Low-carbon high-performance tunnel shotcrete composite cementing material

A tunnel injection, high-performance technology, applied in the field of building materials manufacturing, can solve the problems of poor concrete compactness, weak corrosion resistance, and low quality, and achieve the effects of reducing output, benefiting environmental protection, and reducing the proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

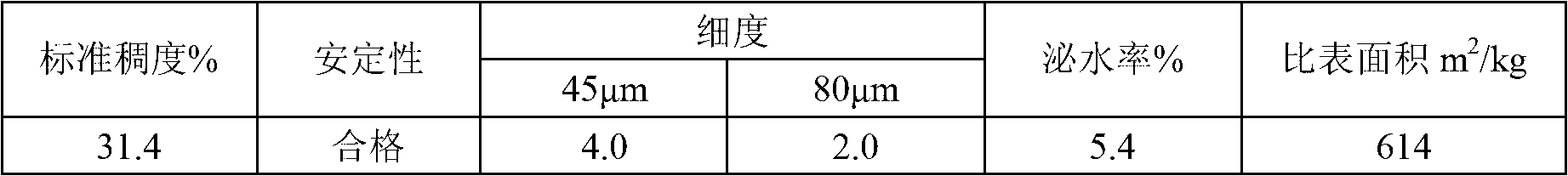

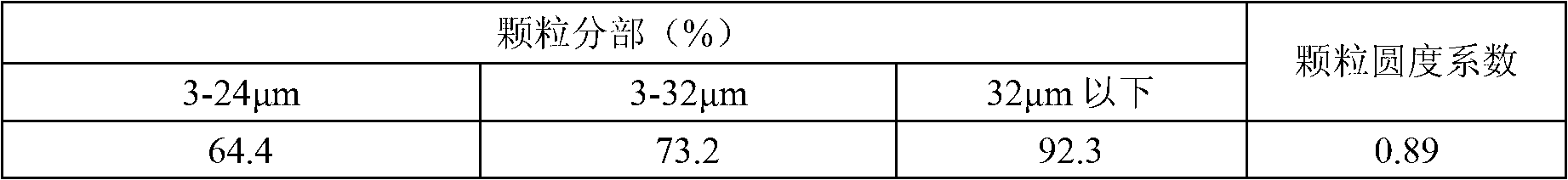

[0020] 1. The design strength level of the low-carbon high-performance tunnel sprayed concrete composite gelling material is 52.5MPa. The material ratio is: cement clinker 40%, slag powder 25%, fly ash 15%, silica fume 8%, mixed material 12% (limestone powder 6%, gypsum 5%, Shandong Hongyi grinding aid 1%) .

[0021] The requirements for each component are:

[0022] Before grinding, the free calcium oxide of cement clinker should be less than 1.0%, the alkali content should be less than 0.6%, the 3d compressive strength should be more than 29MPa, the 28d compressive strength should be more than 60MPa, and the specific surface area after grinding should be more than 500m 2 / kg or so, 80μm sieve <2.0%, 45μm sieve <4.0%;

[0023] The fly ash is grade I, the content of sulfur trioxide is less than 3.0%, the content of calcium oxide is less than 10%, CL - Content 80%, 28d compressive strength activity index > 90%, specific surface area after grinding ≥ 650m 2 / kg;

[0024] Sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com