Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

362 results about "Hydrophilic membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophilic membranes from PIL Membranes have a solid structure that physically stops water passing through the membrane. They breathe by absorbing and dissipating sweat through the diffusion of water vapour molecules. The chemical structure of the membrane is made up of hydrophilic (water loving) groups that attract water vapour molecules.

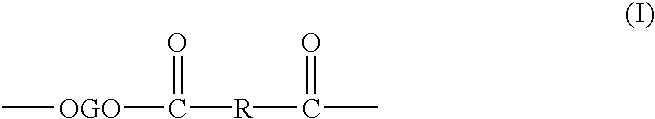

Vinylidene fluoride copolymers

ActiveUS20100133482A1Maximize the effectHigh viscosityMembranesSemi-permeable membranesPolymer scienceMeth-

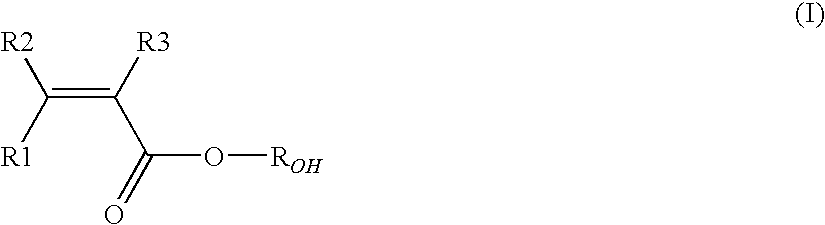

The present invention pertains to a linear semi-crystalline copolymer [polymer (A)] comprising recurring units derived from vinylidene fluoride (VDF) monomer and at least one hydrophilic (meth)acrylic monomer (MA) of formula (I) wherein each of R1, R2, R3, equal or different from each other, is independently an hydrogen atom or a C1-C3 hydrocarbon group, and ROH is a hydrogen or a C1-C5 hydrocarbon moiety comprising at least one hydroxyl group, said polymer (A) comprising from 0.05 to 10% by moles of recurring units derived from said hydrophilic (meth)acrylic monomer (MA) and being characterized by a fraction of randomly distributed units (MA) of at least 40%, having improved thermal stability, to a process for its manufacture, to a composition comprising the same, and to its use as binder in batteries or for the manufacture of hydrophilic membranes.

Owner:SOLVAY SOLEXIS

Membrane post treatment

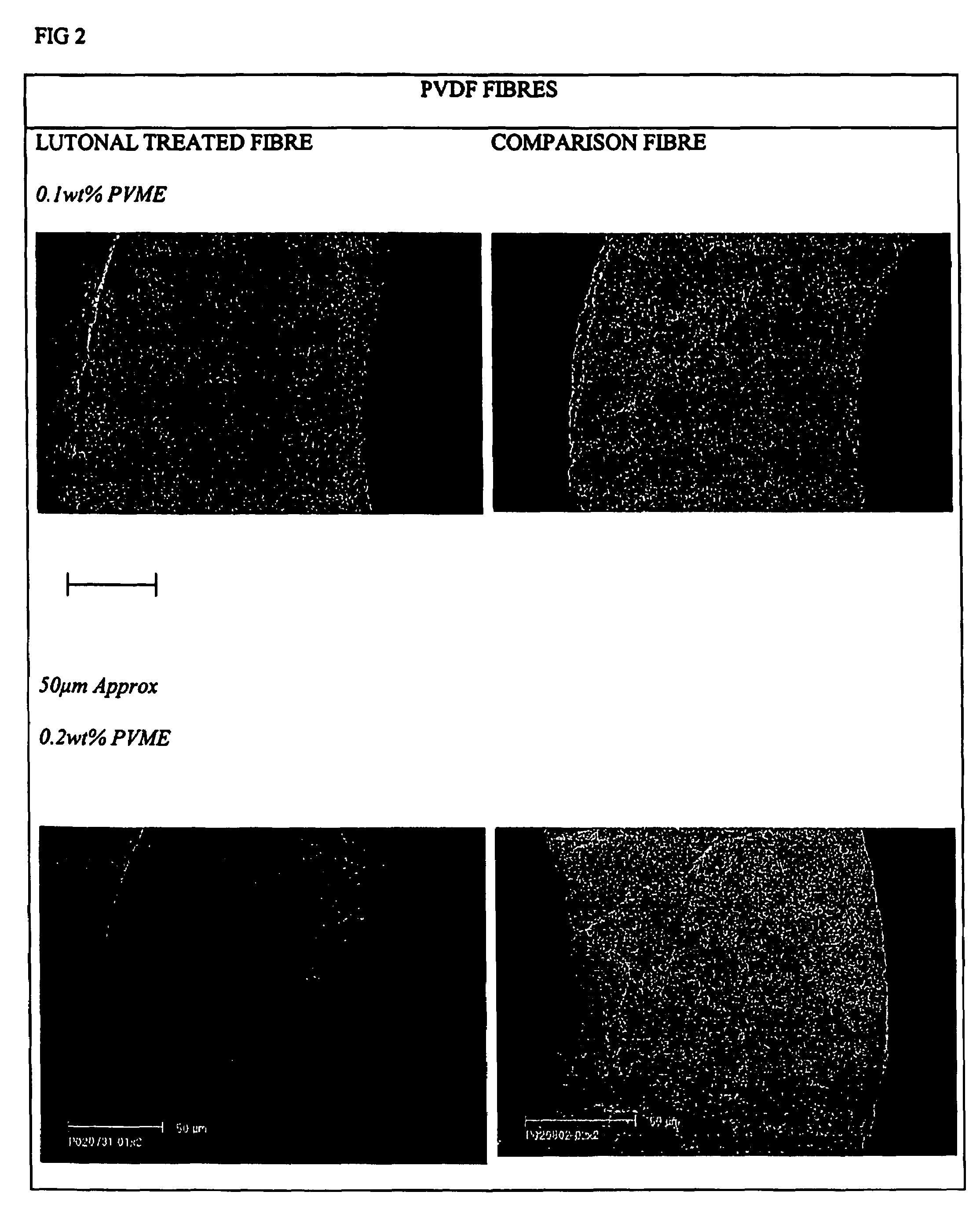

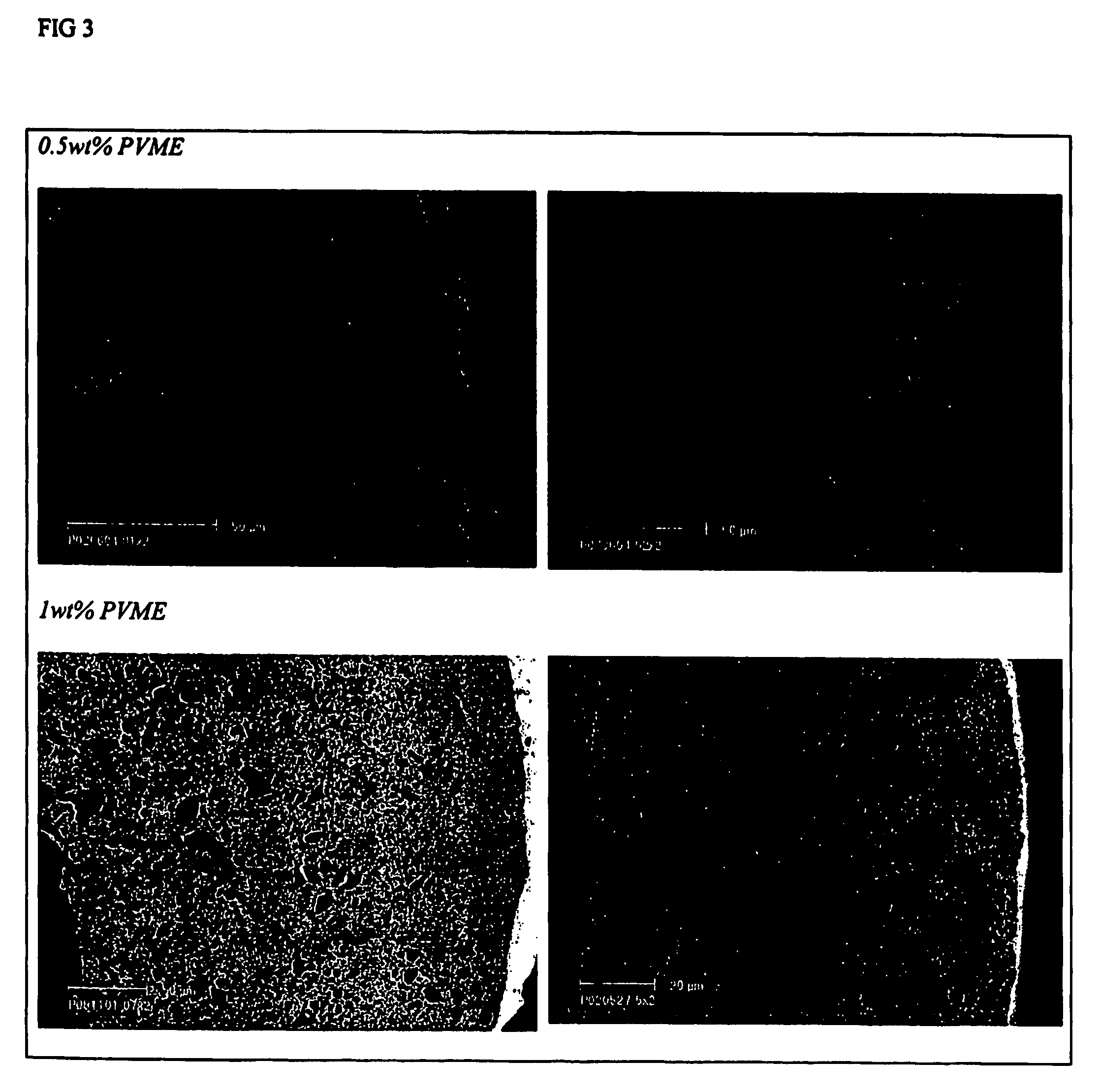

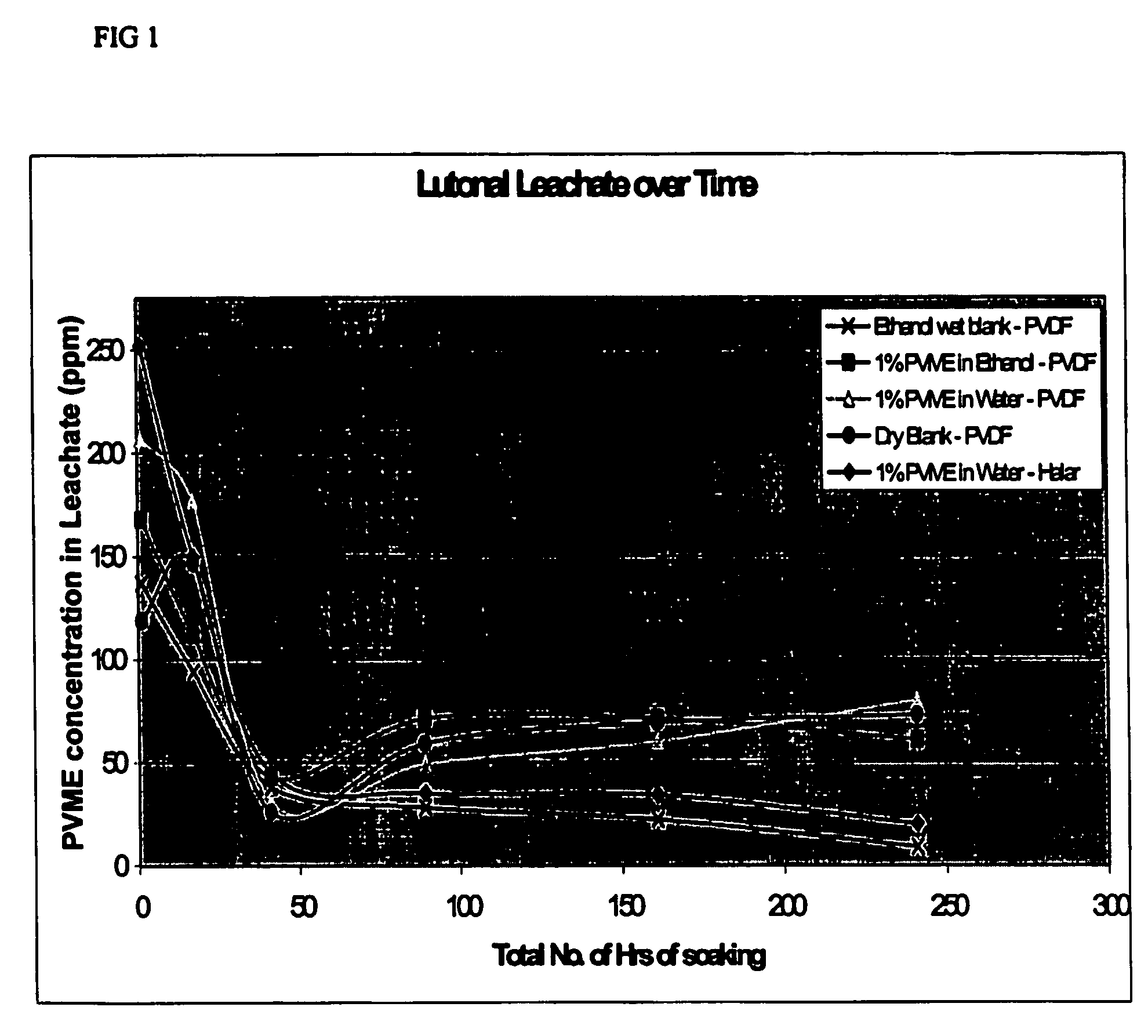

InactiveUS7662212B2Low toxicityReduce riskSolid sorbent liquid separationPretreated surfacesHydrophilizationMicrofiltration membrane

