Method for manufacturing vacuum mould closing of false ogive

A manufacturing method and fairing technology, applied to other household appliances, household appliances, household components, etc., can solve the problems of high investment and manufacturing costs, expensive mold manufacturing costs, difficult molding process, etc., and achieve low investment and production costs , high production efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

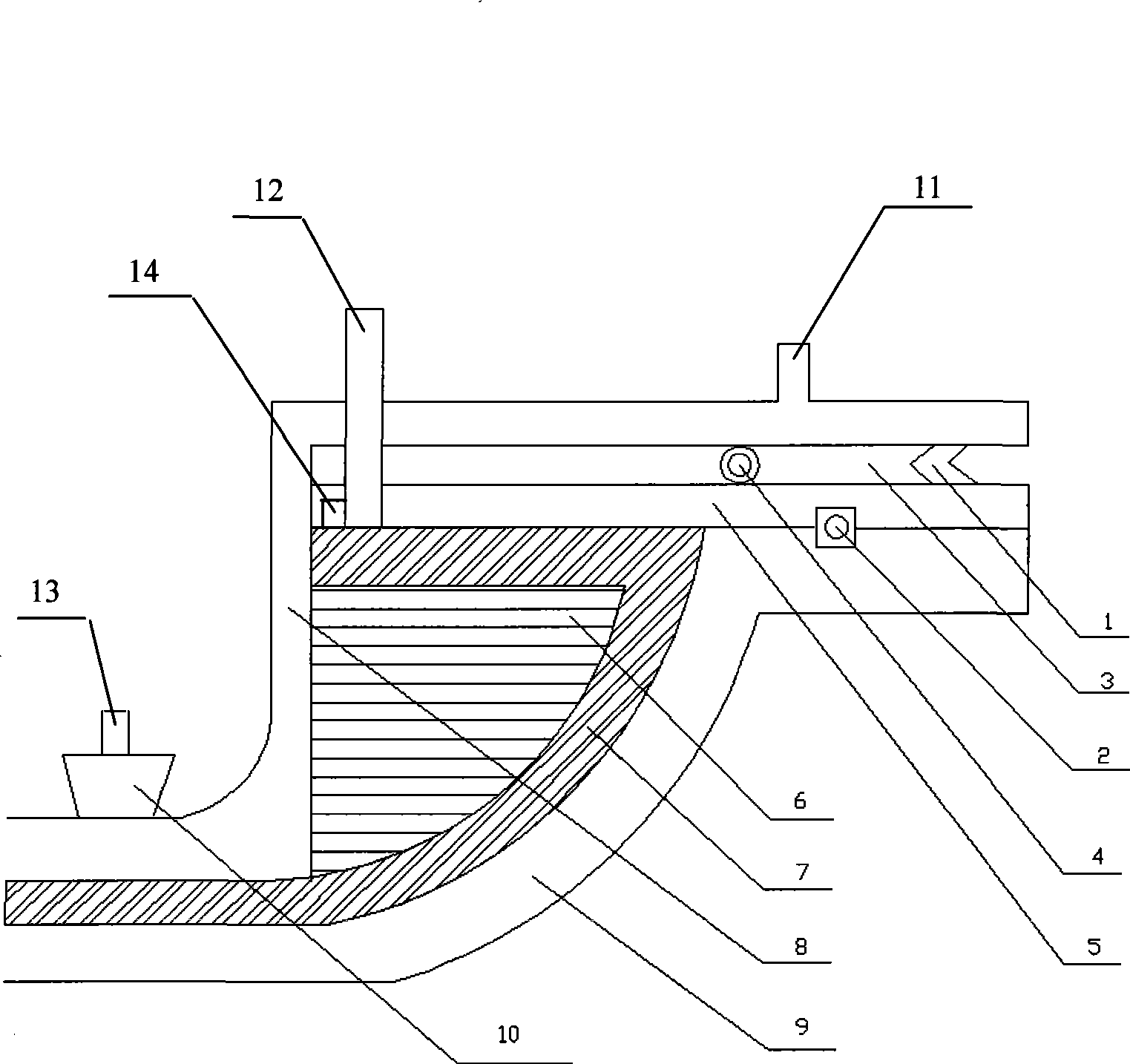

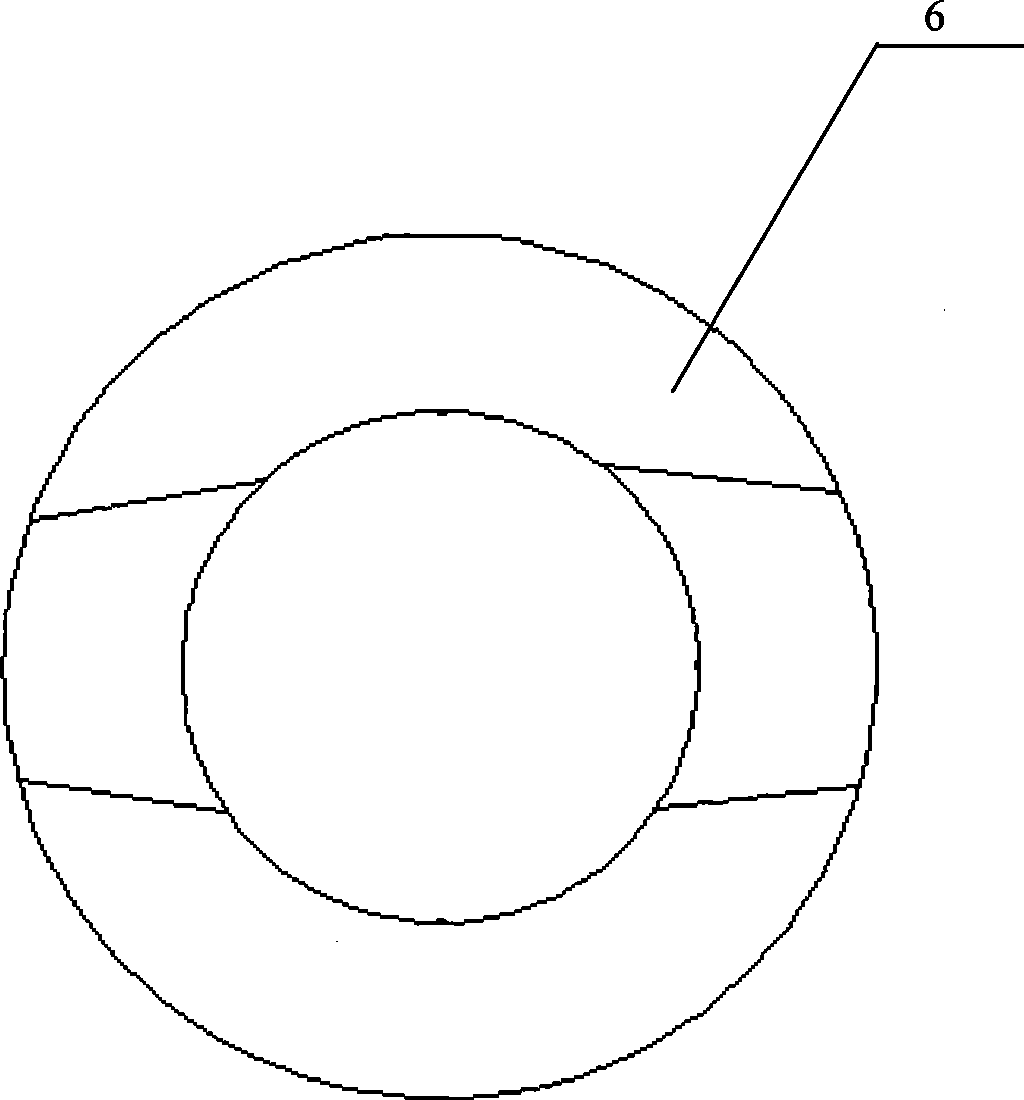

[0021] As shown in Figure 1, it is a side sectional view of a vacuum closed mold provided by the present invention, consisting of an airfoil sealing ring 1, a circular sealing ring 2, a dynamic sealing ring 4, a composite lower mold upper module 5, and a semi-rigid composite material The upper mold 8, the composite lower mold 9, the glue storage device 10, the vacuum port 11, the glue injection port 12, the glue outlet 13 and the flow channel 14 are composed.

[0022] A rubber storage device 10 is provided at the lower part of the semi-rigid composite material upper mold 8, and a glue outlet 13 is provided at the upper end of the rubber storage device 10, and at the height of the semi-rigid composite material upper mold 8 and the upper module 5 of the composite lower mold There is a glue injection port 12, a flow channel 14 is provided at the lower end of the glue injection port 12, a dynamic sealing ring 4 is provided on the edge of the bottom of the semi-rigid composite upper...

Embodiment 2

[0031] The difference between this embodiment and embodiment 1 is that in step 4, an injection machine is used to inject the resin, and a positive pressure of 10KPa is applied to the resin. Other structures and steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com