Method and equipment for raising effect of steam stripping at stripping section of catalytic cracking

A technology of catalytic cracking and stripping stage steam, which is applied in catalytic cracking, cracking, petroleum industry, etc. It can solve the problems of complex structure and difficult cleaning of foreign matter, so as to improve the stripping effect, reduce the maintenance amount of the device, and increase the reliability of the device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

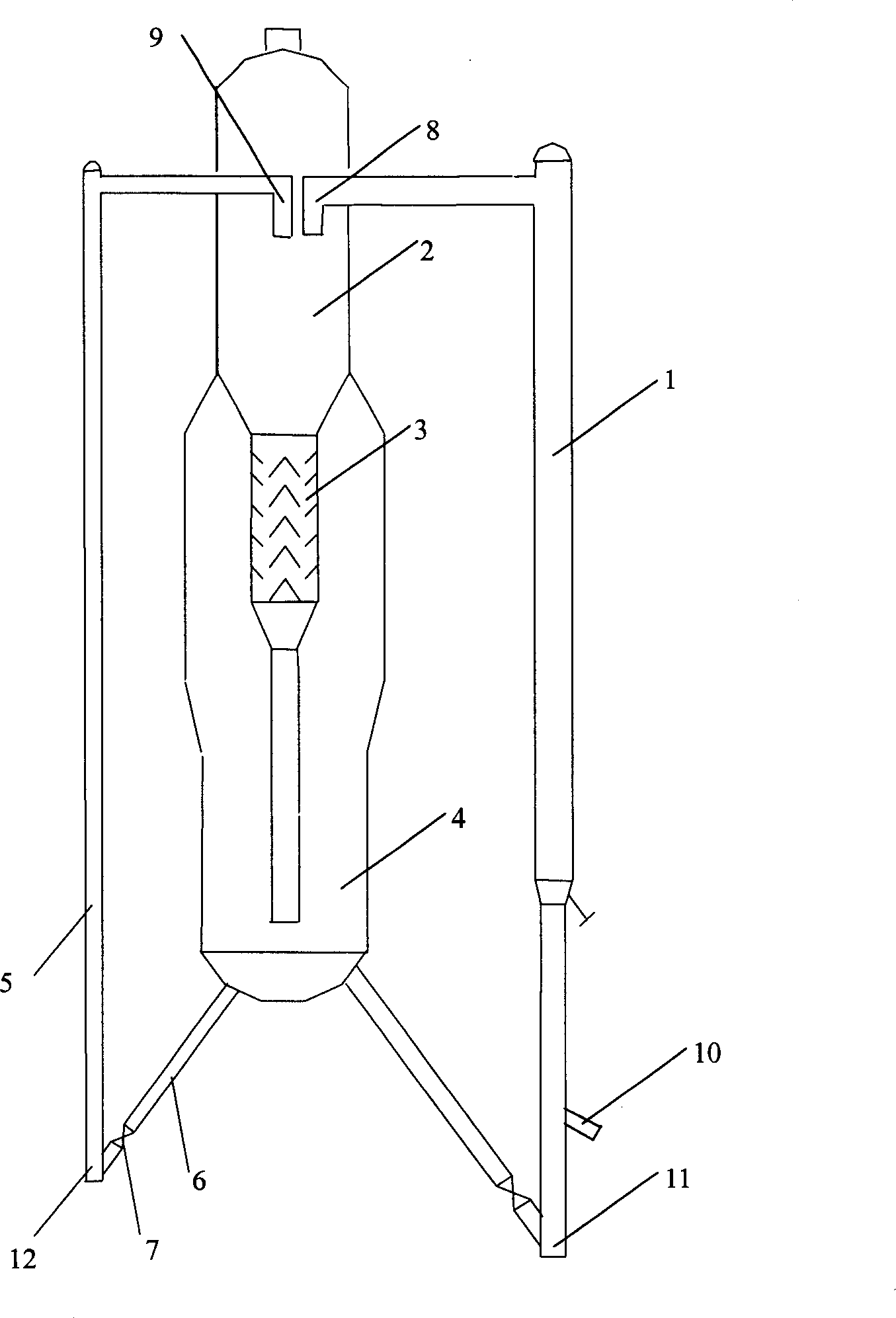

[0010] As shown in the figure, the catalytic cracking unit includes a riser reactor 1, a settler 2, a stripping section 3 and a regenerator 4. The bottom of the riser reactor 1 is provided with a raw oil inlet 10 and a catalyst inlet 11, and the top is provided with a lift The outlet 8 of the tube reactor is located in the settler 2, and a catalyst lifting delivery pipe 5 is arranged outside the regenerator 4. The lower part of the catalyst lifting delivery pipe 5 is connected to the regenerator 4 through the catalyst inclined pipe 6, and the upper part is provided with an outlet of the catalyst lifting delivery pipe. 9. Located in the settler 2, the slide valve 7 is set on the catalyst inclined tube 6.

[0011] The method for improving the stripping effect of the catalytic cracking stripping section as shown in the figure: the feed oil and the catalytic cracking catalyst enter the riser reactor 1 through the feed oil inlet 10 and the catalyst inlet 11 at the bottom of the rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com