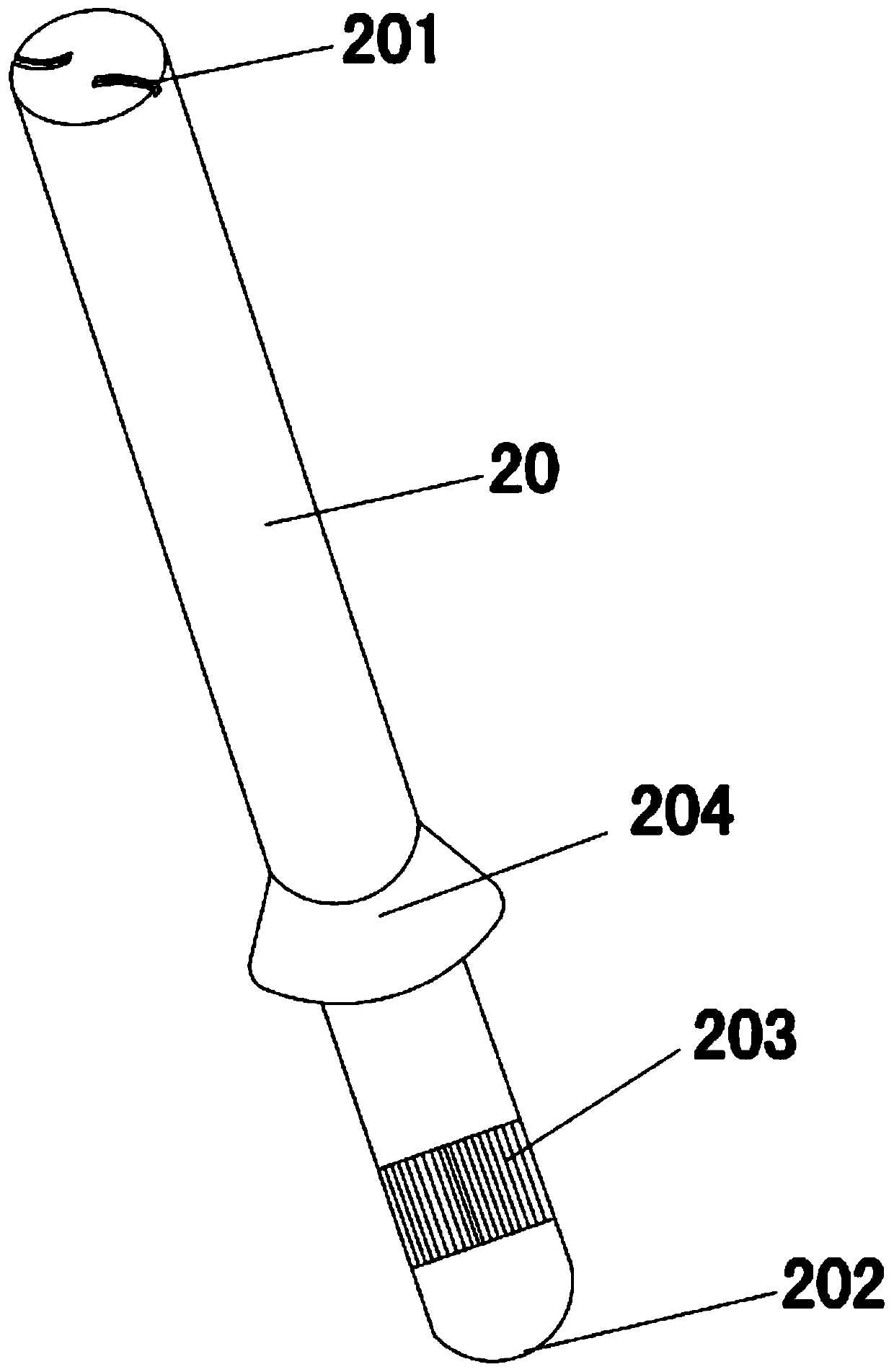

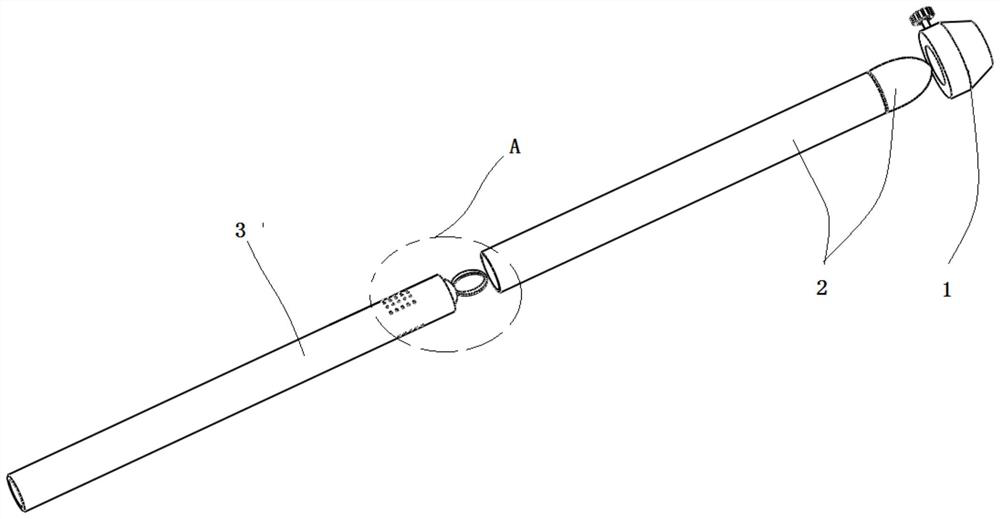

Embedded plant drug injection device

InactiveCN110786174BEvenly attachedUniform attachment strengthHorticulture methodsBiotechnologyDrug injection