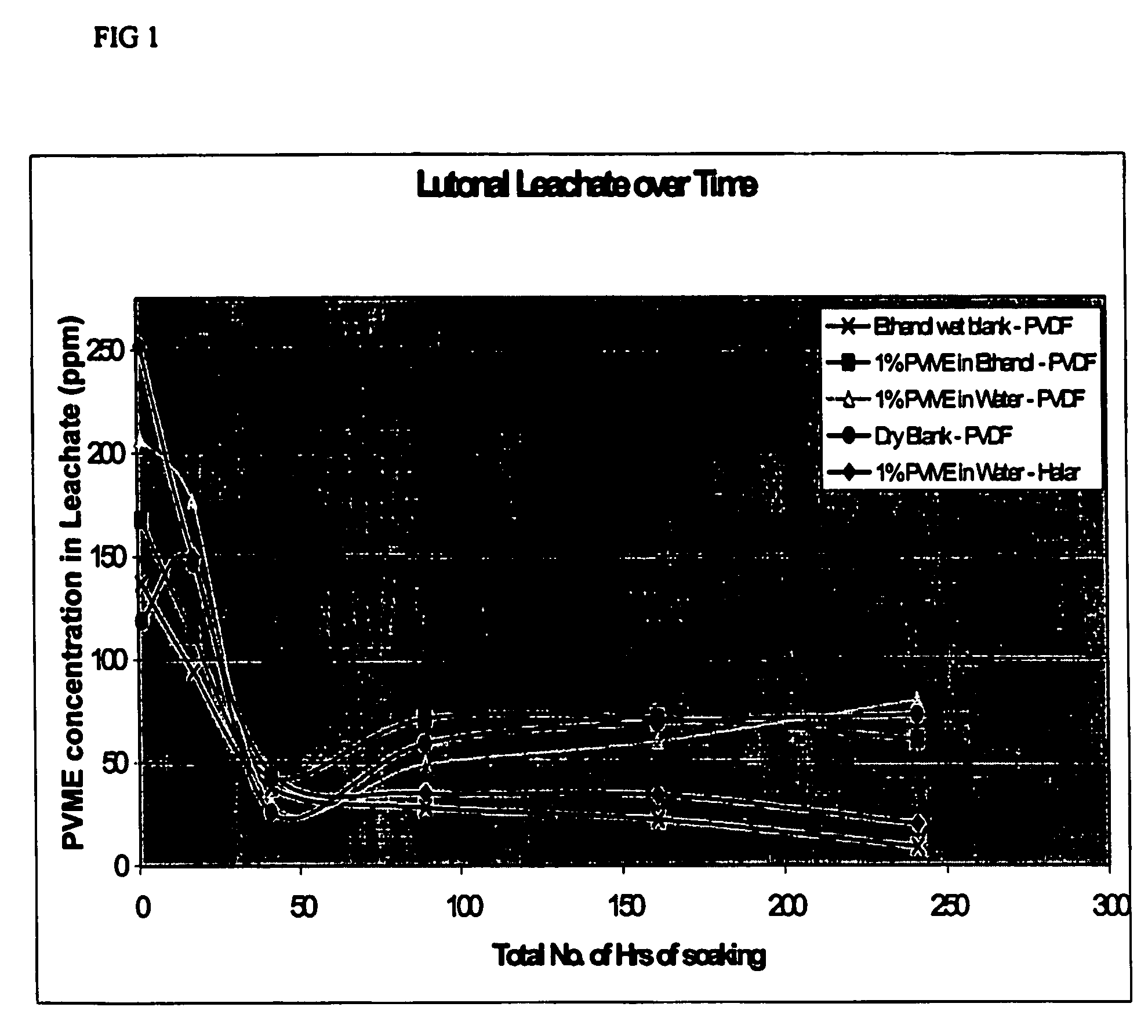

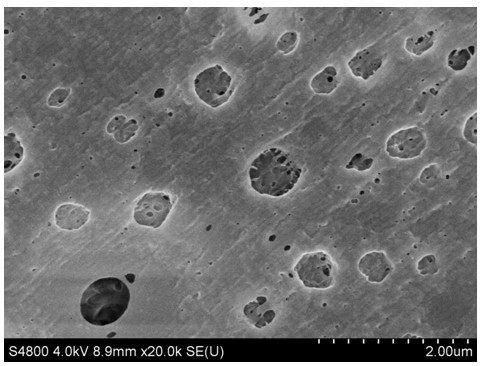

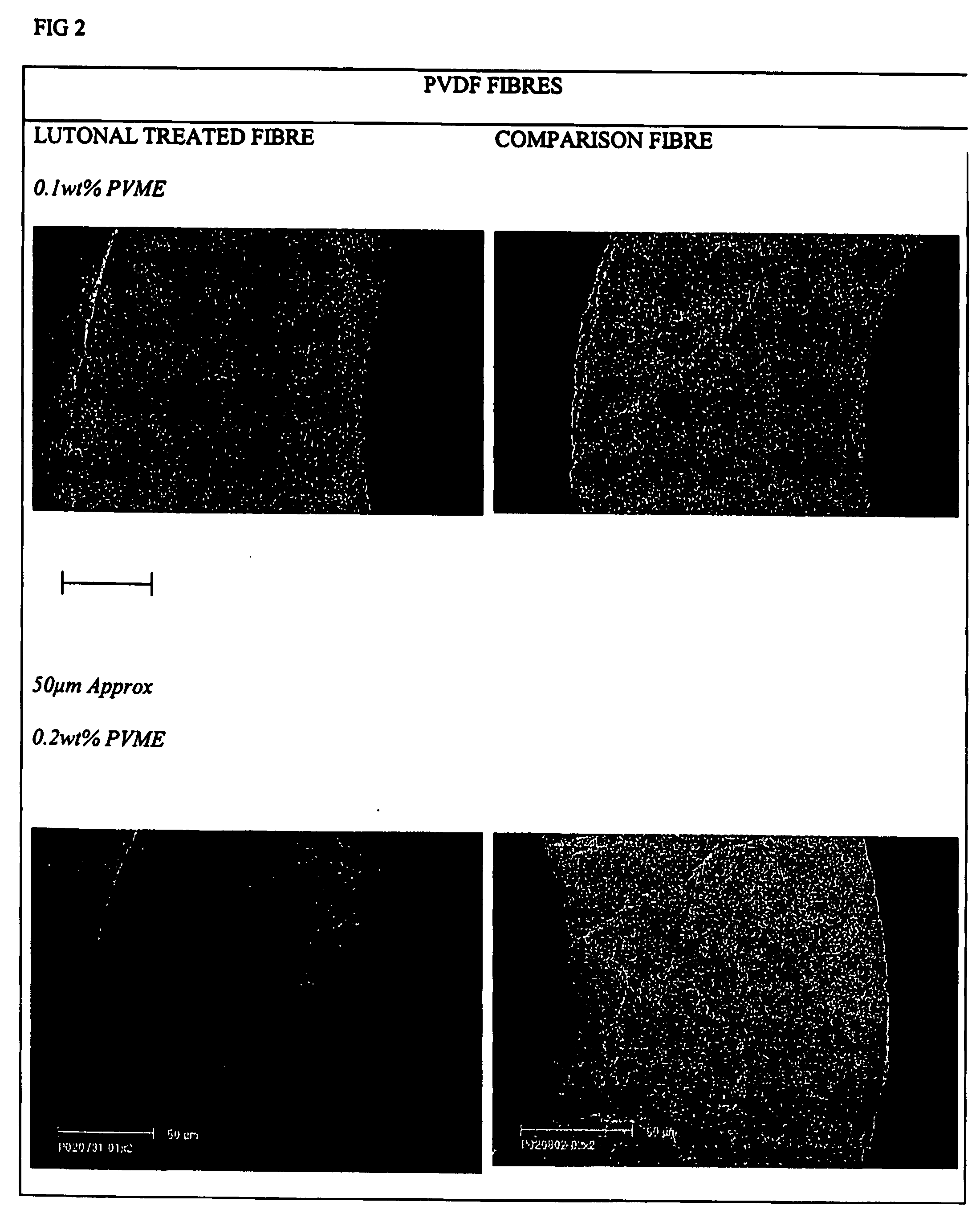

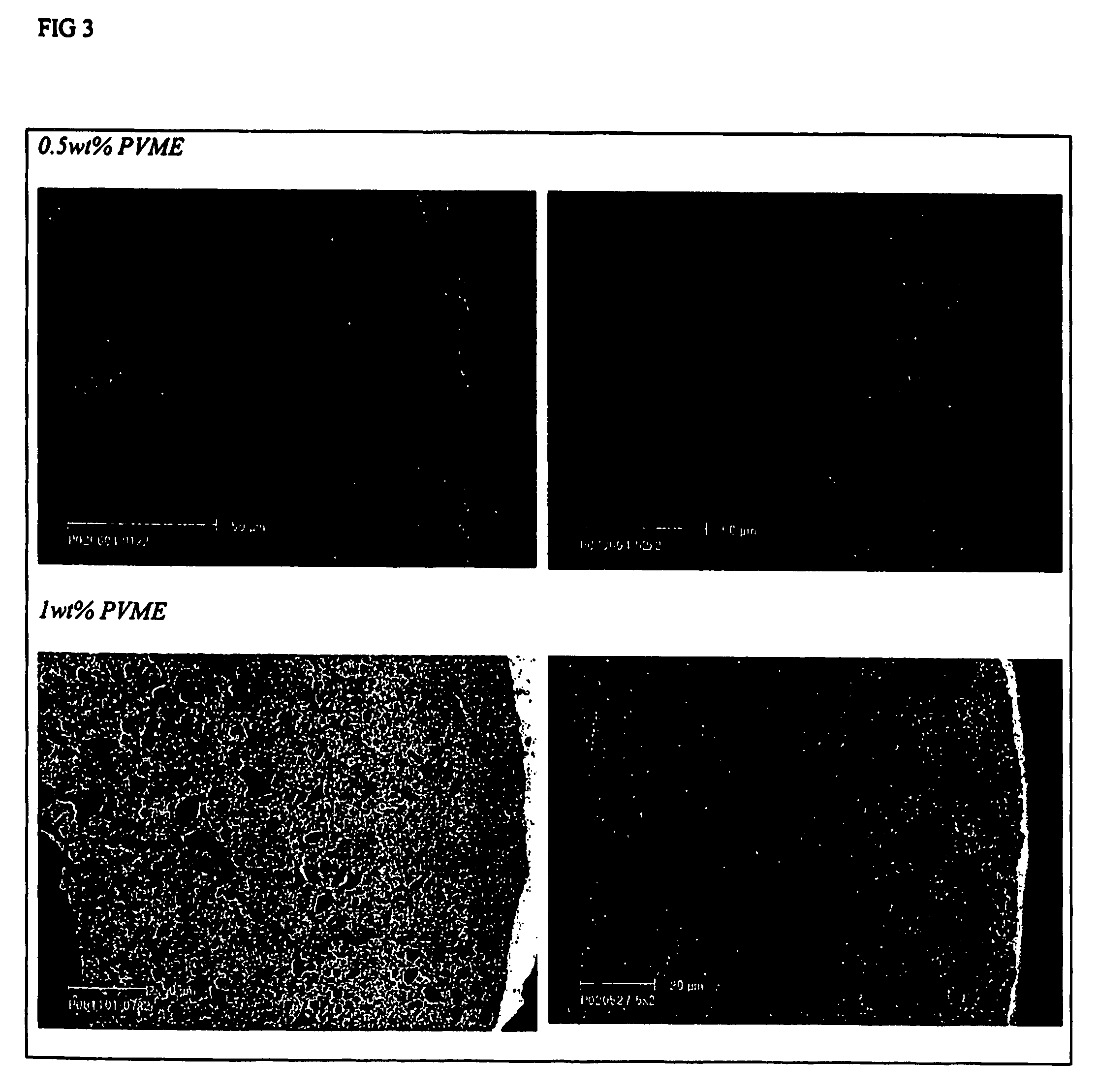

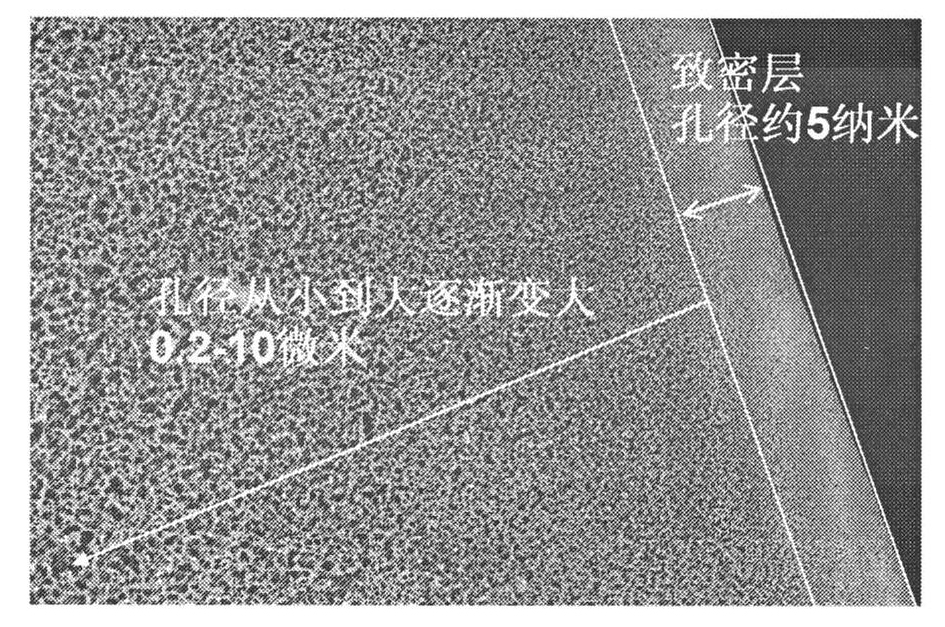

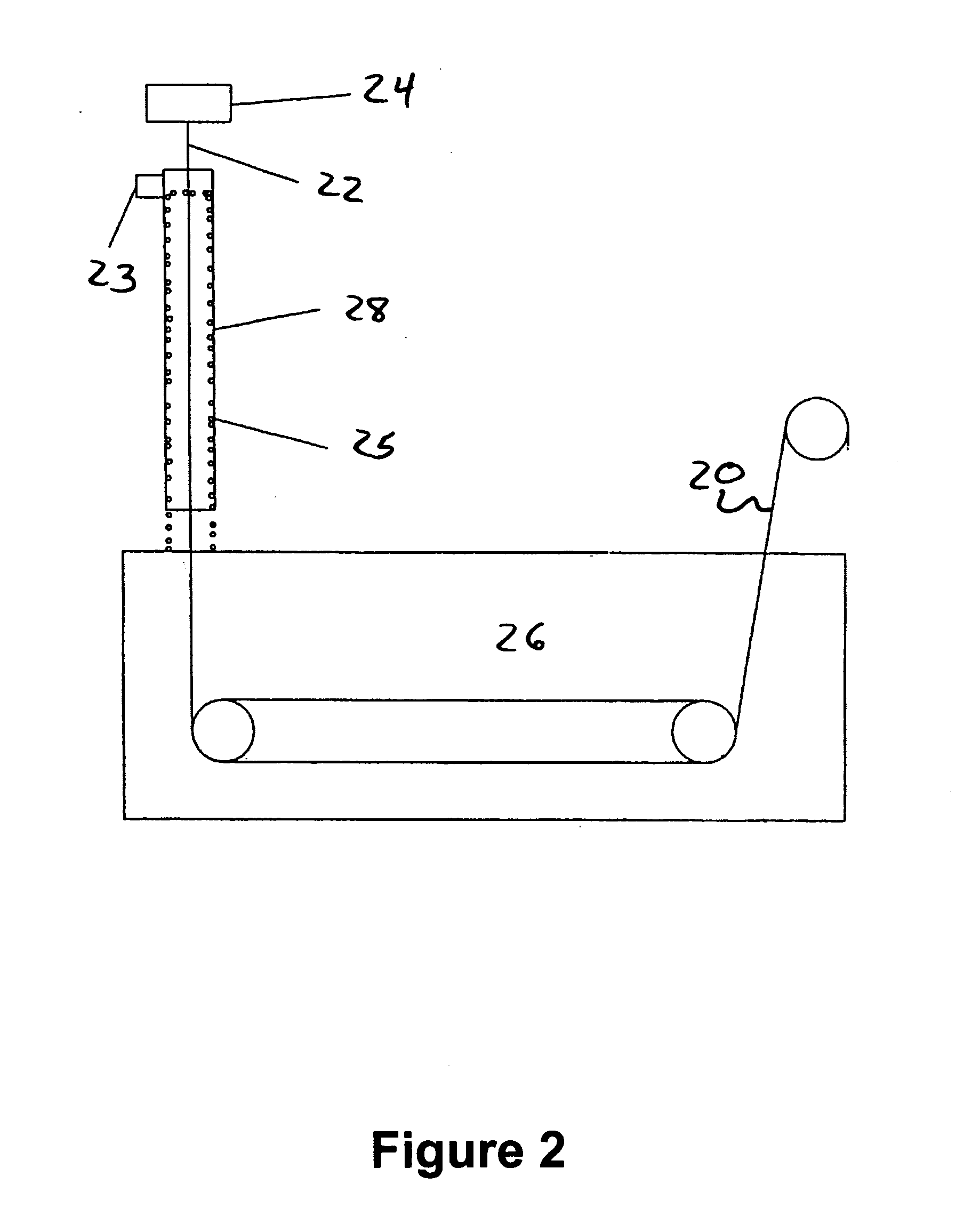

The invention relates to polymeric ultrafiltration or microfiltration membranes of, for instance, Halar, PVDF or PP, incorporating PVME or vinyl methyl ether monomers. The PVME may be present as a coating on the membrane or dispersed throughout the membrane or both. The membranes are preferably hydrophilic with a highly asymmetric structure with a reduced pore size and / or absence of macrovoids as a result of the addition of PVME. The PVME maybe cross-linked. The invention also relates to methods of hydrophilising membranes and / or preparing hydrophilic membranes via thermal or diffusion induced phase separation processed.

Owner:EVOQUA WATER TECH LLC

Fluorescence lateral flow immunoassay

InactiveUS20060263907A1Inhibit migrationFacilitates resuspensionBioreactor/fermenter combinationsBiological substance pretreatmentsAssayFluorescence

The present invention relates to devices, kits, instruments and methods for conducting lateral flow assays. A naturally hydrophilic membrane a fluorescent or luminescent label are used in the present devices, kits, instruments and methods. Preferably, a single naturally hydrophilic membrane and / or a fluorescent or luminescent particle label is used.

Owner:BECKMAN COULTER INC

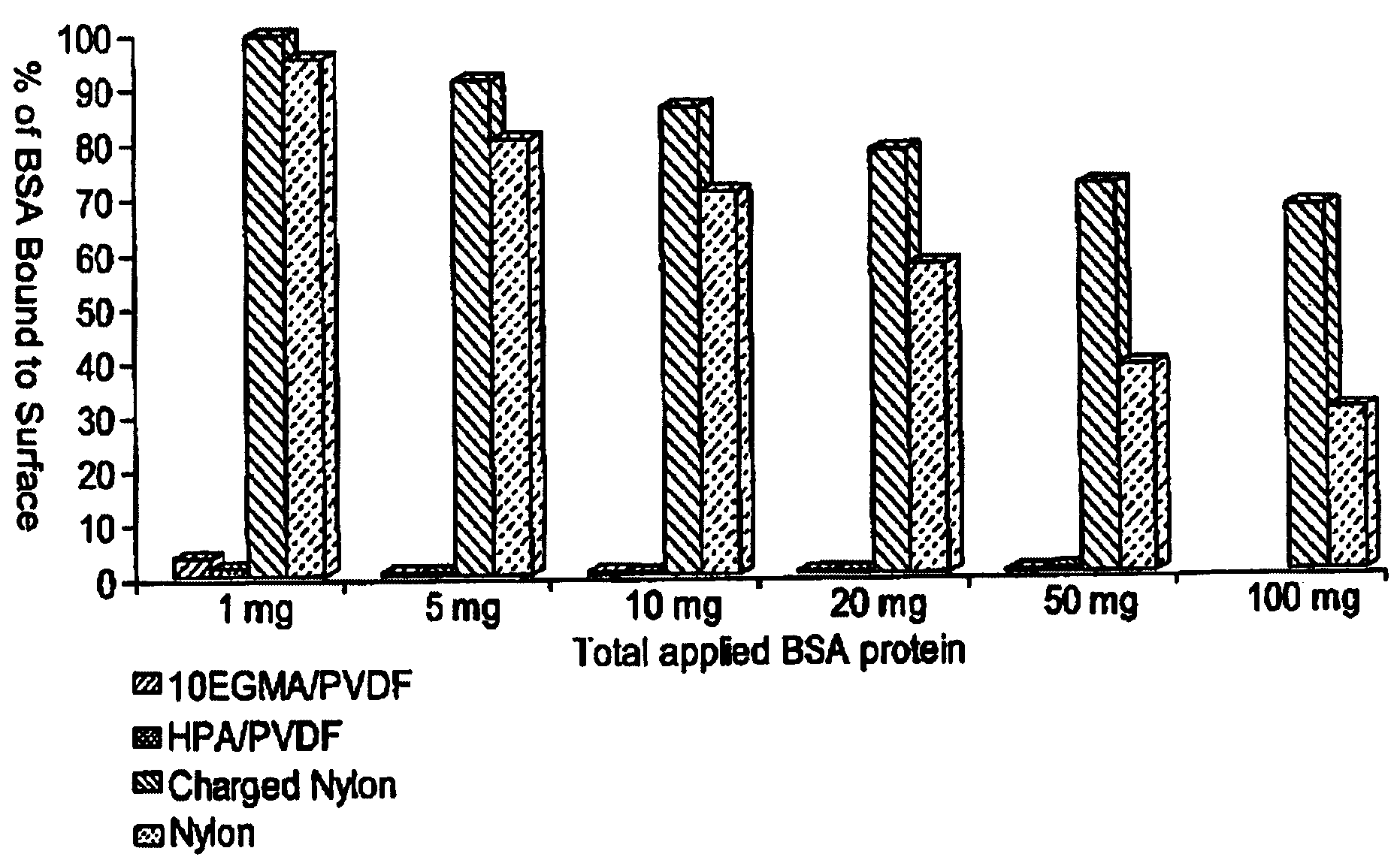

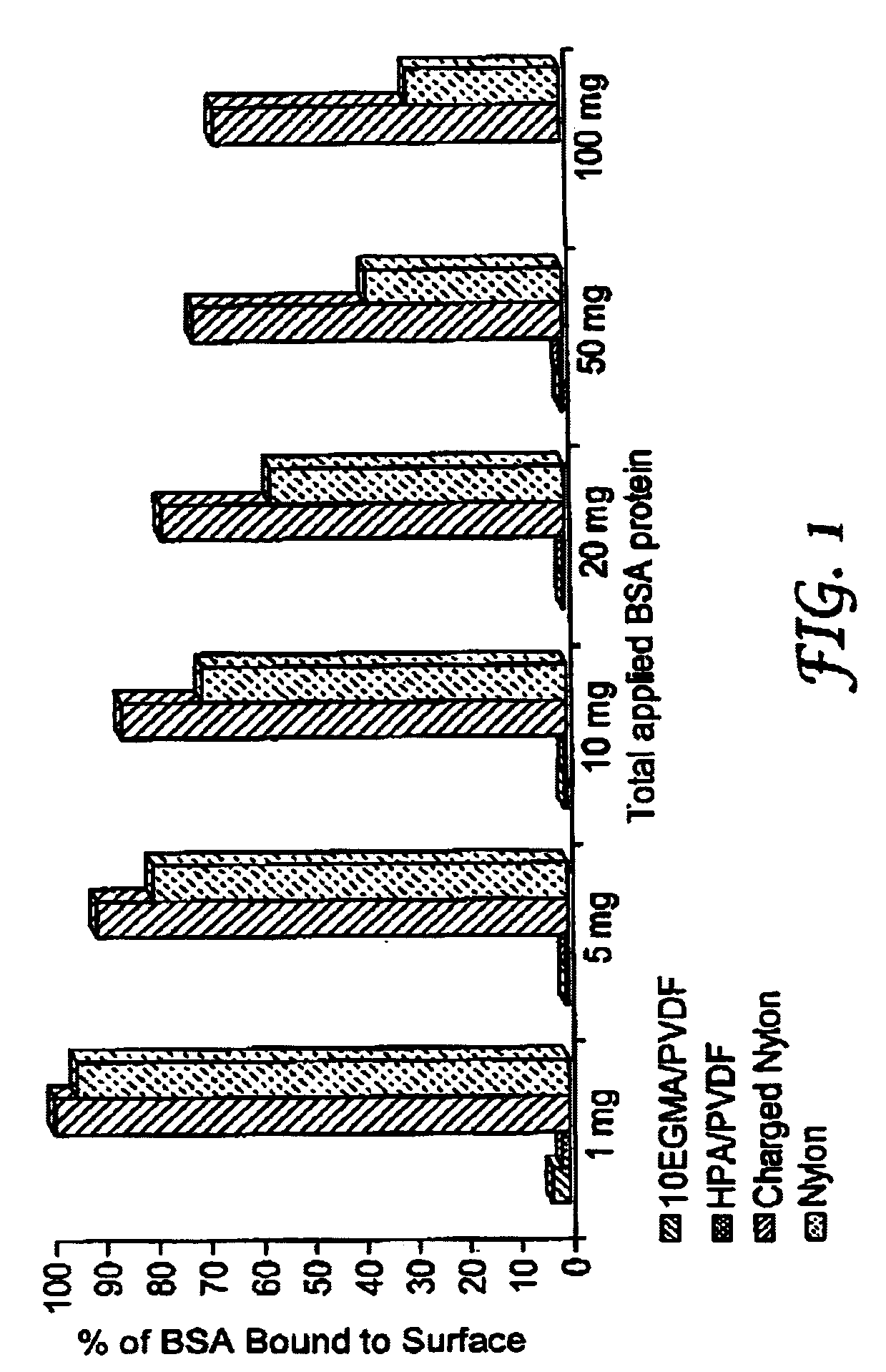

Hydrophilic membrane and process for making the same

InactiveUS7067058B2Practical and convenientEconomical and simpleMembranesSemi-permeable membranesDiacrylate esterEthylene oxide

A process for imparting hydrophilic properties to a polymeric membrane by exposing the membrane to an acrylate monomer containing hydrophilic segments, such as ethylene oxide, and a hydrophilic functional group, a diacrylate monomer containing hydrophilic functional groups, and an initiator for facilitating crosslinking and polymerization reactions.

