Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

196results about How to "Speed up penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

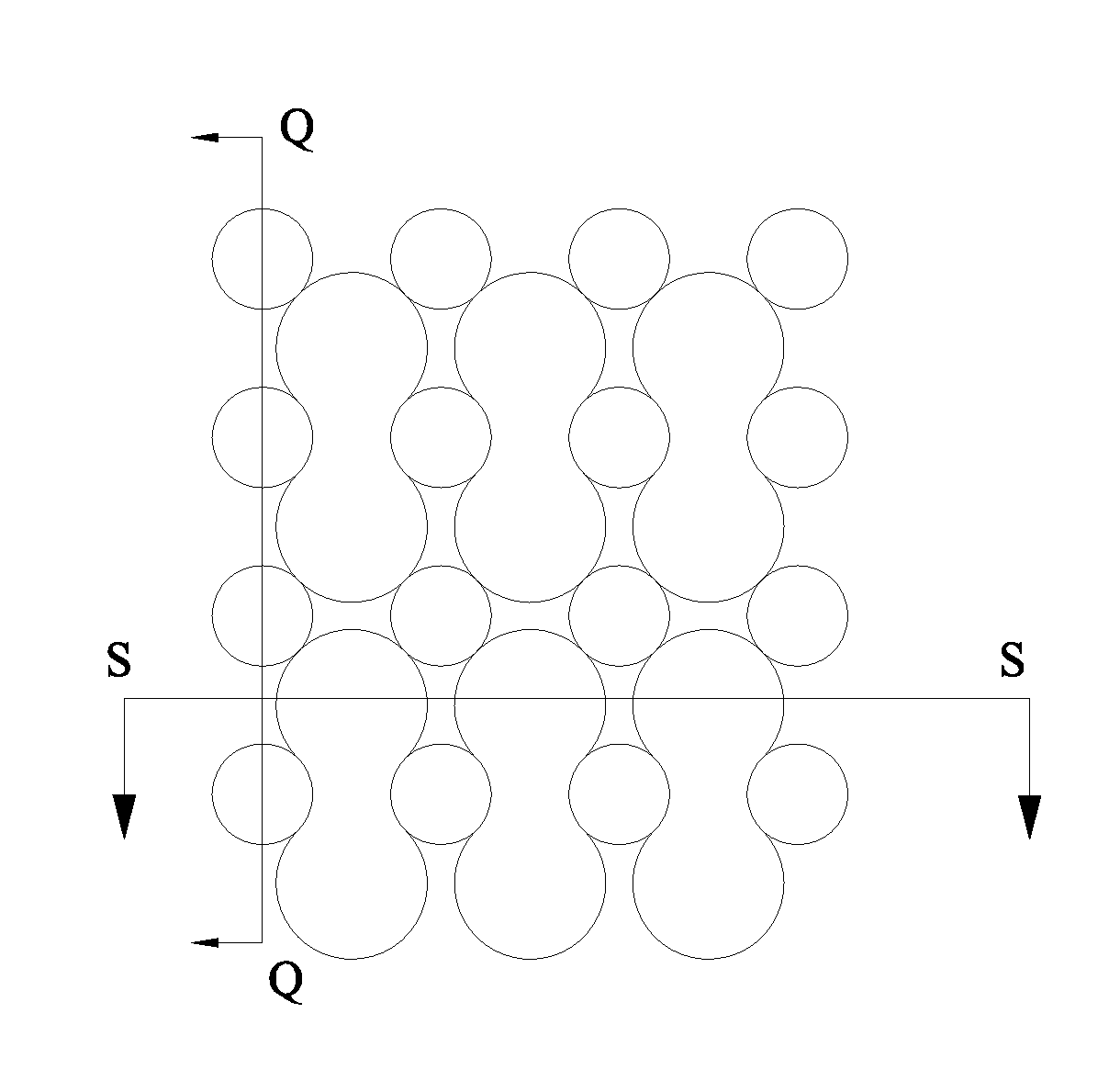

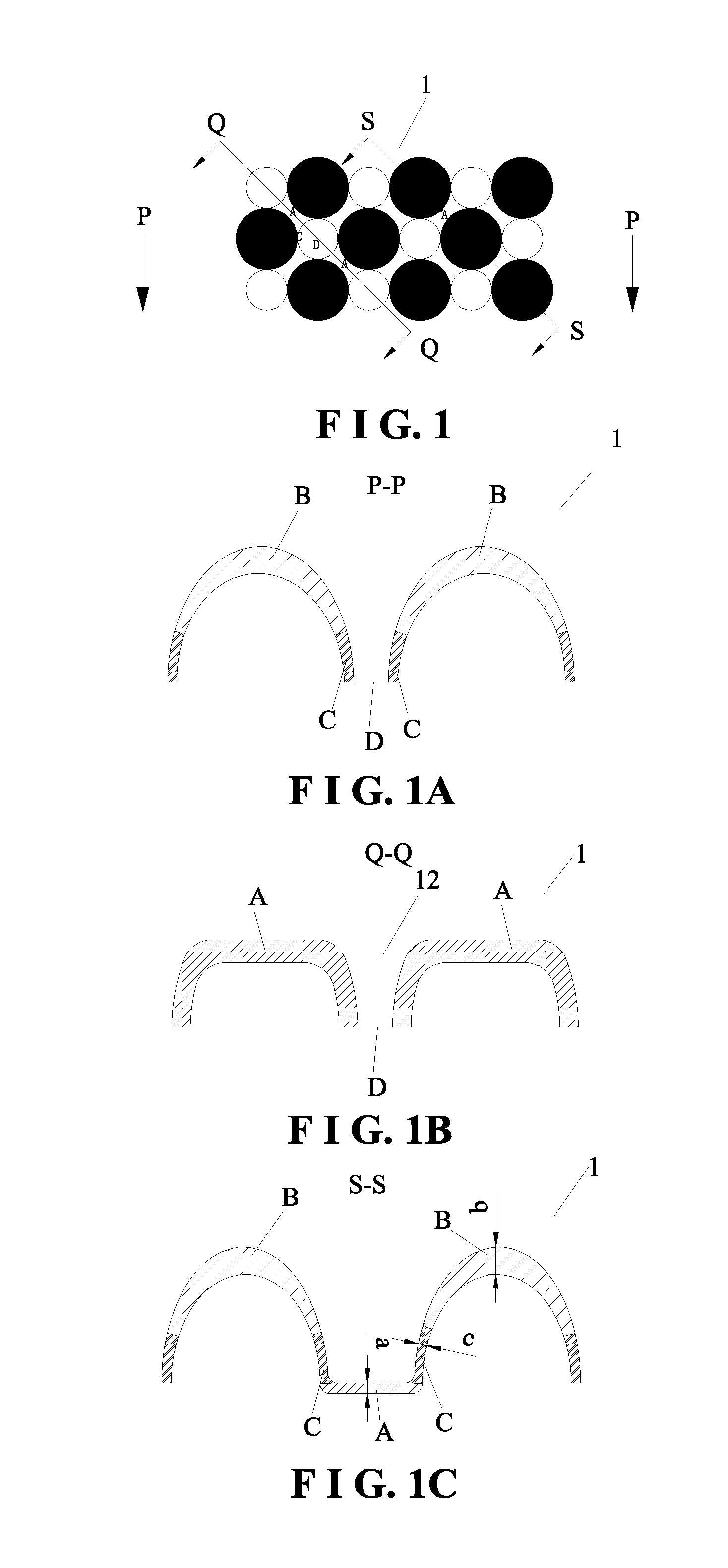

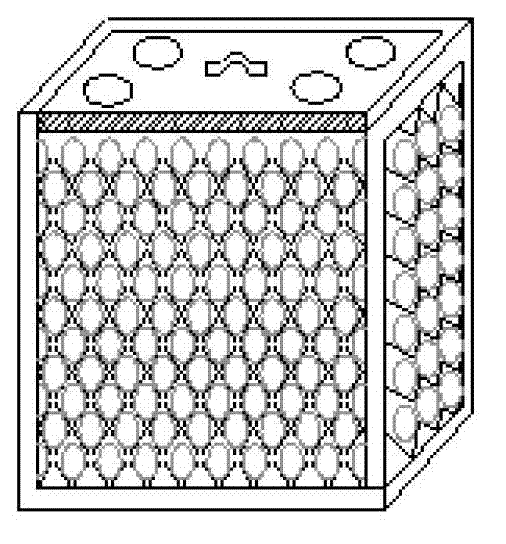

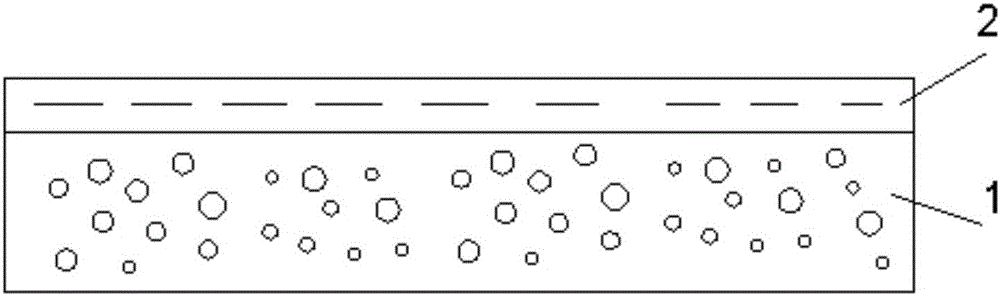

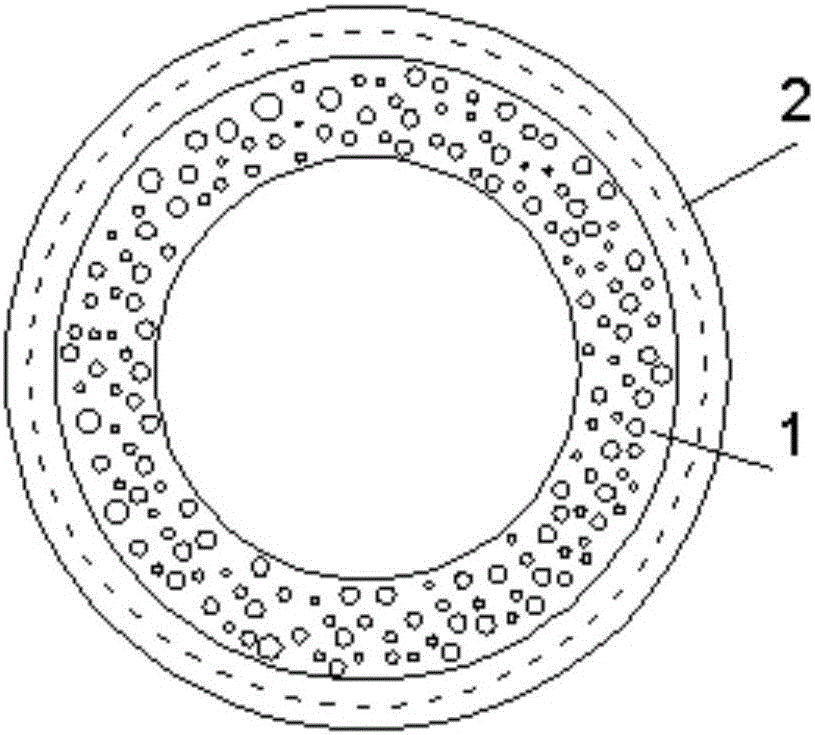

Three-dimensional nonwoven fabric with pore structure

InactiveUS20170014281A1Soft and comfortableGood compressibilityNon-woven fabricsBandagesHigh densityEngineering

A three-dimensional nonwoven fabric with a pore structure includes raised regions, recessed regions, and the pore structure. Fiber densities from the raised regions to the recessed regions are gradient. That is, the fiber density of the edges transiting from the raised regions to the recessed regions is higher than that of the tops of the raised regions. Pressure resistance performance of the high-density fiber regions keeps the three-dimensional nonwoven fabric significantly uneven, and quickens liquid permeation and reduces residues, and the three-dimensional nonwoven fabric has a high permeating speed and is dry and comfortable.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

