Method for preparing rare earth titanate nanocrystalline with controllable size through self-propagating combustion

A technology of rare earth titanate and self-propagating combustion, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. The effect of simplicity, short reaction time and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Add 10ml of tetrabutyl titanate to 20ml of water, stir to hydrolyze tetrabutyl titanate to obtain white precipitated titanium oxyhydroxide, add 4.5ml of 16mol L -1 The nitric acid solution completely dissolves the precipitate to obtain titanyl nitrate.

[0018] (2) Mix the above-mentioned titanyl nitrate solution, 12.827 g of neodymium nitrate and 4.393 g of glycine according to the molar ratio of 1:1:2, and then put them in an evaporating dish, place the evaporating dish on a magnetic stirrer and heat while stirring, magnetic The surface temperature of the stirrer is 250° C., the speed of magnetic stirring is 2500 rpm, and the liquid is volatilized under stirring.

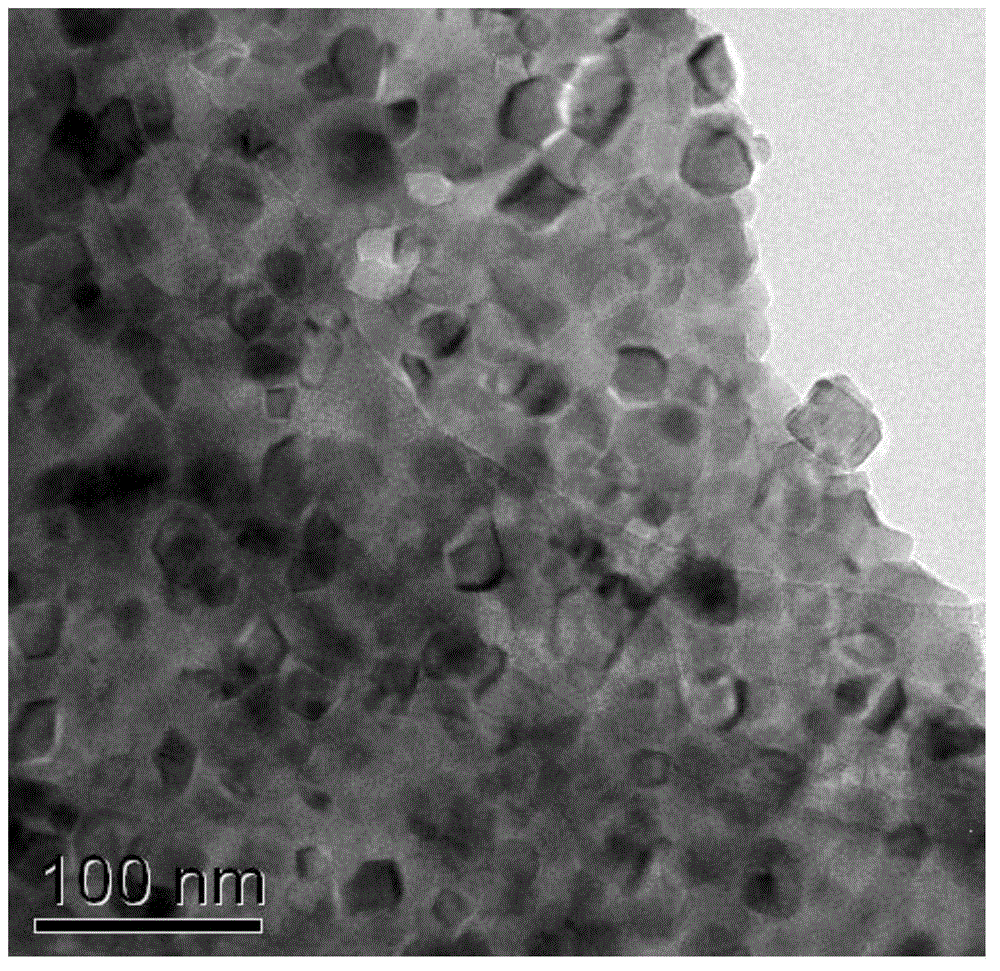

[0019] (3) Stop stirring when sparks appear, sparks spread and burn rapidly, and finally get fluffy powder neodymium titanate (Nd 2 Ti 2 o 7 ), with an average grain size of about 28 nm.

