Organization control method of large-size pre-hardening type plastic die steel module

A technology of plastic mold steel and control method, applied in the direction of heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problems of difficult hardening, roughness, affecting mold processing and service performance, etc., to achieve good process stability and reduce microcracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

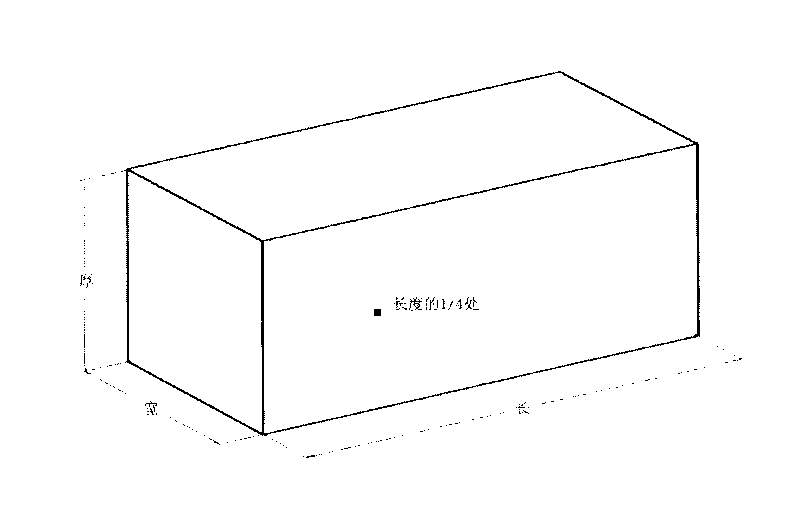

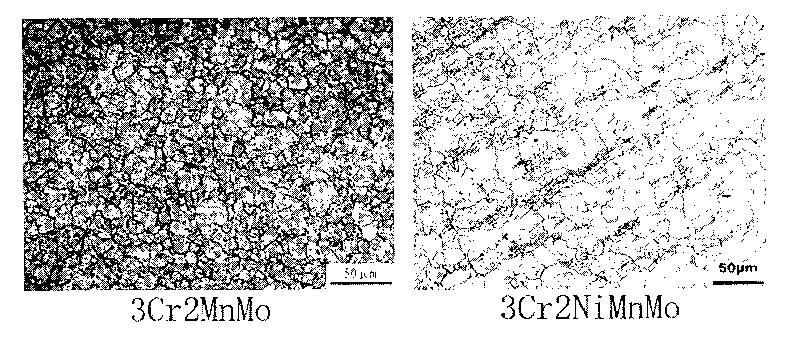

[0023] Example 1: 3Cr2NiMnMo large-scale pre-hardened plastic mold steel module with dimensions of 1020mm (thickness) × 1220mm (width) × 2620mm (length). After forging, it is cooled by strong wind for 6 hours, and the temperature control point is reduced to 350°C before air cooling. When the temperature at the temperature control point drops to 250°C, enter the 350°C trolley-type gas furnace for 6 hours and heat it at a heating rate of 50°C / h, after the temperature control point temperature is 750°C, the heating rate is 100°C / h, at 880°C Keep holding for 15 hours to austenitize.

[0024] After the heat preservation is over, the trolley is lifted out and cooled by strong wind for 5 hours. The temperature at the temperature control point drops to 350°C and then air-cooled to room temperature. Afterwards, it is tempered at 560°C for 30 hours; finally, the surface hardness of the module is adjusted to 33±2HRC, and the crystal grain size is 6-7.

Embodiment 2

[0025] Example 2: 3Cr2MnMo large-scale pre-hardened plastic mold steel module with dimensions of 300mm (thickness) × 790mm (width) × 3500 (length) mm. After forging, it is cooled by strong wind for 4 hours, and the temperature control point is reduced to 350°C and then air-cooled When the temperature at the temperature control point drops to 250°C, enter the 350°C trolley-type gas furnace for 5 hours and then heat it at a heating rate of 50°C / h. After the temperature control point temperature is 750°C, the heating rate is 100°C / h, at 890 Austenitize at ℃ for 13 hours.

[0026] After the heat preservation, the trolley was lifted out and cooled by strong wind for 4 hours. The temperature at the temperature control point was reduced to 350°C and then air-cooled to room temperature. Afterwards, it is tempered after holding at 560℃ for 24 hours; finally adjust the surface hardness of the module to 30±2HRC and the grain size to 7-8.

Embodiment 3

[0027] Example 3: 10Ni2MnCuAl large-scale pre-hardened plastic mold steel module, the external dimension is 1100mm (thickness) × 1120mm (width) × 2600mm (length), after forging, controlled strong wind cooling for 8 hours, temperature control point reduced to 350 ℃ and then air cooling, When the temperature at the temperature control point drops to 250°C, enter the 350°C trolley-type gas furnace for 7 hours and heat it at a heating rate of 50°C / h, and after the temperature control point temperature is 750°C, the heating rate is 100°C / h, at 880°C Keep holding for 18 hours to austenitize.

[0028] After the heat preservation, the trolley was lifted out and cooled by strong wind for 6 hours. The temperature at the temperature control point dropped to 350°C and then air-cooled to room temperature. Afterwards, the temperature is kept at 560°C for 33 hours for tempering; finally, the surface hardness of the module is adjusted to 36±2HRC, and the grain size is 7-8.

[0029] For the locati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com