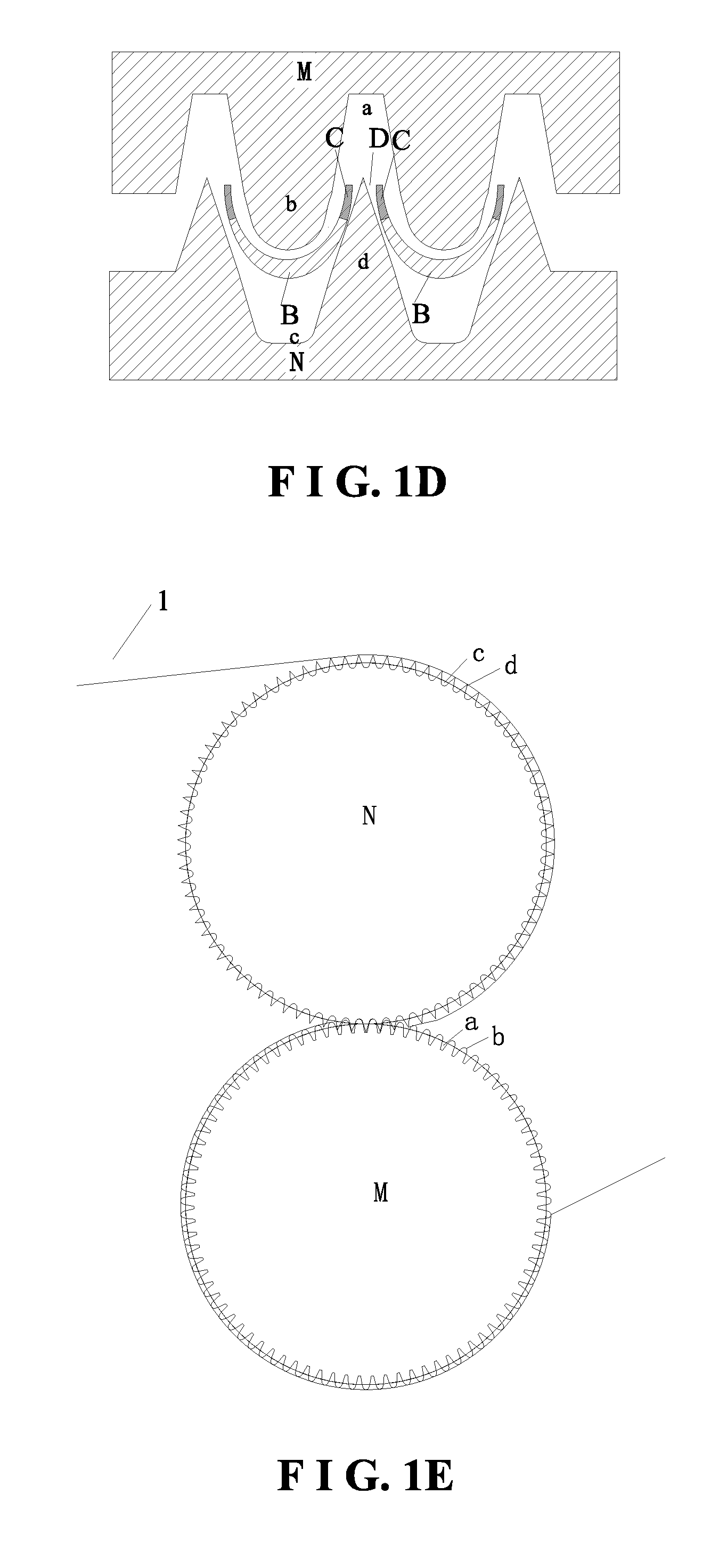

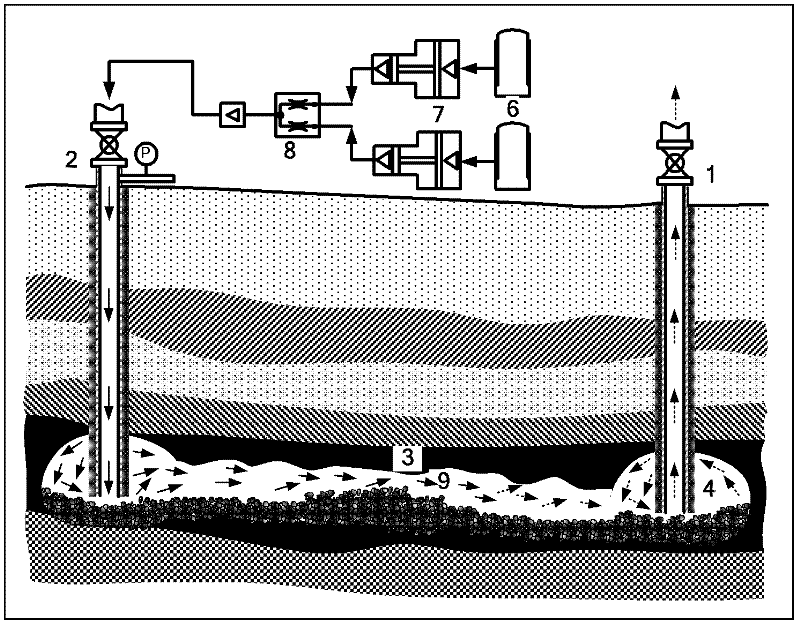

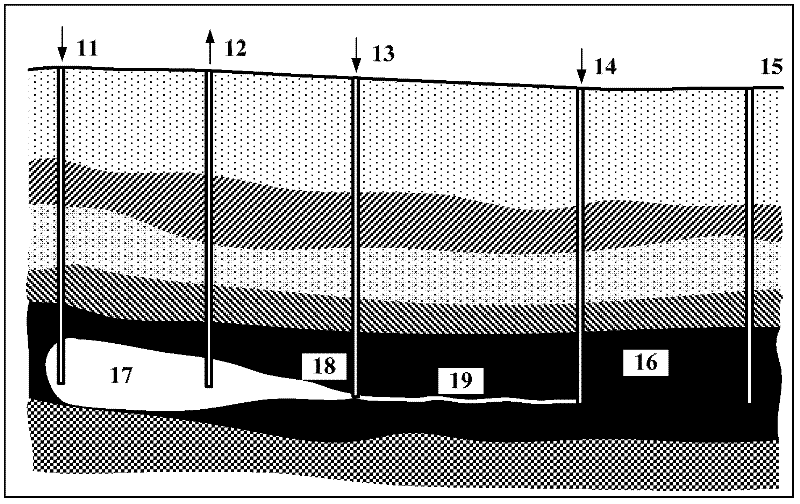

Passage formation method for underground coal gasification

A passage formation method for underground coal gasification is provided. The method comprises the following steps of: (a) building a fire area in the bottom coal bed of a first bore hole; (b) performing mechanical and directional drilling operation in a neighbor coal bed close to the bottom of the first bore hole in the vicinity of the fire area through the lower end of a second bore hole which is another existing bore hole or a newly-drilled bore hole outside the fire area, so as to pre-penetrate the neighbor coal bed and thus to form a directional passage communicated with the fire area in the neighbor coal bed; and (c) delivering an oxygen-containing gas to the fire area through the second bore hole and the directional passage, and thermally processing the directional passage to enlarge the directional passage and thus to form a gasification passage used for a underground coal gasification furnace.

Owner:ENN SCI & TECH DEV

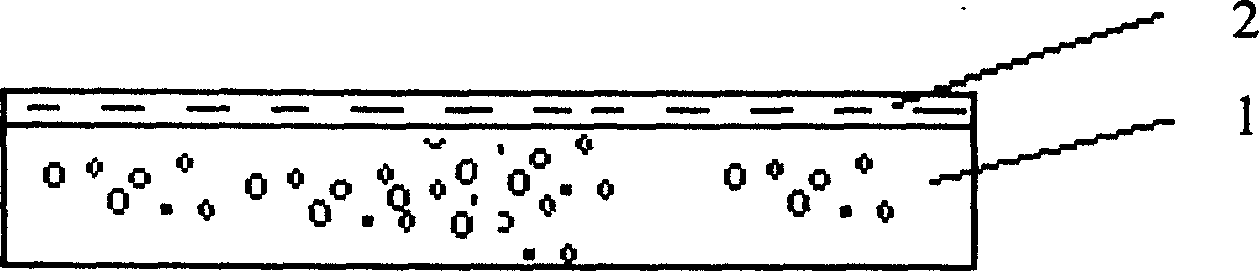

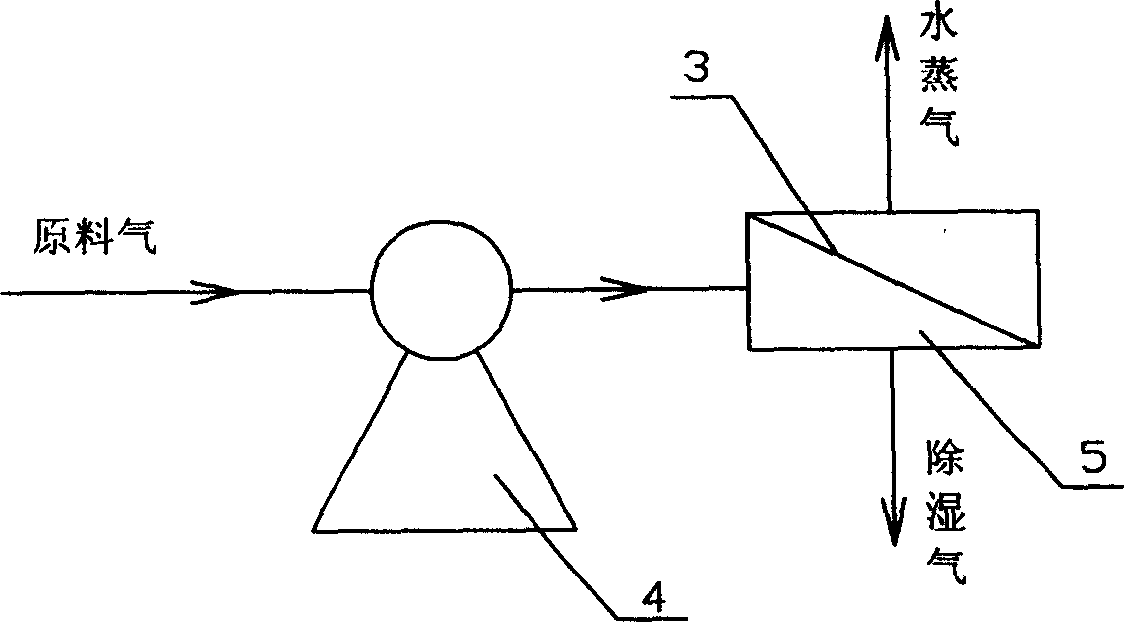

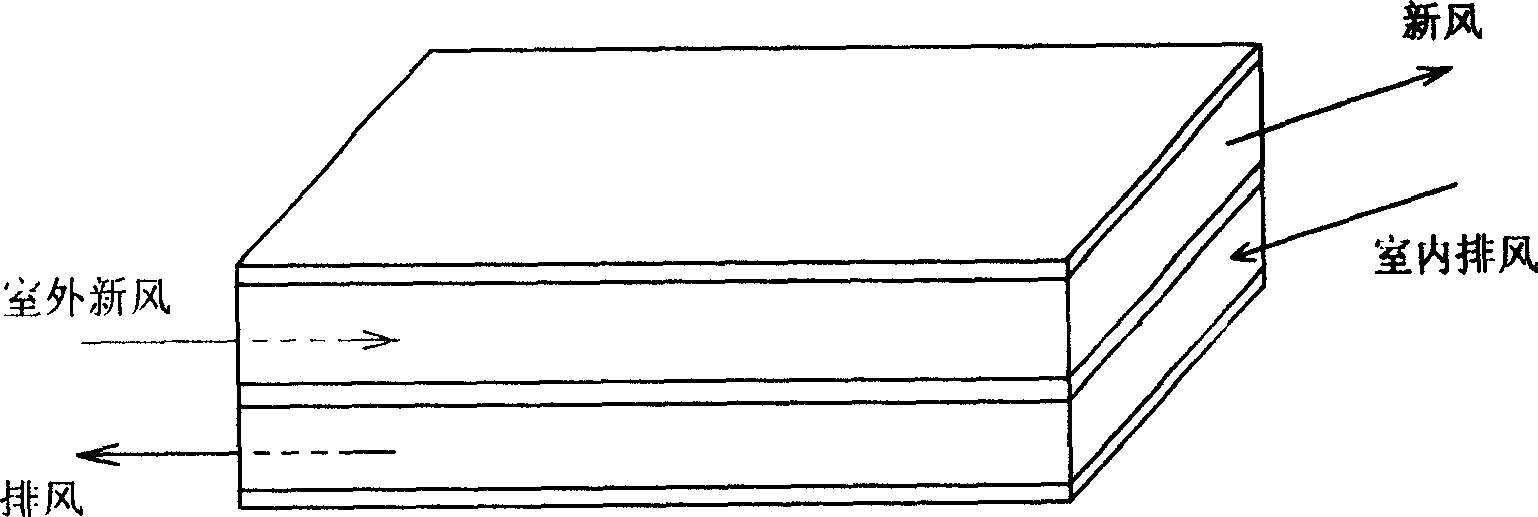

A hydrophilic-hydrophobic bipolar composite membrane and method for preparing same

InactiveCN1864829ASpeed up penetrationReduced Diffusion ResistanceSemi-permeable membranesLighting and heating apparatusChemical industrySupporting system

The invention discloses a hydrophilic-hydrophobic bipolar complex membrane and the method for preparing the same. Said complex membrane comprises two layers, the bottom one is porous supporting system, and upper one is ultra-fine cerebral cortex; said porous supporting system is hydrophobic membrane and nonpolar, to avoid condensation of water vapour; ultra-fine membrane is hydrophilic membrane and polar, and LiCl with 1-5% by weight of main component can be doped to increase polarity; the thickness of porous supporting system is 30-100 um, and that of ultra-fine cerebral cortex is 5-20 um. The invention is characterized by simple process and low cost. The prepared bipolar complex membrane is characterized by good penetration property and gas selectivity, high intensity and wide application in water treatment, air conditioner engineering, energy, chemical industry, metallurgy and biochemical engineering. The product is especially suitable for air dehumidification and heat recycle of air cinditioner new gas.

