Method for producing optical element and optical element wafer

A technology of optical components and wafers, which is applied in the direction of polarizing components, optical head manufacturing, optical recording heads, etc., and can solve problems such as optical film peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be described in detail.

[0037] (Optical element)

[0038] The optical element of the present invention is an element in which an optical film is attached to a substrate, and is characterized in that the optical film is only partially formed.

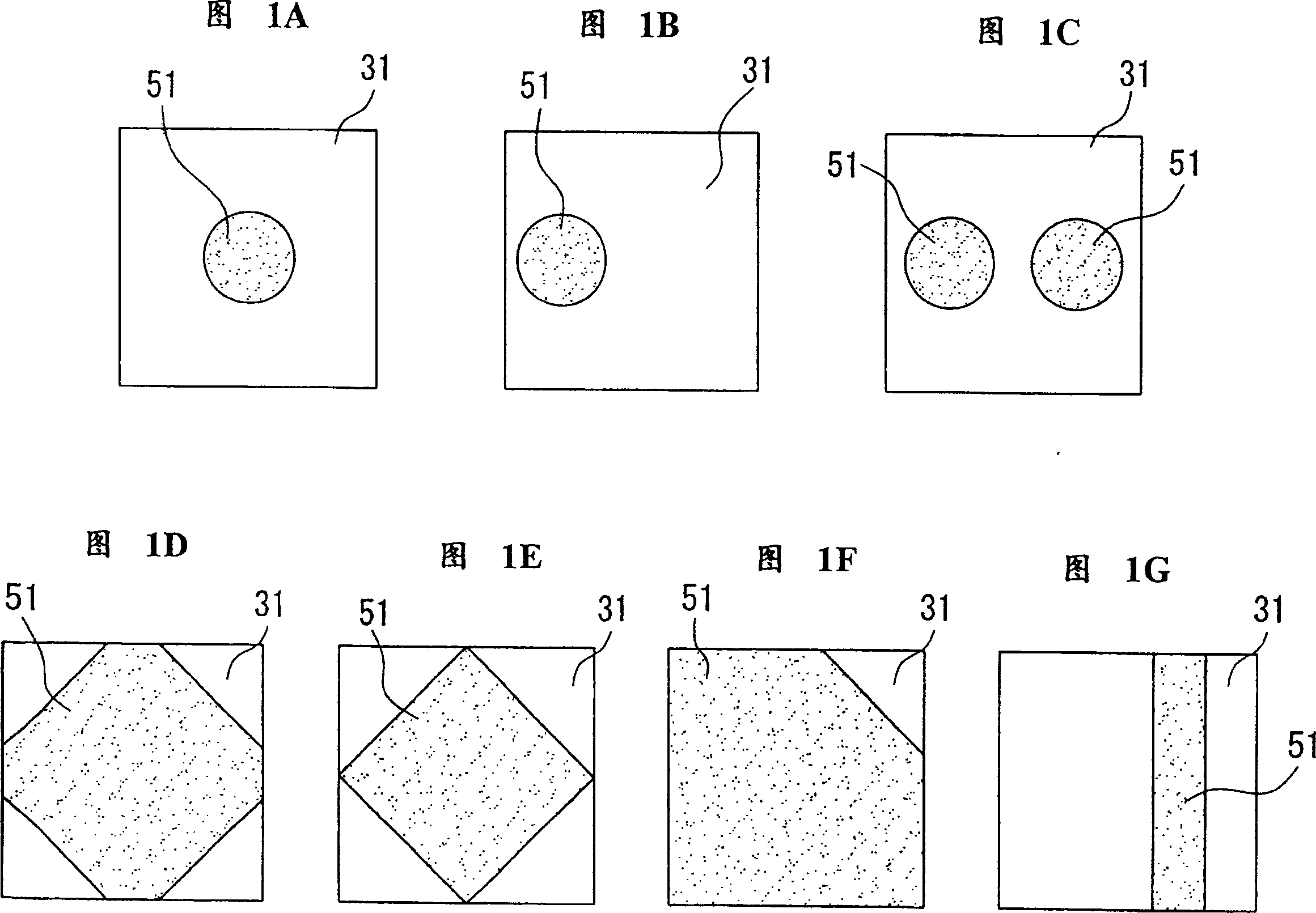

[0039] As a specific configuration example of the optical element of the present invention, as shown in FIG. The sticking position of the optical film 51 on the base 31 is not limited to the central portion of the base 31 , as shown in FIG. 1( b ), the optical film 51 may be attached to the end of the base 31 . As shown in FIG. 1( c ), it is also possible to form a structure in which a plurality of optical films 51 are attached.

[0040] As other configuration example shown in Fig. 1 (d) and (e), can enumerate following configuration: place all sticks optical thin film 51 except the four jiaos of substrate 31, as shown in Fig. 1 (f), An optical film is attached to all but one corner of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com