Camellia seed coldly-pressed tea-seed oil and processing process

A processing technology and camellia seed technology, applied in the field of oil making technology of camellia seed oil, can solve the problems of easy smooth bore, high oil temperature, unfavorable camellia oil, etc., to prevent the increase of acidity, high quality of refined oil, and uniform moisture. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

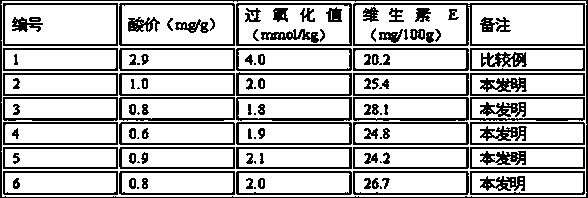

Examples

Embodiment 1

[0032] This embodiment discloses a process for making oil from camellia oleifera seeds by cold pressing, which includes the following steps:

[0033] (1) Pretreatment of camellia oleifera seeds, the camellia oleifera is not removed during the storage and transportation process after the camellia oleifera fruit is picked; within 2 hours after the removal of the camellia oleifera, the screened fresh tea seeds are dried using a flat-panel dryer and an exhaust fan, Drying is carried out twice, the first drying temperature is 50-55°C, the drying time is 50-65 minutes, the water content of tea seeds is reduced from 35-40% to 20%, and the second drying temperature is 60-65 ℃, drying time 45-55min, the moisture content of tea seeds after drying is 6-10%, preferably 8%. This time, it is carried out in batches, and the water loss of tea seeds is uniform, which is conducive to drying efficiency.

[0034] The dried tea seeds are stored in low temperature at a temperature of 5-10°C.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com