Owner:SOUTH CHINA UNIV OF TECH

Dust fall agent for water mist dust fall

ActiveCN101735771AReduce surface tensionImprove contact effectOther chemical processesDust removalPermeationSURFACTANT BLEND

The invention relates to a dust fall agent for water mist dust fall. 0.06-0.2wt% of wetting agent permeation assistant is added to water, wherein the wetting permeation assistant comprises anionic surfactant, or cationic surfactant, or zwitterionic surfactant, or non-ionic surfactant. Because in the dust fall agent of the invention, 0.06-0.2wt% of wetting agent permeation assistant is added to water, thus the surface tension of the water can be reduced, the contact capacity of the water with dust particles is promoted, and solid materials can be soaked by water more easily through the wetting agent permeation assistant, thereby accelerating the wetting permeation velocity of water to the dust particles, accelerating the fall velocity of the dust particles, and reducing the fall time of the dust particles. Thus, the invention reduces the operation time and the operation cost, protects the health and safety of operation personnel, and can be widely applied to water spray, water sprinkling, dust fall and dust suppression of mines, tunnels or roads.

Owner:北京首创大气环境科技股份有限公司

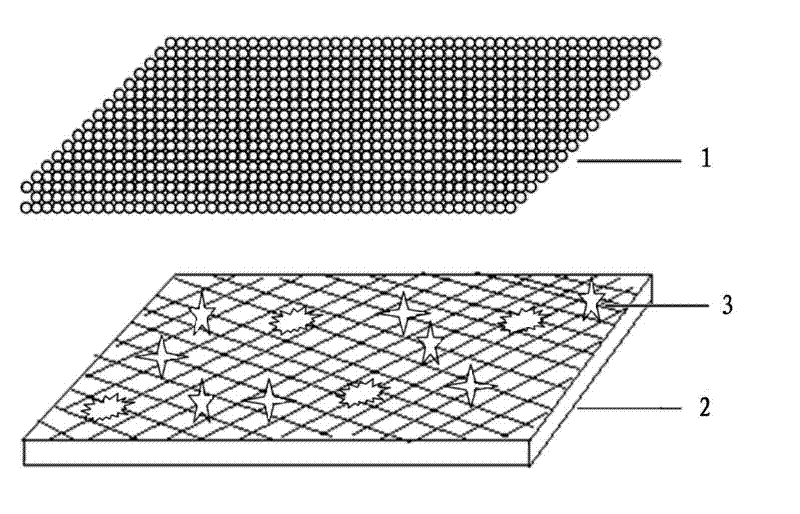

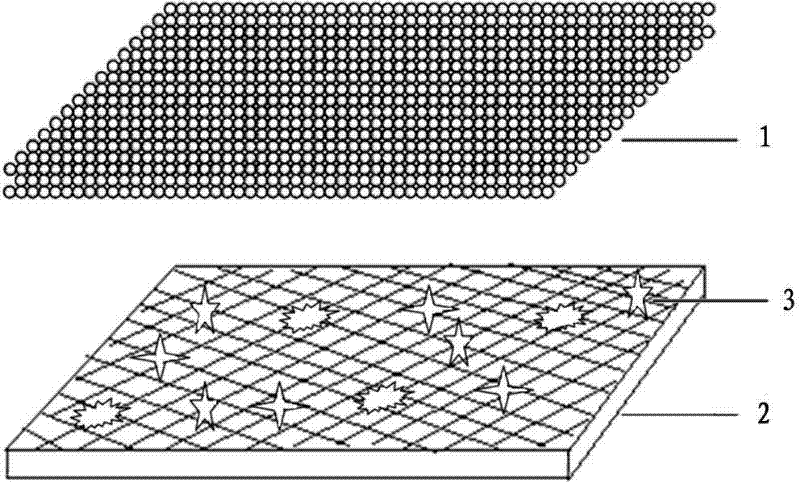

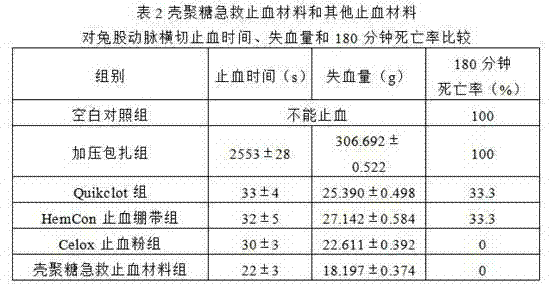

Chitosan emergent hemostasis material

ActiveCN102648985AStrong water absorptionSpeed up penetrationAbsorbent padsBandagesSuction forceTissue repair

The invention provides a chitosan emergent hemostasis material, which is provided with at least two layers of structures: a chitosan hemostasis layer as an upper layer, and a polyacrylic acid grafting chitosan lining layer as a lower layer, wherein the chitosan hemostasis layer is of a structure of a porous microsphere, porous fiber, porous sponge, or a compound of the porous microsphere, the porous fiber and the porous sponge; and the polyacrylic acid grafting chitosan lining layer is of a structure of porous fiber, porous sponge, or a compound of the porous fiber and the porous sponge. According to the chitosan emergent hemostasis material, the polyacrylic acid grafting chitosan is used as the lining layer of the chitosan, so that powerful water suction force can be provided, seepage velocity of blood in the chitosan hemostasis material is improved, blood is further concentrated, the density of the hemostasis material is improved simultaneously, the hemostasis material is easier to sink to arrive at a bleeding point, gravity press of a bleeding part is formed, pressurization is convenient, and the hemostasis effect is improved. Meanwhile, the polyacrylic acid grafting chitosan layer also can be used as a medicine-carrying substrate, can be used for carrying antibacterial drug, acesodyne, factors for promoting tissue repair and the like, and is good for preventing and controlling infection while stopping bleeding, relieving pains, and accelerating wound tissue healing.

Owner:欣乐加生物科技温州有限公司

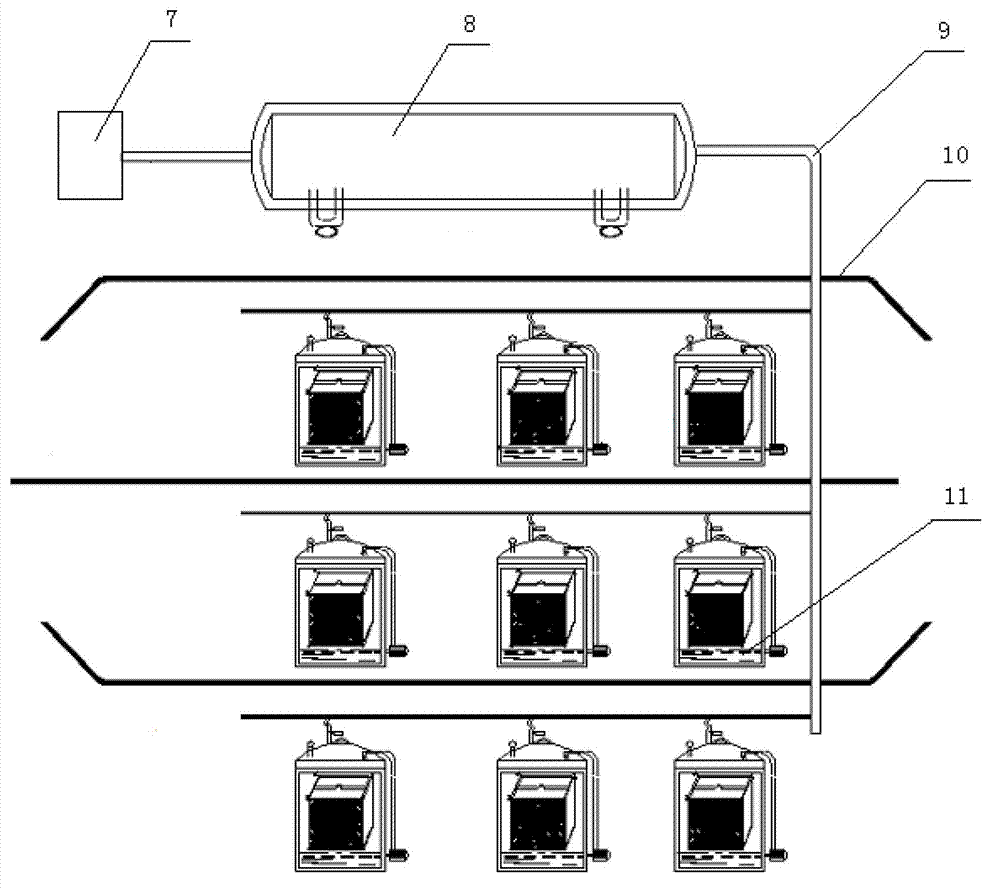

Method and system for producing runny preserved duck egg semi-continuously and rapidly through vacuum decompression

ActiveCN103110137AShorten curing cycleIncrease productivityFood preparationPressure differenceZoology

The invention relates to a method for producing a runny preserved duck egg semi-continuously and rapidly through vacuum decompression. The preserved duck egg is soaked by adopting a vacuum decompression semi-continuously production technology, air in the duck egg can be pumped out through repeated vacuumizing, then in the process of rising to normal pressure, alkali liquor can permeate into the duck egg rapidly due to the pressure difference of the interior and the exterior of the duck egg at the beginning of salting, so that the salting period of the preserved duck egg is shortened. The method has high degree of mechanization, can be operated semi-continuously, can improve the production efficiency of the preserved duck egg, uses unleaded feed liquid, and can prepare safe and harmless preserved duck eggs.

Owner:TIANJIN DIMUSHENG TECH CO LTD +1

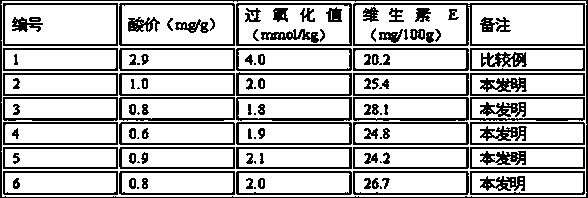

Camellia seed coldly-pressed tea-seed oil and processing process

ActiveCN104212628APrevent acidity riseQuality assuranceFatty-oils/fats refiningFatty-oils/fats productionChemistryFiltration

The invention provides camellia seed coldly-pressed tea-seed oil and a processing process. The processing process comprises the following steps: 1, pre-processing camellia seeds: selecting fresh camellia fruits; peeling and separating to obtain fresh camellia seeds; drying the camellia seeds at a low temperature; and storing; and 2, coldly pressing: cleaning the camellia seeds; shelling and removing shells; grinding; adding water and homogenizing; pressing to obtain primary oil; filtering; and finely filtering to obtain pure natural tea-seed oil. The fresh camellia seeds are dried at the low temperature within four hours and the drying temperature is controlled to be lower than 70 DEG C; the water is controlled to be 6%-10% and the camellia seeds are stored in a low-temperature warehouse to be processed; in the step of shelling and removing shells, the camellia seed shells with the weight percent of 15%-25% are remained in the camellia seeds; and the temperature of the water in the step of adding the water and homogenizing is 40-60 DEG C. By adopting the process to press the camellia seed oil, the quality of an obtained finished product is stable and the efficiency is improved; and the oil yield is guaranteed to the great extent.