Owner:3M INNOVATIVE PROPERTIES CO

Hydrogen generator

InactiveUS7323148B2Promotes generation of hydrogen gasAvoid accumulationSemi-permeable membranesMembranesHydrogenProcess engineering

A hydrogen generator capable of operating in any orientation and having no moving parts includes a catalyst retaining structure. The catalyst retaining structure is disposed in a housing and serves to separate the housing into a fuel holding portion and a hydrogen chamber. The catalyst retaining structure also includes one or more pores, each pore being in communication with the fuel holding and hydrogen chambers. A catalyst, that promotes the generation of hydrogen gas upon contact with the fuel, is disposed within the pores. The fuel enters the pores and thereupon generates hydrogen gas which passes into the hydrogen chamber. Contact of the fuel with the catalyst in the pores may be controlled and the position of the fuel-hydrogen interface within the pore may be moved so as to regulate the generation of hydrogen. The catalyst retaining structure can take different forms, including one or more hollow elongated members or plates, and may further incorporate hydrophobic and / or hydrophilic membranes.

Owner:SILICON VALLEY BANK

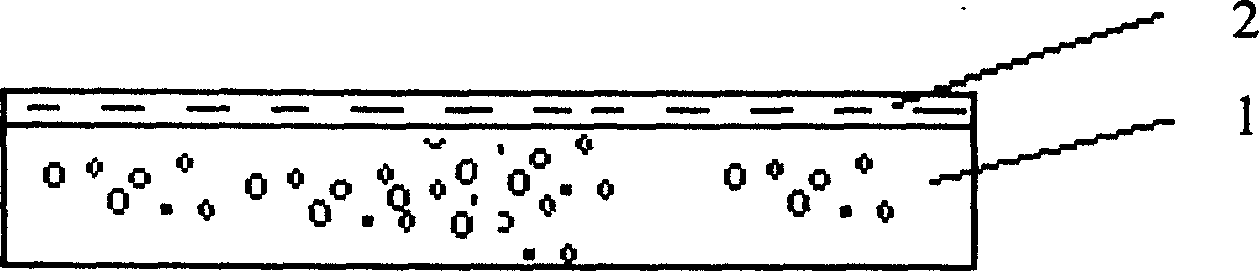

A hydrophilic-hydrophobic bipolar composite membrane and method for preparing same

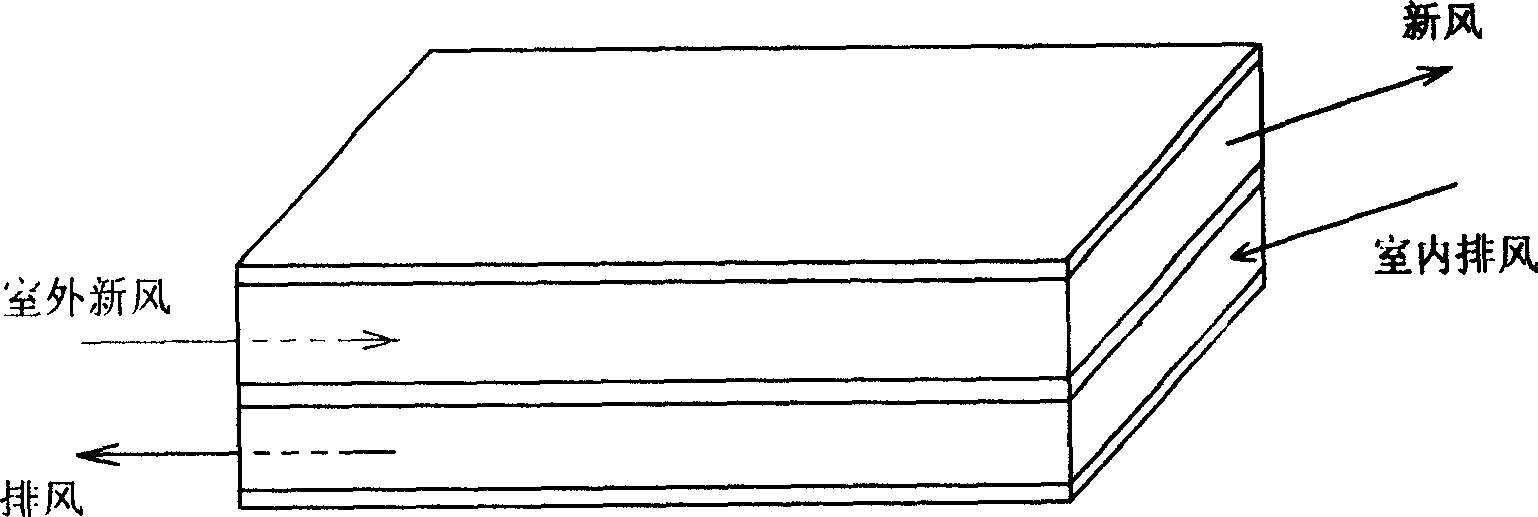

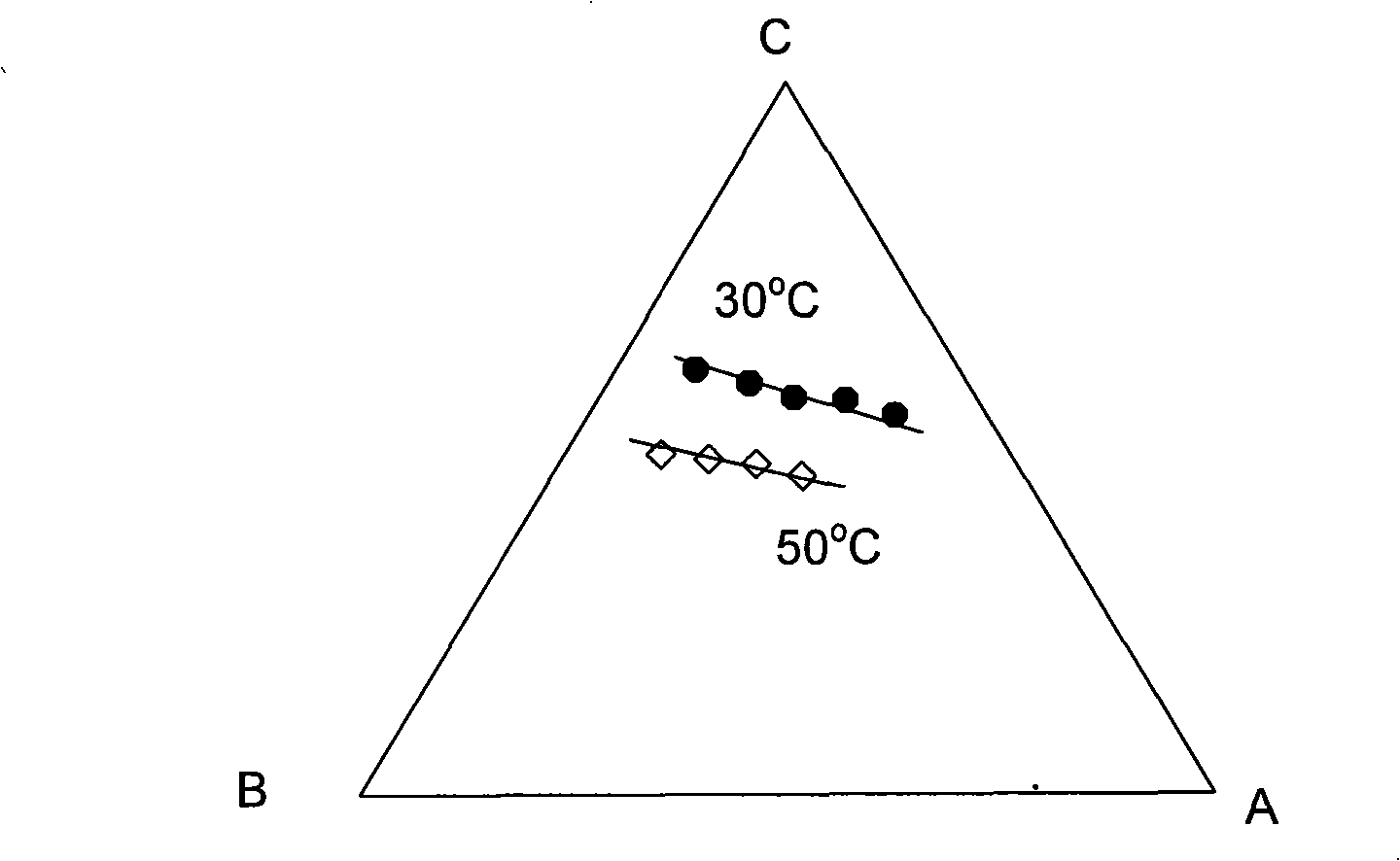

InactiveCN1864829ASpeed up penetrationReduced Diffusion ResistanceSemi-permeable membranesLighting and heating apparatusChemical industrySupporting system

The invention discloses a hydrophilic-hydrophobic bipolar complex membrane and the method for preparing the same. Said complex membrane comprises two layers, the bottom one is porous supporting system, and upper one is ultra-fine cerebral cortex; said porous supporting system is hydrophobic membrane and nonpolar, to avoid condensation of water vapour; ultra-fine membrane is hydrophilic membrane and polar, and LiCl with 1-5% by weight of main component can be doped to increase polarity; the thickness of porous supporting system is 30-100 um, and that of ultra-fine cerebral cortex is 5-20 um. The invention is characterized by simple process and low cost. The prepared bipolar complex membrane is characterized by good penetration property and gas selectivity, high intensity and wide application in water treatment, air conditioner engineering, energy, chemical industry, metallurgy and biochemical engineering. The product is especially suitable for air dehumidification and heat recycle of air cinditioner new gas.

Owner:SOUTH CHINA UNIV OF TECH

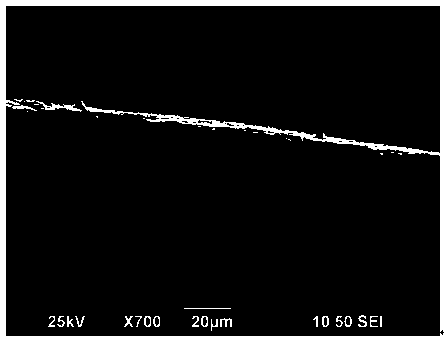

Dopamine-based method for improving surface hydrophilicity and biocompatibility of medical polyurethane material

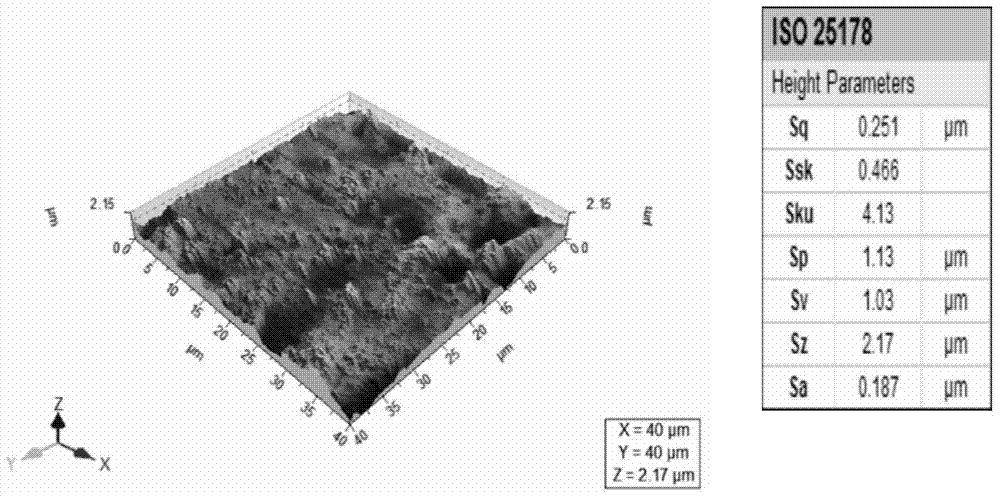

The invention discloses a dopamine-based method for improving surface hydrophilicity and biocompatibility of a medical polyurethane material. The method comprises the following steps: carrying out pretreatment on a medical polyurethane material by using dopamine so as to obtain a site with proper surface roughness and abundant reaction activity; putting the medical polyurethane material subjected to dopamine pretreatment into hydrophilic membrane concentrate, and carrying out heating reaction for 4-8 hours; and fully cleaning and drying the reaction product. According to the method disclosed by the invention, a layer of film is prepared on the material surface on the basis of the dopamine, and the prepared film has high hydrophily, the blood compatibility can be improved, the damage to tissue is reduced, the film has good stability, and low water contact angle and high hydrophily of a sample can be kept for a long period of time.

Owner:SOUTHEAST UNIV

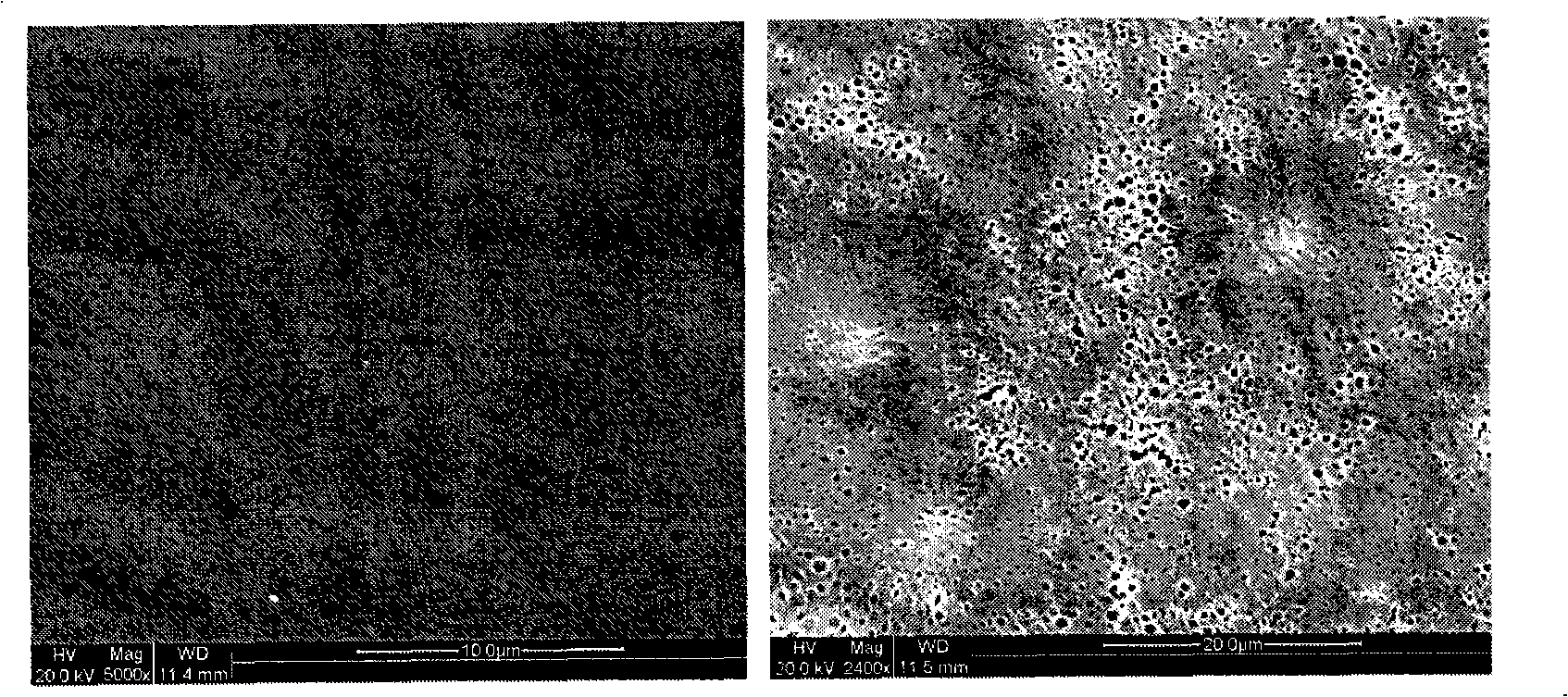

Non-crystallization permanent hydrophilic PVDF membrane material and preparation method thereof

InactiveCN101269302AReduce intensityReduce replacement frequencySemi-permeable membranesSolventCrystallinity

The invention relate to a non-crystallization type permanent hydrophilic polyvinylidene fluoride material and the preparation method thereof. The invention adopts crystalline non-crystallization type polyvinylidene fluoride macromolecules, mixes the polyvinylidene fluoride macromolecule with long chain hydrophilic or long chain hydrophilic and noncrystalline hydrophobic macromolecules; thus, the polyvinylidene fluoride macromolecules and water-soluble long chain macromolecules physical cross-linking are formed in polar excellent solvent, and liquid-liquid phase separation is realized via adding micromolecule addictives and improving the temperature of coagulation bath at the same time to speed up the phase separation of the macromolecules; after treatment, the permanent hydrophilic membrane material is obtained, the membrane material is mainly formed by amorphous macromolecule material, the crystallinity of the material is 0 to 0.4; the water contact angle is 0 to 50 degrees with permanent hydrophilicity.

