Low-impedance solid-liquid mixed electrolyte as well as preparation method and application thereof

A solid-liquid mixing, low-impedance technology, applied in the field of electrolytes to improve performance and increase capacity extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

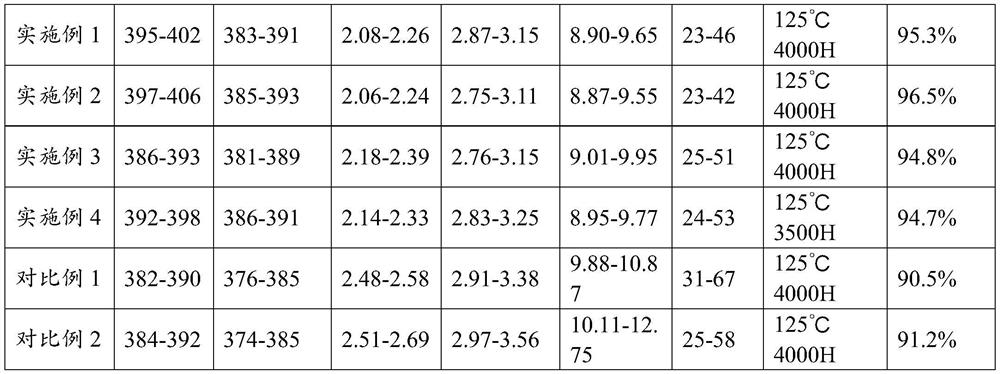

Embodiment 1

[0029] This embodiment provides a low-impedance solid-liquid mixed electrolyte, comprising the following components in weight percentage: 8% of PEDOT / PSS polymer, 2% of sodium persulfate, 1% of sulfuric acid, 2% of polyethylene glycol, isopropanol 1%, sulfolane 20%, γ-butyrolactone 10%, p-nitrophenol 0.5%, boric acid 0.5%, salicylic acid 2%, ethylene glycol balance.

[0030] The preparation method of the low-impedance solid-liquid mixed electrolyte in this embodiment comprises the following steps:

[0031] (1) Add 3,4-ethylenedioxythiophene and sodium persulfate to water, add one-third of the total amount of sodium polystyrene sulfonate, heat to 50°C, stir mechanically for 10 minutes; cool to room temperature, and then Add one-third of the total amount of sodium polystyrene sulfonate, sulfuric acid, polyethylene glycol and isopropanol, heat to 50°C, and stir ultrasonically for 10 minutes; finally add the remaining sodium polystyrene sulfonate, stir ultrasonically for 20 minute...

Embodiment 2

[0034] The present embodiment provides a low-impedance solid-liquid mixed electrolyte, comprising the following components in weight percent: PEDOT / PSS polymer 8%, sodium persulfate 3%, sulfuric acid 1%, polyethylene glycol 1.5%, isopropanol 1%, sulfolane 15%, γ-butyrolactone 15%, p-nitrophenol 0.5%, boric acid 0.5%, salicylic acid 2%, ethylene glycol balance.

[0035] The preparation method of the low-impedance solid-liquid mixed electrolyte in this embodiment comprises the following steps:

[0036] (1) Add 3,4-ethylenedioxythiophene and sodium persulfate to water, add one-third of the total amount of sodium polystyrene sulfonate, heat to 55°C, and ultrasonically stir for 15 minutes; cool to room temperature, then add One-third of the total amount of sodium polystyrene sulfonate, and sulfuric acid, polyethylene glycol and isopropanol, heated to 50 ° C, ultrasonically stirred for 10 minutes; finally added the remaining sodium polystyrene sulfonate, ultrasonically stirred for 2...

Embodiment 3

[0039] This embodiment provides a low-impedance solid-liquid mixed electrolyte, comprising the following components in weight percentage: 8% of PEDOT / PSS polymer, 2% of sodium persulfate, 1% of sulfuric acid, 2% of polyethylene glycol, isopropanol 1%, p-nitrophenol 0.5%, boric acid 0.5%, salicylic acid 2%, the balance of ethylene glycol.

[0040] The preparation method of the low-impedance solid-liquid mixed electrolyte in this embodiment comprises the following steps:

[0041] (1) Add 3,4-ethylenedioxythiophene and sodium persulfate to water, add one-third of the total sodium polystyrene sulfonate, heat to 50°C, stir mechanically for 10 minutes; cool to room temperature, then add One-third of the total amount of sodium polystyrene sulfonate, and sulfuric acid, polyethylene glycol and isopropanol, heated to 50 ° C, ultrasonically stirred for 10 minutes; finally added the remaining sodium polystyrene sulfonate, ultrasonically stirred for 20 minutes, prepared Obtain PEDOT / PSS d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com