Stripping method and equipment for hydrocarbon catalytic converting catalyst

A catalytic conversion and catalyst technology, which is applied in the field of petrochemical industry, can solve the problems of difficult manufacturing and installation, complex packing structure of the stripper, etc., and achieve the effects of reducing back-mixing, improving gas-solid contact efficiency, reducing short-circuit and back-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

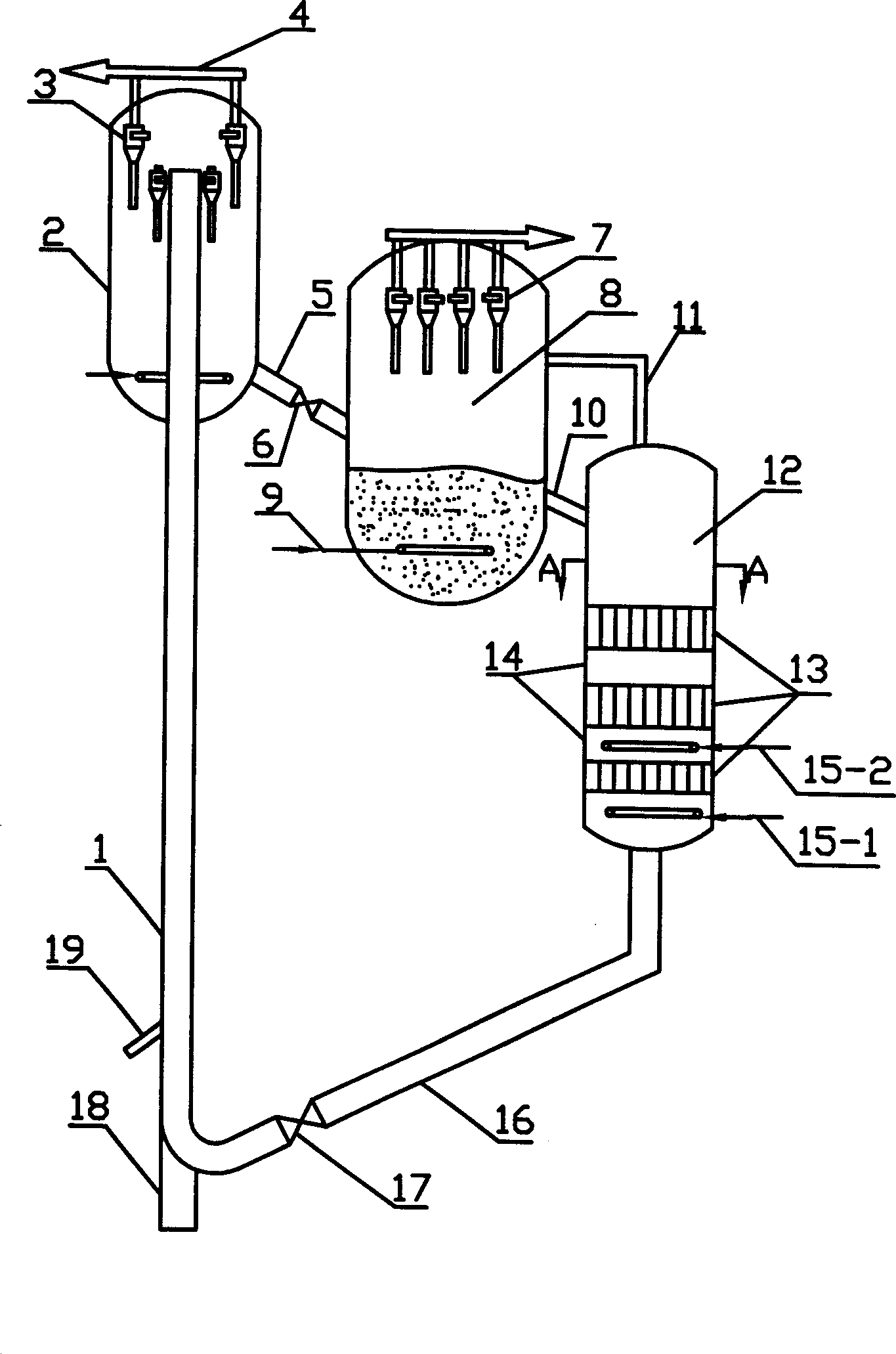

[0017] Such as figure 1 As shown, the hydrocarbon feedstock coming in from the bottom line 19 contacts the catalyst particles coming in from the catalyst outlet pipe 16 in the riser 1 , and the pre-lift steam enters the riser 1 from the gas line 18 .

[0018] The top of the riser 1 is connected to the settler 2 . The separation of the conversion products and the stripping of the deactivated catalyst take place in the settler 2 . The treated raw material is separated in the cyclone 3 located at the top of the settler 2, and the converted stream after the separation goes out of the settler 2 from the outlet line 4, and at the same time, the deactivated catalyst flows downward by gravity into the bottom of the settler 2, A general deactivated catalyst stripping is performed. The deactivated catalyst after stripping flows out from the bottom of the settler 2 and passes through the delivery pipeline 5 to the regenerator 8, on which a control valve 6 is installed. In the regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com