Low thermal conductivity hydrophilic-hydrophobic bipolar composite membrane as well as preparation method and application thereof

A composite membrane and low thermal conductivity technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of immature technology, frosting on the cooler surface, high sensible heat transfer, etc., to reduce moisture diffusion resistance, high water The effect of steam permeation speed and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

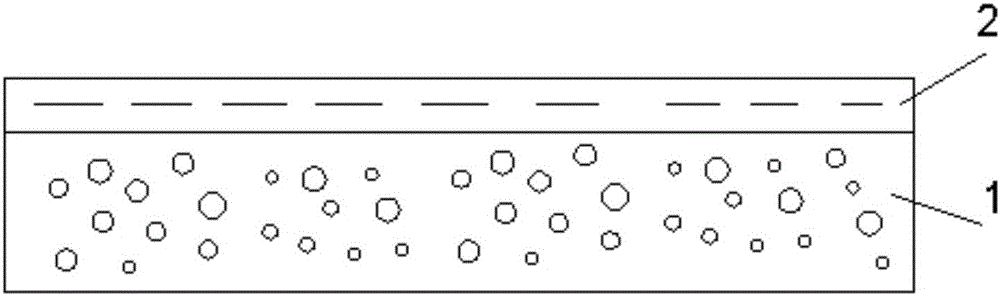

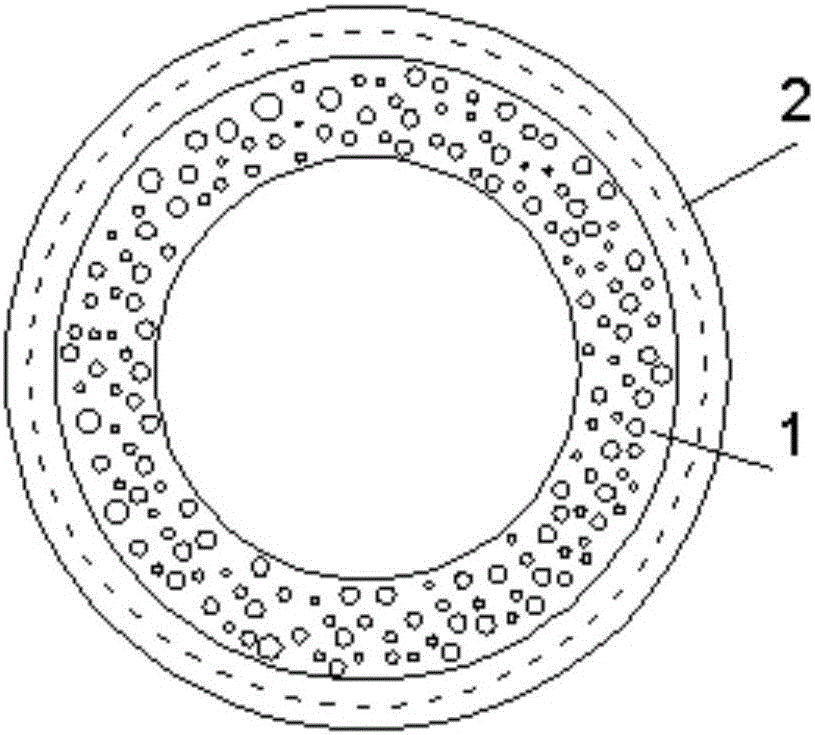

[0050] (1) Dissolve 7g of polyvinylidene fluoride and 1g of porogen in 100g of dimethyl sulfoxide and add 1g of hydrophobic silica aerogel, control the temperature to 60°C, and fully stir for 4 hours to dissolve , And let it stand for 12 hours to defoam, and use a wiper to control the wet thickness of the film at 100μm. After that, the coated glass plate was quickly thrown into the tap water bath. After 1 minute, the formed membrane was peeled off the glass plate, transferred to another water bath and allowed to stand for 24 hours to remove excess solvent, picked up and dried to obtain a porous membrane.

[0051] (2) 4g polyvinyl alcohol, 2g hydrophilic silica aerogel and 0.12g lithium chloride were stirred with 120g deionized water at 90°C for 1 hour to prepare a polyvinyl alcohol solution, and the above solution was allowed to stand still One day, the casting solution is formed; the above casting solution is poured on the 100 μm polyvinylidene fluoride porous film obtained in ...

Embodiment 2

[0054] (1) Dissolve 8g of polyvinylidene fluoride and 1g of porogen in 110g of dimethyl sulfoxide and add 2g of hydrophobic silica aerogel, control the temperature at 60°C, and fully stir for 4 hours to dissolve , And let it stand for 12 hours to defoam, and use a wiper to control the wet thickness of the film at 100μm. After that, the coated glass plate was quickly thrown into the tap water bath. After 1 minute, the formed membrane was peeled off the glass plate, transferred to another water bath and allowed to stand for 24 hours to remove excess solvent, picked up and dried to obtain a porous membrane.

[0055] (2) 2g polyvinyl alcohol, 1g hydrophilic silica aerogel and 0.10g lithium chloride were stirred with 120g deionized water at 90°C for 1 hour to prepare a polyvinyl alcohol solution, and the above solution was allowed to stand still One day, the casting solution is formed; the above casting solution is poured on the 100 μm polyvinylidene fluoride porous film obtained in ...

Embodiment 3

[0058] (1) Dissolve 9g of polyvinylidene fluoride and 2g of porogen in 100g of dimethyl sulfoxide and add 3g of hydrophobic silica aerogel, control the temperature to 60°C, and fully stir for 4 hours to dissolve , And let it stand for 12 hours to defoam. Use a wiper to control the wet thickness of the film to 70μm. After that, the coated glass plate was quickly thrown into the tap water bath. After 1 minute, the formed membrane was peeled off the glass plate, transferred to another water bath and allowed to stand for 24 hours to remove excess solvent, picked up and dried to obtain a porous membrane.

[0059] (2) 15g of polyvinyl alcohol, 5g of hydrophilic silica aerogel and 0.15g of lithium chloride were stirred with 150g of deionized water at 100°C for 2 hours to prepare a polyvinyl alcohol solution, and the above solution was allowed to stand still 3 days to form a casting solution; pour the casting solution onto the 70μm polyvinylidene fluoride porous membrane obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com