Owner:南京奥特高科技有限公司

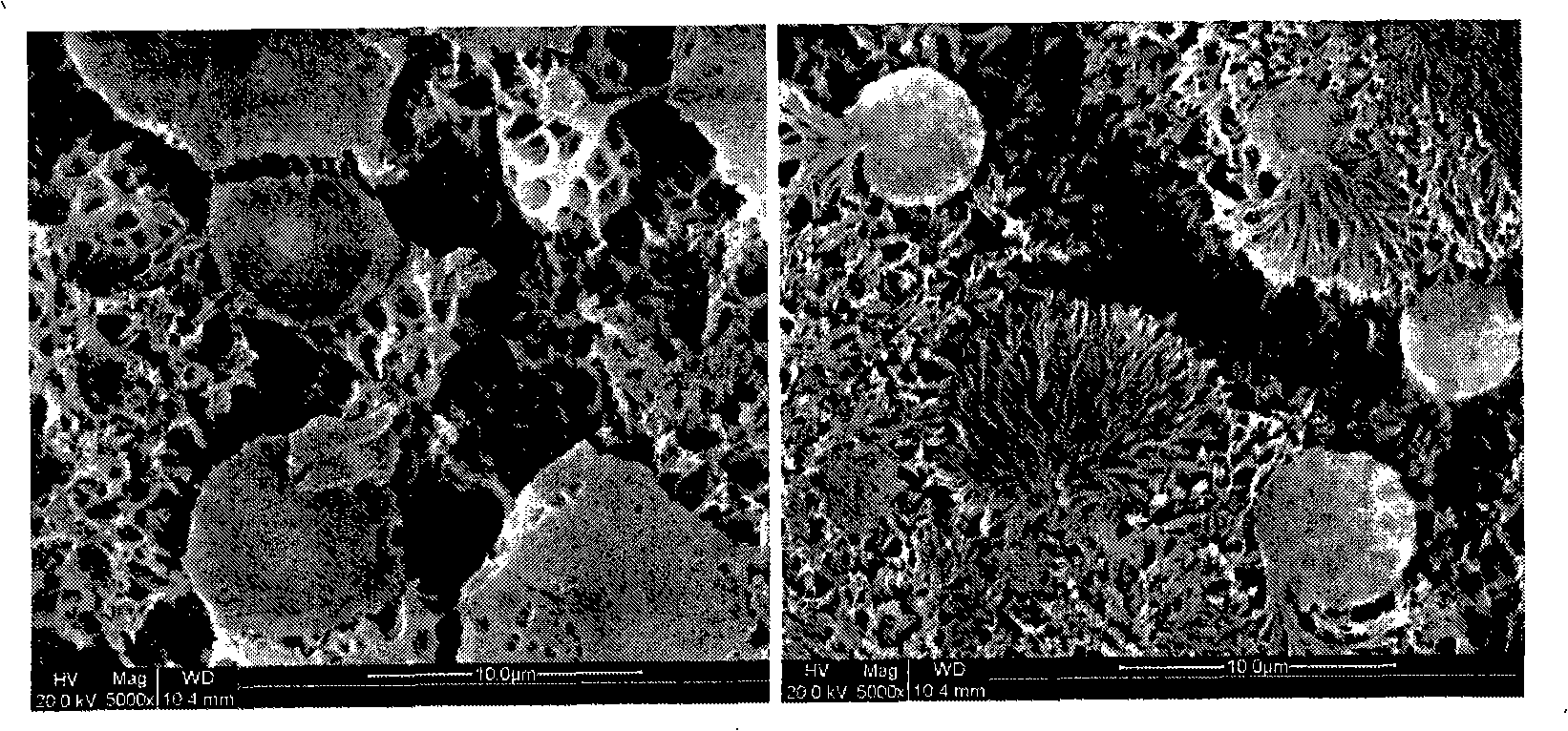

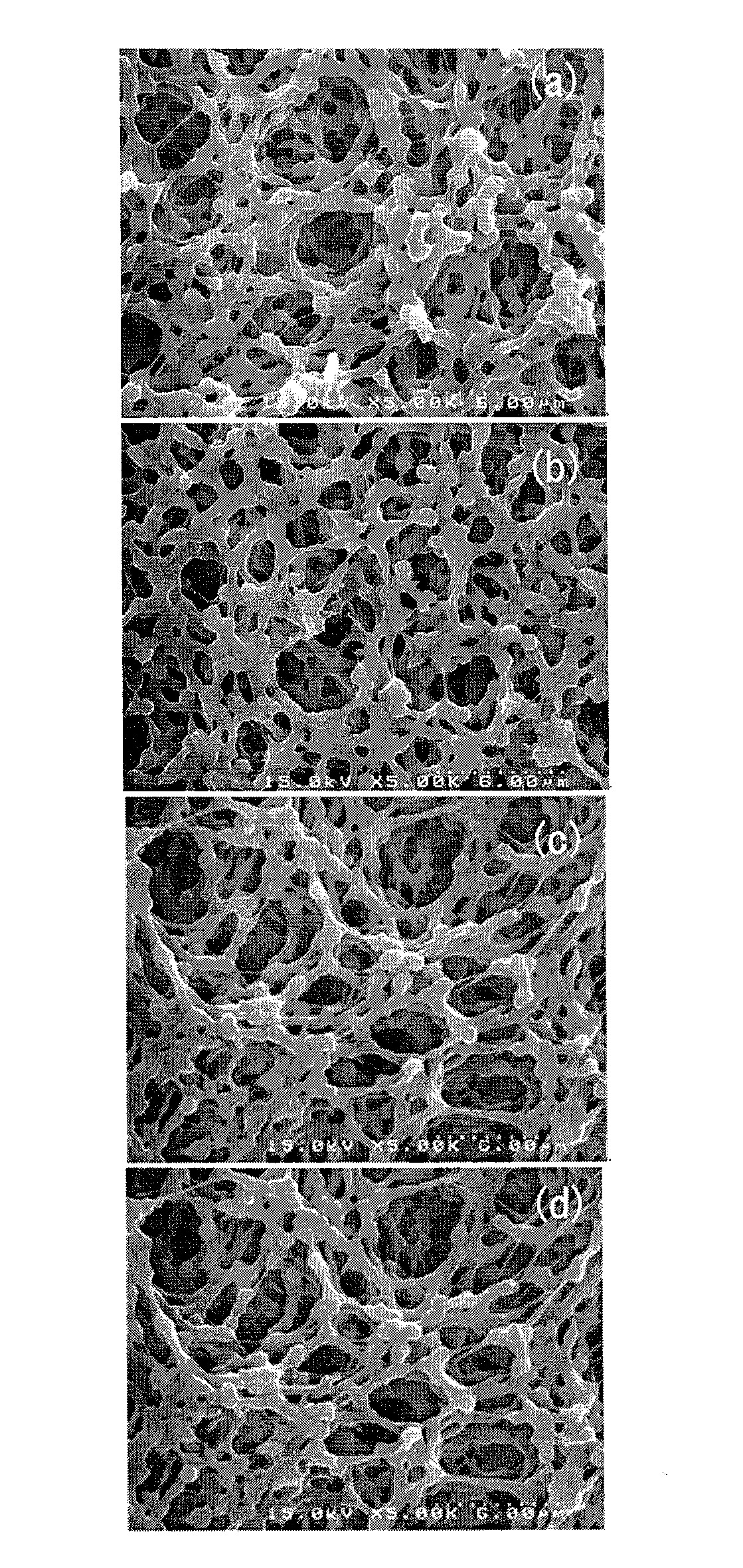

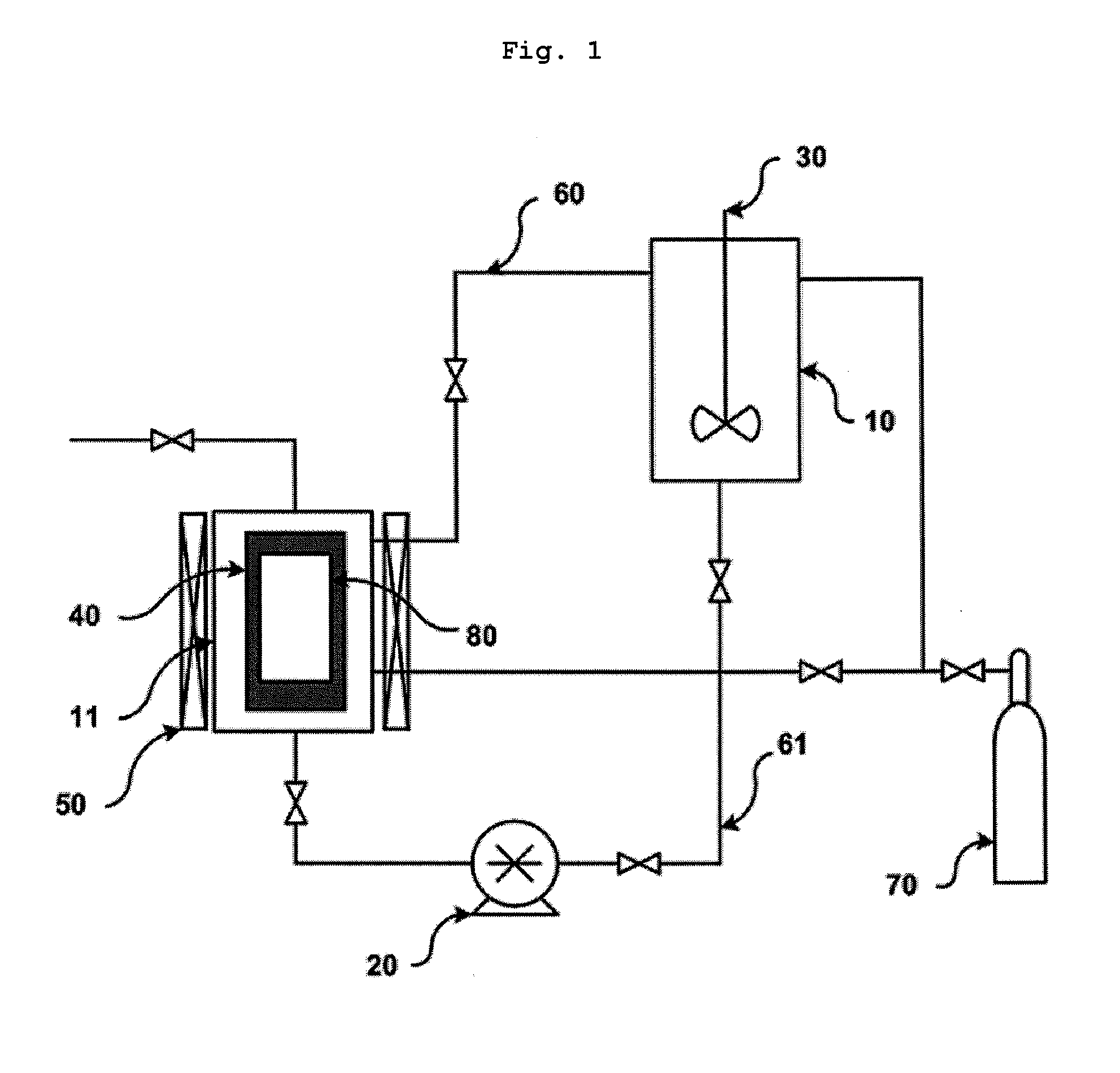

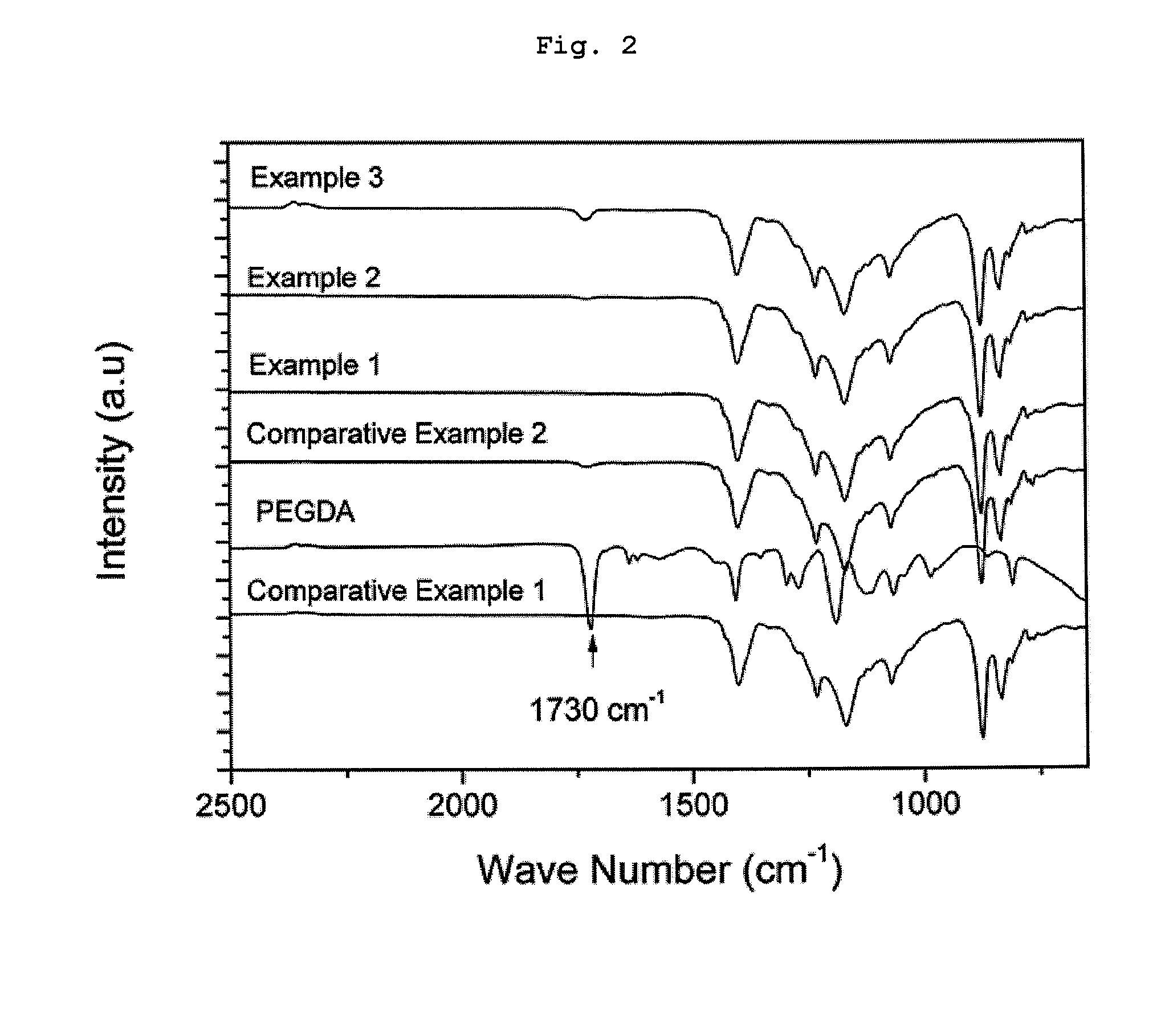

Method of manufacturing hydrophilic membrane having improved antifouling property and hydrophilic membrane manufactured by the method

InactiveUS20110253621A1Maintain good propertiesHigh permeation fluxMembranesSemi-permeable membranesCross-linkHigh pressure

A method of manufacturing a hydrophilic membrane and hydrophilic membranes having improved antifouling property using a supercritical fluid or a subcritical fluid. The method involves combining a coating solution from a hydrophilic group-containing monomer, an initiator, a cross-linking agent and a supercritical fluid or subcritical fluid in a high pressure solution vessel and transferring the coating solution to a membrane in a high pressure coating vessel, coating the surfaces and micropores of the membranes through cross-linking polymerization reactions. Non-reacted coating material is returned to the high pressure solution vessel. The membranes are removed from the coating vessel, cleaned and dried. The hydrophilic membrane manufactured by the present invention is excellent in properties of hydrophobic membranes such as thermal stability, chemical stability and mechanical strength, and surfaces and micropores of the membranes are uniformly coated.

Owner:KOREA INST OF SCI & TECH

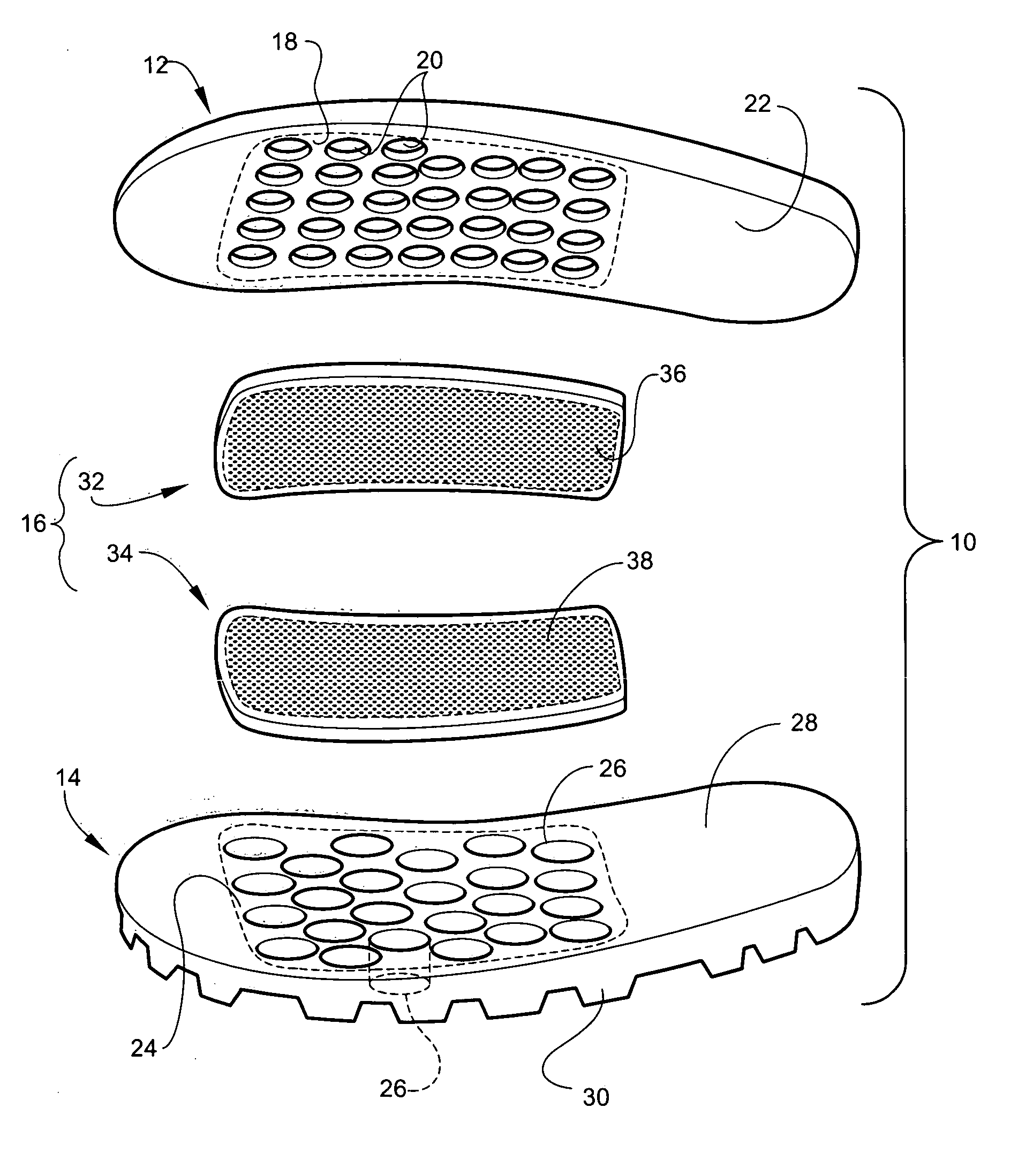

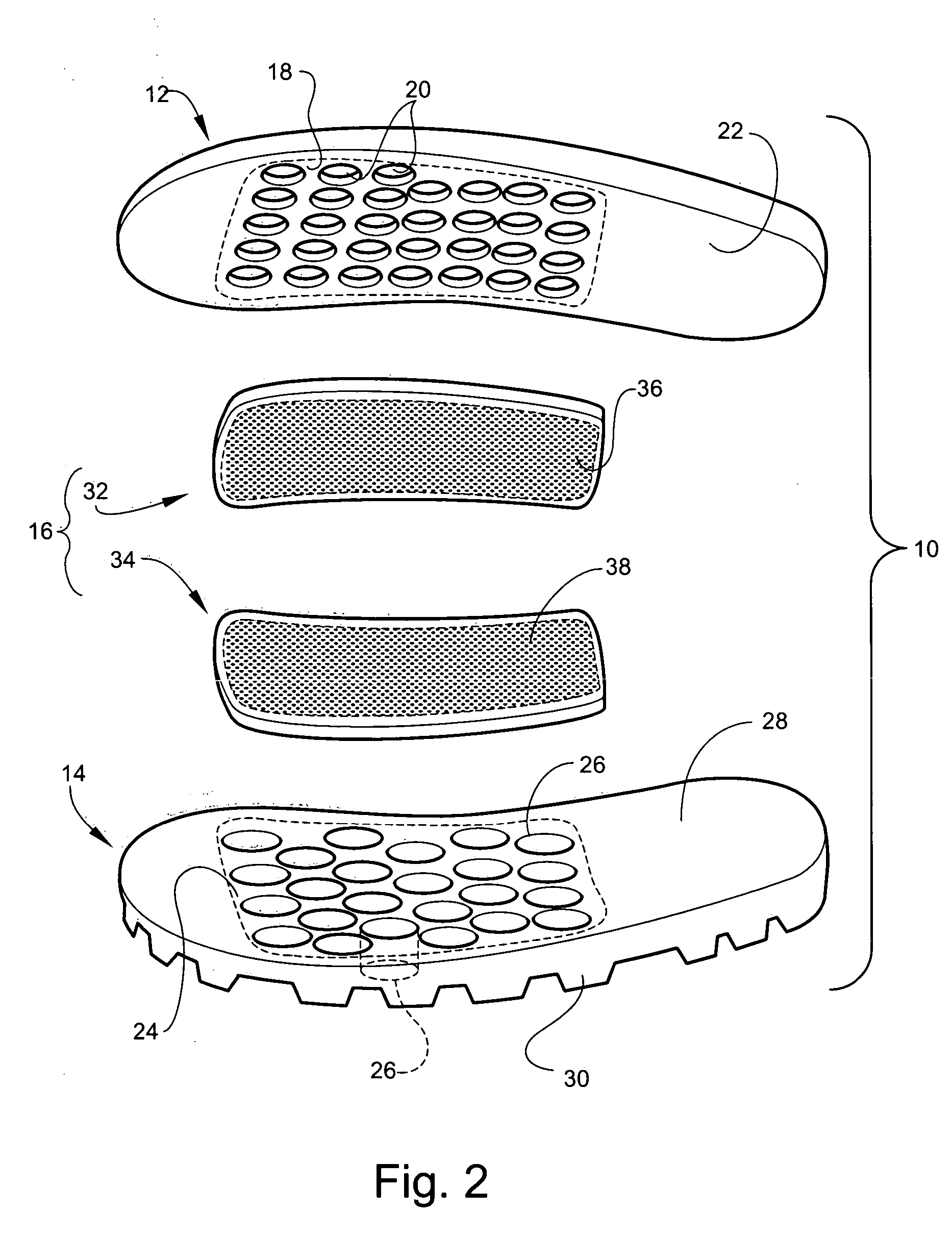

Breathable sole structure for footwear

The instant invention is a breathable sole structure for footwear. The footwear sole structure includes an insole, an outsole, and a functional membrane system. The insole has an area with a plurality of holes therethrough. The outsole has an area with a plurality of holes therethrough. The functional membrane system has a microporous hydrophilic membrane and a microporous hydrophobic membrane. The insole and the outsole are bonded to each other, so that the functional membrane system is sandwiched therebetween; and furthermore, the functional membrane system is juxtaposed to said areas.