Owner:HUBEI HUANGPAOSHAN GREEN PROD

Environment-friendly recycled concrete and preparation method thereof

ActiveCN109279843ASpeed up penetrationHigh strengthSolid waste managementPolyvinyl alcoholPortland cement

The invention discloses environment-friendly recycled concrete and a preparation method thereof, and relates to the field of building materials. Raw materials of the environment-friendly recycled concrete comprise the following components in parts by weight: 200-220 kg / m<3> of water, 440-460 kg / m<3> of ordinary Portland cement, 380-400 kg / m<3> of natural river sand, 10-15 kg / m<3> of a polycarboxylate water reducer, 580-600 kg / m<3> of natural gravel, 600-650 kg / m<3> of polyvinyl alcohol modified recycled coarse aggregates and 30-40 kg / m<3> of silica fume. The preparation method has the advantages of improving compressive strength and bending strength, waste concrete and waste polypropylene fibers can be recycled, pollution is reduced, and the recycled concrete is green and environmentally friendly.

Owner:曙光装配式建筑科技(浙江)有限公司

Preparation method for soft porous synthetic paper

The invention discloses a preparation method for soft porous synthetic paper, which mainly includes the steps: proportionally adding diisocyanate, polyester dihydric alcohol, solvent and chain extender into a reactor to undergo a heating reaction so as to obtain thick polyurethane solution; adding a certain amount of solvent to prepare polyurethane solution after cooling, and adding a certain amount of inorganic filler with uniformly stirring and mixing so that mixed solution is obtained; spreading partial mixed solution on release paper, placing the release paper into a dryer for drying, andobtaining a base material for producing the synthetic paper after a film on the release paper is completely dried; and spreading the rest mixed solution on the base material, then immersing the base material into water solution, immediately placing completely solidified mixed solution on the surface into the dryer for forced air drying, stripping the film on the release paper after the film on the release paper is completely dried, and the film is the soft synthetic paper product. The method is low in production energy consumption, and the prepared synthetic paper is porous, soft, quick in ink penetration and easy in drying.

Owner:HUNAN UNIV OF SCI & TECH

Spicy salted duck egg pickling liquid, preparation method and salted duck egg production method

The invention discloses spicy salted duck egg pickling liquid, a preparation method and a salted duck egg production method. The pickling liquid comprises following components in parts by weight: 20g-40g of peppers, 20g-40g of fresh ginger, 20g-40g of fennels, 3g-60g of garlic, 20g-40g of cinnamons, 5g-15g of fructus piperis longi, 150g-300g of table salt, 30g-60g of white spirit and the balance of water. The preparation method comprises the following steps: after washing and disinfecting fresh duck eggs; treating by using a pickling auxiliary agent; adding the fresh duck eggs into the prepared pickling liquid to be pickled to be cooked; washing and sterilizing; pre-boiling and bagging in vacuum; and sterilizing to obtain a finished product. Salted duck eggs produced by the preparation method disclosed by the invention are moderate in saltiness degree and small in air chamber; the egg white is pure white and tender and the yolk is red, yellow and bright in color and luster and is fine, soft and loose; an egg shell is brown or light brown; the salted duck eggs have slight faint scent, lasting taste and short pickling period. Material liquid can be repeatedly utilized so that the production cost is reduced.

Owner:JIANGXI TIANYUN AGRI DEV

Gradient wheat wetting process

The invention discloses a gradient wheat wetting process, and belongs to the technical field of processing of wheat powder. Ultrasound, microwaves, refrigeration and functional wheat wetting solution are combined to perform gradient wheat wetting for wheat grains by three times, so that the separation of bran from wheat germs is improved, the evacuating degree and the permeation capacity between such structures as wheat grain epidermises, seed coats, germs and endosperm, and macromolecular nutrient substances are improved, the water permeation speed is accelerated, the total wheat wetting process time is shortened to 6-12 h, the flour yield is 78.5-79.5%, the oxidation resistance and the nutrient value of flour are improved, the appearance quality, the physicochemical quality and the food safety of wheat flour are improved, the consumption of such processes as subsequent flour milling is reduced, the production cost is reduced, and a new road is sought for the wheat wetting process.

Owner:宁夏鑫德粮油工贸有限公司

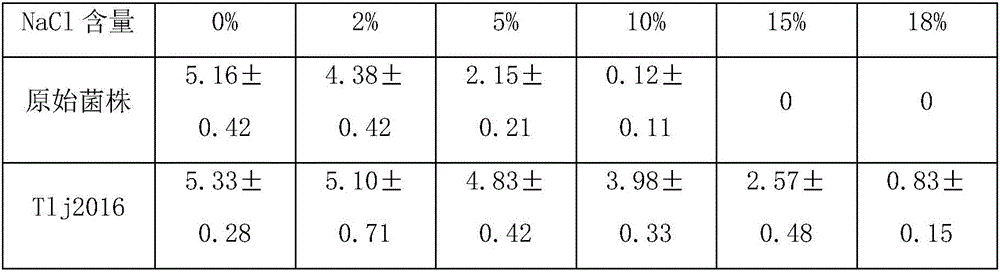

Acceleration method for barrel properties test of organic coating

InactiveCN1570591AImprove the protective effectStrong adhesionWeather/light/corrosion resistancePreparing sample for investigationUltrasonic vibrationElectrochemistry

An accelerating method for measuring barrier property of organic coating, which is to put a smeared multiple-electrode probe or smeared coupon into a liquor with three to five percent of NaCl for some time of ultrasonic vibration. Later to test the barrier property of the organic coating through wet heat and electrochemistry. With the deployment of ultrasonic vibration, this invention can greatly decrease the testing time of barrier property to the ten percent of original time and can effectively shorten the circle of new product development and on-line measuring and monitoring and can overall evaluate adhesive force of organic coating and can improve the measuring efficiency of barrier property of organic coating so as to save manpower and materials. This invention is especially suitable for the measuring of barrier property of organic coating with good barrier property.

Owner:HUNAN UNIV

Ultrasonic-assisted bio-enzyme ligin removing method and device thereof

ActiveCN106087508ARealize the purpose of industrialized mass productionPulping speed is fastCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpFiberEngineering

The invention relates to the technical field of biodegradation, in particular to an ultrasonic-assisted bio-enzyme ligin removing method and a device thereof. The method comprises the steps that wood fiber raw materials such as reed or bamboo willows are purified, then soaked with water and ground into filamentous fibers; water and a bio-enzyme ligin removing auxiliary are mixed evenly, and the filamentous fibers are added; air is introduced, the temperature is raised, an ultrasonic generator is started, and a constant-temperature and constant-pressure reaction is carried out; hydrogen peroxide is added into the materials for a reaction, and the reaction is terminated when the whiteness of pulp is higher than or equal to 75% ISO. The device used in the method comprises a bucket, a feeding port, a safety valve, a motor, a coupler, an air inlet, a water inlet, a pulp outlet and a supporting part. A mechanical rubbing and stirring device is arranged in the bucket, and the ultrasonic generator and an ultrasonic transducer are further arranged outside the bucket and are connected through a connecting device. According to the ligin removing method and the device, the treatment cycle is short, and the treatment capability and efficiency are high.

