Full-automatic waste tire circular-cutting and tire bead cutting and wire stripping system and method

A waste tire, fully automatic technology, applied in the field of waste tires, can solve the problems of low manual operation precision, low efficiency, low utilization rate of waste materials, etc., to reduce manual labor, facilitate wire stripping, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

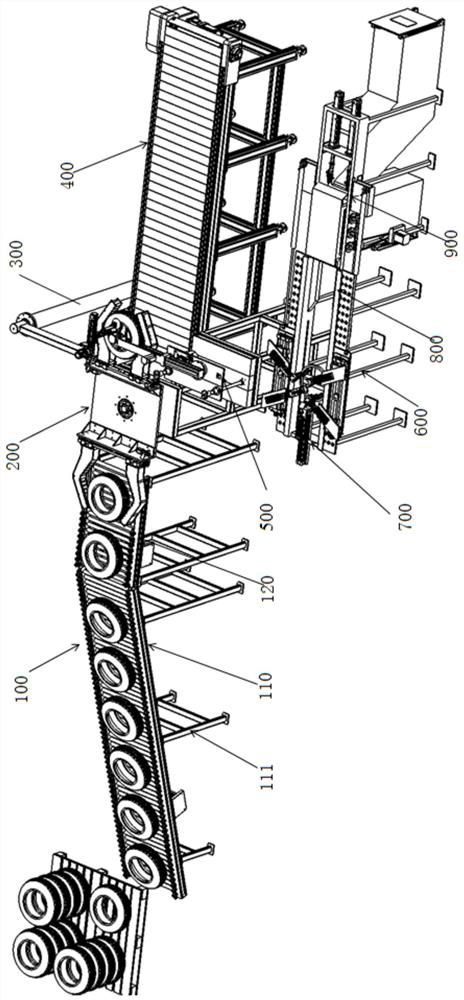

[0060] Such as figure 1 As shown, the fully automatic waste tire ring cutting and bead cutting and stripping system includes a tire ring cutting and conveying device, a bead handling device and a bead cutting and stripping device;

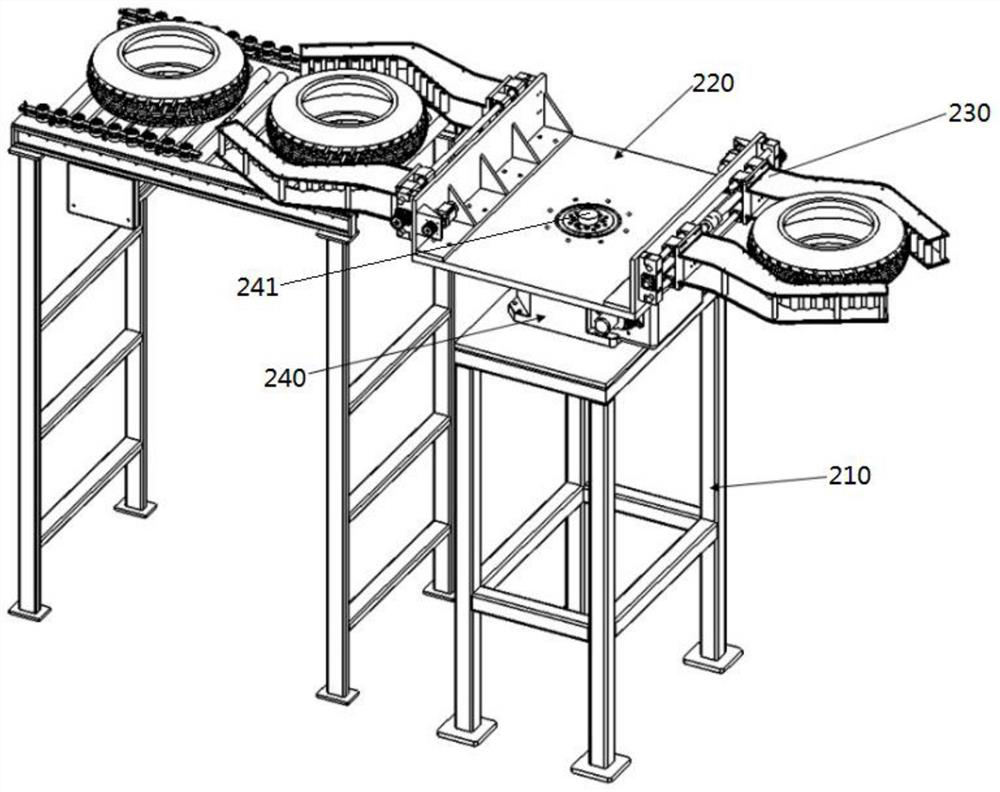

[0061] The tire circumcision conveying device includes a front-end conveying mechanism 100 for conveying waste tires to the rotary conveying mechanism; a rotary conveying mechanism 200 for conveying waste tires to the bead bead cutting mechanism and assisting tire bead circumcision; The bead cutting mechanism 300 cuts off the bead of the waste tire under the joint action of the rotating conveying mechanism and the bead conveying device; the rear end conveying mechanism 400 is used to convey out the waste tire after the bead has been cut;

[0062] The bead handling device 500 is arranged on one side of the bead circumcision device, assists the bead circumcision device in cutting the bead, and transports each cut bead to the bead cutting and strippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com