Owner:贵州省烟草公司黔南州公司

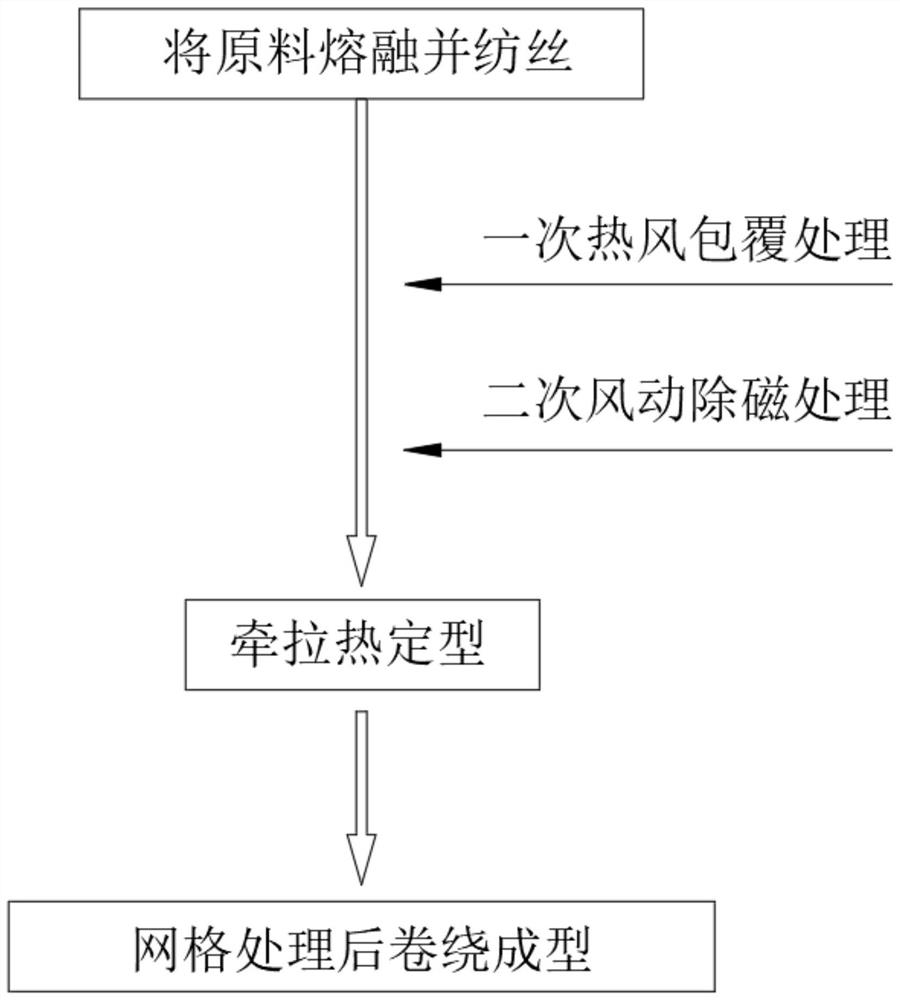

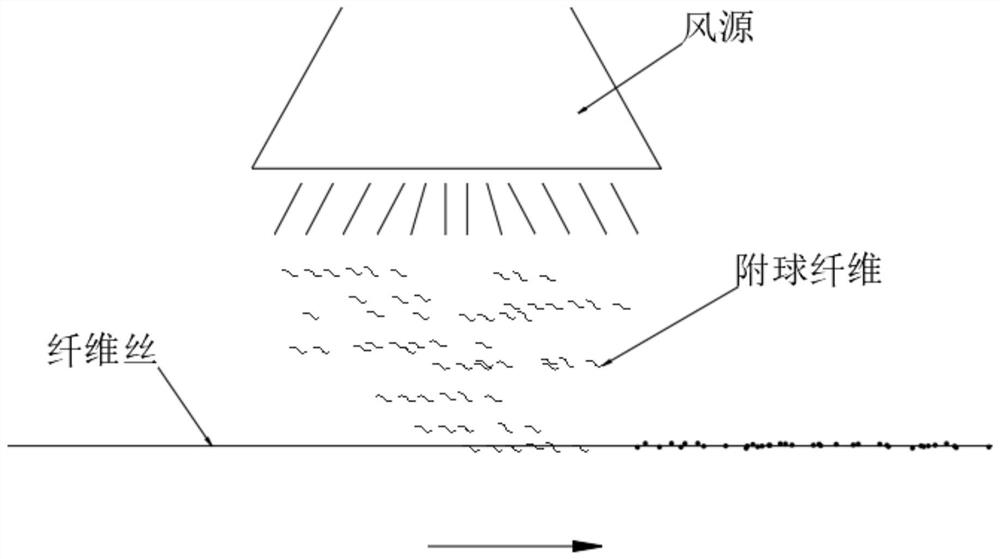

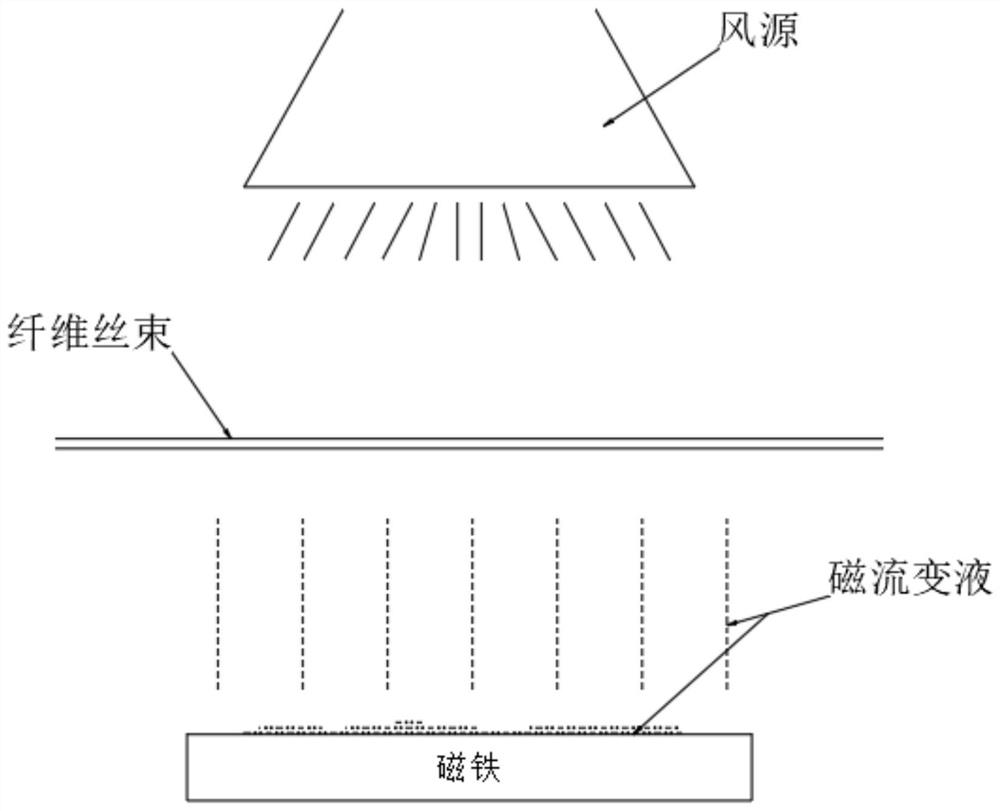

A kind of preparation technology of tensile type polyester fiber industrial yarn

ActiveCN113337901BReduce liquidityInhibition of droplet phenomenonFilament manufactureMelt spinning methodsPolyesterYarn

Owner:德州市盛源纤维科技有限公司

Wall cloth attaching device

InactiveCN112706558AEvenly attachedAchieve flat attachmentPaperhangingStructural engineeringMechanical engineering