Owner:福建祥业实业有限公司

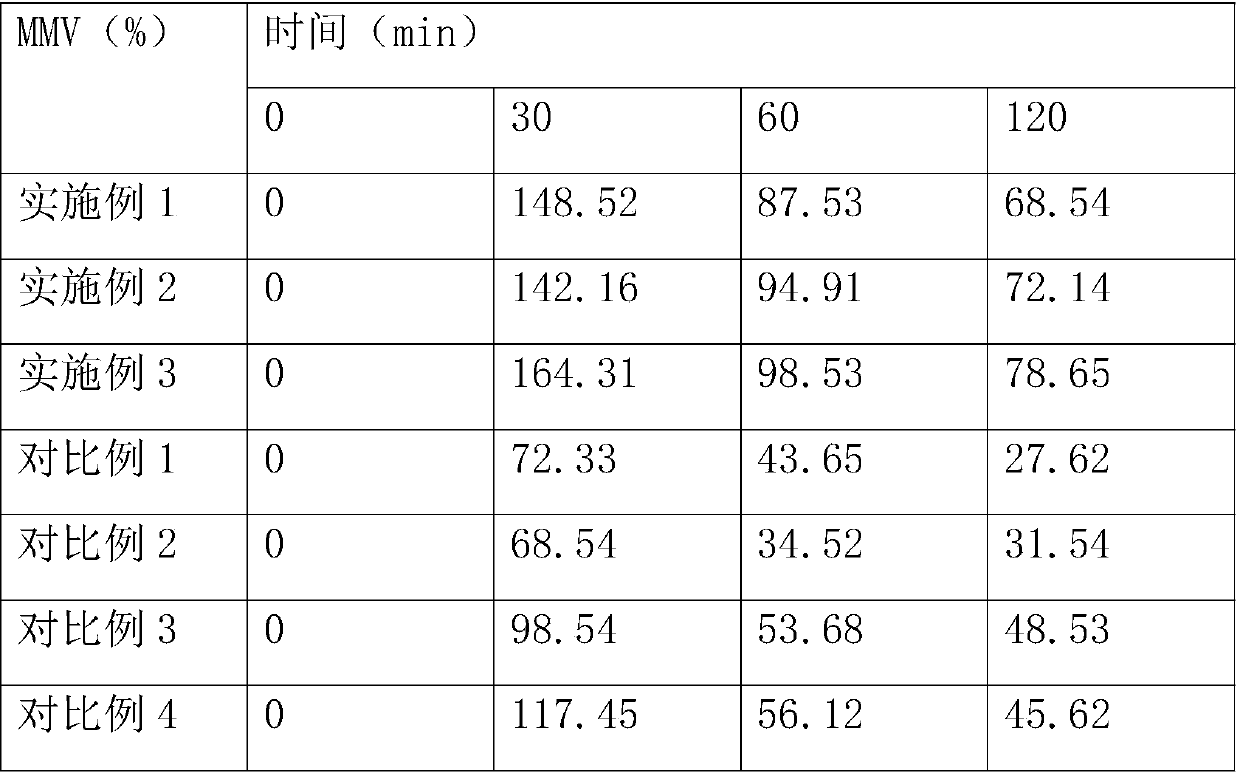

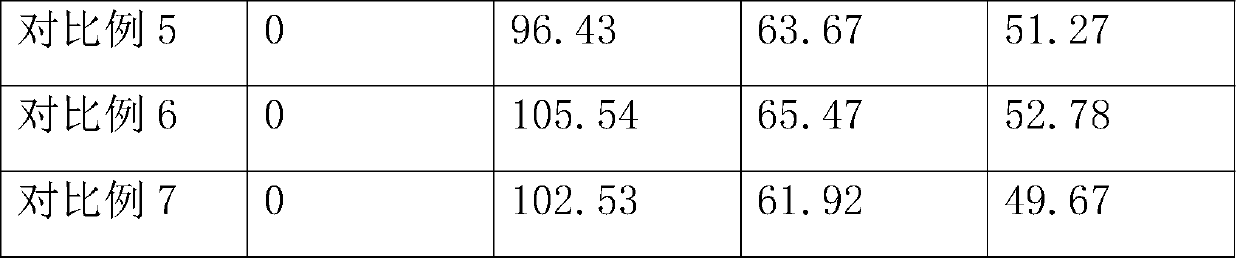

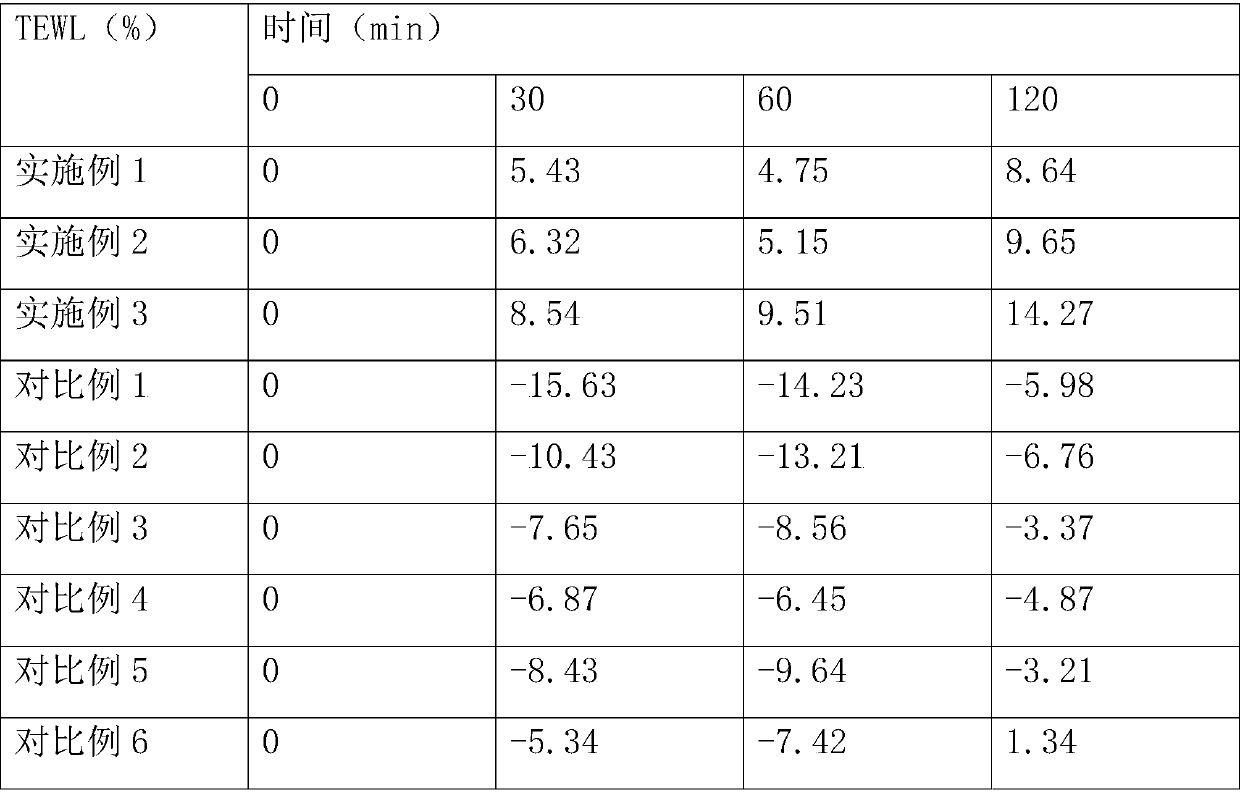

Nursing agent for skin moisturizing and repairing and preparation method thereof

PendingCN110192985APromotes long-lasting hydrationGood compatibilityCosmetic preparationsToilet preparationsCentella asiatica extractAcetophenone

The invention discloses a nursing agent for skin moisturizing and repairing. The nursing agent for skin moisturizing and repairing comprises the following components by mass percentage: 0.05 0.15% ofdisodium EDTA, 0.5-3.0% of nicotinamide, 2.0-5.5% of glycerin, 2.5-5.5% of propylene glycol, 0.05-0.35% of xanthan gum, 0.05-0.5% of sodium hyaluronate, 0.15-0.5% of p-hydroxyl acetophenone, 1.0-5.0%of caprylic / capric triglyceride, 1.0-3.0% of polydimethylsiloxane, 1.0-5.0% of isononyl isononanoate, 0.5-5.0% of jojoba seed oil, 0.5-2.5% of avocado tree fruit oil, 1.75-10.5% of repair essential oil, 0.05-0.5% of fullerenes, 0.35-2% of repairing essence, 0.2-3.5% of cetostearyl alcohol, 1.0-2.5% of cetearyl olivate, 1.0-2.5% of sorbitan olivate, 0.1-1.0% of lecithin, 0.5-5.0% of oligopeptide-1, 0.1-0.5% of D-panthenol, 0.5-2.5% of a Centella asiatica extract, 0.5-2.5% of 1,2-hexanediol, and the balance of deionized water. The product of the invention can quickly improve the moisture retention of the skin, obviously improves the dryness of the skin, increases the moisture content in the skin, and makes the skin appear young. .

Owner:广州市百爱神生物科技有限公司

Animal hide fiber loosening method based on xylanase effect

ActiveCN107312896AReduce dosageReduce processing difficultyPre-tanning chemical treatmentFiberDepilations

The invention discloses an animal hide fiber loosening method based on the xylanase effect and relates to the field of production of leather and fur leather. The method is characterized in that xylanase is added as a hide fiber loosening additive during the steps such as water soaking, depilation, softening and pickling of leather making or during the steps such as water soaking, softening and pickling of fur leather making. By means of the method, the components such as proteoglycan and glycosaminoglycan, which have a cohesive effect on hide fiber, in the animal hide can be efficiently and specifically destroyed. Hide protein ingredients cannot be destructed. The method has wide applicability and is suitable for the manufacturing process of all-purpose leather or fur leather with various kinds of animal hides as raw materials. The effects of promoting loosening of hide fiber and improving the softness, hand feeling and physical and mechanical properties of finished leather products are achieved. Through the method in the leather making process, pollutants such as lime and sodium sulfide are reduced, and the depilation effect is improved.

Owner:SICHUAN UNIV

Low thermal conductivity hydrophilic-hydrophobic bipolar composite membrane as well as preparation method and application thereof

InactiveCN106000117ASpeed up penetrationReduced Diffusion ResistanceSemi-permeable membranesMembranesHydrophobic polymerPhysical chemistry

The invention belongs to the technical field of membrane separation materials and discloses a low thermal conductivity hydrophilic-hydrophobic bipolar composite membrane as well as a preparation method and application thereof. The composite membrane is composed of a porous supporting body layer with the thickness of 30-100mu m and an ultrathin skin layer with the thickness of 5-20mu m, wherein the porous supporting body layer is prepared from a hydrophobic polymer and hydrophobic silicon dioxide aerogel, and the ultrathin skin layer is prepared from a hydrophilic polymer and hydrophilic silicon dioxide aerogel. The preparation method of the composite membrane adopts a coating method, technology is simple, and equipment cost is low; and the obtained composite membrane has good permeability and gas selectivity, relatively low thermal conductivity and relatively high strength, can be widely applied to the fields of water treatment technology, air conditioning engineering, energy sources, chemical engineering, metallurgy, biochemical engineering and the like and is especially applicable to sea water desalination and independent air dehumidification.

Owner:SOUTH CHINA UNIV OF TECH

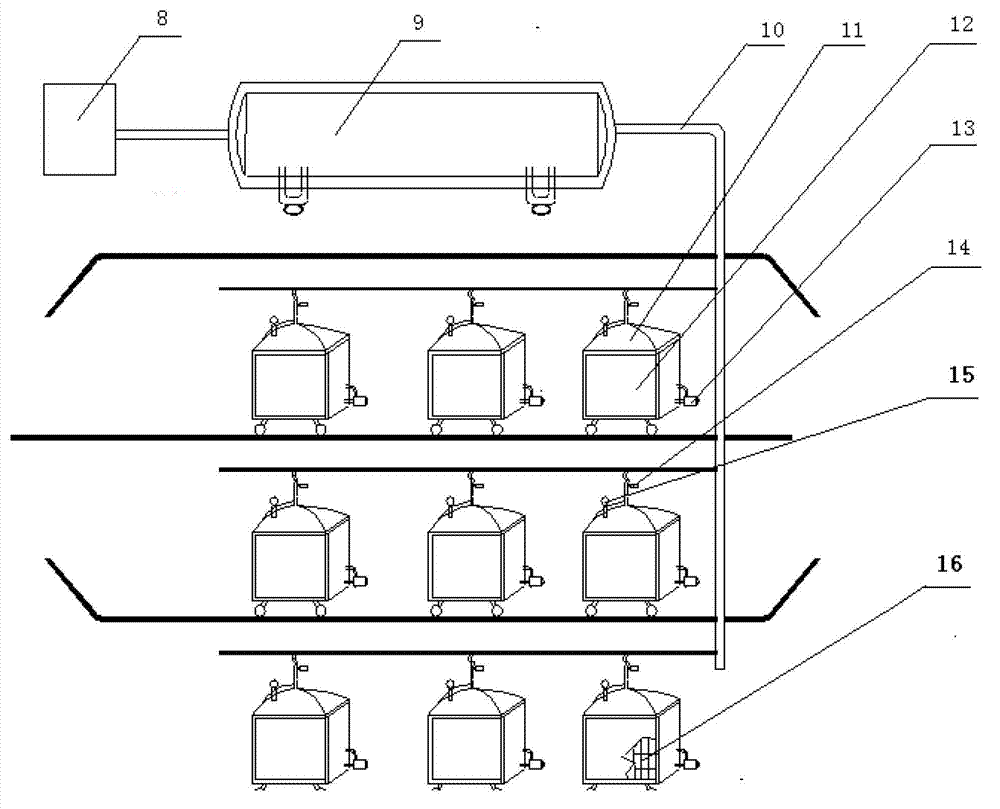

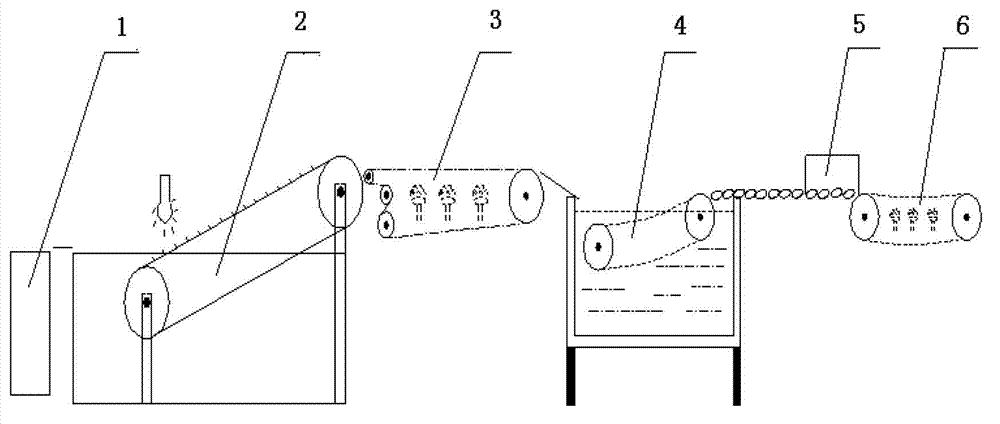

Method and system for rapidly producing hard-core preserved duck eggs in semi-continuous mode by vacuum decompression and sponge permeation method

ActiveCN103082334AShorten the production cycleIncrease productivityFood preparationPressure differenceZoology

The invention relates to a method for rapidly producing hard-core preserved duck eggs in a semi-continuous mode by a vacuum decompression and sponge permeation method. The method comprises the following steps of: preparing pickling material liquid, putting eggs, spraying the pickling material liquid on the eggs, carrying out vacuum decompression treatment on the eggs, taking out the eggs from a jar, washing the eggs, drying the eggs in air, coating membranes on the eggs, and maturing the eggs so as to obtain the hard-core preserved duck eggs. According to the method, the hard-core preserved duck eggs are rapidly produced by the vacuum decompression and sponge permeation method, air in the duck eggs can be sucked out in a repeated vacuuming mode, and subsequently, due to the pressure difference inside and outside the duck eggs, alkali liquid can rapidly permeate into the eggs in the primary pickling period during the process of rising to a normal pressure, so that the pickling period of the preserved duck eggs is shortened. Compared with a mud coating method, the method enables the eggs to be cleaner and more sanitary, ensures a high mechanization degree and semi-continuous operation, and can effectively improve the production efficiency of the preserved duck eggs; and as the material liquid is leadless, the produced preserved duck eggs are safe and harmless.