Owner:CELGARD LLC

Preparation method for microporous membrane having multi-scale gradient micro-structure surface

ActiveCN103611437APlay the role of inner support reinforcementControllable areaSemi-permeable membranesMicro structureUltrafiltration

The present invention relates to a preparation method for a microporous membrane having a multi-scale gradient micro-structure surface. The method comprises: fixing a screen mesh on the upper surface of a rough flexible substrate, coating a polymer solution layer with a thickness of 50-500 mum on the upper surface of the screen mesh at a constant speed, curing, washing, and carrying out simple mechanical peeling to remove the rough flexible substrate to obtain the microporous membrane having the multi-scale gradient micro-structure surface. According to the present invention, the process of the method is simple, the membrane area can be controlled, continuous production can be achieved, mechanical properties of the membrane are high, and the membrane has super-hydrophobic or super-hydrophilic property, wherein the super-hydrophobic membrane has super-lipophilic property, and the super-hydrophilic membrane has super-oleophobic property under water and has super-hydrophobic property under oil; and the obtained membrane can be adopted to effectively separate various oil and water mixtures including nano-scale oil water emulsions, and can further be used in fields of self-cleaning ultrafiltration / microfiltration membrane sewage treatments, medical sterilization, food turbidity removal, sterilization, material separation, membrane distillation, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Microporous hydrophilic membrane

ActiveUS7459085B2Good removal effectHigh in quantityMembranesGas treatmentHydrophilizationPolymer science

A hydrophilic microporous membrane comprising a thermoplastic resin, having been subjected to hydrophilizing treatment and having a maximum pore size of 0 to 100 nm, wherein when 3 wt % bovine immunoglobulin having a monomer ratio of 80 wt % or more is filtered at a constant pressure of 0.3 MPa, an average permeation rate (liter / m2 / h) for 5 minutes from the start of filtration (briefly referred to as globulin permeation rate A) satisfies the following formula (1) and an average permeation rate (liter / m2 / h) for 5 minutes from the time point of 55 minutes after the start of filtration (briefly referred to as globulin permeation rate B) satisfies the following formula (2):Globulin permeation rateA>0.0015 ×maximum pore size (nm)2.75 (1)Globulin permeation rate B / globulin permeation rate A>0.2 . (2)

Owner:ASAHI KASEI MEDICAL CO LTD

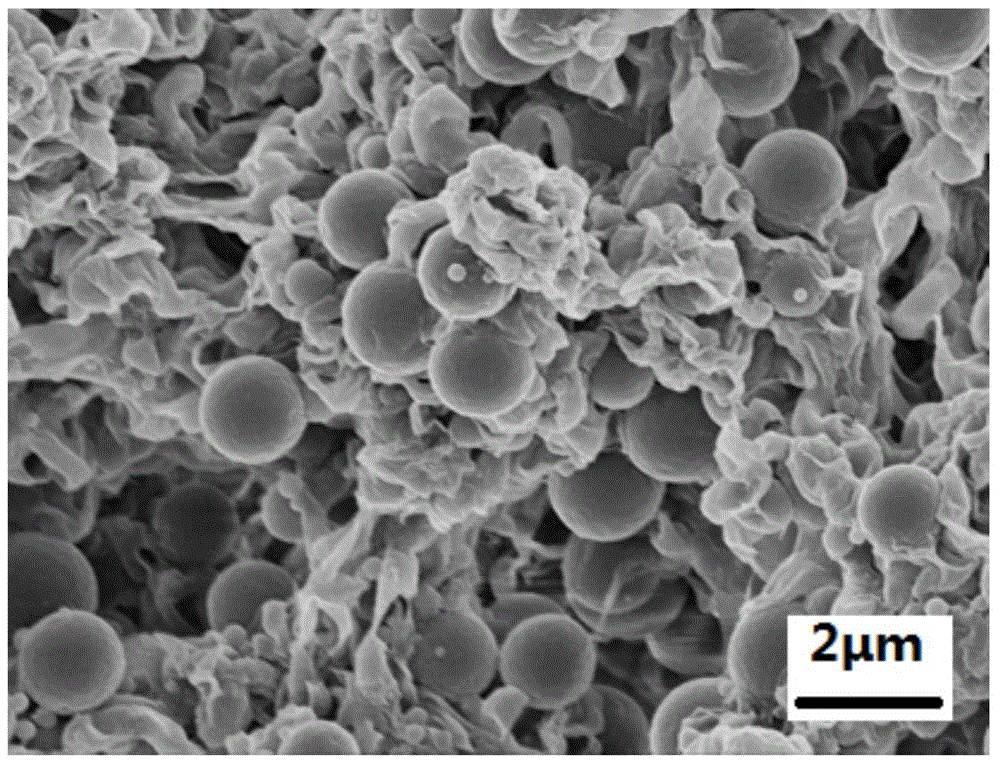

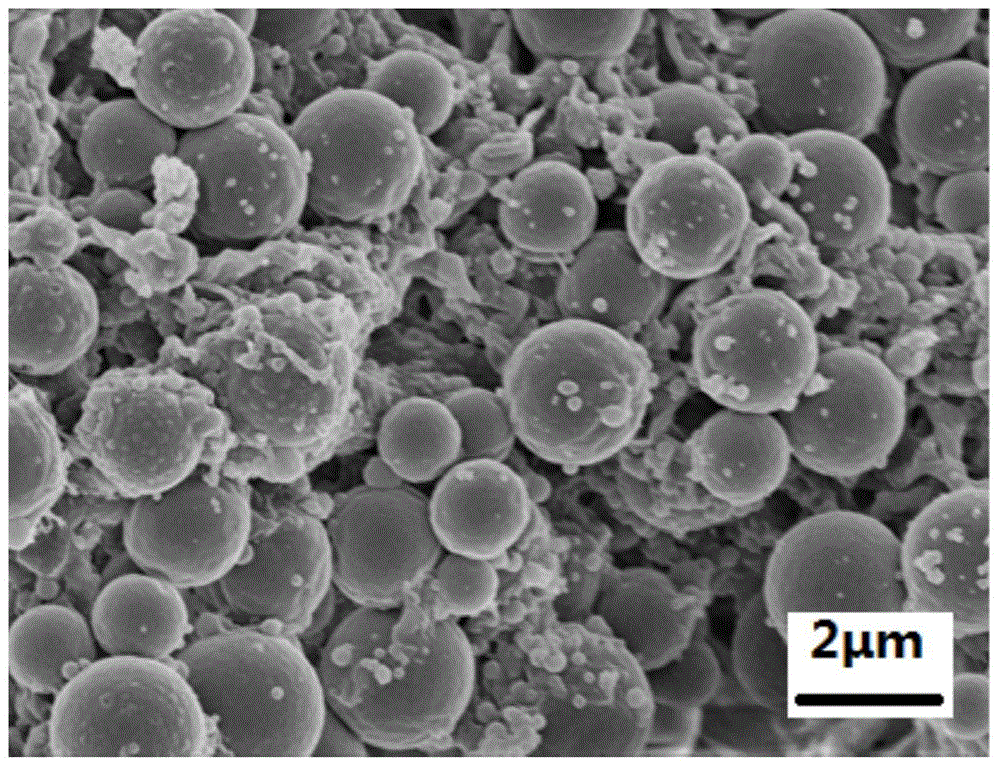

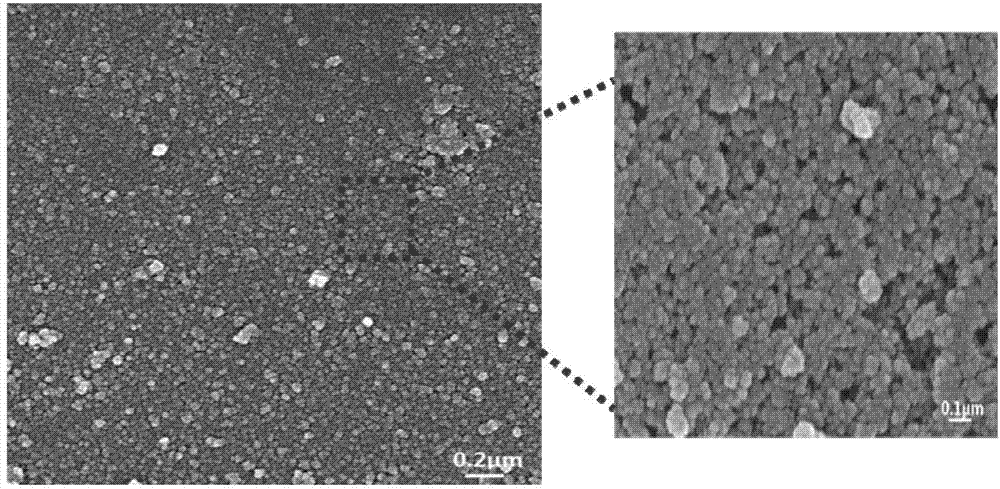

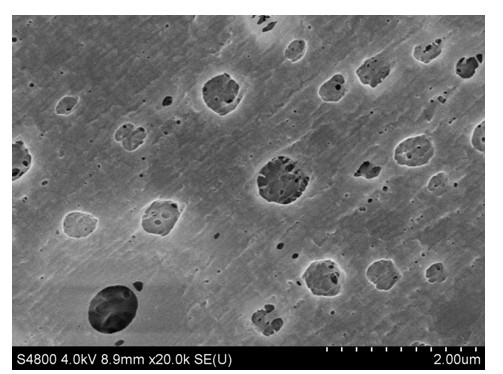

Polyvinylidene fluoride super-hydrophilic composite porous membrane and preparation method of silver-loaded super-hydrophilic membrane thereof

The invention discloses a polyvinylidene fluoride super-hydrophilic composite porous membrane and a preparation method of a silver-loaded super-hydrophilic membrane thereof. A blending method and a phase to membrane conversion method are adopted, a micro-nano-level rough surface is formed while the phase conversion is performed between a phase-splitting material and a main material, then the membrane material is soaked in a solution containing dopa compounds to perform surface modification, the surface is modified through the adoption of features of oxidation, auto-agglutination, crosslinking and adhesion of the dopa compounds to prepare the super-hydrophilic membrane, the weak reducibility of polydopa or polydopamine is further used for reducing silver ions, and finally the silver-loaded super-hydrophilic membrane surface is prepared through the reaction of the dopa compounds. The super-hydrophilic surface formed by the method and the silver-loaded super-hydrophilic surface thereof have durable super-hydrophilic performance and antibacterial property.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

Reverse osmosis membrane and preparation method thereof

ActiveCN103071405AExcellent salt rejectionImprove uniformitySemi-permeable membranesGeneral water supply conservationDesalinationReverse osmosis

The invention discloses a reverse osmosis membrane and a preparation method thereof. The reverse osmosis membrane comprises a non-woven support layer, a polysulfone base membrane layer, a polyamide desalination layer and a transition layer, wherein the non-woven support layer is coated with the polysulfone base membrane layer; the transition layer is a hydrophilic membrane layer and is arranged between the polysulfone base membrane layer and the polyamide desalination layer. According to the reverse osmosis membrane, as the hydrophilic transition layer is inserted between the polysulfone base membrane layer and the polyamide desalination layer, the hydrophilic transition layer improves dispersion uniformity of a polyamine solution on the surface of the polysulfone base membrane layer, a binding force of the hydrophilic polyamide desalination layer with the polysulfone base membrane layer is increased greatly, the reverse osmosis membrane is high in desalinization ratio, uniformity and water flux, and long in service life, and can bear at least 0.5 MPa backpressure, and significantly lower engineering cost and manufacturing cost.

Owner:BEIJING ORIGIN WATER FILM TECH

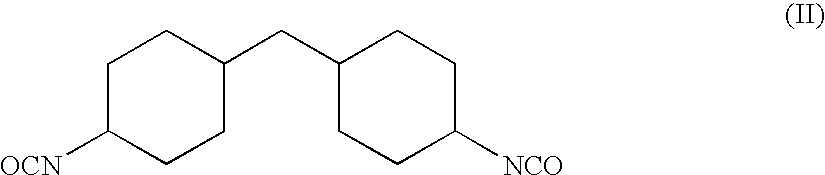

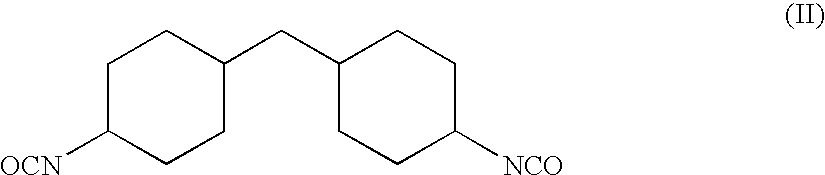

Hydrophilic membrane and associated method

InactiveUS7381331B2Reduce and minimize residual stressMembranesSolid electrolytesHydrophilic membranePolymer

A membrane is provided, which may include a microporous base membrane; and a cross-linkable coating disposed on a surface of the membrane. The coating may include polyvinyl nucleophilic polymer and a urethane or a blocked isocyanate. The coating may be cross-linked. Also provided is a method of making the membrane.

Owner:BHA ALTAIR

Preparation method of superhydrophilic/superhydrophobic composite nanofiltration membrane

ActiveCN104759214ARealize roughness controlAchieving cut-off separationSemi-permeable membranesPolyelectrolyteOrganic solvent

The invention relates to a preparation method of a superhydrophilic / superhydrophobic composite nanofiltration membrane, belonging to the technical field of membrane separation. The preparation method comprises the following steps: putting a pretreated base membrane in a polycation electrolyte solution, washing with water, putting in a polyanion electrolyte solution, washing with water, and alternately assembling many times to form a predissociation layer; putting the membrane containing the predissociation layer in a soluble calcium salt polycation electrolyte solution, taking out, washing with water, putting in a soluble-silicate-containing polyanion electrolyte solution, taking out, washing with water, and repeating many times to obtain a polyelectrolyte / calcium silicate hydrate superhydrophilic composite nanofiltration membrane; and putting the superhydrophilic membrane in a fluorosilane ethanol water solution, immersing for 40-90 minutes, flushing with deionized water, and drying and solidifying in a drying oven. The superhydrophilic nanofiltration membrane can implement entrapping separation on the water-soluble dye molecules, and the superhydrophobic nanofiltration membrane can implement entrapping separation on organic solvent dye molecules.

Owner:陕西禹慧智通环保科技有限公司

Polyvinylidene fluoride hollow fiber ultrafiltration membrane with permanent hydrophilcity and preparation method thereof

The invention discloses a polyvinylidene fluoride hollow fiber ultrafiltration membrane with permanent hydrophilcity and a preparation method thereof. The preparation method comprises the following steps of: sequentially adding 13 wt% to 25 wt% of polyvinylidene fluoride, 8 wt% to 16 wt% of additives and 0.02 wt% to 3.0 wt% of surface active agents and solvents in a dissolving tank, and then stirring for dissolving for 2 to 16 hours at 15 to 90 DEG C to the fully uniform state to prepare that initial membrane casting liquid; sequentially adding initiating agents accounting for 0.1 wt% to 3.5 wt% of polar monomers and the polar monomers accounting for 0.1 wt% to 5.0 wt% of the membrane casting liquid in the membrane casting liquid, and reacting for 1 to 12 hours at 15 to 90 DEG C to prepare hydrophilic membrane casting liquid; and preparing the hydrophilic hollow fiber ultrafiltration membrane by adopting the traditional dry-wet spinning technology. For the hydrophilic polyvinylidene fluoride hollow fiber ultrafiltration membrane prepared in the preparation method, the pure water permeability coefficient is greater than 230 L / m2*hr*0.1MPa, the retention rate of bovine serum albumin (67000MW) is greater than 95.0%, the breaking elongation rate of fibers is greater than 200%, and the fracture pressure is greater than 0.55 MPa. The polyvinylidene fluoride hollow fiber ultrafiltration membrane with permanent hydrophilcity is especially suitable for deep treatment and recycling of waste water, clarification and separation in the fields of biochemical engineering and medicament, and the like.

