3D printing konjac glue gel stent, preparing method and application

A 3D printing, konjac gum technology, applied in medical science, prosthesis, additive processing, etc., can solve the lack of shear thinning properties of hydrogels, does not meet the needs of extrusion printing, and the stent is difficult to maintain the desired shape and other problems, to achieve the effect of controllable shape and microstructure of the stent, to achieve shape fidelity, and to achieve fidelity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

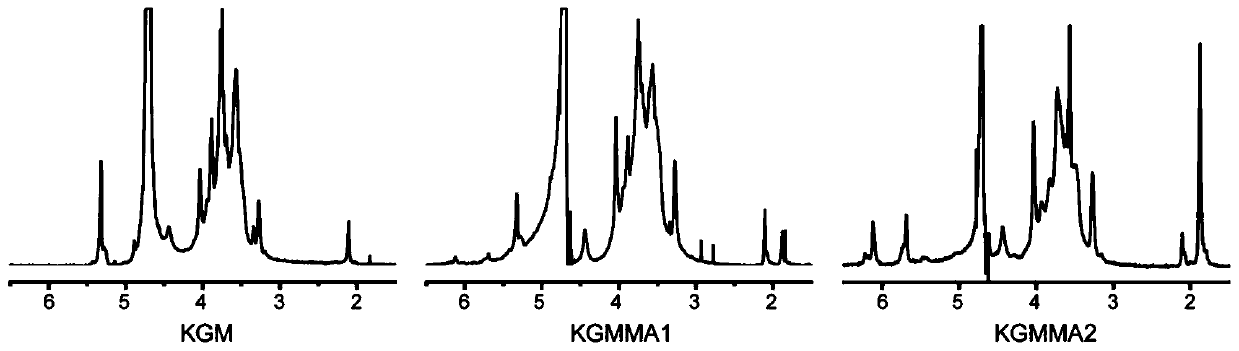

[0025] Wherein in the methacrylic anhydride modified konjac gum experiment, dropwise add 5M sodium hydroxide to maintain a certain pH to react, the pH selection is 7-8,8-9, prepare methacrylated konjac gum as follows: At 50°C, prepare 2% (w / v) konjac gum solution, add methacrylic anhydride, stir and mix evenly, then add 5M sodium hydroxide drop by drop to maintain pH 7-8, 8-9 respectively. After continuing to react for 6 hours, dialyze with ultrapure water for one week at 4°C and freeze-dry to obtain the product.

[0026] By comparing the degree of grafting of the product methacrylic anhydride, it was found that when the pH was 7-8, the efficiency of the grafted methacrylic anhydride of the product was higher.

Embodiment 2

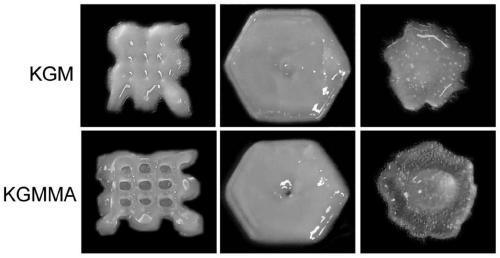

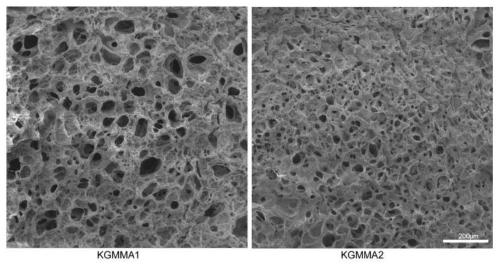

[0028] Wherein the printing concentration of konjac gum can be 6%, 7%, 8%, and the hydrogel of three kinds of concentrations prepares 3D printing support as follows: Use photoinitiator (0.1 %w / v) of PBS was completely dissolved to prepare a hydrogel; then the resulting hydrogel or chondrocytes (1*10 7 cell / ml) compound is extruded and printed through 3D-Bioplottersystem, and the ejected fiber filaments are piled up layer by layer to form a scaffold, and the printed scaffold is cross-linked by ultraviolet light for 60s to obtain the product.

[0029] Comparing the three scaffolds with printing parameters, it was found that the number of printed layers was between 8-10 layers, and 6% (w / v) required a lower printing voltage, which had less damage to the cell activity of composite cell printing .

example 3

[0031] The concentration of konjac gum raw material can be 1%-2% (w / v) when modified, and its preparation method is as follows: a kind of 3D printing konjac glue hydrogel support, and this support is prepared by the following method: konjac gum raw material is 50 Prepare a 1%-2% (w / v) aqueous solution of konjac gum at ℃, add different concentrations of methacrylic anhydride to modify it to prepare derivatives with different grafting degrees, dialyze the obtained product, and freeze-dry to obtain modified konjac gum.

[0032] By comparison, it was found that the degree of grafting of methacrylic anhydride in the solution with 2% concentration was higher than other concentrations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com