Owner:南京奥新可工程科技有限公司

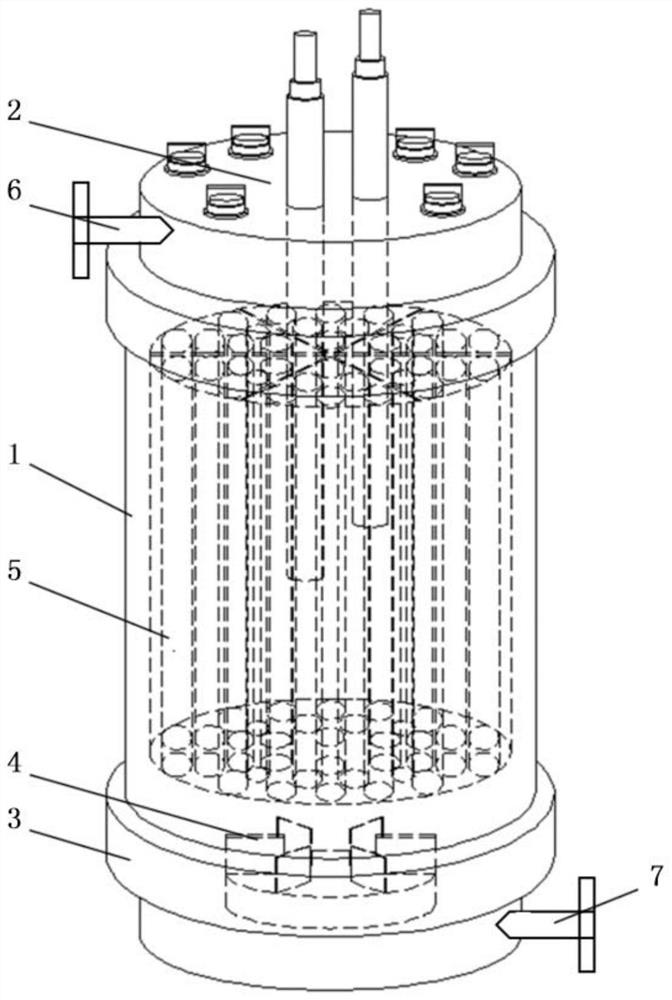

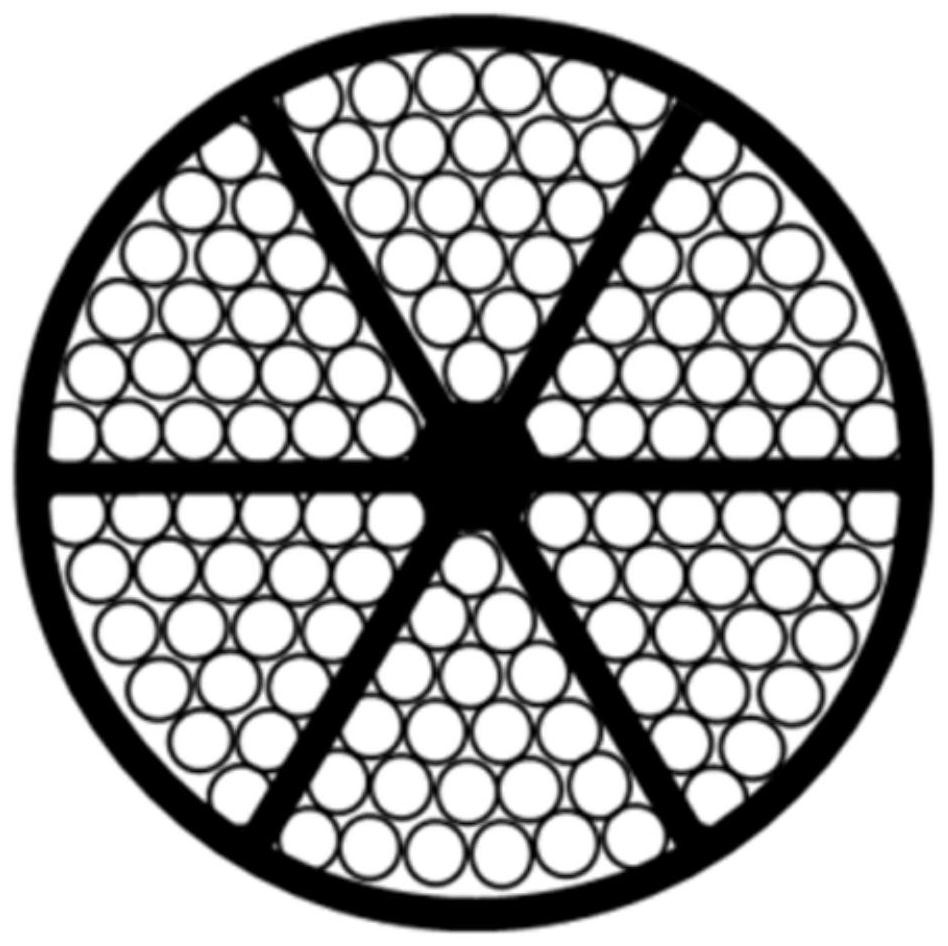

Hollow tube bundle type fixed bed bioreactor for adherent culture of mammalian cells

PendingCN112980649AEvenly attachedEvenly distributedBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFixed bed bioreactor

The invention provides a hollow tube bundle type fixed bed bioreactor for adherent culture of mammalian cells, and can effectively solve the technical problems that cells are unevenly distributed on a carrier, the center of a carrier stack is prone to produce a cell-free "dead zone", shear force of a fluid medium in the reactor is large, and the cells are difficult to harvest. The hollow tube bundle type fixed bed cell bioreactor comprises a tank body, a carrier, a culture medium driving unit and a gas supply unit; a flange cover is mounted at the top of the tank body, and the carrier is arranged in the tank body. The hollow tube bundle type fixed bed cell bioreactor is characterized in that only flow channels vertical and evenly distributed are arranged in the carrier; gaps are arranged between the upper end of the carrier and the flange cover and between the carrier and the side wall of the tank body; and culture mediums in the tank body flow in from the opening at lower ends of the flow channels under the action of the culture medium driving unit, and then return to the bottom of the tank body after sequentially passing through the flow channels, the gap between the carrier and the flange cover and the gap between the carrier and the side wall of the tank body.

Owner:JIANGNAN UNIV

A method for ceramic rotary spray molding

ActiveCN110126078BSpray evenlySimple structureFeeding arrangmentsAuxillary shaping apparatusCeramic moldingSlurry

The invention discloses a ceramic rotary slurry spraying forming method. The ceramic rotary slurry spraying forming method is characterized by comprising the following steps that (1) mold arrangementis conducted, specifically, molds needing to be machined are arranged on a rotary mold conveying device; (2) mold transporting is conducted specifically, the molds needing to be machined are transported to slurry spraying stations; (3) slurry spraying is conducted, specifically, after the molds are transported to the slurry spraying stations, nozzles located below the stations are made to stretchinto the molds through a lifting device, the nozzles rotatably spray the slurry onto the inner walls of the molds uniformly, and blank bodies are formed; (4) mold blank transporting is conducted, specifically, the blank bodies are transported to blank taking stations; and (5) blank taking is conducted, specifically, the bank bodies are taken down after being transported to the blank taking stations. According to the ceramic forming method, through the mode that the nozzles spray the slurry rotationally, the slurry can be sprayed onto the interiors of the molds more uniformly, the probability that pores occur to the blank bodies due to traditional slurry injection can be reduced, and the phenomenon that the slurry is not sprayed uniformly is decreased.