Owner:UNIV OF JINAN

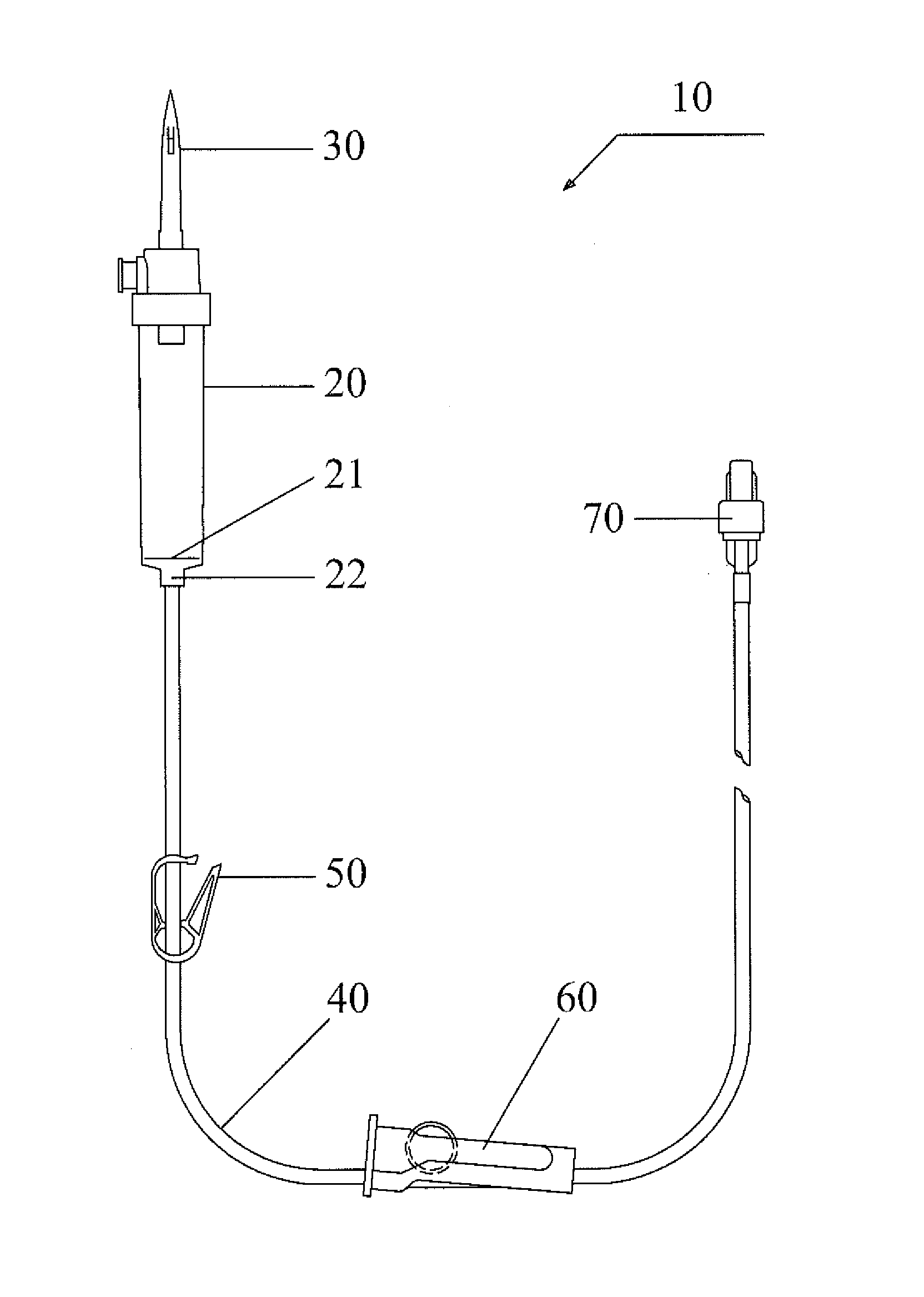

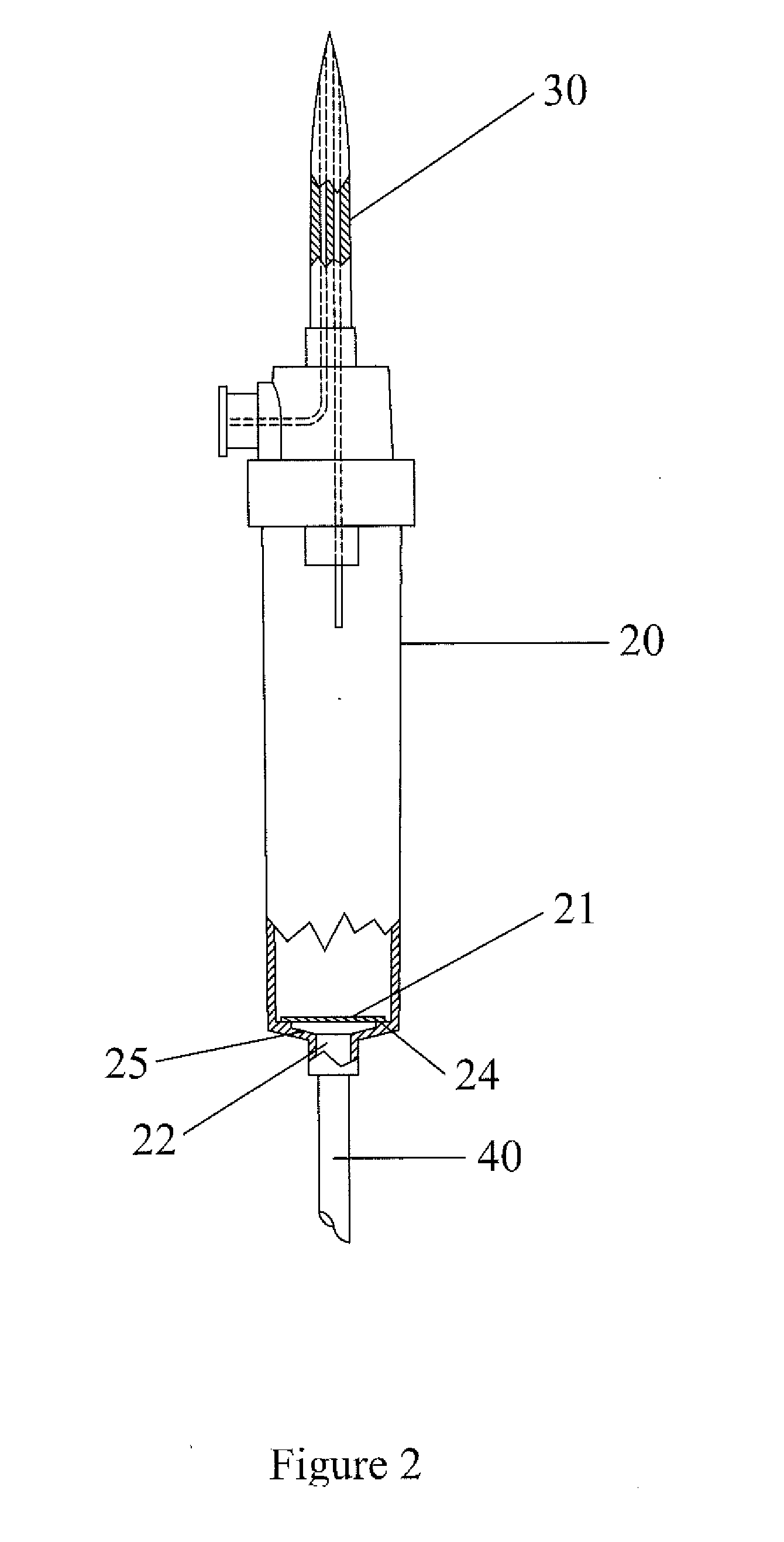

Infusion set that prevents air entry into infusion tubing

The present invention relates to an infusion set (10) that provides for continuous air free delivery of liquid to patients undergoing infusion procedures. In particular, the invention provides for an infusion set (10) that prevents air entering the infusion tubing (40) through the drip chamber (20) by using a hydrophilic membrane (21) having a defined wetting time and a defined mean pore size that will provide a defined bubble pressure point under gravitational pull to permit continuous air free infusion liquid flow there-through. The invention further provides for a clip (50) that once closed, no air bubble is able to pass through the hydrophilic membrane (21) due to the adjustment of the roller clamp (60) along the infusion tubing (40) thereby ensuring safe replacement of the infusion bottle during multiple infusion procedures, thus preventing the occurrence of air embolism in patients especially when the drip chamber (20) is empty.

Owner:WELFORD MFG M

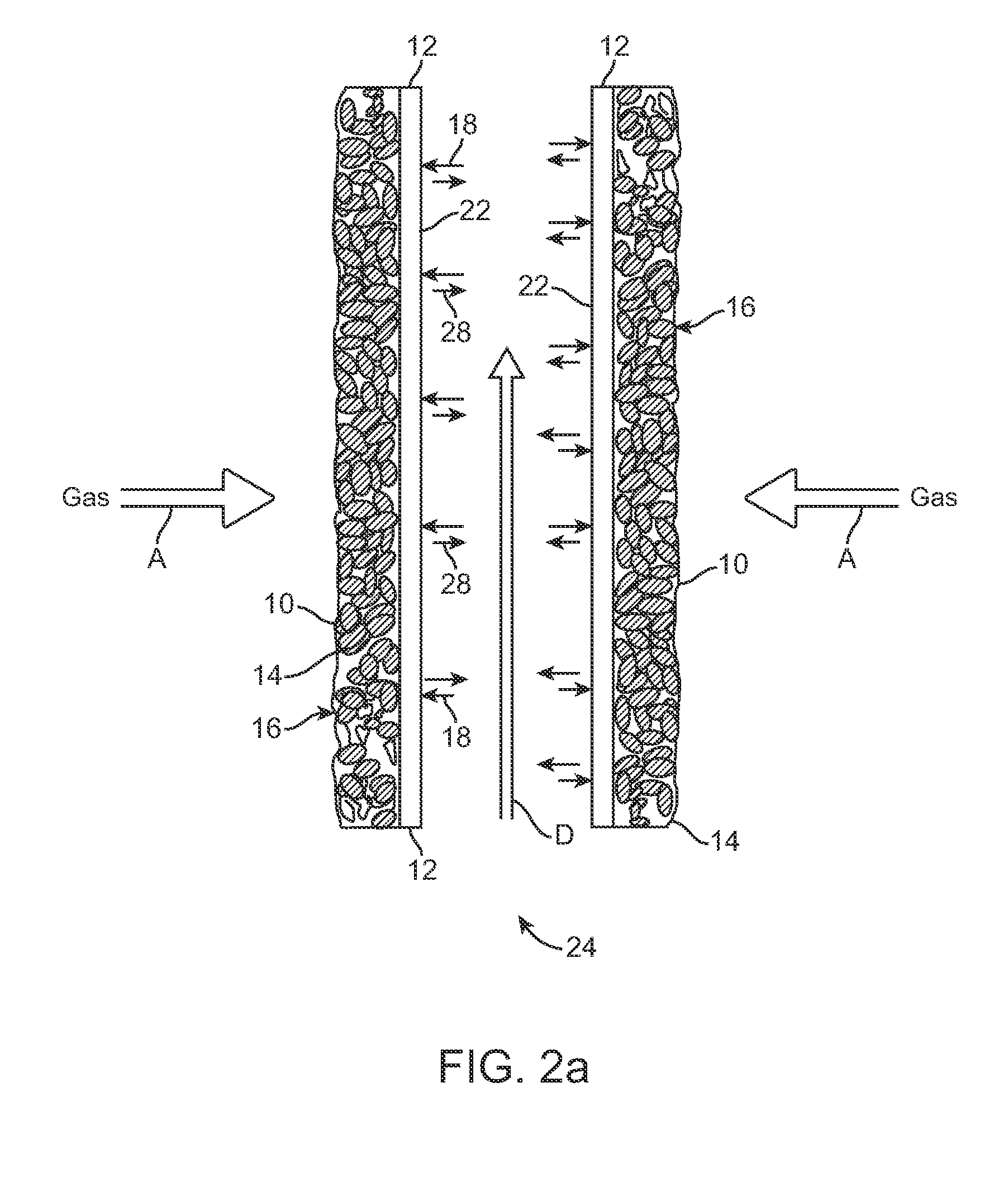

Method of conversion of syngas using microorganism on hydrophilic membrane

InactiveUS20100047886A1Increase productionPeriodic maintenanceBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid productSyngas

A stable system for producing liquid products such as ethanol, butanol and other chemicals from syngas components contacts CO or a mixture of CO2 and H2 with a hydrophilic membrane under anaerobic conditions and transfers these components into contact with microorganisms contained as a biofilm on the membrane. Maintaining the microorganisms as a biolayer on the surface of the membrane facilitates cleaning of the membrane surface that retains the biofilm. In addition the shell gas space that surrounds the membranes may be flooded to reduce or remove the biofilm. Agitation of the liquid, by for example the bubbling of gas in the surrounding shell space, can fully or partially remove the biofilm from the membrane.

Owner:SYNATA BIO INC

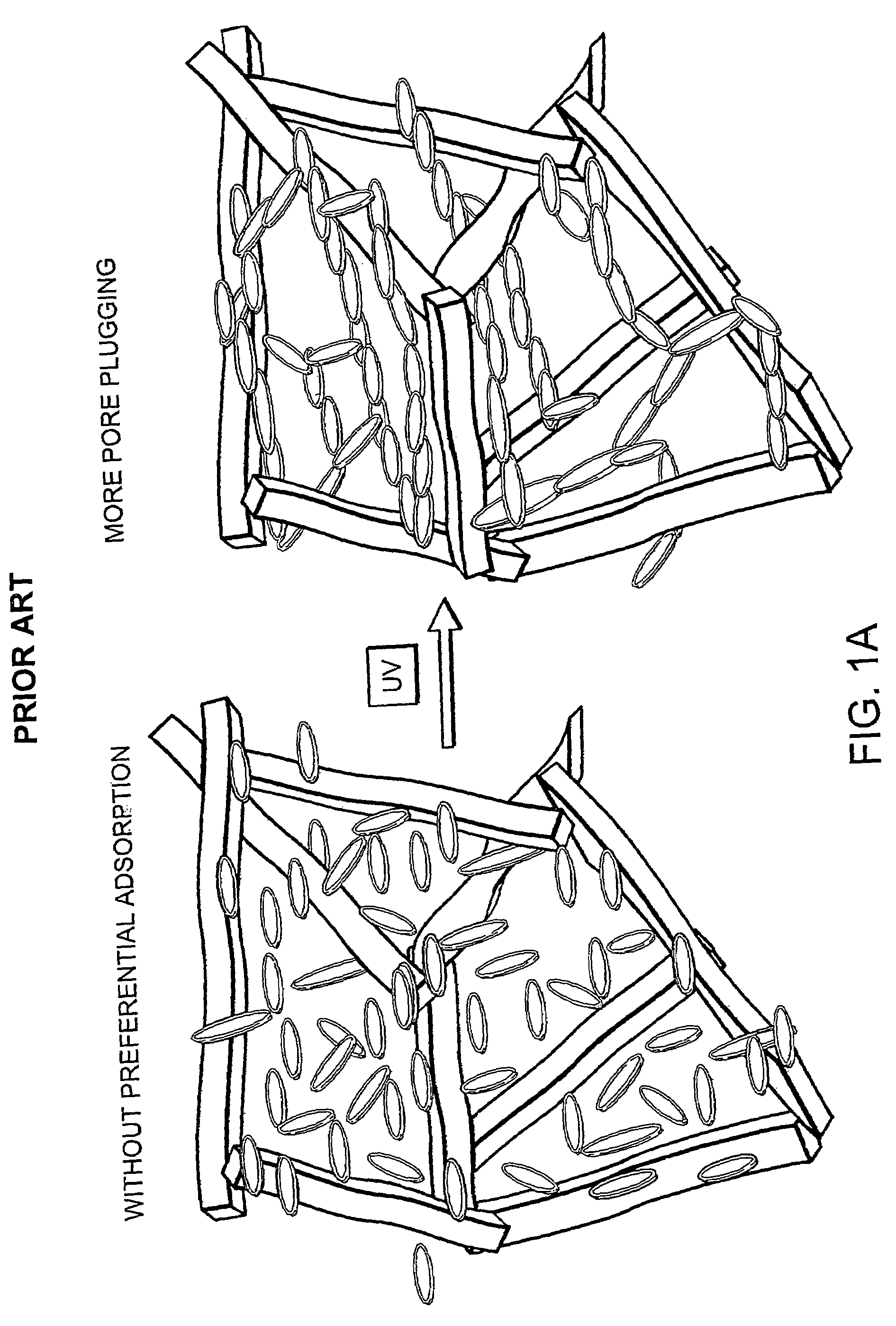

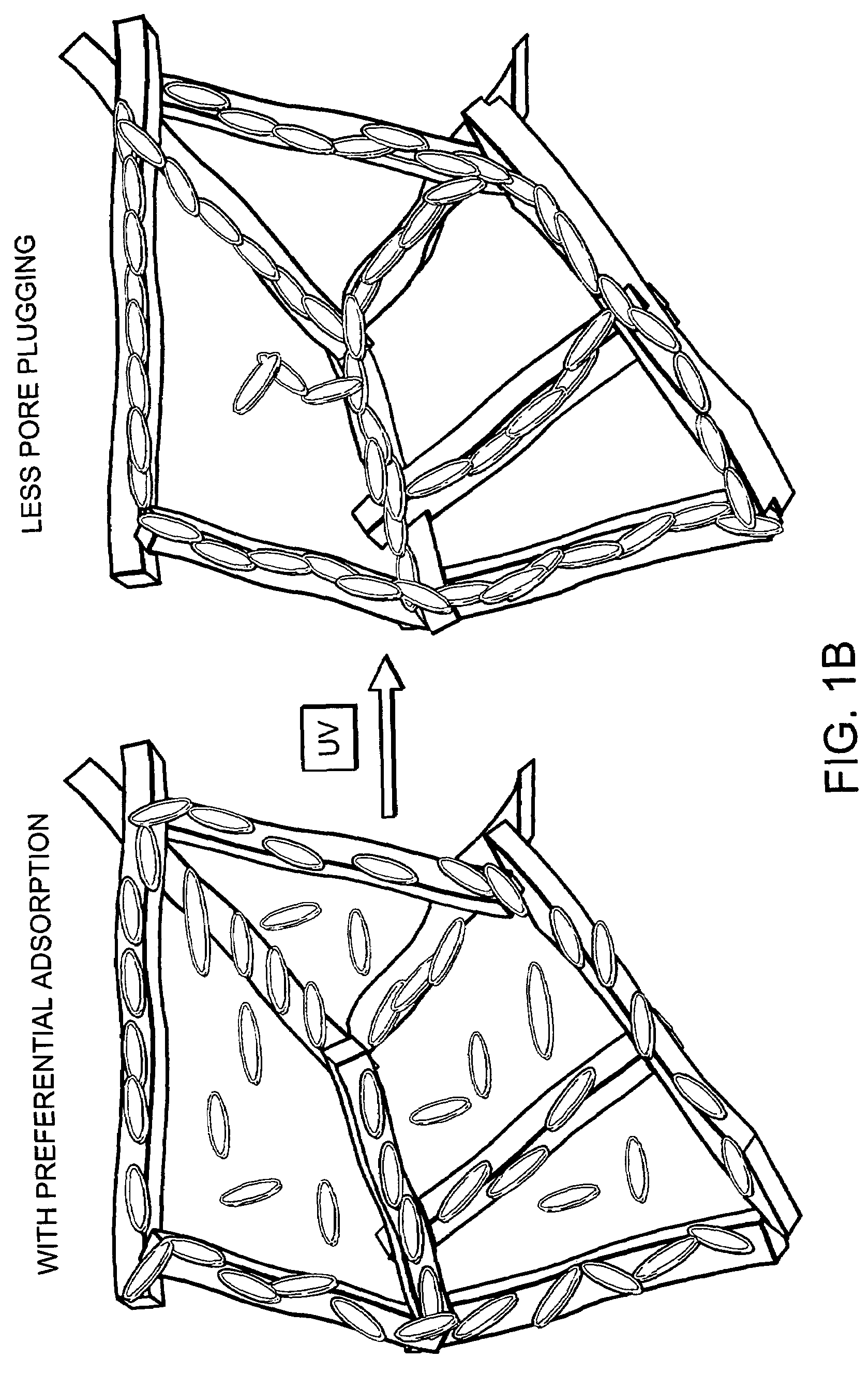

Porous composite membrane and method for making the same

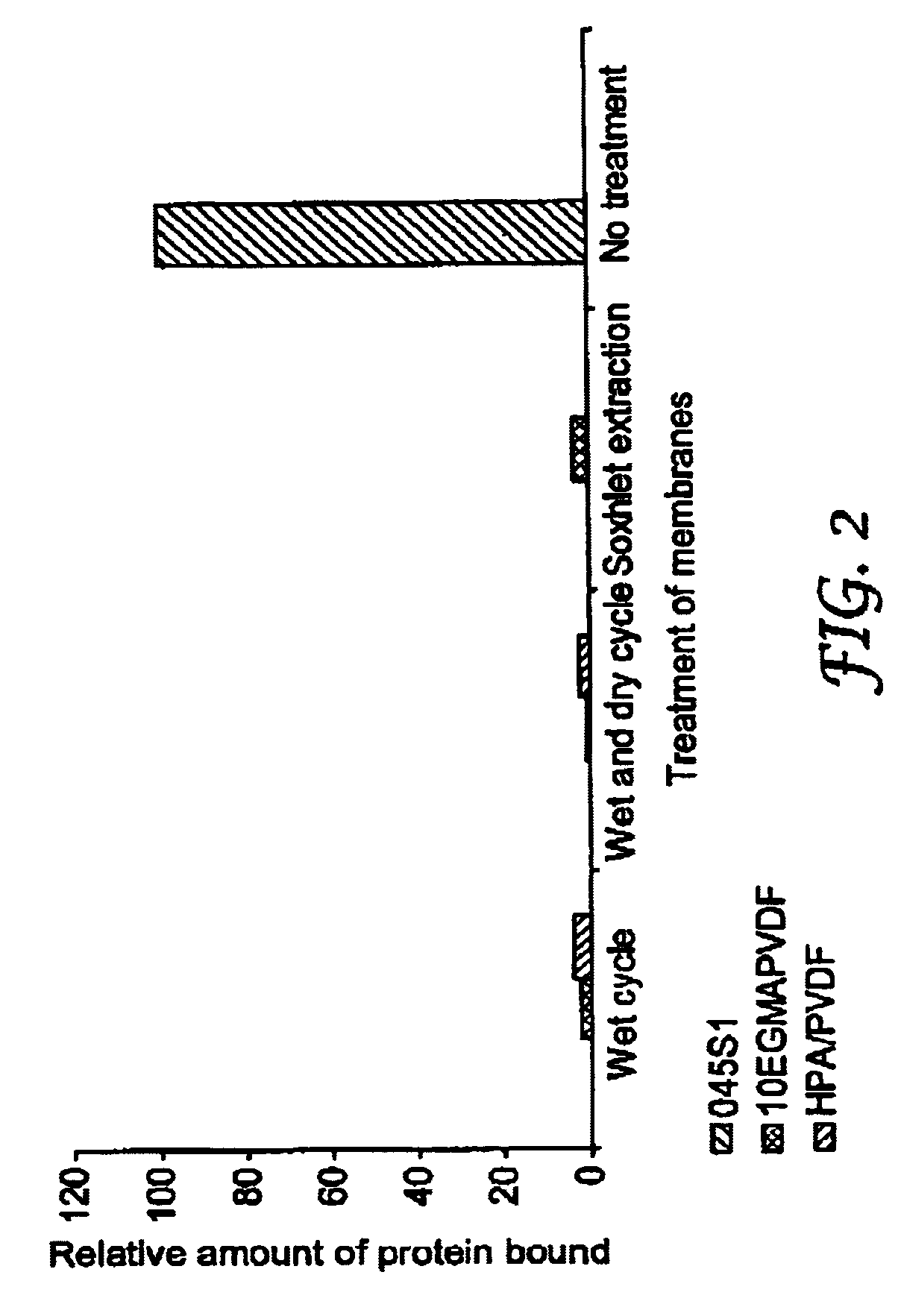

InactiveUS7628917B2Quantity maximizationSemi-permeable membranesMembranesPorous membraneHydrophilic membrane

