Non-crystallization permanent hydrophilic PVDF membrane material and preparation method thereof

A technology of polyvinylidene fluoride membrane and polyvinylidene fluoride, applied in the field of hydrophilic polyvinylidene fluoride membrane material and its preparation, can solve the problem of affecting the permeability of membrane materials, high viscosity of polymer solutions, and long-term instability of solutions and other problems to achieve the effect of reducing the frequency of replacement, improving the performance and avoiding the reduction of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

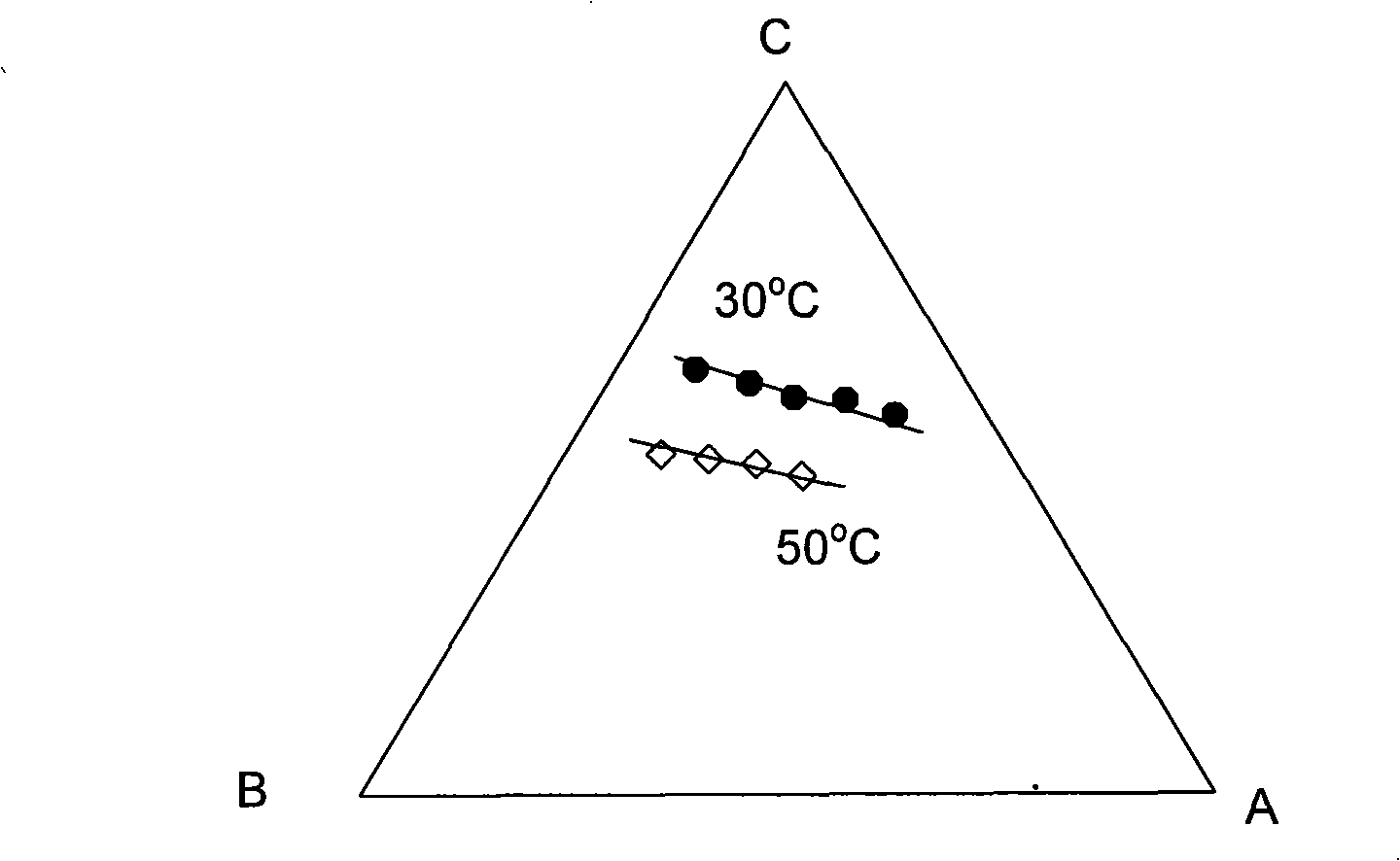

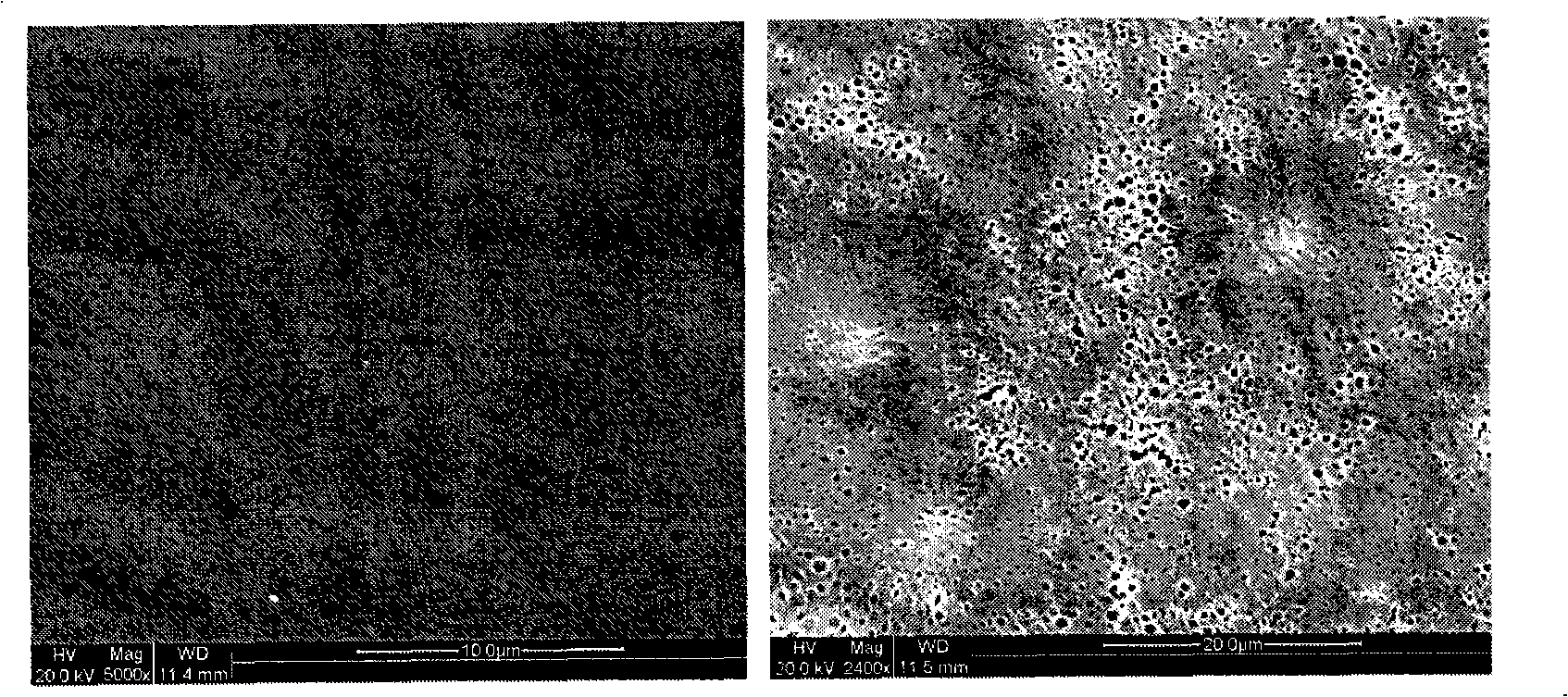

[0034] 20 grams of polyvinylidene fluoride and 15 grams of long-chain polyvinylpyrrolidone (K120) were dissolved in a mixed solvent of 65 grams of dimethylacetamide and 8 grams of ethylene glycol at 80° C. with thorough stirring. After the polymer was completely dissolved, it was filtered through a stainless steel mesh with a pore size of 40 microns and left to stand in an oven at 100°C for defoaming. The proximity ratio α of the solution is 0.8. Using a stainless steel spatula with a thickness of 300 microns, the polymer solution was applied to a glass plate, placed in air (22°C, relative humidity 50%) for about 2 seconds, then immersed in 60°C water for phase separation and solidification. After the membrane material is completely cured, take out the membrane material for further cleaning. After cleaning, the membrane material was immersed in a hydrogen peroxide solution with a concentration of 5000ppm for 48 hours for post-treatment, and then the pure water permeability of...