Owner:TIANJIN UNIV OF SCI & TECH

Functional sanitary towel containing cannabidiol extractive and manufacturing method thereof

InactiveCN110152050AGood effectImprove antibacterial propertiesAbsorbent padsBandagesCyclooxygenaseSurface-active agents

The invention discloses a functional sanitary towel containing a cannabidiol extractive and a manufacturing method thereof. The sanitary towel includes a sanitary towel body and an effect solution, the effect solution is prepared from, by weight, 0.002-0.008 part of a cannabidiol extractive, 5-9 parts of a penetration enhancer, 30-40 parts of traditional Chinese medicine agents, 1-5 parts of a lavender extractive, 0.05-0.2 part of nano-silver, 2-6 parts of a surface active agent and 90-100 parts of purified water. The cannabidiol extractive is added; the cannabidiol achieves the effects of relieving pain and resisting inflammatory due to dual inhibition of cyclooxygenase and lipoxygenase; by adding the penetration enhancer, penetration and absorption speed of effective ingredients on skinis increased, when a woman uses the sanitary towel, the antibacterial anti-inflammation and pain-relief effects are achieved rapidly; by adding the lavender extractive, the traditional Chinese medicine smell of the sanitary towel is effectively improved, and the comfort level of the user is improved.

Owner:厦门梓蔓生物科技有限公司

Environmentally friendly anti-siphon afterfinishing method for suede microfiber synthetic leather

ActiveCN105463857AImprove the anti-siphon effectSpeed up penetrationFibre treatmentFluorine freeMicrofiber

The present invention discloses an environmentally friendly anti-siphon afterfinishing method for a suede microfiber synthetic leather. The method is as below: (1) immersing the dyed microfiber synthetic leather into an anti-siphon treatment solution, and padding; (2) then drying the product obtained in the step (1), cooling, rolling and crumpling to obtain the anti-siphon suede microfiber synthetic leather. The anti-siphon treatment solution for suede microfiber synthetic leather has a pH value of 4-6, and comprises the following components by weight: 5-10 parts of a fluorine-free waterproof finishing agent, 2-5 parts of reactive polysiloxane, 1-3 parts of an aqueous crosslinking agent and 100 parts of water. The agent of the invention uses the fluorine-free environment-friendly waterproof finishing agent without APEO, PFOA or PFOS, and the ultrasonic technology; and the obtained microfiber synthetic leather achieves anti-siphon effect of rise of impregnating solution of less than 1cm after 2h immersion, and has good creases and velvety sense, so as to improve the grade of the suede microfiber synthetic leather.

