Method and system for producing runny preserved duck egg semi-continuously and rapidly through vacuum decompression

A technology of vacuum decompression and loosening eggs, which is applied in the field of food science, can solve the problems of less than 50% utilization rate of material and liquid, long pickling time, affecting the economic benefits of enterprises, etc., so as to shorten the pickling period and achieve good color Flavor, the effect of shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

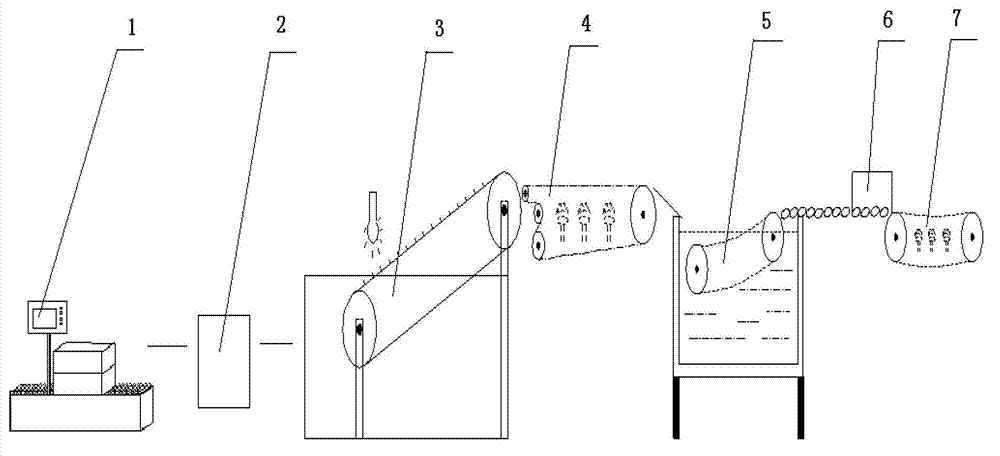

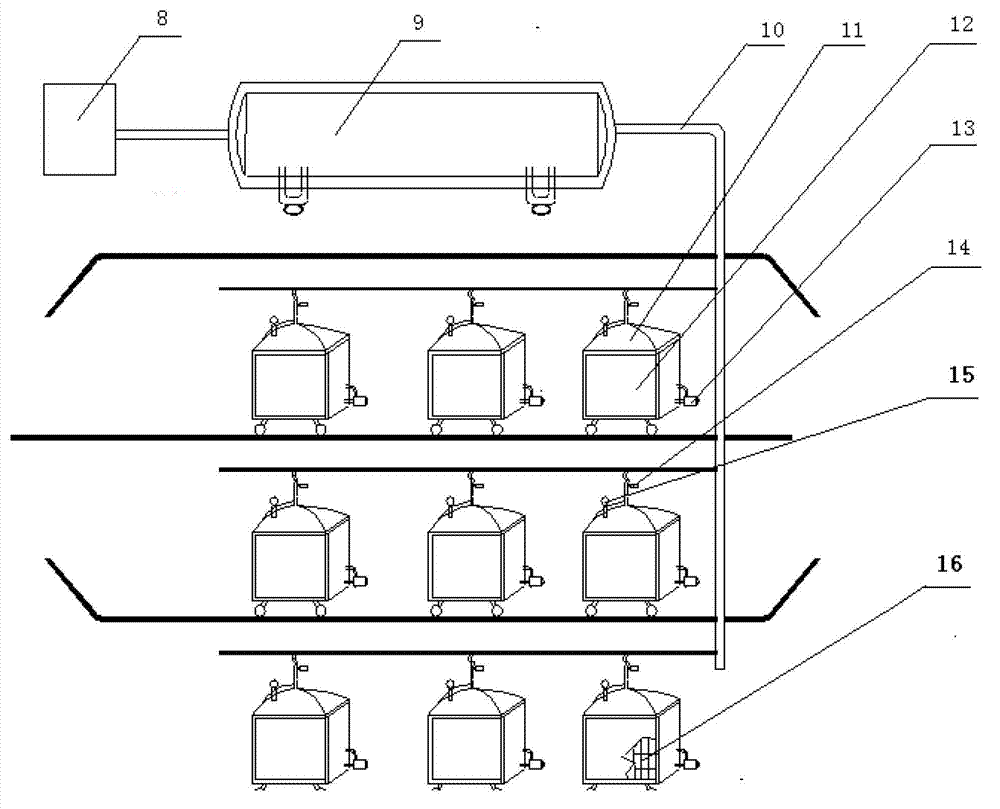

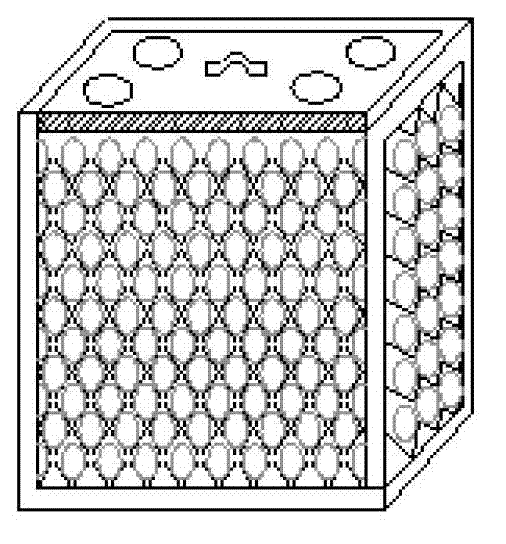

Method used

Image

Examples

Embodiment 1

[0050] A method for semi-continuous rapid production of soft-boiled preserved eggs by vacuum decompression method, its concrete steps are as follows:

[0051] ⑴Material selection: Strictly select fresh duck eggs, remove damaged eggs, cracks, oil shells, steel shells and other inferior eggs, wash them with cold boiled water or disinfectant water, and then dry them with an egg washing machine;

[0052] ⑵Basic preparation of feed liquid: boil black tea powder and fresh cypress leaves with water, filter out black tea powder and fresh cypress branches, add a certain amount of NaOH, NaCl, CuSO after a little cooling 4 , sodium citrate, stir well to make it all dissolve and constant volume, and let the material liquid dry to room temperature for use, in which black tea powder accounts for 2.5%, fresh cypress leaves 2.5%, NaOH 4.5%, NaCl 5%, CuSO 4 0.4%, sodium citrate 0.15%.

[0053] In this step, the penetration speed of the feed liquid is related to the concentration of the feed ...

Embodiment 2

[0061] A method for semi-continuous rapid production of soft-boiled preserved eggs by vacuum decompression method, its concrete steps are as follows:

[0062] ⑴Material selection: Strictly select fresh duck eggs, remove damaged eggs, cracks, oil shells, steel shells and other inferior eggs, wash them with cold boiled water or disinfectant water, and then dry them with an egg washing machine;

[0063] ⑵Basic preparation of material liquid: boil black tea powder and fresh cypress leaves with water, filter out the tea leaves and fresh cypress branches, add a certain amount of NaOH, NaCl, CuSO after a little cooling 4 , sodium citrate and ZnSO 4 mixed mixture, fully stirred to make it completely dissolved, and the material liquid was aired to room temperature for use, among which, black tea powder accounted for 3%, fresh cypress leaves 3%, NaOH 4.5%, NaCl 5%, CuSO 4 0.3%, ZnSO 4 0.2%, sodium citrate 0.15%.

[0064] ⑶ Cracked egg detection and placement: Cracked eggs are detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com