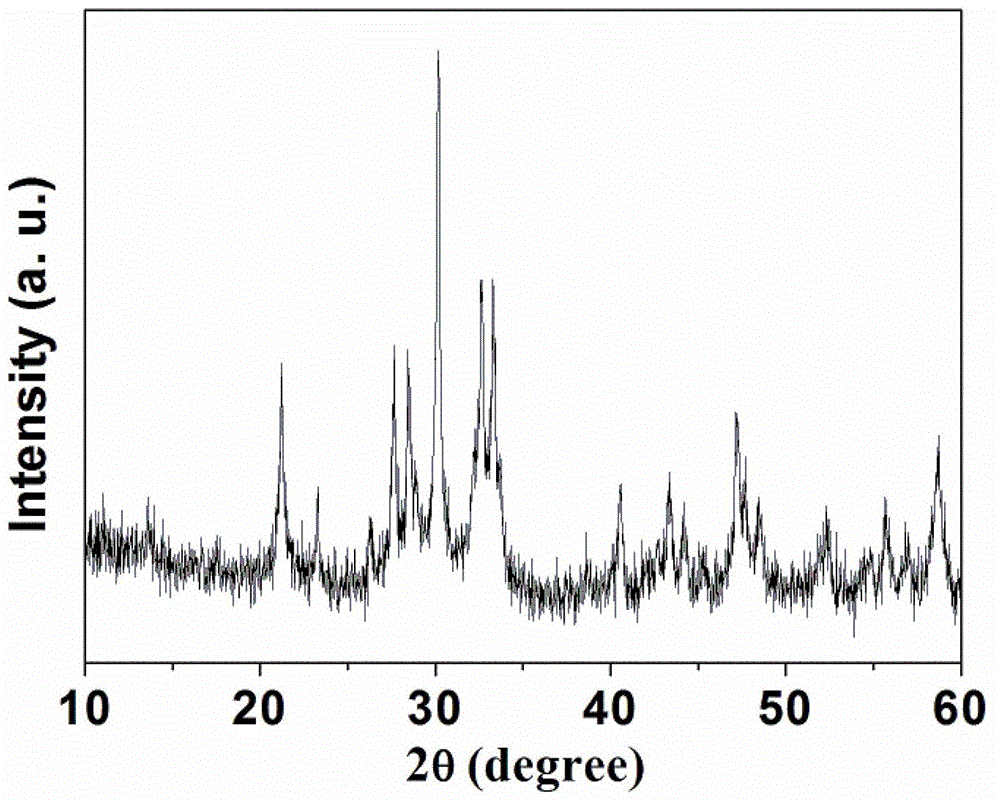

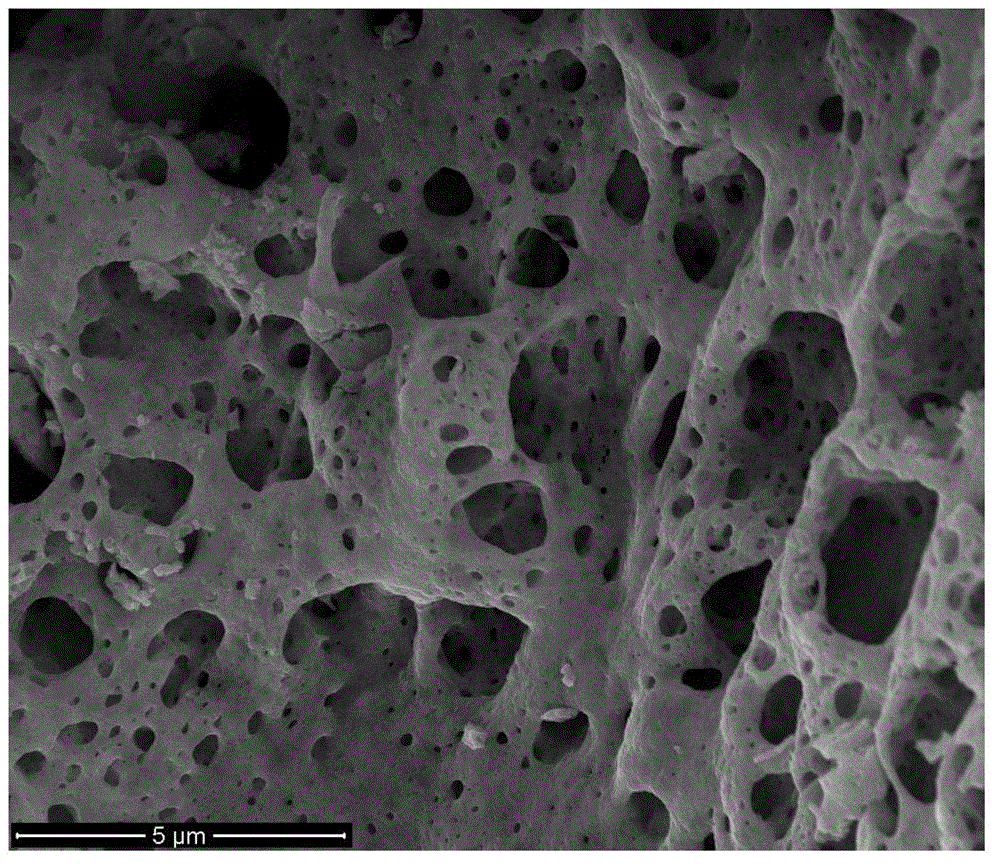

[0020] Neodymium titanate (Nd 2 Ti 2 o 7 ) X-ray diffraction, SEM and TEM images are shown in Fig. 1, Fig. 2...

Embodiment 2

[0022] (1) Add 10ml of tetrabutyl titanate to 20ml of water, stir to hydrolyze tetrabutyl titanate to obtain white precipitated titanium oxyhydroxide, add 4.5ml of 16mol L -1 The nitric acid solution completely dissolves the precipitate to obtain titanyl nitrate.

[0023] (2) Mix the above-mentioned titanyl nitrate solution, 12.827 g of neodymium nitrate and 6.590 g of glycine according to the molar ratio of 1:1:3 and place them in an evaporating dish, place the evaporating dish on a magnetic stirrer and heat while stirring. The surface temperature of the stirrer is 350° C., the speed of magnetic stirring is 2500 rpm, and the liquid is volatilized under stirring.

[0024] (3) Stop stirring when sparks appear, sparks spread and burn rapidly, and finally get fluffy powder neodymium titanate (Nd 2 Ti 2 o 7 ), with an average grain size of about 41 nm.

Embodiment 3

[0026] (1) Add 5ml of tetraisopropyl titanate to 5ml of water, stir to hydrolyze tetraisopropyl titanate to obtain white precipitated titanium oxyhydroxide, add 5ml of 8mol·L -1 The nitric acid solution completely dissolves the precipitate to obtain titanyl nitrate.

[0027] (2) Mix the above-mentioned titanyl nitrate solution, 7.574 g of gadolinium nitrate and 3.149 g of aminoacetic acid according to the molar ratio of 1:1:2.5, and then place them in an evaporating dish, place the evaporating dish on a magnetic stirrer and heat while stirring. The surface temperature of the stirrer is 300° C., the speed of magnetic stirring is 2000 rpm, and the liquid is volatilized under stirring.

[0028] (3) Stop stirring when sparks appear, sparks spread and burn rapidly, and finally get fluffy powder gadolinium titanate (Gd 2 Ti 2 o 7 ), with an average grain size of about 40 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com