Ceramic rotary slurry spraying forming method

A technology of spraying grouting and ceramics, which is applied in ceramic molding machines, auxiliary molding equipment, supply devices, etc., and can solve problems such as increasing grouting time and amount of slurry, nozzle height cannot be adjusted, and pinholes on the surface of the green body, etc., to avoid Possibility of pinholes, ease of automatic control, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

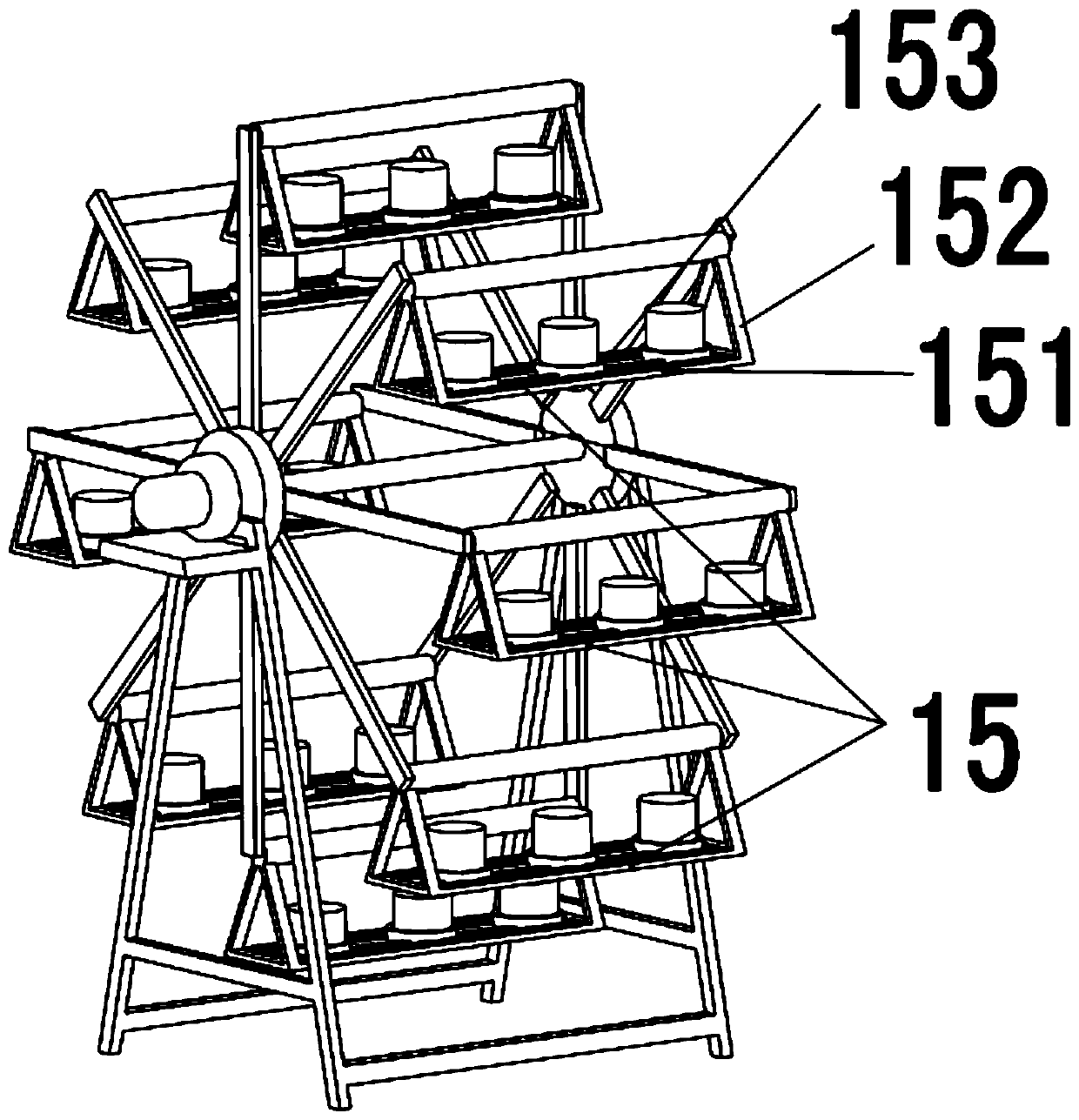

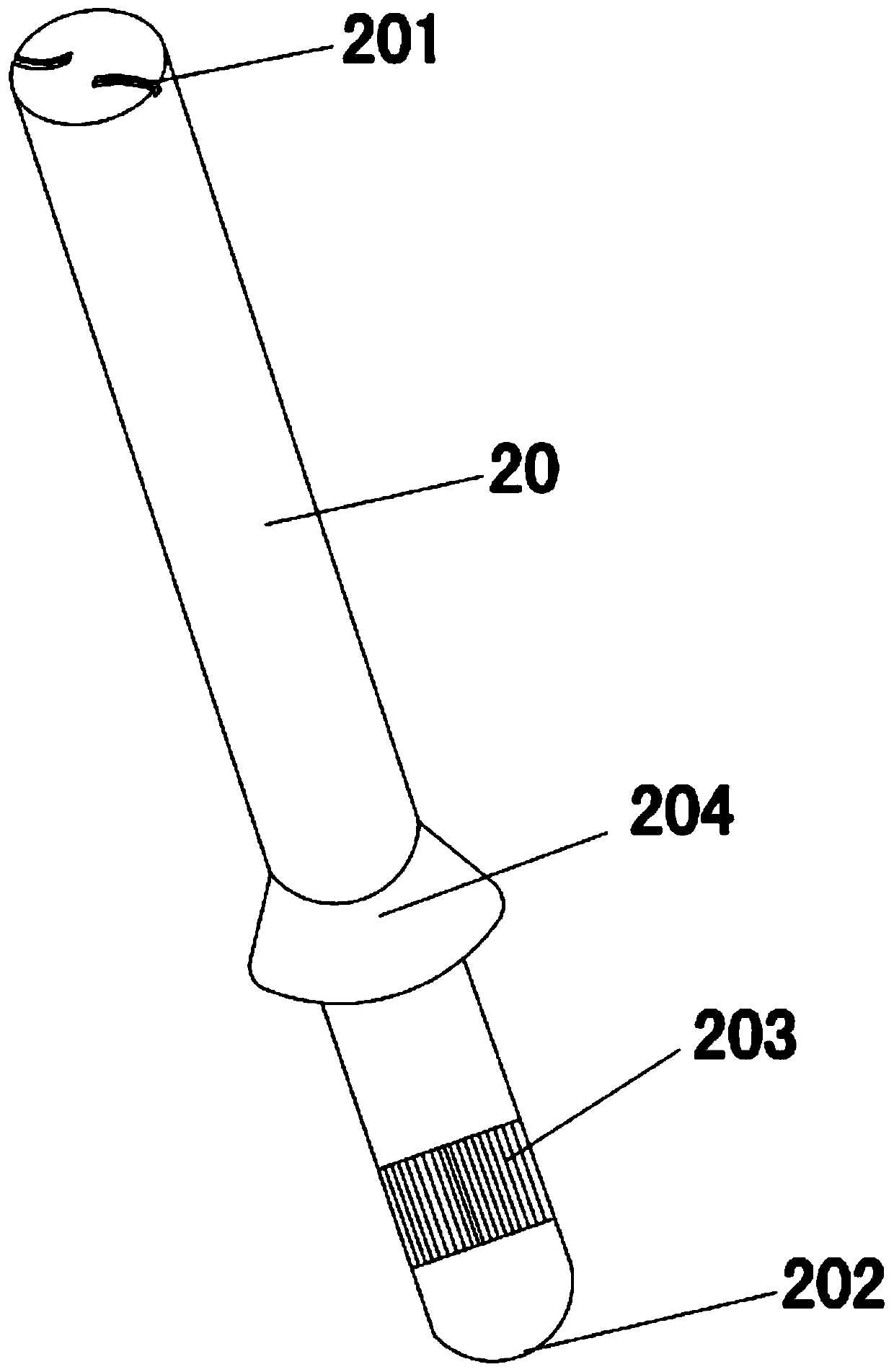

[0033] like Figure 1 to Figure 6 As shown, a method for ceramic rotary spray molding comprises the following steps: (1) mold distribution, the mold that needs to be processed is arranged on the rotary mold transport device 1; (2) mold transport, and the rotary transport mold is operated Die device 1, the mold that needs to be processed is transported to the spraying station; (3) spraying, after the mold is transported to the spraying station, stop the operation of the rotary mold transporting device 1, and extend the nozzle 20 below the station to In the mould, the nozzle 20 rotatably sprays the slurry evenly on the inner wall of the mould, forming a green body; (4) transporting the mold, operating the rotary mold transporting device 1, and transporting the green body to the embryo taking station; (5) ) to take the embryo, after the green bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com