Owner:福建省德化县豪鹏机械有限公司

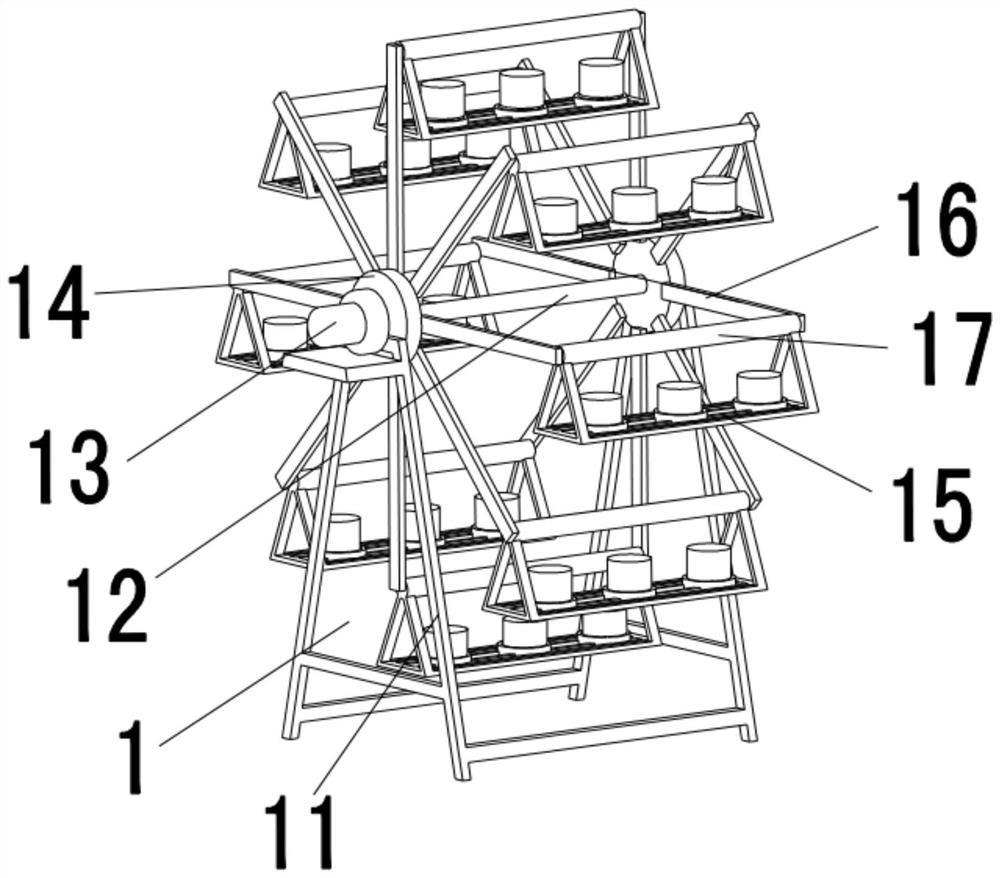

Method for improving nitrogen fixation of legume plants

InactiveCN112772333AImprove nitrogen fixation capacityMeet the needs of rapid growth and developmentRotary stirring mixersNon-rotating vibration suppressionBiotechnologyPlanting seed

The invention discloses a method for improving nitrogen fixation of legume plants. The method comprises the following steps of selecting legume plant seeds to be sown, taking the selected legume plant seeds as sowing materials, pretreating the sowing materials, washing the pretreated sowing materials with cold water, and independently storing the pretreated sowing materials; screening and selecting the pretreated sowing materials, and after damaged seeds and collapsed seeds in the sowing materials are selected out, enabling the sowing materials to be subjected to seed dressing treatment; and selecting proper rhizobium powder, proportioning the sowing materials and the rhizobium powder according to a ratio of 100: 1, and putting the elutriated sowing materials and rhizobium powder into a mixing device. According to the method, the seeds of the legume plants are treated, so that the epidermis of the seeds is adhered with the rhizobium powder, the nitrogen fixation effect of the seeds is greatly improved, and meanwhile, the planted seeds are subjected to topdressing treatment, so that the breeding effect of the legume plants is effectively improved.

Owner:HENAN UNIVERSITY

Method for producing optical element and optical element wafer

InactiveCN1333275CLow costShorten the cutting processPolarising elementsOptical head manufactureEngineeringOptical thin film

The invention provides a method for producing optical elements. The method comprises the following steps of: dividing a base material of an optical film into a plurality of optical films, removing sections free of optical films from the base material of the optical film, dividing a substrate into a plurality of substrates, adhering each optical film onto each substrate to form a plurality of optical elements, and taking out the optical elements.

Owner:TOMOEGAWA PAPER CO LTD

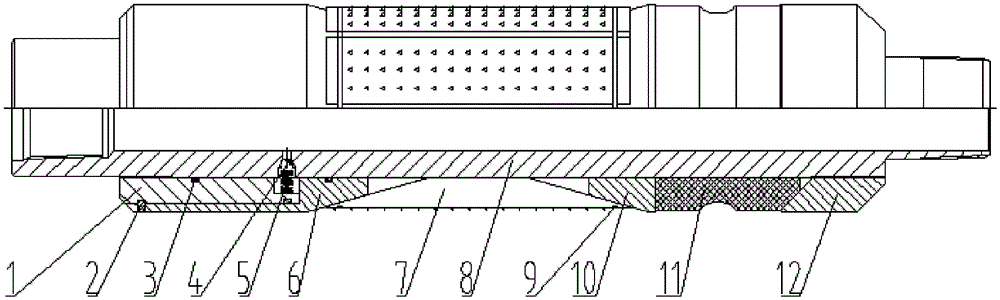

The method of clamping the bottle blowing mold by using the clamp during turning

ActiveCN108972091BAvoid tiny wigglesEvenly attachedPositioning apparatusMetal-working holdersEngineeringBottle

The invention discloses a method of using a fixture to clamp a bottle blowing mold during turning. The method includes: clamping the bottom end of a half core with a left clamping device having a first elastic positioning component, wherein the first elastic positioning component is attached tightly to the peripheral face of the bottom end of the half core; clamping the bottleneck end of the halfcore with a right clamping device having a second elastic positioning component, wherein the second elastic positioning component is attached tightly to the peripheral face of the bottleneck end of the half core, and the left and right clamping devices are connected via a connection haft; using a three-jaw chuck of a lathe to clamp and hold the clamping end, coaxial to the first elastic positioning component, of the left clamping device such that an ejector pin at the tail of the lathe is inserted into an ejector pin hole in the right clamping device end of the connection shaft, and such thatcylindrical turning can be started for the half core. The method can provide better internal and external coaxiality for a half core during cylindrical turning, extrusion indentations in the surface of the half core are avoided, and processing quality and efficiency of the half core are improved accordingly.