The invention provides composite porous membranes comprising a porous hydrophobic substrate coated with difunctional surface-modifying molecules. The difunctional surface-modifying molecules provide a hydrophilic surface without forming branches of interconnected polymer molecules in the pores. The invention also provides a method for making composite porous membranes, such as a composite hydrophilic membrane with reduced concentration of surface modifying molecules required to coat a hydrophobic substrate.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

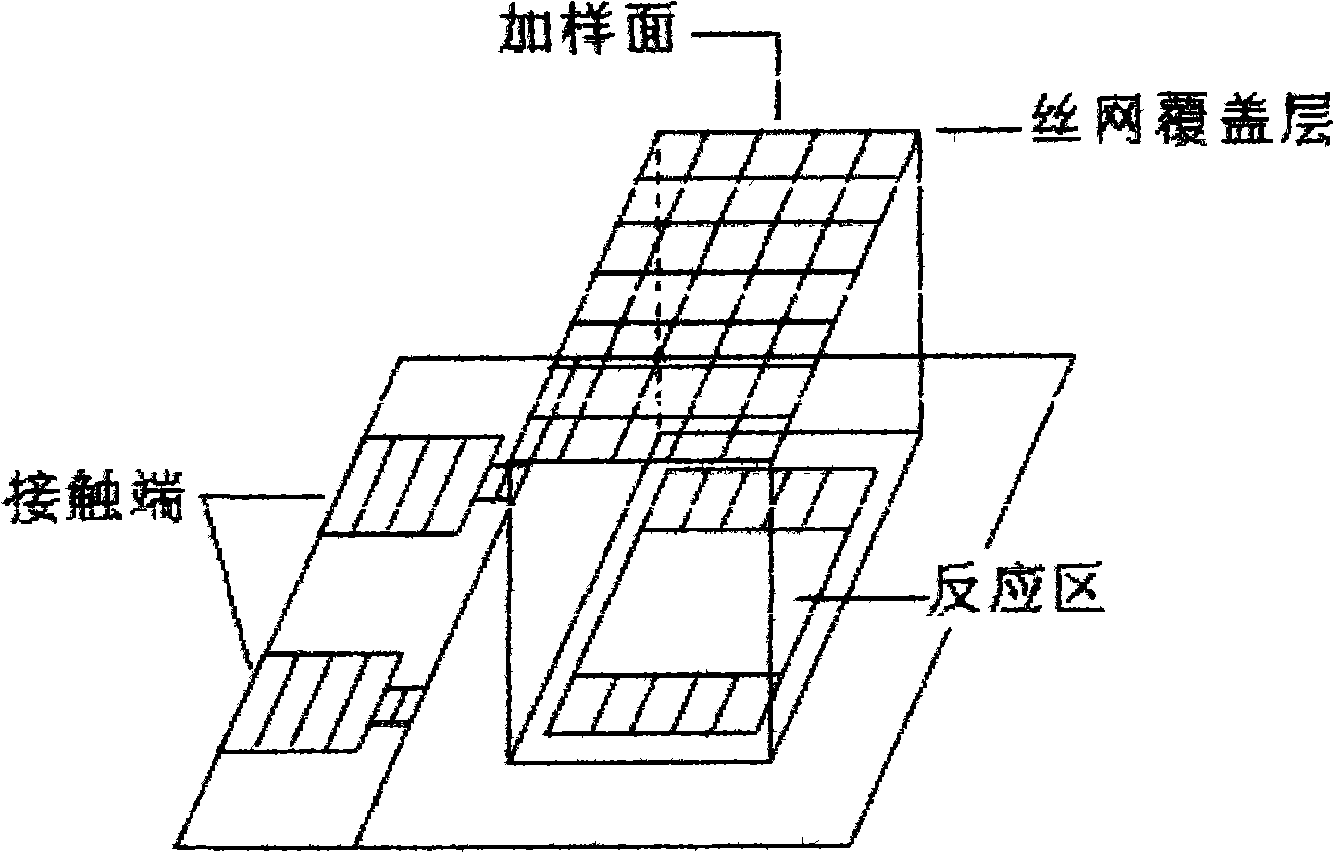

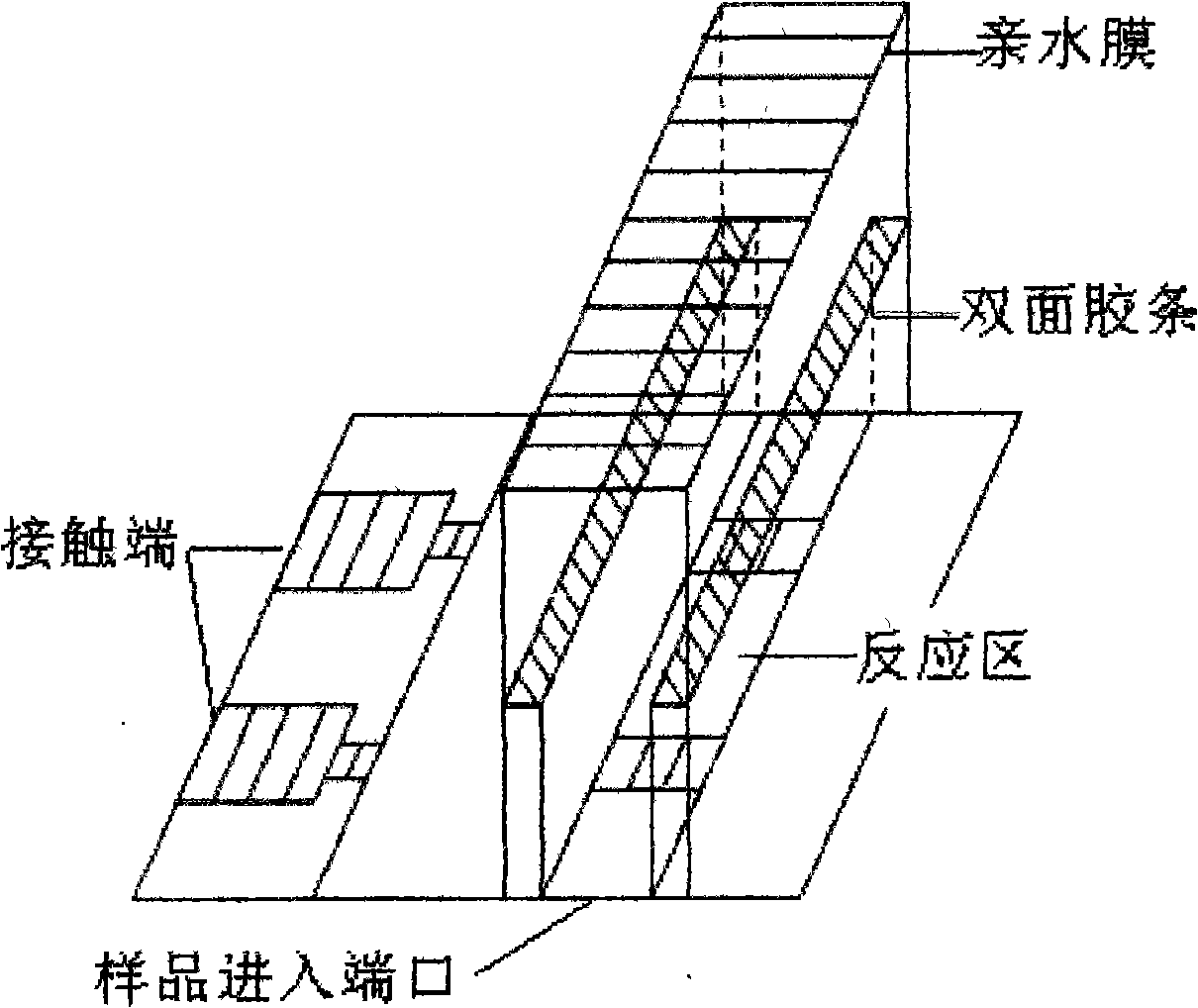

Siphoning type blood sugar test paper

InactiveCN101303358AGood repeatabilityHigh precisionMicrobiological testing/measurementMaterial analysis by electric/magnetic meansCarbon coatingSiphon

The invention discloses a siphon test paper, which pertains to the technical field of bio-sensor. The substrate of the test paper is printed with a working electrode, a reference electrode, an electrical circuit and an interface port connected with a read-out instrument. The working electrode and the reference electrode are composed of carbon coatings which are printed on the substrate at once and printed with a reaction working coating, the components by weight percentage include: 12 to 16 percent of enzyme, 15 to 20 percent of a conducting medium, 10 to 20 percent of an adhesive and 42 to 60 percent of buffer. Two sides of the reaction coating are bonded with a double-sided adhesive layer which is adhered with a hydrophilic membrane that is convenient for sucking sample blood and can limit the quantity of sample blood. The invention applies a screen printing method to produce the siphon glucose test paper at high speed and on large scale. The quality indexes of the test paper such as repeatability and precision further can limit the quantity of samples owning to the improvement of the sampling and introduction structure of the test paper, thereby improving quality and greatly reducing production cost. Raw materials applied can be obtained from various resources, processing is simple, technique maneuverability is strong and the test paper is suitable for large scale industrial production. Once the test paper of the invention sucks human blood, results can be read out conveniently and visually from a corresponding matching testing instrument.

