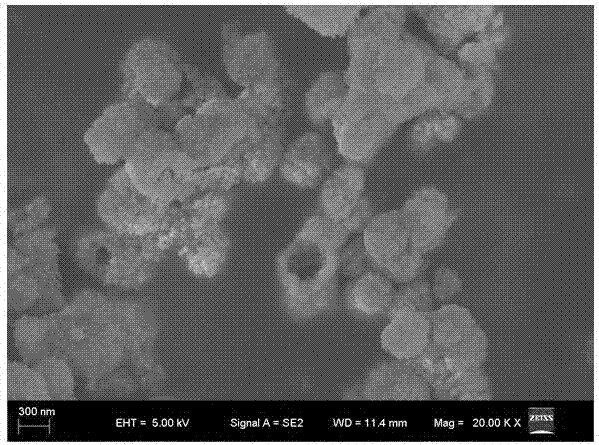

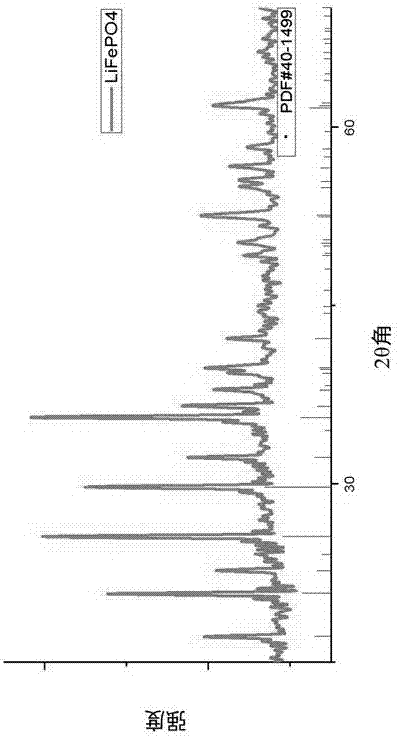

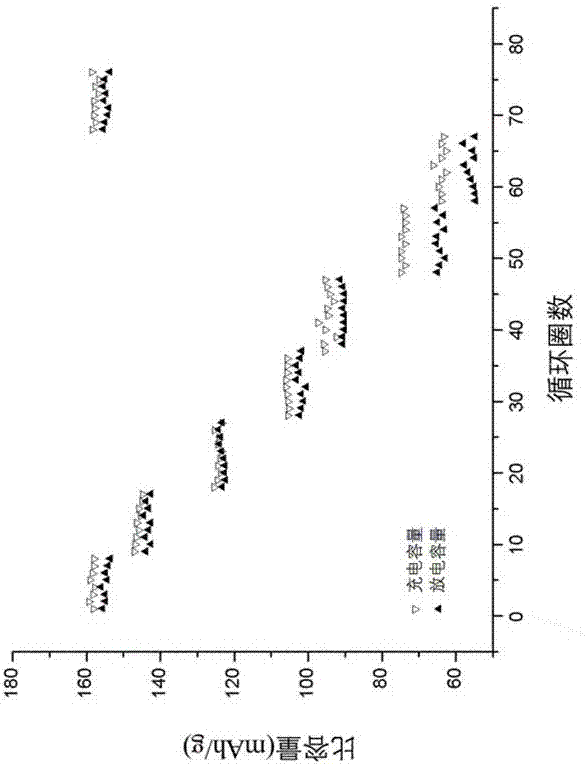

Preparation method of carbon-coated lithium iron phosphate hollow nanospheres

A technology of carbon-coated lithium iron phosphate and lithium iron phosphate, which is applied to electrical components, battery electrodes, circuits, etc., can solve problems such as poor conductivity, low tap density, and small diffusion coefficient of lithium ions, and achieve a simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Preparation of lithium phosphate precursor:

[0034] Mix 20 mL of polyethylene glycol 600 and 20 mL of deionized water as a binary solvent.

[0035] Dissolve 0.008mol phosphoric acid and 0.016mol lithium hydroxide monohydrate in 15mL binary solvent, stir magnetically for 15 minutes to form a reaction system. After the reaction is completed, centrifuge at 5000rpm for 5 minutes, take the solid phase and wash it with water and ethanol 3 times respectively. Dry for 6 hours in an environment of 60°C to obtain a lithium phosphate precursor.

[0036] 2) Preparation of hollow lithium iron phosphate nanospheres:

[0037] Add 0.003 mol of the lithium phosphate precursor to 100 mL of ethylene glycol, add 0.0015 mol of ferrous chloride tetrahydrate while stirring, and sonicate for 30 minutes while stirring.

[0038] Pour the upper reaction system into a 150mL autoclave while stirring. After sealing, put it into a high-temperature blast box and heat to 180°C for 3 hours. After cooling to ...

Embodiment 2

[0042] 1) Preparation of lithium phosphate precursor:

[0043] Mix 20 mL of polyethylene glycol 600 and 60 mL of deionized water as a binary solvent.

[0044] Dissolve 0.008mol phosphoric acid and 0.024mol lithium hydroxide monohydrate in 20mL binary solvent, stir magnetically for 15 minutes to form a reaction system. After the reaction is completed, centrifuge at 5000rpm for 5 minutes, take the solid phase and wash it with water and ethanol 3 times respectively. Dry for 6 hours in a 60°C environment to obtain a lithium phosphate precursor.

[0045] 2) Preparation of hollow lithium iron phosphate nanospheres:

[0046] Add 0.002 mol of the lithium phosphate precursor to 80 mL of ethylene glycol, add 0.002 mol of ferrous chloride tetrahydrate while stirring, and sonicate for 30 minutes while stirring.

[0047] Pour the upper reaction system into a 150mL autoclave while stirring. After sealing, put it into a high-temperature blast box and heat to 180°C for 3 hours. After cooling to room t...

Embodiment 3

[0051] 1) Preparation of lithium phosphate precursor:

[0052] Mix 20 mL of polyethylene glycol 600 and 160 mL of deionized water as a binary solvent.

[0053] Dissolve 0.008mol phosphoric acid and 0.04mol lithium hydroxide monohydrate in 40mL binary solvent, stir magnetically for 15 minutes to form a reaction system. After the reaction is completed, centrifuge at 5000rpm for 5 minutes, take the solid phase and wash it with water and ethanol 3 times respectively. Dry for 6 hours in a 60°C environment to obtain a lithium phosphate precursor.

[0054] 2) Preparation of hollow lithium iron phosphate nanospheres:

[0055] Take 0.001 mol of lithium phosphate precursor and add it to 100 mL of ethylene glycol, add 0.003 mol of ferrous chloride tetrahydrate while stirring, and sonicate for 30 minutes while stirring.

[0056] Pour the upper reaction system into a 150mL autoclave while stirring. After sealing, put it into a high-temperature blast box and heat to 180°C for 3 hours. After cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com