Owner:HANGZHOU WAHAHA PRECISION MACHINERY

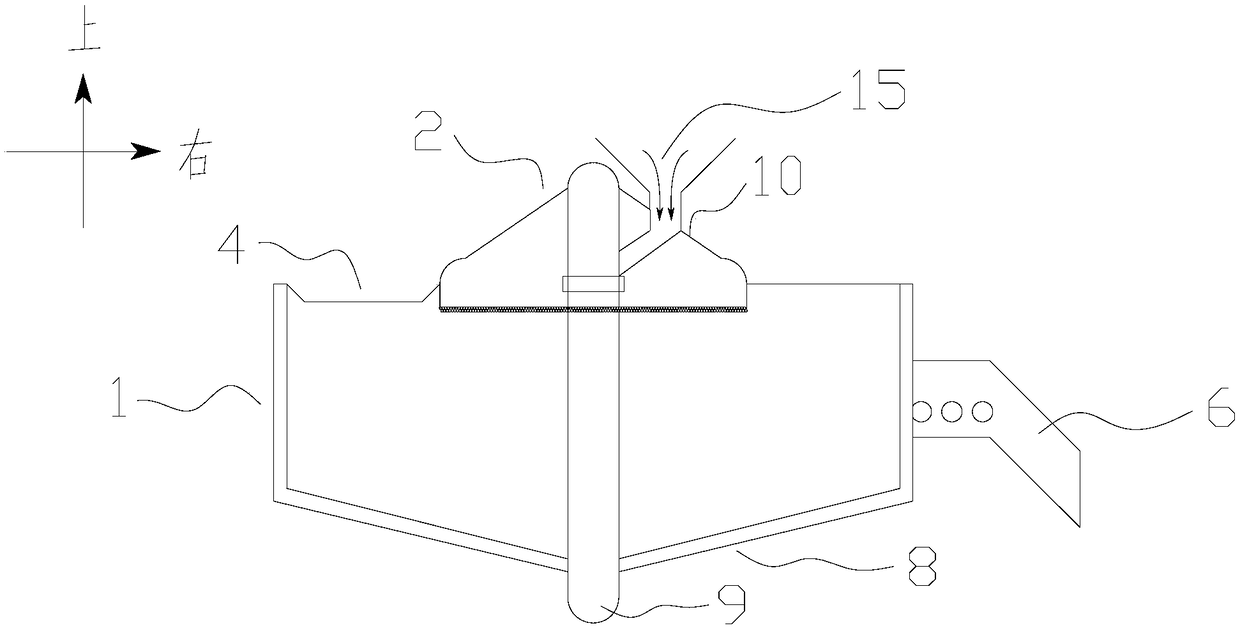

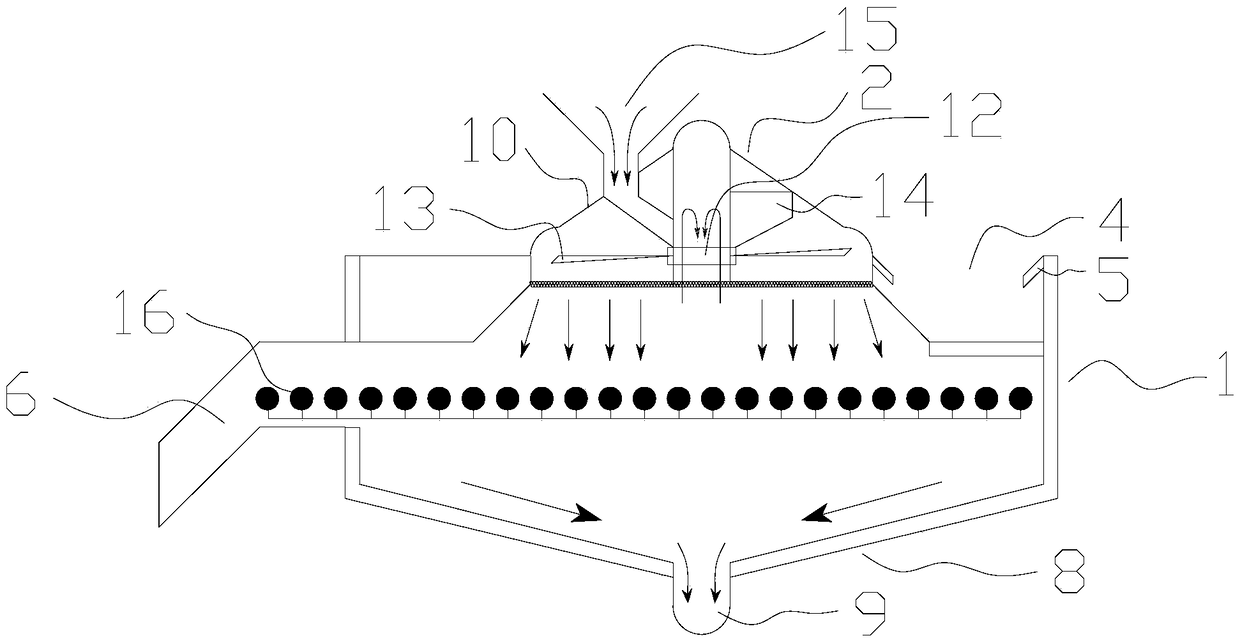

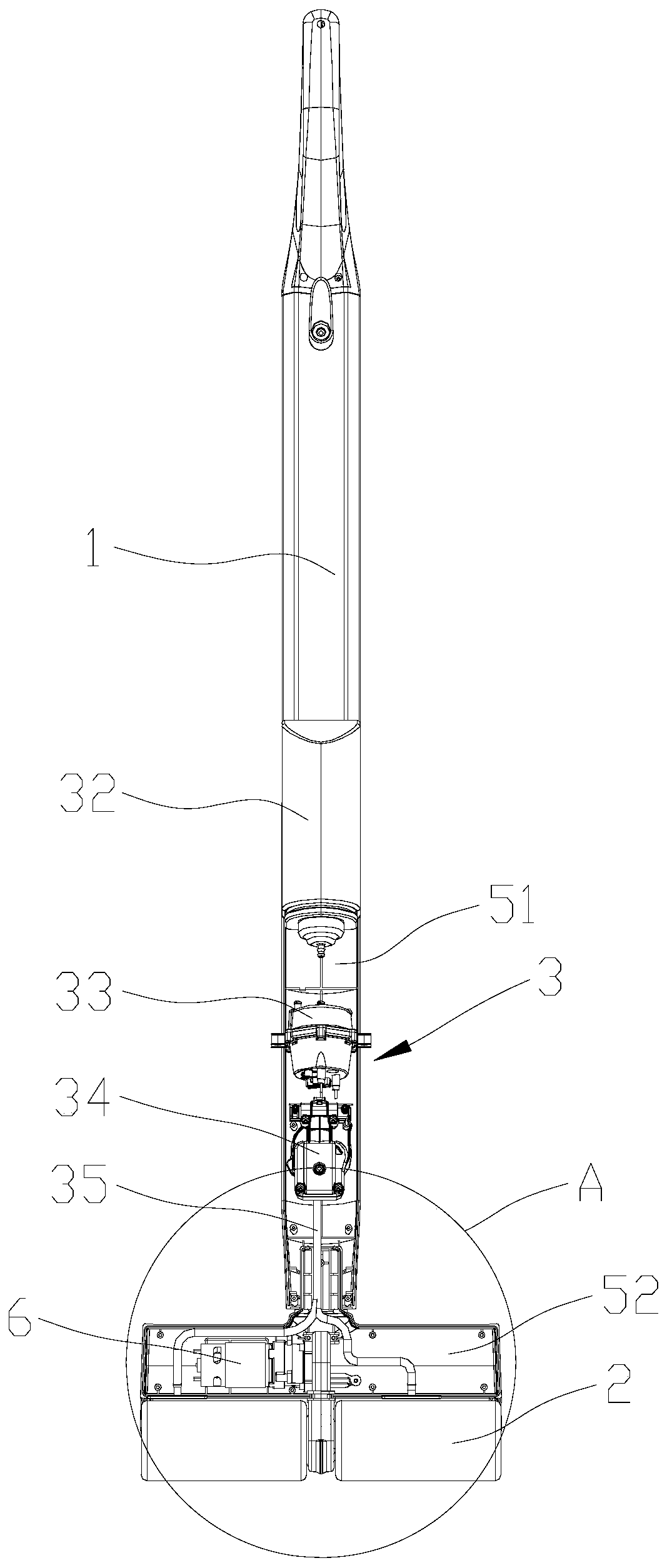

Rolling steam mop

The invention discloses a rolling steam mop, which comprises a rack.The rack is provided with a cleaning roller and a steam generating device, the cleaning roller is used for rotation cleaning a surface to be cleaned, the steam generating device is provided with a steam nozzle,the steam nozzle is arranged at the periphery of the cleaning roller and used for spraying steam onto the cleaning roller and / or the surface to be cleaned. Through the structural arrangement, when in use, steam generated by the steam generating device can be ejected through the steam nozzle in particular to the cleaning roller and / or the surface to be cleaned; the steam is directly sprayed on the cleaning roller, so that the cleaning roller can perform more efficient rotation cleaning on the surface to be cleaned; the steam is directly sprayed on the surface to be cleaned, so that cleaning water can be more evenly attached to the surface of an object to be cleaned, and cleaning of the surface to be clean is facilitated;meanwhile, the two methods can ensure that the surface of the object to be cleaned is not too wet, and the safety accidents are avoided.

Owner:ZHONGSHAN JINSHUN HOUSEHOLD WARES +1

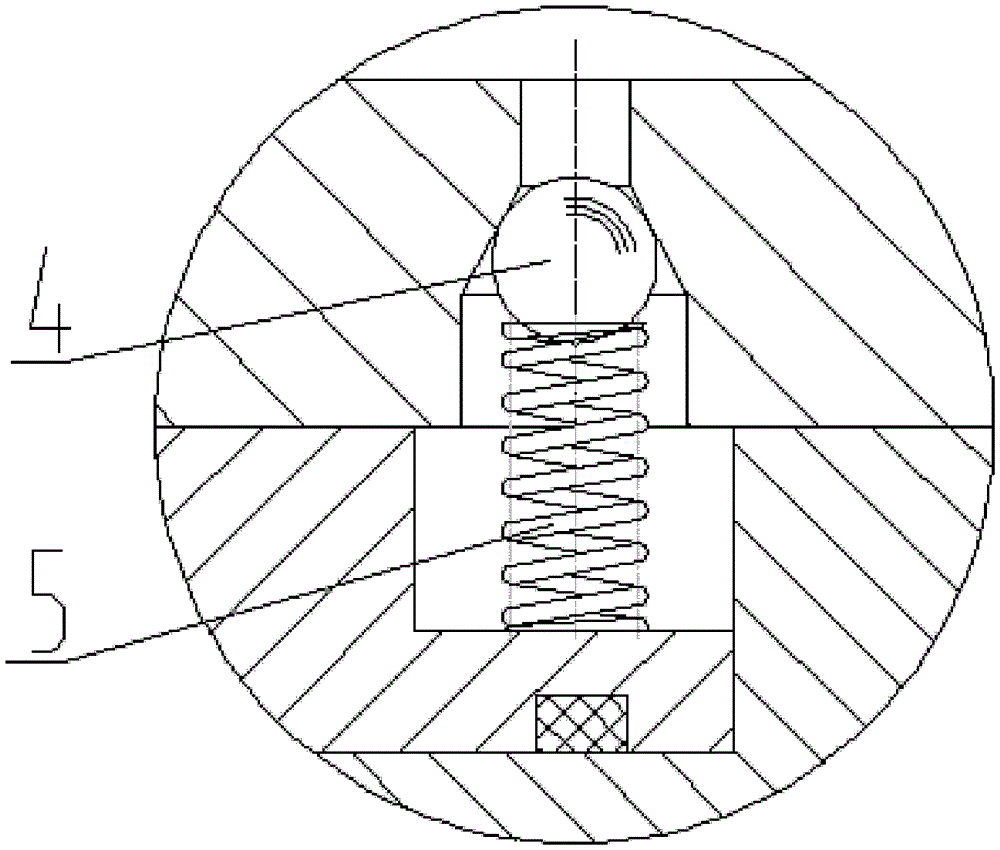

A drillable fracturing bridge plug

The invention provides a drilling type fracture bridge plug and belongs to the field of fracture well completion in the petroleum industry. A whole kava is adopted by the drilling type fracture bridge plug, and anchoring teeth in shapes of oblique triangles are evenly distributed on an outer surface of the kava; and a check valve is designed in a pressure transmission channel of the bridge plug. The kava can be evenly adhered to an inner wall of the sleeve when the bridge plug is sealed, stress is even, and damage to the sleeve is small. A check valve mode is adopted by the drilling type fracture bridge plug to guarantee that a piston does not draw back after sealing, an anti-retraction mechanism is removed, and the length of the bridge plug is shortened. When the fracture is carried out, a structure of the pressure transmission channel of the bridge plug enables pressure in a bridge plug pressure chamber to be no less than maximum pressure of construction, and plugging reliability of the bridge plug is guaranteed. All components except for a spring at the position of the check valve can be made of non-metallic materials, so that the bridge plug is guaranteed to be easy to drill, complete drilling can be achieved, and operation time is greatly shortened.

Owner:CHINA PETROLEUM & CHEM CORP +1