Owner:胡军

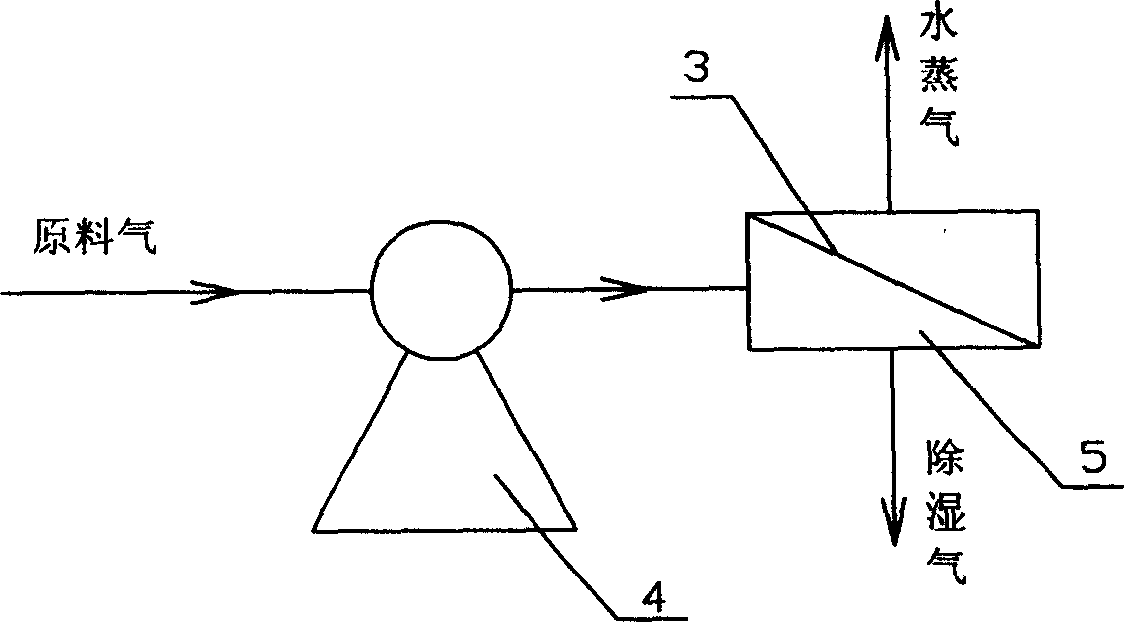

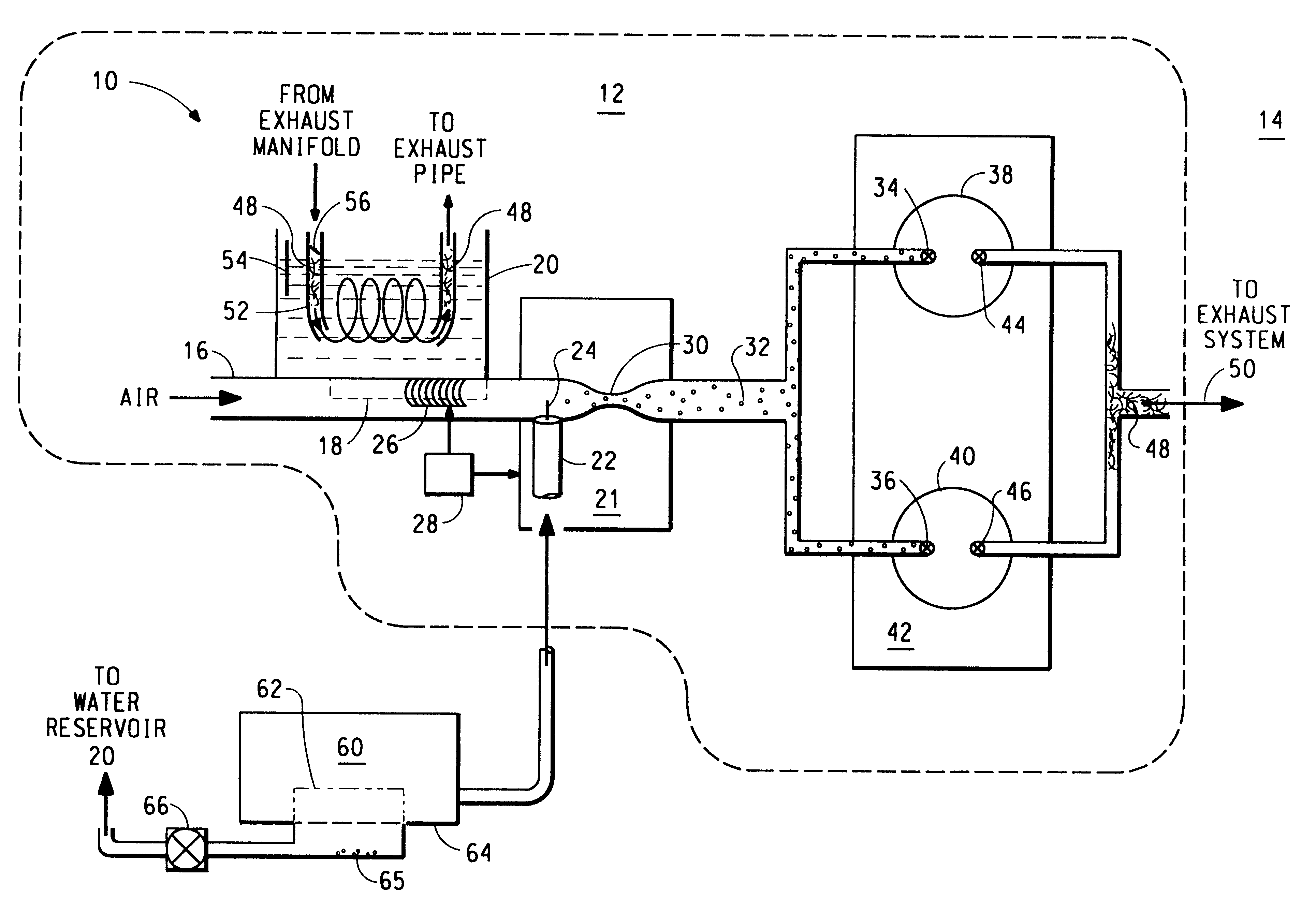

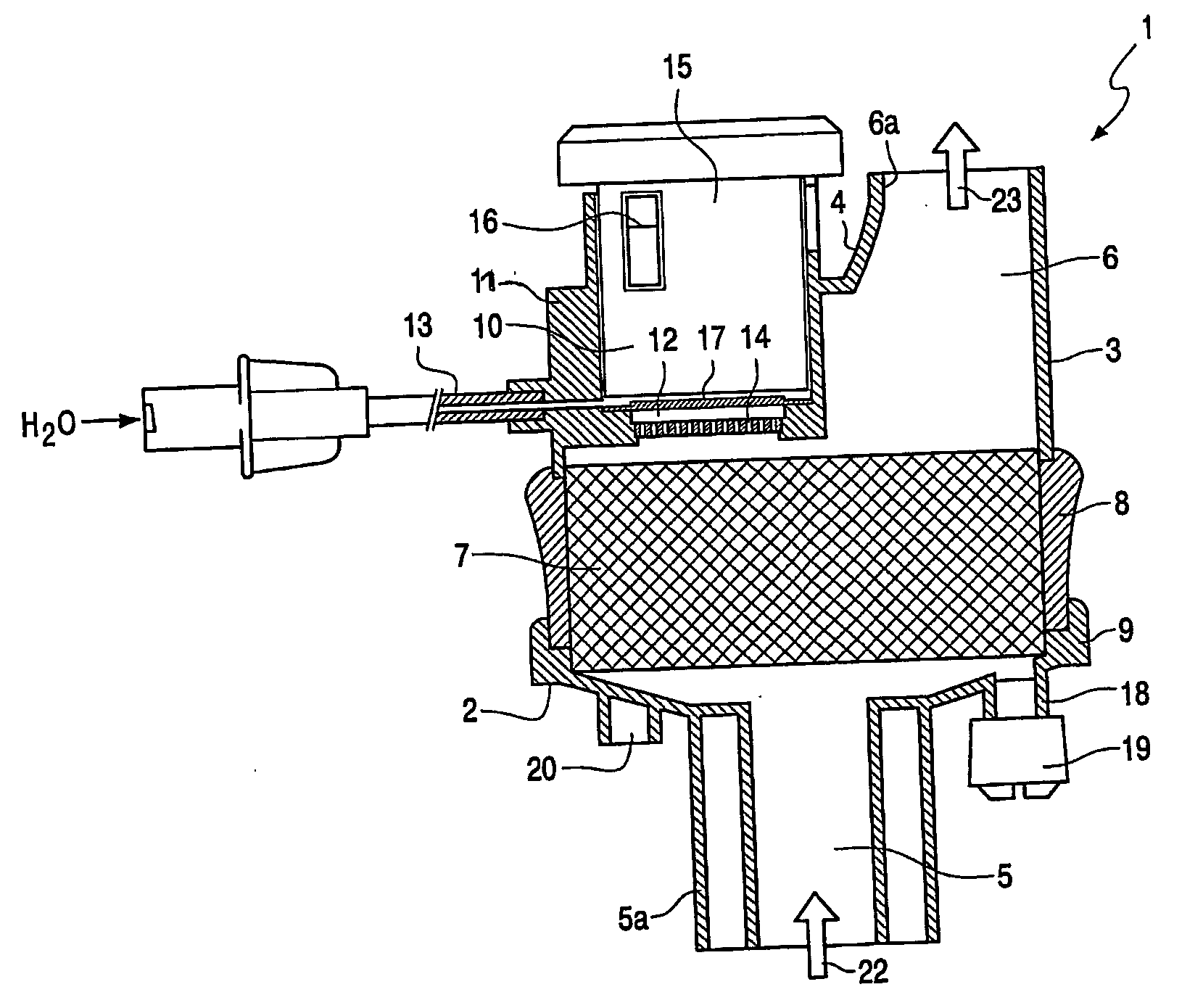

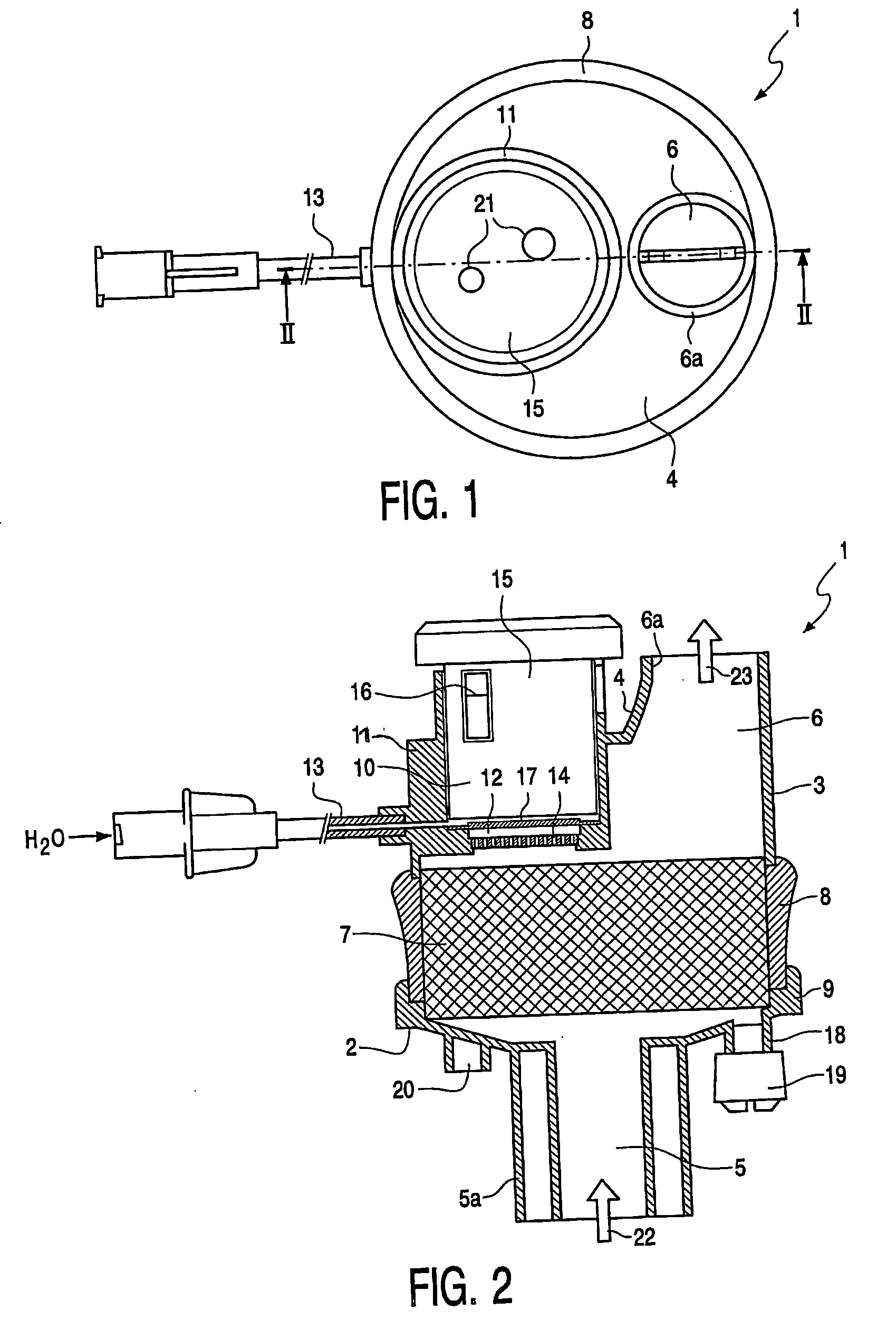

Humidifying gas induction or supply system

InactiveUS6511052B1Maximize efficiencyReduce the amount requiredInternal combustion piston enginesUsing liquid separation agentWater vaporGas induction

Water vapor is introduced into an inlet air stream (16) of an engine (12), for example, by a pervaporation process through a non-porous hydrophilic membrane (18). A water reservoir (20), which can contain contaminated water, provides a vapor pressure gradient across the hydrophilic membrane (18) into the inlet air stream (16), while the rate of delivery of the water vapor to a cylinder (38-40) is self-regulated by the rate of flow of air across the membrane. The hydrophilic membrane (18) therefore also filters the water from the water reservoir (20) to an extent that pure water vapor is provided to the air inlet stream (16). Delivery of water vapor can nevertheless be controlled using a hood (26) that slides over the hydrophilic membrane to limit its exposed surface area. Alternatively, water vapor is introduced into one or more of the gas streams of a fuel cell by separating the gas stream from the wet exhaust gas stream by a hydrophilic membrane such that moisture passes across the membrane to moisten the gas stream and thereby prevent drying out of the proton exchange membrane.

Owner:DESIGN TECH & INNOVATION

Hydrophilic membrane and associated method

InactiveUS20070075013A1Reduce and minimize residual stressMembranesSemi-permeable membranesHydrophilic membraneMembrane configuration

A membrane is provided, which may include a microporous base membrane; and a cross-linkable coating disposed on a surface of the membrane. The coating may include polyvinyl nucleophilic polymer and a urethane or a blocked isocyanate. The coating may be cross-linked. Also provided is a method of making the membrane.

Owner:BHA ALTAIR

Waterproof and moisture permeable composite membrane and preparation method thereof

ActiveCN103963393AGood high and low temperature resistanceImprove barrier propertiesNon-woven fabricsRubber layered productsFiberElastomer

The invention discloses a waterproof and moisture permeable composite membrane and a preparation method thereof. The waterproof and moisture permeable composite membrane includes a hydrophobic film and a hydrophilic membrane; a thermoplastic polyester elastomer (TPEE) membrane is used as the receiving base, a hydrophobic polymer spinning solution is stretched into nanoscale / sub-micron fibers through the electrostatic spinning nanotechnology, and is deposited on a non-porous membrane to form the composite membrane (hydrophilic membrane and microporous membrane). With adoption of the electrostatic spinning one-step forming method, the preparation technology of the composite membranes is greatly shortened. The preparation technology is simple and practical, and the spinning process is stable and free from contamination. The prepared composite membrane has high adhesive fastness, is applicable to fire control chemical protective clothing fabric, and also can be widely used in individual protective equipment fabric in the industries and fields of metallurgy, petroleum, military, dangerous chemicals, decontamination and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

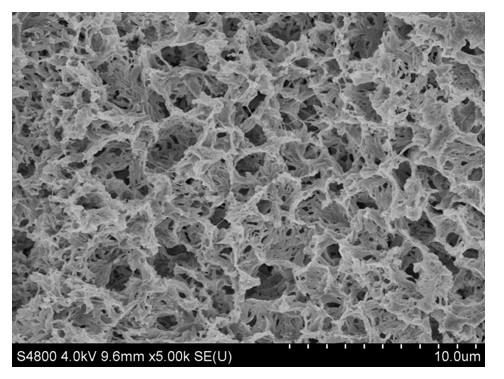

Method for in-situ polymerization and modification of polyvinylidene fluoride microporous membrane

ActiveCN102553465AImprove throughputHigh cut-offSemi-permeable membranesWater bathsIn situ polymerization

The invention relates to a method for in-situ polymerization and modification of a polyvinylidene fluoride microporous membrane. In the method, polyvinylidene fluoride microporous is dissolved in triethyl phosphate at first to prepare membrane-forming precursor solution, active solution is added into the membrane-forming precursor solution for in-situ polymerization under nitrogen protection, the mixture is kept static for 18-36 hours at the reaction temperature after reaction, membrane casting solution is prepared via deaeration and is processed by a membrane forming machine to prepare a primary membrane, the primary membrane is soaked in a coagulating bath for 0-3 hour(s) and is then transferred into an deionized water bath to be immersed for 1-48 hour(s) so as to be cured into a membrane, the membrane is naturally dried in the air at the room temperature, and thus the dry hydrophilic polyvinylidene fluoride membrane is prepared. The method is environmentally friendly, the reaction conditions are mild, the preparation method is simple, modification and preparation are completed simultaneously, the repeatability is good, the method cannot be limited by the type of the microporous membrane, a high-flux separating membrane can be obtained with no needs for external pore-forming agents, and the prepared microporous membrane is a dry hydrophilic membrane.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

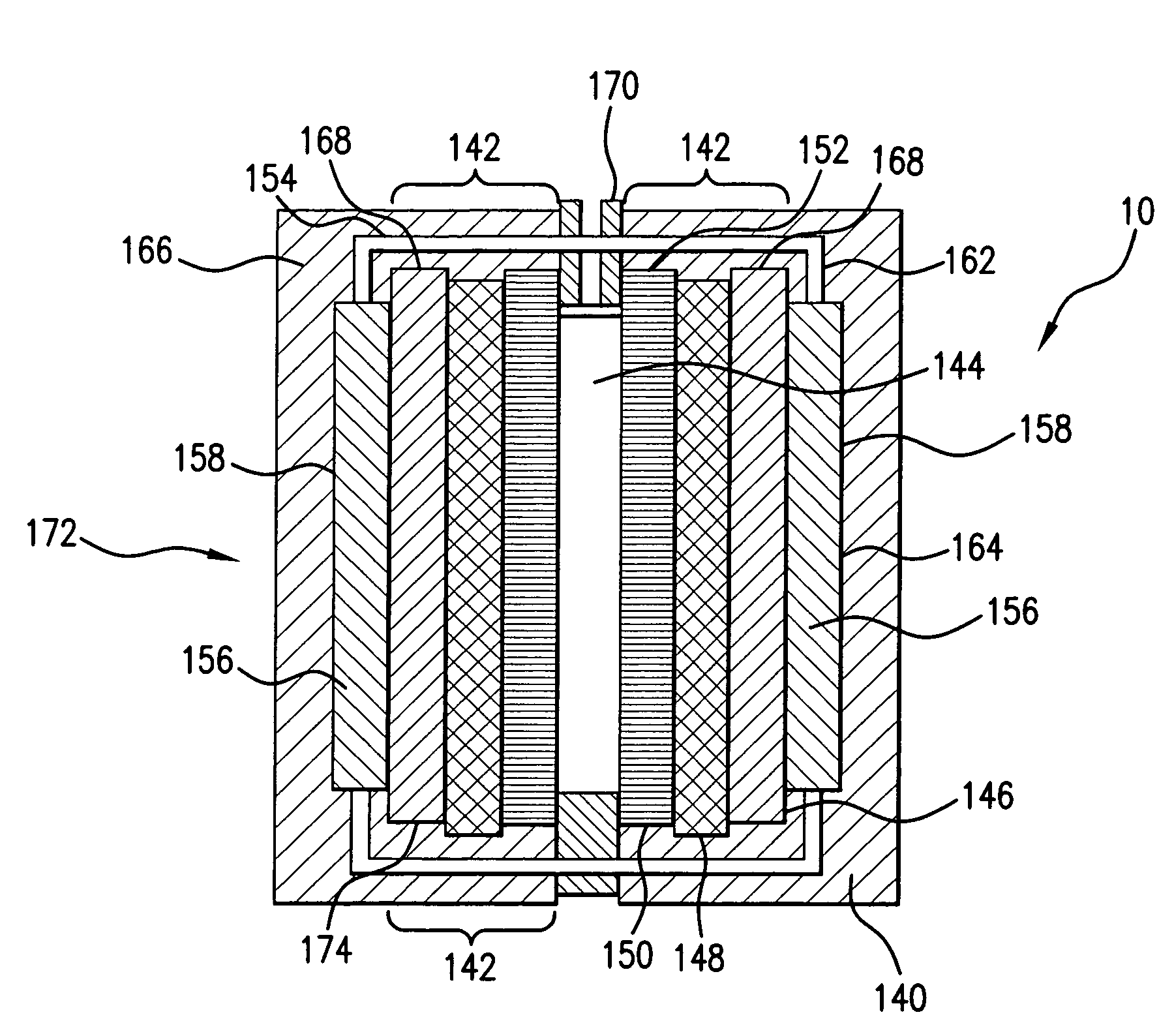

Device for heating and moistening breathing air

ActiveUS20050248045A1Precise vapor outputEasy to handleRespiratorsBreathing masksWater vaporHydrophilic membrane

The present invention relates to a device for conditioning breathing air comprising a housing (1) provided with an inlet (5) for non treated breathing air and an outlet (6) for the treated breathing air, wherein said housing (1) comprises passive humidifying means (7) and active humidifying means wherein said active humidifying means comprises a water supply inlet (13), a heating device for the supplied water, a membrane (12) having substantial water impermeable and water vapor permeable characteristics, and a heat exchange element (14), characterized by the fact that said membrane (12) is divided into a hydrophilic membrane (12a) and a water vapor permeable and water impermeable membrane (12b), and that said heat exchange element is selected from the group comprising perforated metal plate (14) and / or a heating resistance. The invention further relates to a method for the conditioning of breathing air, comprising the steps of supplying through the inlet opening non treated breathing air, passively humidifying said supplied air through the passive humidifying means, and actively humidifying said breathing air, through the active humidifying means of a device.

Owner:BVBA MEDISIZE BELGIE

Membrane post treatment

InactiveUS20060157404A1Low toxicityReduce riskSolid sorbent liquid separationPretreated surfacesCross-linkPhase separation process

The invention relates to polymeric ultrafiltration or microfiltration membranes of, for instance, Halar, PVDF or PP, incorporating PVME or vinyl methyl ether monomers. The PVME may be present as a coating on the membrane or dispersed throughout the membrane or both. The membranes are preferably hydrophilic with a highly asymmetric structure with a reduced pore size and / or absence of macrovoids as a result of the addition of PVME. The PVME maybe cross-linked. The invention also relates to methods of hydrophilising membranes and / or preparing hydrophilic membranes via thermal or diffusion induced phase separation processed.

Owner:EVOQUA WATER TECH LLC

Hydrophilic film material and preparation method thereof

InactiveCN101773789AHydrophilic hasKeep hydrophilicSemi-permeable membranesSurface layerFilm material

The invention discloses a hydrophilic film material and a preparation method thereof. The film material is formed by winding amorphous high molecules and hydrophilic high molecules. The structure of the film material is divided into a compact surface layer and a pore supporting structure connected with the compact surface layer, wherein both the compact surface layer and the pore supporting structure have interconnected pore structures. The film material has hydrophilicity through physical cross-linking of a film-forming material and the hydrophilic high molecules on production molecular scale; and the contact angle of water on a film surface of the hydrophilic film material is about 0 degree; and therefore, the method improves the service performance of the film material, reduces the replacement frequency of the film material, reduces the using amount of chemical medicaments, reduces the using cost of film technology and provides good core material for broad application of the film.

Owner:何涛

Semipermeable hydrophilic membrane

A hydrophilic semipermeable membrane can include a porous polymeric structure containing a blend of PVDF and hydroxyalkylcellulose. The membrane may be used for ultrafiltration. A method of making a hydrophilic semipermeable membrane can include providing a blend containing PVDF and hydroxyalkylcellulose, forming the blend into a porous polymeric structure, and purifying the porous polymeric structure.

Owner:DOMNICK HUNTER ADVANCED FILTRATION

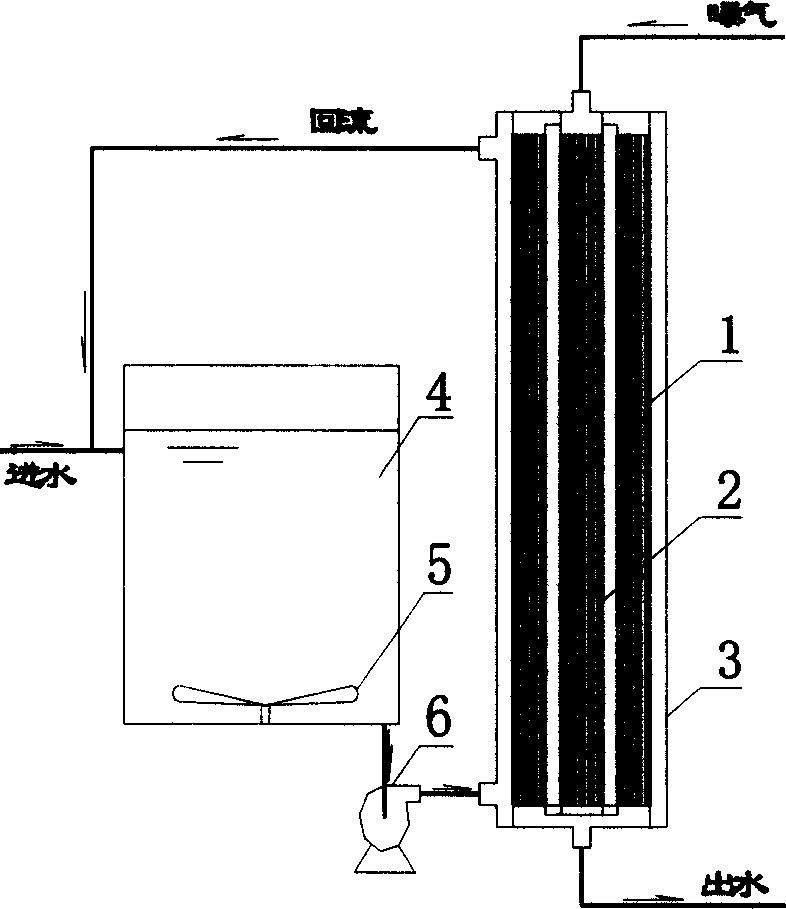

Membrane aeration and membrane separation coupled sewage treatment device and method

InactiveCN1569682AEasy to handleReduce energy consumptionMembranesTreatment using aerobic processesRefluxCoupling

The invention provides a membrane aeration and membrane separation coupled sewage treatment device and method, wherein the hydrophobic membrane for aeration and the hydrophilic membrane for separation are mounted in a common cylinder shaped reactor, forming a membrane aeration and separation reactor, a bioreactor is also arranged on the reflux line, so as to realize circulatory flow of the treated sewage water between the two reactors, thus achieving the coupling of aeration, membrane separation and biological degradation.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com