Owner:HUAFON MICROFIBER SHANGHAI

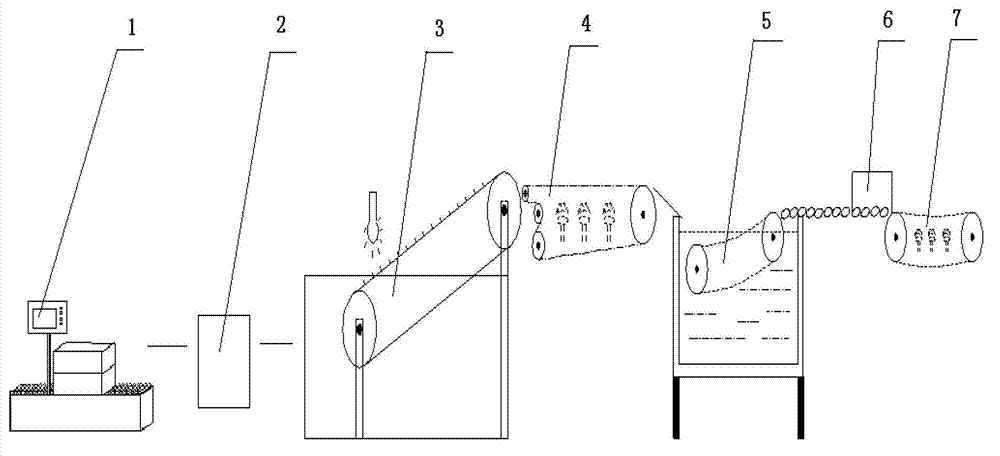

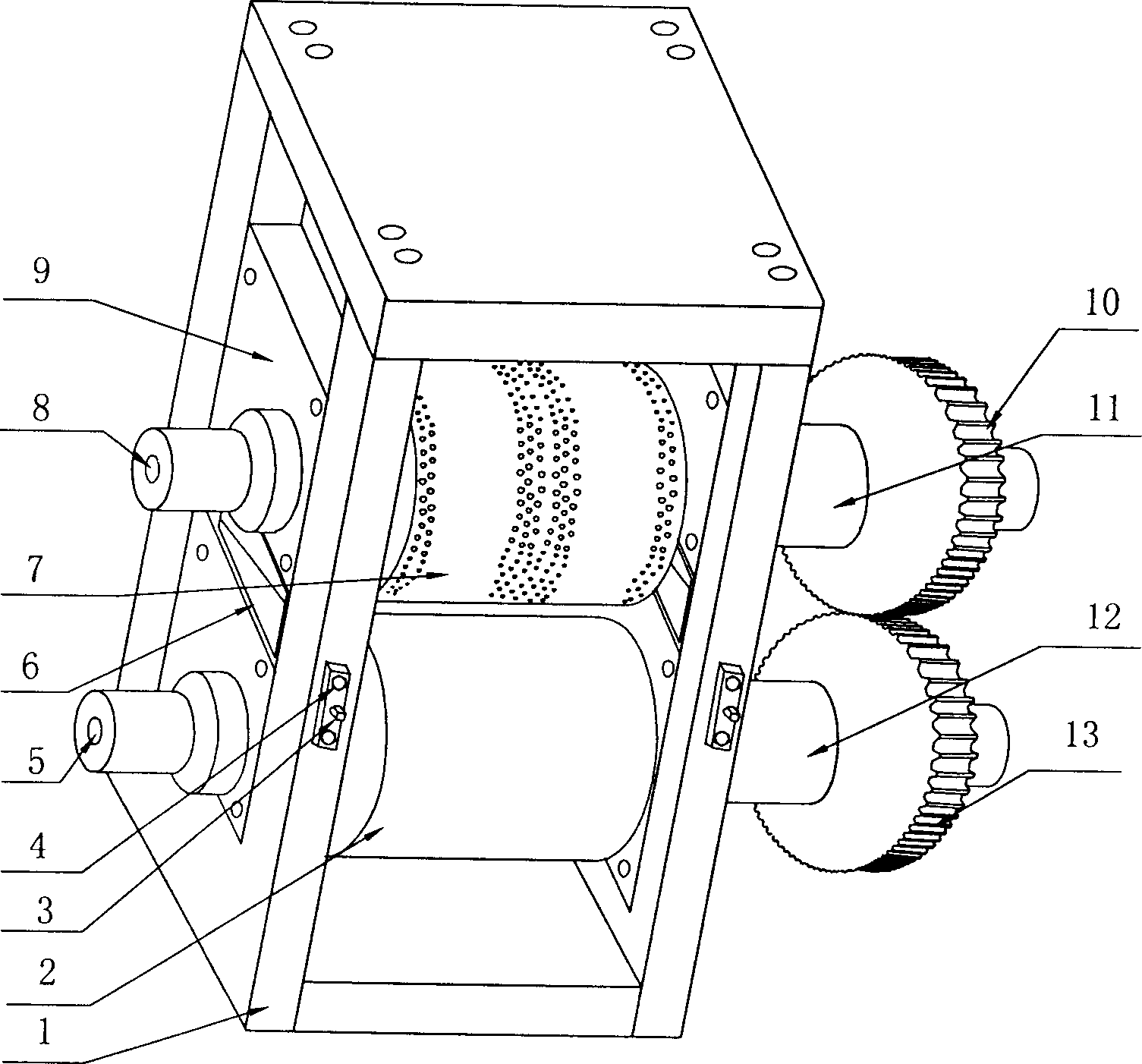

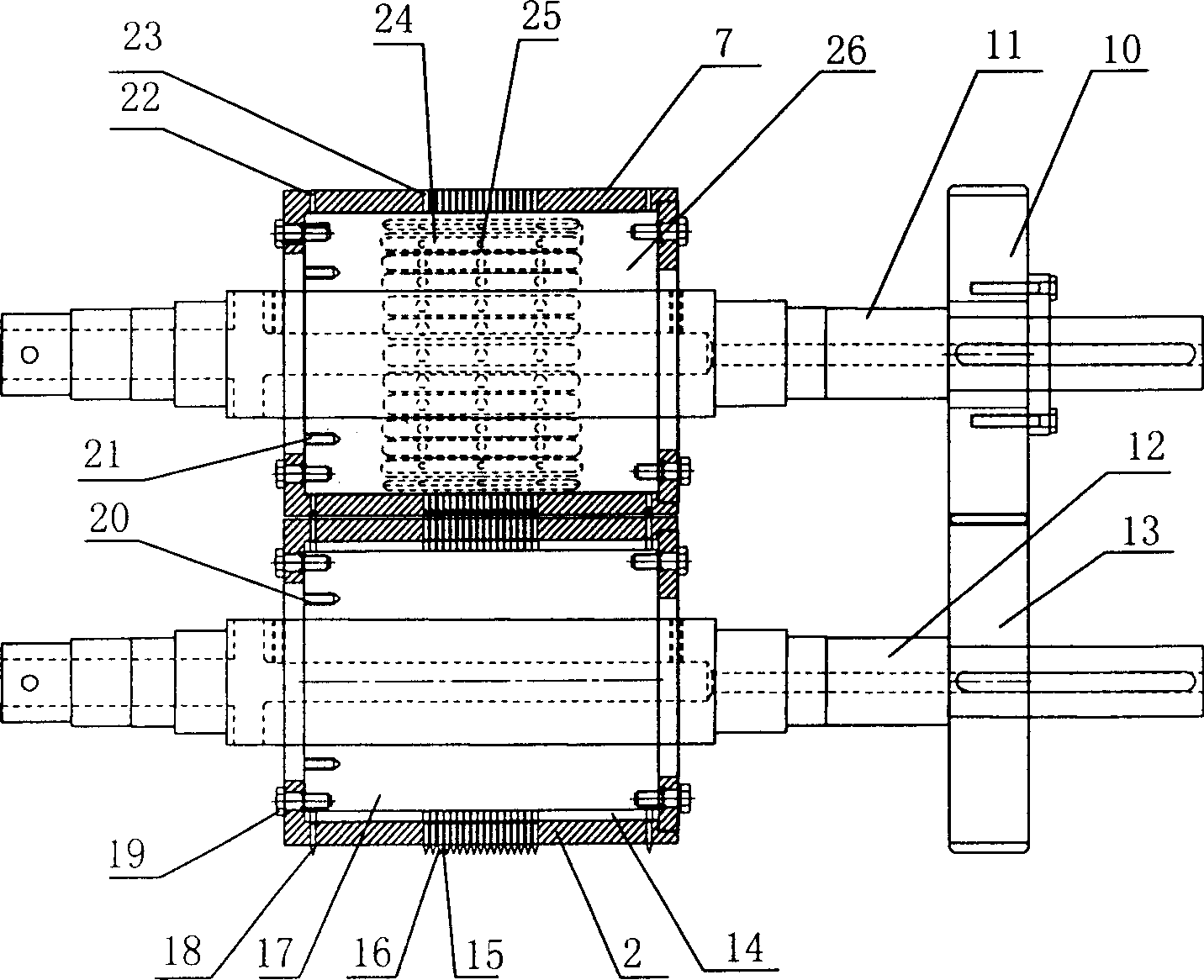

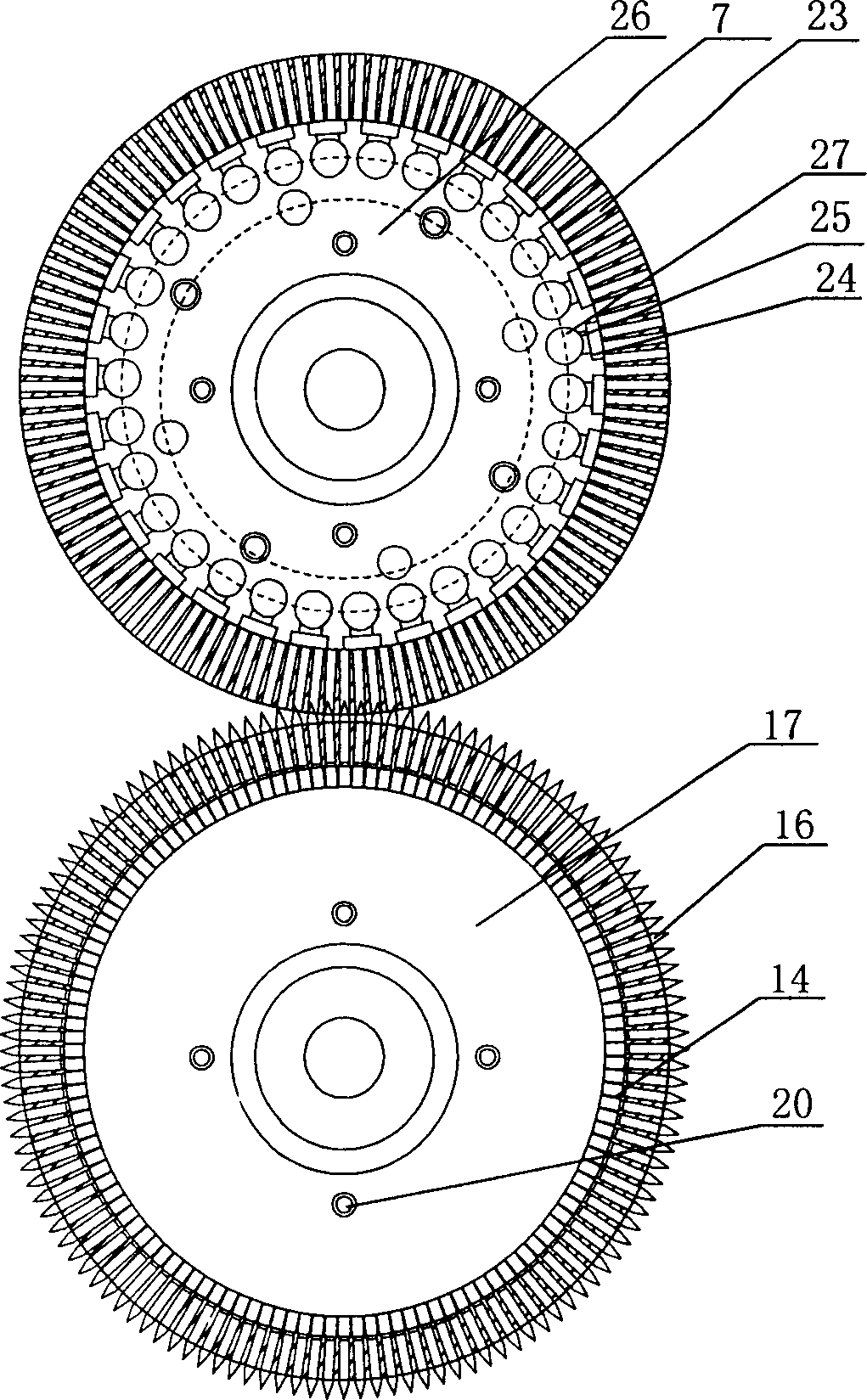

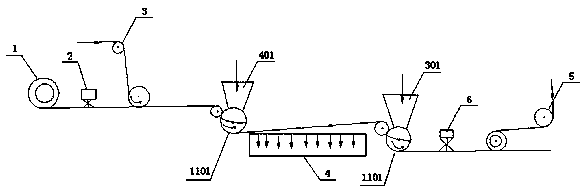

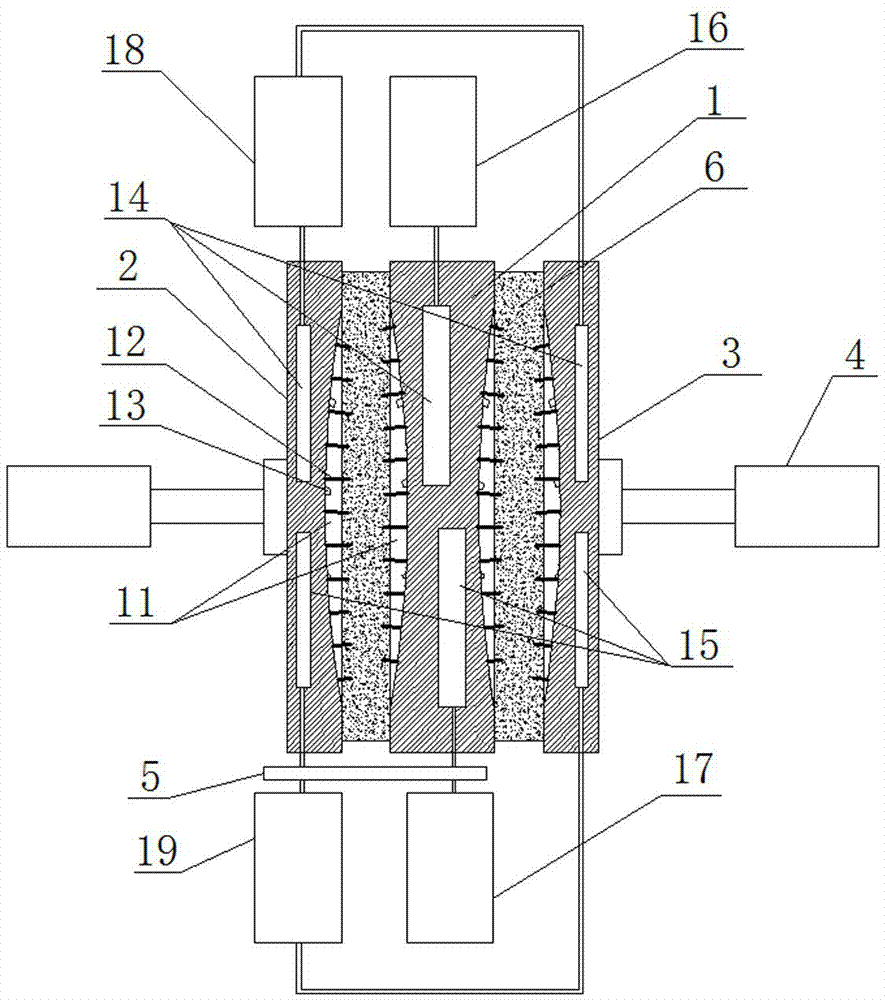

Preparation method of composite absorbent core and production device thereof

PendingCN109223317ASpeed up penetrationIncrease the speed of diffusionAbsorbent padsBaby linensReverse osmosisEngineering

The invention discloses a preparation method of a composite absorbent core and a production device thereof. The production device comprises a conveying device, a front glue spraying device, a cloth guide roller, a lower polymer injection device, a negative pressure device, an upper polymer injection device and a rear glue spraying device connected in sequence. The lower polymer injection device isa blanking roller, a plurality of grooves are arranged on the outer wall of the blanking roller, and when the blanking roller rotates, the polymer water-absorbent resin is injected into the non-wovenfabric through the grooves; The blanking roller is also provided with a filling area matched with the flow guiding groove, and a filler is arranged in the filling area for closing the groove, so thatthe filling area is free of macromolecule water-absorbent resin, thereby forming the flow guiding groove when blanking. The flow guide groove formed by the invention is accurate in positioning and clear in outline, avoids the drift and accumulation of macromolecules, reduces reverse osmosis water and leakage phenomenon, improves the permeation speed and diffusion speed of the core, and is simpleand easy to replace the position and shape of the flow guide groove.

Owner:广东昱升个人护理用品股份有限公司

Composite rubber hose for conveying LPG, LNG and strongly corrosive chemical solvent and preparation method thereof

ActiveCN105042219AImprove adhesionAvoid safety hazardsFlexible pipesLow-density polyethyleneCorrosive chemical

The invention discloses a composite rubber hose for conveying LPG, LNG and strongly corrosive chemical solvent and a preparation method thereof. Low density polyethylene, ultra-high molecular weight polyethylene and macromolecule cross-linked polyethylene serve as raw materials; after scientific compound and vulcanization of a rubber hose, a chemical substance with a good adhesive property is obtained for preparing a liner film; meanwhile, corona treatment is carried out on the bonding face of the liner film and the bonding face of the rubber hose, and fiberglass reinforcing fiber with radiation protection performance is compounded on the surface layer; therefore, the surface layer of the rubber hose has good radiation protection performance, hidden danger of conveying pipelines caused by ionizing radiation is avoided, and finally the composite rubber hose which has the firmly bonded liner film, and is high in radiation protection and capable of conveying LPG, LNG and strongly corrosive chemical solvents is prepared, the hose can absorb as much as 97.5% to 99.5% of X-rays, gamma-rays and various neutrons in nuclear radiation, and the adhesive force (N / 25mm) between the liner film and a rubber layer reaches 160-180.