Protective film for special-shaped display panel and its attachment method, special-shaped display panel

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

Light bar attachment equipment

ActiveCN105499975BShorten the timeEvenly attachedMaterial gluingMetal working apparatusEngineeringLED lamp

The invention discloses a light strip attaching apparatus for attaching LED light strips to a lamp which has an inner circular wall used for attaching the light strips. The light strip attaching apparatus comprises a base as well as a turntable and a compression mechanism disposed on the base; the base comprises a rotation drive mechanism which is in transmission connection with the turntable to drive the turntable to rotate; the side of the turntable opposite to the base is provided with a mounting site for mounting the lamp; a presser mechanism is located on the inner side of the mounting site and used for abutting LED light strips to the inner circular wall of the lamp. The technical scheme may improve the attaching efficiency of LED light strips and reducing rework cost of LED lamps.

Owner:SHENZHEN SKYWORTH LIGHTING ELECTRIC +1

Furniture fitting

InactiveCN102575701BEasy to connect correctlyConducive to manipulationSheet joiningFurniture joiningEngineeringMechanical engineering

The invention relates to a furniture fitting (1) for connecting two furniture parts that are brought together in a horizontal longitudinal motion, comprising at least two fitting parts (2, 3), of which a first fitting part (1) is provided on a first of the two furniture parts and a second fitting part (3) is provided on a second furniture part, the first fitting part being designated as a guide part (2), and the second fitting part being designated as a locking part (3) and being movable on the guide part (2)until the second fitting part reaches a locking position, in which the two furniture parts are connected to each other, the two fitting parts (2, 3) engaging one behind the other and thus securing the two furniture parts in their connected arrangement. According to the invention, the two fitting parts have complementary insertion surfaces, which form a guide bevel (12) that lifts the locking part when the locking part is placed against the guide part, and the two fitting parts have complementary transverse guide surfaces (15) such that, when the two fitting parts are brought together horizontally, the two furniture parts thus connected are automatically brought together in a transverse direction, which is likewise horizontal but extends transversely to the prior longitudinal direction of motion, and thus the distance between the furniture parts is reduced, and the locking part (3) can be locked to the guide part (2) in a downward motion.

