A hydrophilic-hydrophobic bipolar composite membrane and method for preparing same

A technology of composite membranes and hydrophobic membranes, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of inability to perform full heat recovery, difficulty in satisfying the penetration of other gas molecules with high moisture permeability at the same time, and achieve Effects of reduced moisture diffusion resistance, strong adhesive force, and high water vapor permeation velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

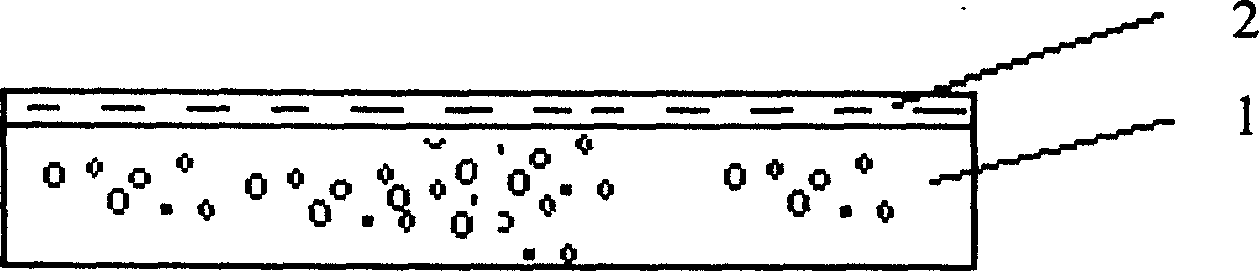

[0051] Stir 4g of polyvinyl alcohol and 0.12g of lithium chloride with 120g of deionized water at 90°C for 1 hour to prepare a polyvinyl alcohol solution, let the above solution stand for 1 day to form a casting solution; pour the above casting solution on On a 100 μm polyvinylidene fluoride film, spread it evenly, and dry the above-mentioned coated composite film naturally in the air for 1 day; configure an aqueous solution of a crosslinking agent, wherein the mass concentration of hydroxysuccinic acid is 1%, and the mass concentration of acetic acid is 3%. The above-mentioned composite film was soaked in the cross-linking agent aqueous solution for 20 seconds, picked up, air-dried, then immediately transferred to an oven at 70° C., and baked for 30 minutes to complete the preparation.

Embodiment 2

[0053] Stir 2g of polyvinyl alcohol and 0.10g of lithium chloride with 100g of deionized water at 95°C for 1.5 hours to prepare a polyvinyl alcohol solution, let the above solution stand for 2 days to form a casting solution; pour the above casting solution on On a 30 μm polyethylene film, spread it evenly, and dry the above-mentioned composite film naturally in the air for 1.5 days; configure an aqueous solution of a cross-linking agent, wherein the mass concentration of hydroxysuccinic acid is 2%, and the mass concentration of acetic acid is 4%, and the above-mentioned compound The film was soaked in the cross-linking agent aqueous solution for 25 seconds, picked up, air-dried, and then immediately transferred to an oven at 80°C for 40 minutes to complete the preparation.

Embodiment 3

[0055] Stir 15g of polyvinyl alcohol and 0.15g of lithium chloride with 150g of deionized water at 100°C for 2 hours to prepare a polyvinyl alcohol solution, leave the above solution for 3 days to form a casting solution; pour the above casting solution on On a 70 μm polypropylene film, spread it evenly, and dry the above-mentioned composite film naturally in the air for 2 days; prepare an aqueous solution of a cross-linking agent, wherein the mass concentration of hydroxysuccinic acid is 3%, and the mass concentration of acetic acid is 5%, and the above-mentioned compound The film was soaked in the cross-linking agent aqueous solution for 30 seconds, picked up, air-dried, and then immediately transferred to an oven at 100°C for 50 minutes to complete the preparation.

[0056] 2. Select sodium polyacrylate as the main component of the hydrophilic membrane

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com