Owner:河北泽邦塑胶科技有限公司

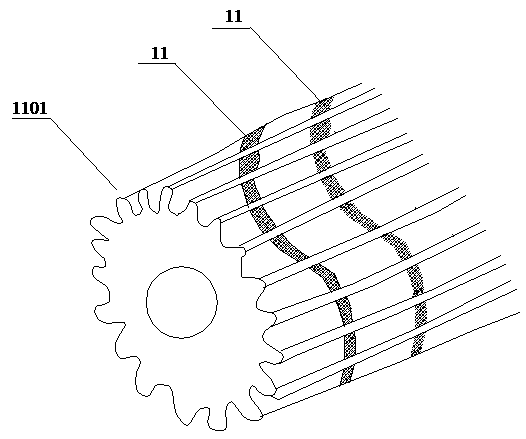

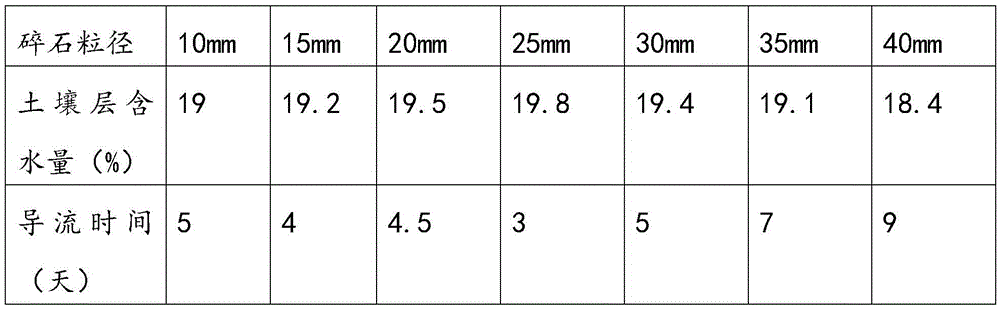

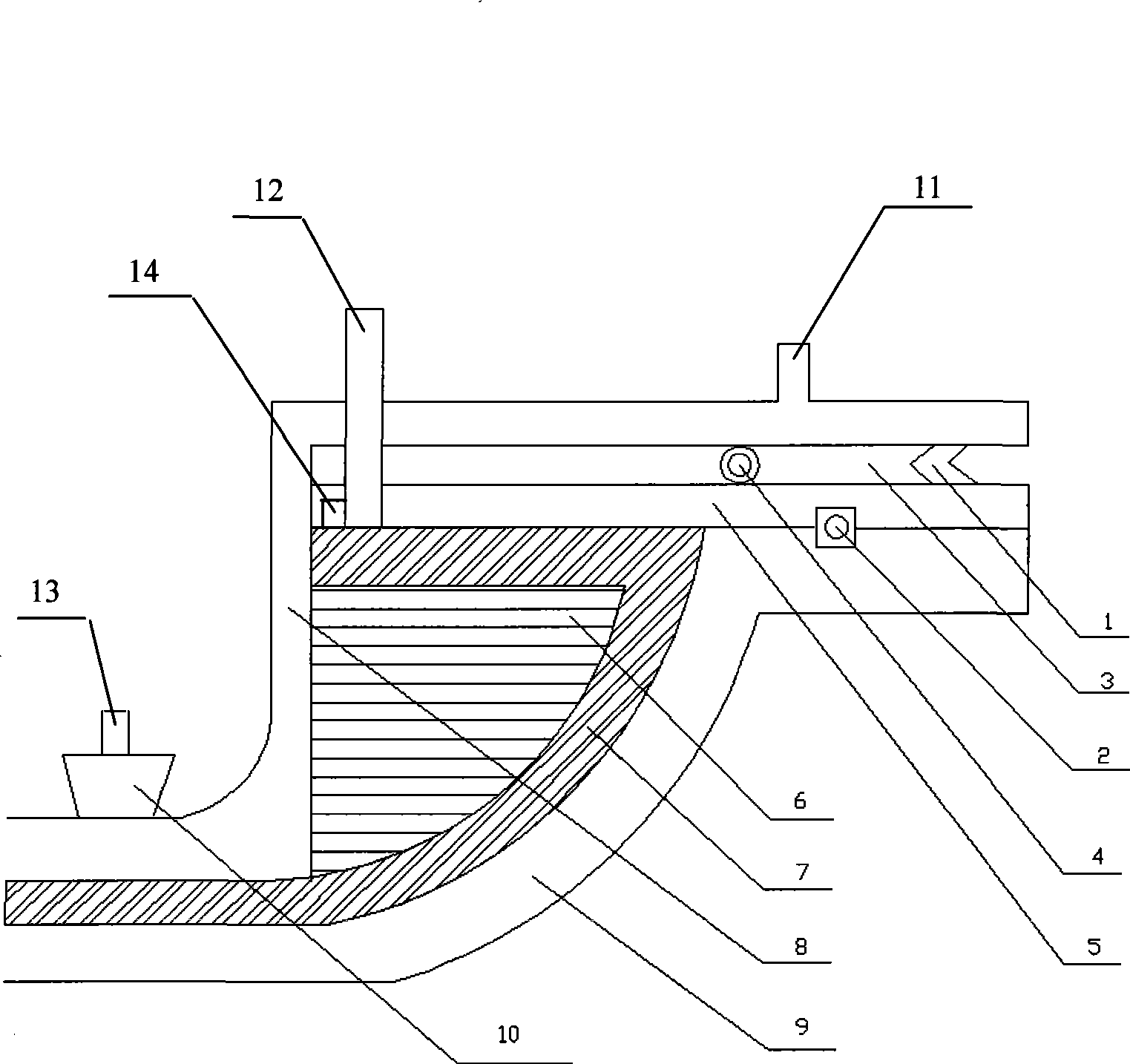

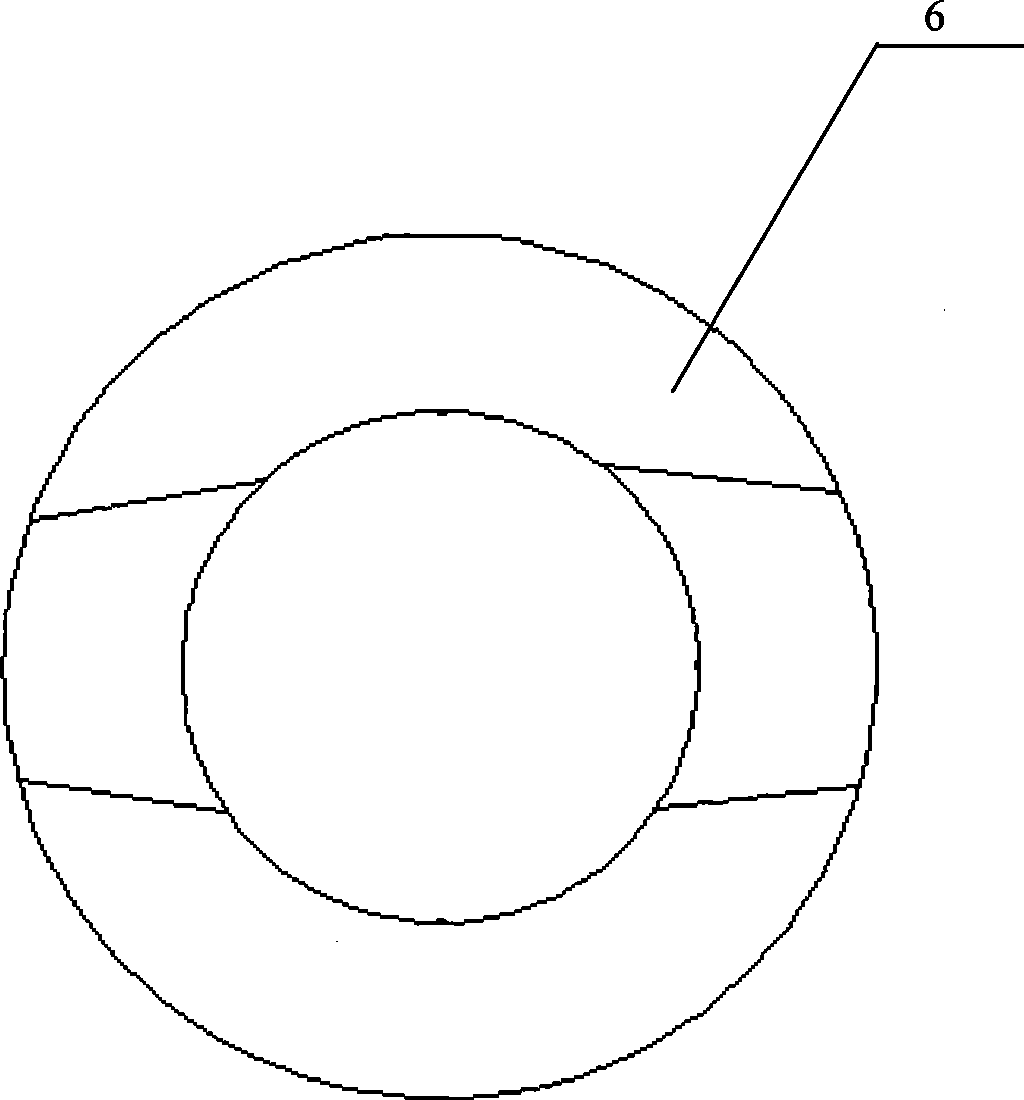

Water seepage structure and method

InactiveCN105569159ASpeed up penetrationAvoid Waterlogging ProblemsSewerage structuresSewage drainingSurface layerWater level

The invention relates to a water seepage structure and method. The water seepage structure comprises a water seepage well and a water permeation layer, wherein the water seepage well is vertically arranged in a soil layer of the ground; the water seepage well is filled with a flow guide object; the water seepage well infiltrates received water into an underground water layer through the flow guide object; the water permeation layer is arranged on the soil layer and covers a well mouth of the water seepage well; and the water permeation layer directly infiltrates surface water into the soil layer or guides the surface water into the water seepage well. The water seepage well is arranged on the ground, so that water in a ground surface layer can be quickly infiltrated into the underground water layer to quickly recover the underground water level, the cost is low, and the efficiency is high; the water seepage well is filled with the flow guide object, so that the seepage velocity of the water can be increased by utilizing a capillary tube principle; and the water permeation layer is arranged on the surface layer of the water seepage well, so that accumulated water can be prevented from being generated on the surface of the soil layer between water seepage wells.

Owner:路金铭

Method for manufacturing vacuum mould closing of false ogive

InactiveCN101428476AAvoid it happening againEasy to close the moldDomestic articlesEngineeringWorking environment

The invention provides a vacuum mold closing die and the application thereof in a fairing vacuum mold closing manufacturing method. The vacuum mold closing die comprises a compound lower die, wherein, a compound lower end upper module is arranged on the upper side of the compound lower die; a dynamic seal ring is arranged along the circumference of the upper side of the upper module of the compound lower die; an aerofoil seal ring is arranged on one side of the dynamic seal ring; a semi-rigid composite material upper die is arranged on the compound lower die and the upper module thereof; a glue storing device is in the lower position of the semi-rigid composite material upper die; a glue outlet is formed at the upper end of the glue storing device; a glue injecting port is formed in the higher position of the semi-rigid composite material upper die; a flow channel is arranged at the lower end of the glue injecting port; and a vacuum orifice is formed on the upper side of the semi-rigid composite material upper die. The vacuum mold closing die can be applied in the fairing vacuum mold closing manufacturing method. The vacuum mold closing die and the application thereof in the fairing vacuum mold closing manufacturing method has the advantages that the investment and the manufacturing cost are low; the production efficiency is high; almost no industrial refuse is generated; the performance of a manufactured product is excellent; and the working environment is good.

Owner:DONGHUA UNIV +1

Method for tenderizing beef steak

Owner:福建佳客来食品股份有限公司

Shuttering hardening agents

InactiveCN105312486AAvoid pollutionFast hardeningFoundry mouldsFoundry coresEconomic benefitsChloride

The invention relates to shuttering hardening agents. The shuttering hardening agents mainly include, by weight, 10-15% of hexahydrate crystallization of aluminum chloride, 22-25% of dihydrate flaky calcium chloride, 1.5-2% of anhydrous boric acid, 0.1-0.15% of permeating agents and the balance clear water. The hexahydrate crystallization of aluminum chloride and the dihydrate flaky calcium chloride serve as the main materials of the hardening agents, so that the defect that the work conditions are seriously worsened as ammonium chloride is used as the main materials of shuttering hardening agents is fundamentally overcome, and the other properties are better than those of the ammonium chloride hardening agents. The shuttering hardening agents have the characteristics of being high in hardening speed, shortening the process and shortening the production period, avoid environmental pollution and obviously improve economic benefits.

Owner:TIANJIN RONGHENG GROUP

Method and device for measuring permeability coefficients of stratums at different depths in field

InactiveCN106018239AFully reflect the real penetration situationEasy to operatePermeability/surface area analysisIn situ soil foundationPermeability coefficientPermeation

A method and device for measuring permeability coefficients at different depths on site, the method comprising the following steps: inserting a connecting pipe into the ground layer to be measured, injecting water into a water injection tank to a designated position, and then injecting water into the water injection tank Apply pressure, calculate and measure the permeability coefficient and the average permeability coefficient of each stage; the device includes a water injection tank at the top, a connecting pipe, a support structure, a pile head, a pressurizing device and a pressure measuring device, and the water injection tank is installed on the top of the support structure , the inner bottom of the water injection tank is equipped with a pressure measuring device for measuring water pressure, and the top of the water injection tank is equipped with a pressurizing device for adjusting the water pressure in the water injection tank; the top water inlet of the connecting pipe is sealed with the inner cavity of the water injection tank In communication, the water outlet at the bottom of the communication pipe passes through the support structure and communicates with the pile head in a sealed manner. The beneficial effects of the invention are: it can fully reflect the real seepage situation of the site, can truly reflect the real situation of the soil body and is easy to operate.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of Chinese smoked sausage

ActiveCN104172220AShorten natural thawing timeAvoid darkeningMeat/fish preservationClimate change adaptationSaline solutionsFood flavor

The invention provides a preparation method of Chinese smoked sausage. The preparation method specially comprises the following steps: 1) selecting and pretreating raw materials of sausage; 2) pickling; 3) cleaning; 4) airing and after-pickling; 5) smoking and roasting; and 6) cleaning, drying, cooling, reshaping and packaging. The preparation method adopts a manure saturated saline solution vacuum thawing, vacuum intermittent pickling, low-temperature roasting and fast drying technology, the sausage can be prevented from deterioration during processing through smoking, and the flavor of the Chinese sausage can be increased.

Owner:HUNAN AGRICULTURAL UNIV

Fast-infiltration breathable absorption object and preparation method thereof

InactiveCN108309578APromote absorptionImprove absorption ratePersonal careLaminationNonwoven fabricPlant sap

The invention relates to the field of disposable sanitary products, in particular to a fast-infiltration breathable absorption object and a preparation method thereof, and mainly solves the problems that an absorption object in the prior art is slow in infiltration and poor in breathability. The fast-infiltration breathable absorption object comprises an absorption core and is characterized in that the absorption core comprises bulky nonwoven fabric, a first sap layer and a second sap layer are respectively arranged on the upper surface and the lower surface of the bulky nonwoven fabric, firstdust-free paper is compositely adhered to the first sap layer, second dust-free paper is compositely adhered to the second sap layer, the first sap layer is provided with at least one first through groove, the second sap layer is provided with at least one second through groove, and the width of each first through groove and each second through groove is 0.1-40mm.

Owner:美佳爽(中国)有限公司

Method for making snack sauced beef jerky

InactiveCN108669466AImprove tendernessTastyFood thermal treatmentFood ingredient as taste affecting agentUltrasonic assistedFiltration

The invention discloses a method for making snack sauced beef jerky. The method comprises the following steps: (1) boiling for producing aniseed water; (2) ultrasonic assisted pickling; (3) deodorizing and filtration; (4) cooking; and (5) packaging. Beef is pickled under the assistance of ultrasound, so the pickling time is greatly shortened, and the beef and the aniseed water are fully fused to make the beef jerky tasty; and the beef is dried by hot air blowing, so the water content of the beef jerky is improved; and blanching in carrot water is adopted, so the odor is reduced, the nutritional values of the product are increased, and the product is loved by people.

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com