Owner:欧仕达家俱制造商

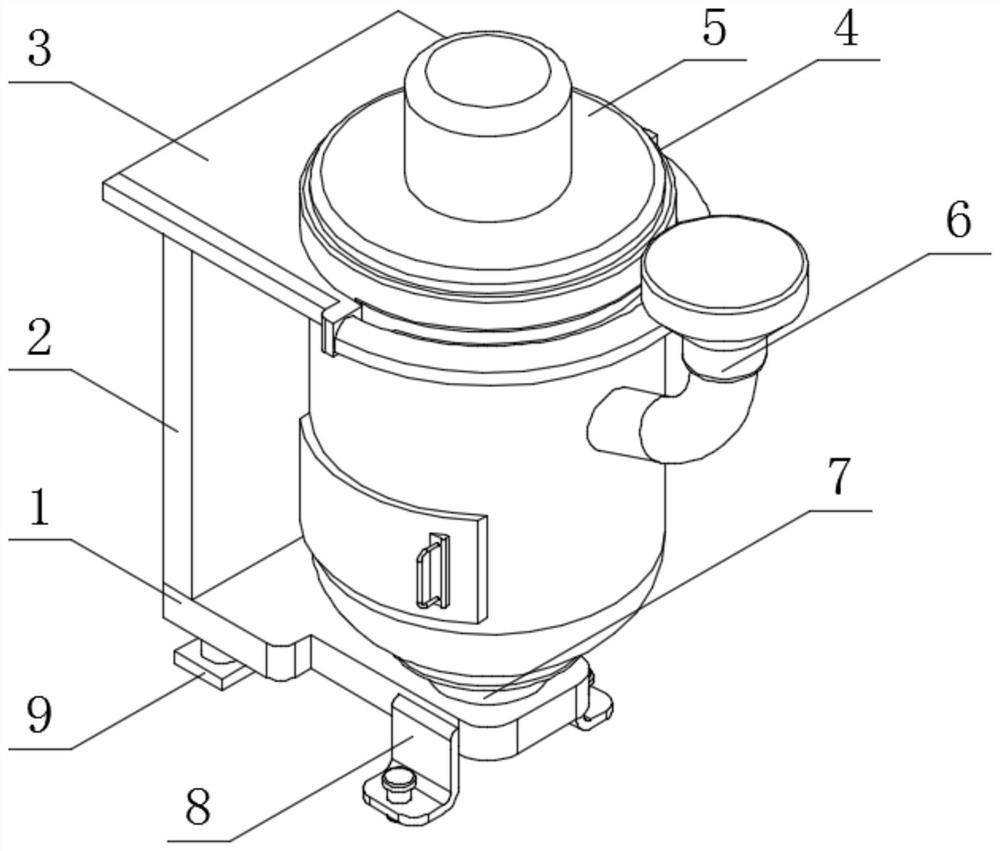

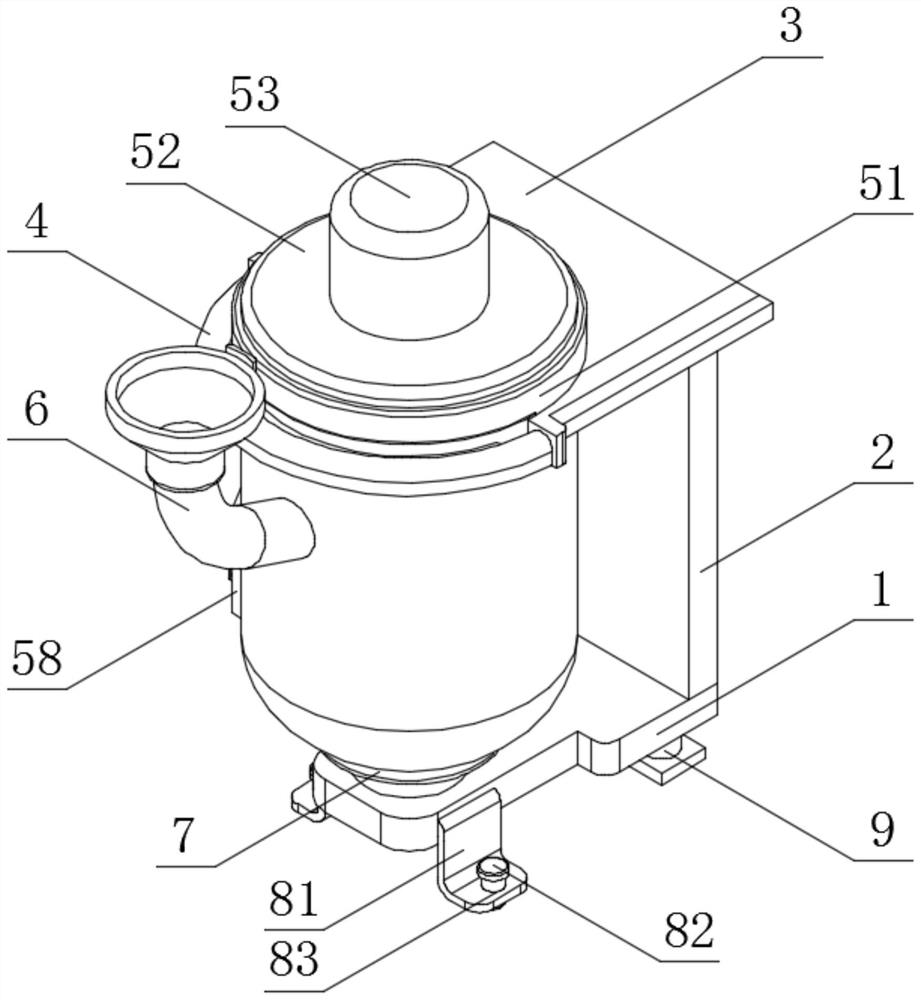

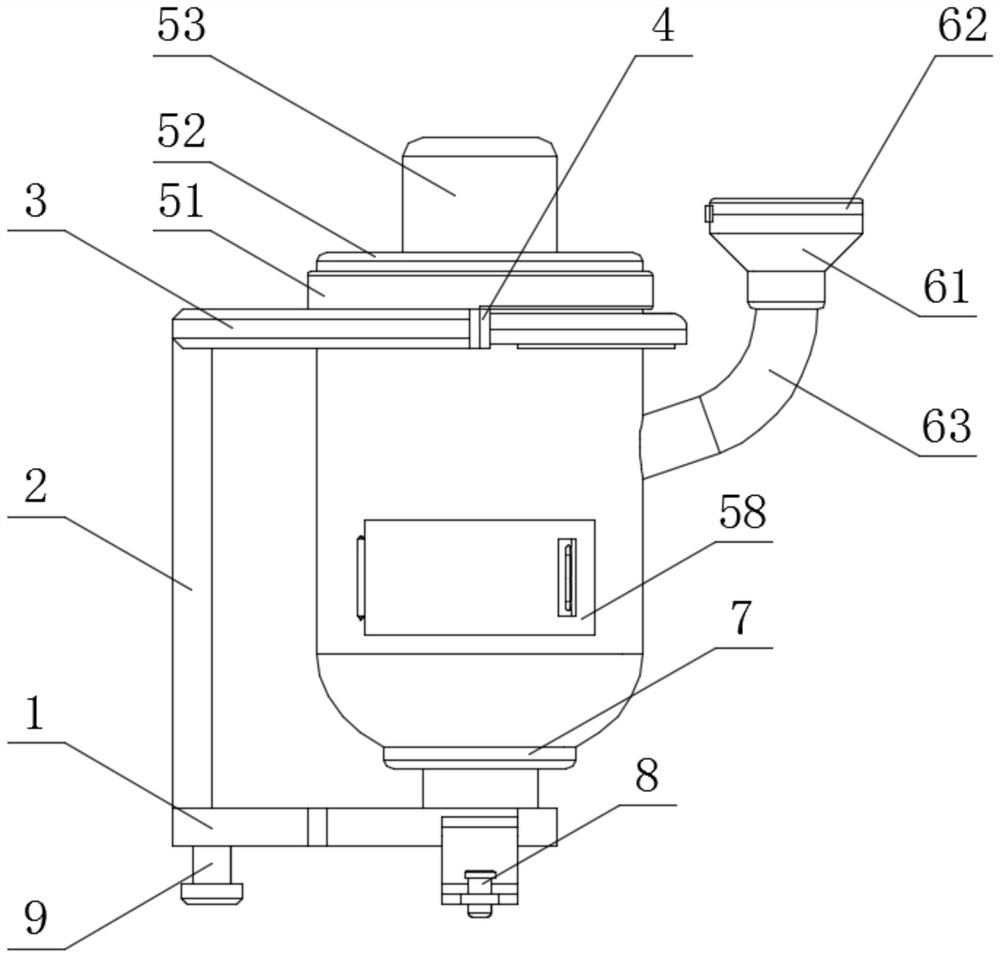

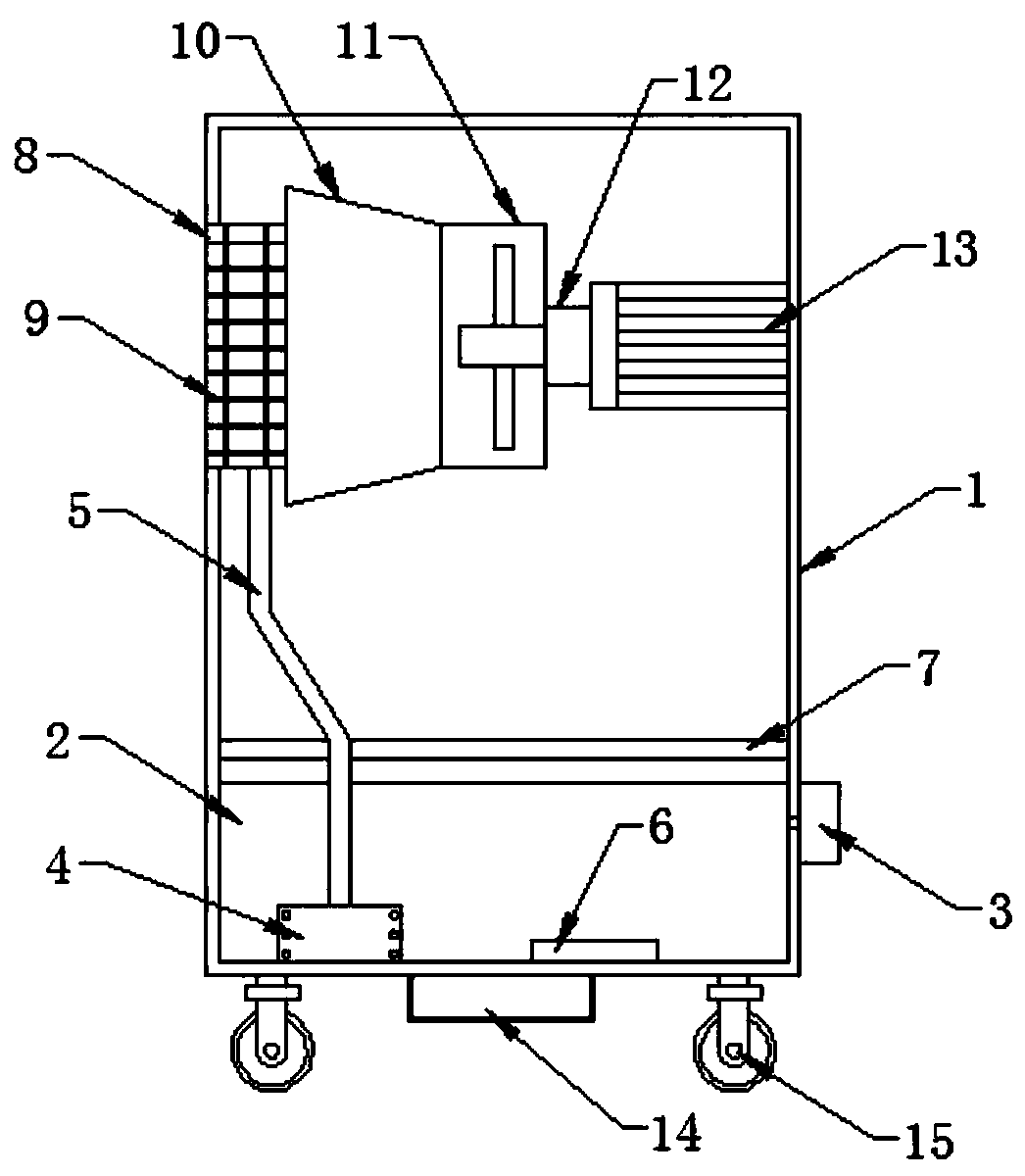

Domestic movable air cooler

PendingCN110749003AEvenly attachedImprove practicalityLighting and heating apparatusAir conditioning systemsThermodynamicsCapillary Tubing

The invention discloses a domestic movable air cooler. The domestic movable air cooler comprises a machine body, a cold water tank is fixedly installed at the bottom part of the inner side of the machine body, a water conveyance device is arranged at one side of the cold water tank, the water conveyance device is installed at the outer end of the machine body, a water pumping device is fixedly installed at the bottom part of the inner side of the cold water tank, one end of the water pumping device is connected with a water pumping pipe, one side of the water pumping device is provided with atemperature control pipe, the top part of the cold water tank is fixedly provided with a water baffle plate, the top part of the inner side of the machine body is fixedly provided with a wet curtain,the inner part of the wet curtain is provided with a plurality of uniformly distributed capillaries, one end of a fan hood is fixedly provided with a fan, one end of the fan is fixedly provided with atransmission device, and one end of the transmission device is fixedly provided with a servo motor. According to the domestic movable air cooler, the plurality of capillaries are arranged in the inner part of the wet curtain, so that water is evenly distributed on the wet curtain through using the capillaries, wind which is blown from the fan to the wet curtain evenly carries with water vapor, and the practicability of the domestic movable air cooler is enhanced.

Owner:HUBEI POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com