Embodiment 2

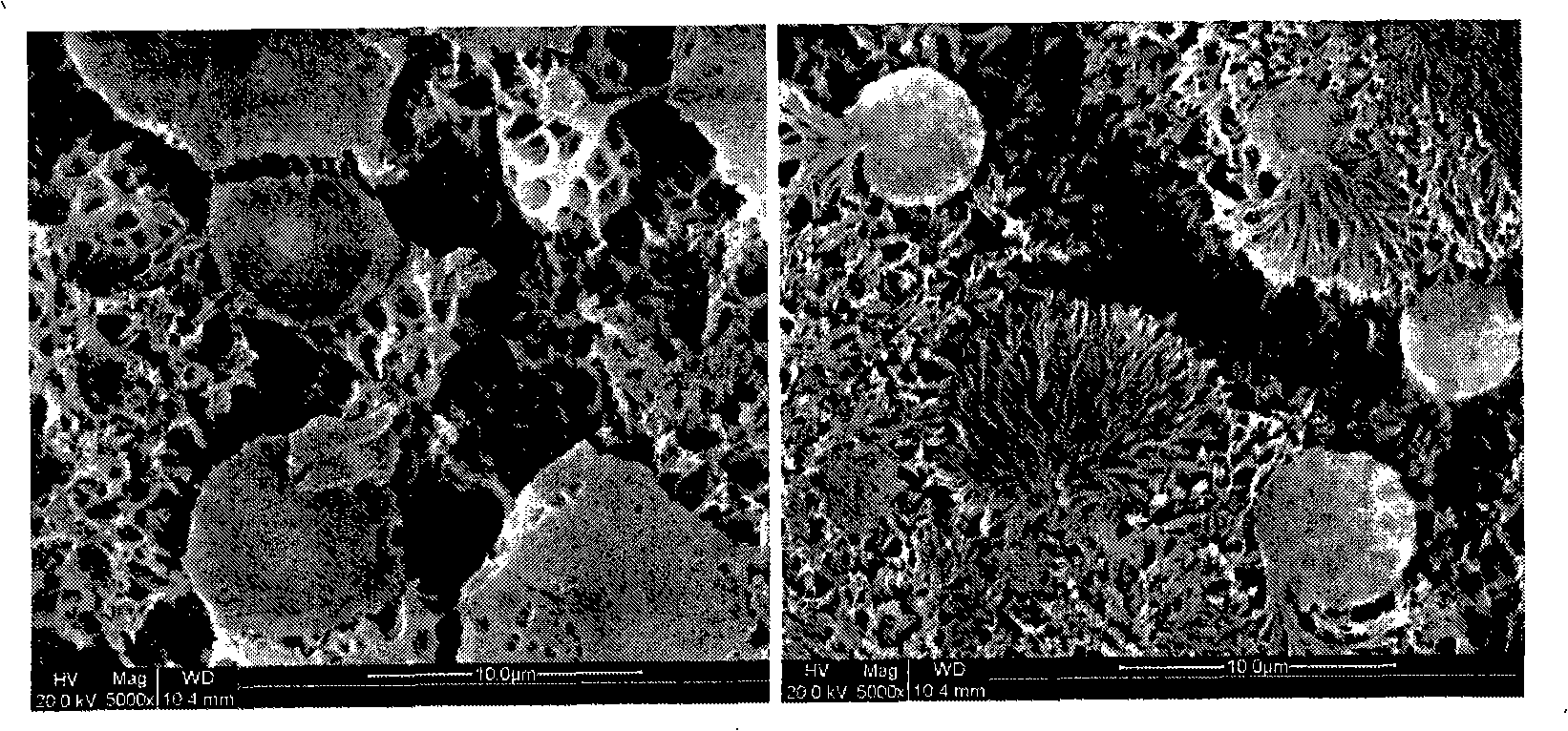

[0038] Prepare the same polyvinylidene fluoride solution as in Example 1. After filtering and defoaming, use a stainless steel spatula with a thickness of 300 microns to apply the polymer solution to a glass plate and place it in the air (20°C, relative humidity 50%) Place in the middle for about 2 seconds and then immerse in water at 20°C for phase separation and solidification. After the membrane material is completely cured, take out the membrane material for further cleaning. The membrane material after cleaning adopts the method identical with above-mentioned embodiment to carry out post-treatment, then the pure water permeability of measuring polyvinylidene fluoride membrane is 70L m -2 ·hr -1 · bar -1 . SEM structure observation revealed polyvinylidene fluoride crystalline structures on the surface and bottom of the film. The measured crystallinity of the film material is 0.3, the breaking strength in the tensile test is 3.5 Newton, and the breaking elongation is 15...

Embodiment 4

[0046] 20 grams of polyvinylidene fluoride, 15 grams of long-chain polyvinylpyrrolidone (K30), dissolved in 65 grams of dimethylacetamide solvent and mixed with 8 grams of ethanol at 80 ° C under full stirring, the proximity ratio of the solution α is 0.95 . After the polymer was completely dissolved, it was filtered through a stainless steel mesh with a pore size of 40 microns, and then left to defoam in an oven at 50°C. Using a stainless steel spatula with a thickness of 300 microns, the polymer solution was applied to a glass plate, placed in air (20°C, relative humidity 50%) for about 2 seconds, and then immersed in 60°C water for phase separation and solidification. After the membrane material is completely cured, take out the membrane material for further cleaning. After cleaning, the membrane material was immersed in a hydrogen peroxide solution with a concentration of 5000ppm for 48 hours for post-treatment, and then the pure water permeability of the polyvinylidene f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com