Preparing method of cement products

A technology for cement products and reinforcing agents, applied in the field of cement products, can solve the problems of long molding time, shortened setting time, poor quality of cement products, etc., and achieve the effects of strong penetration and flow ability, improved toughness, and enhanced strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

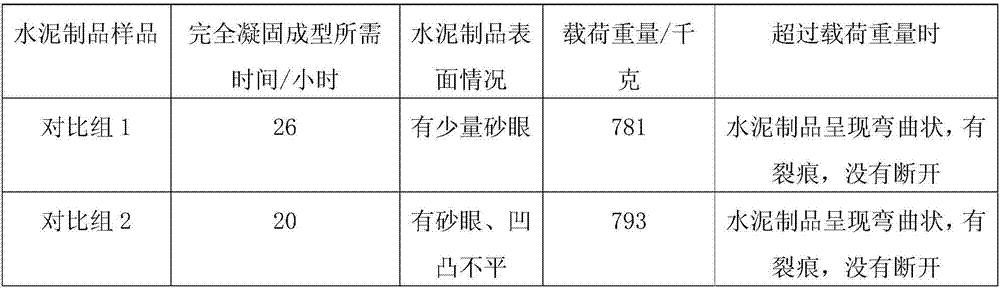

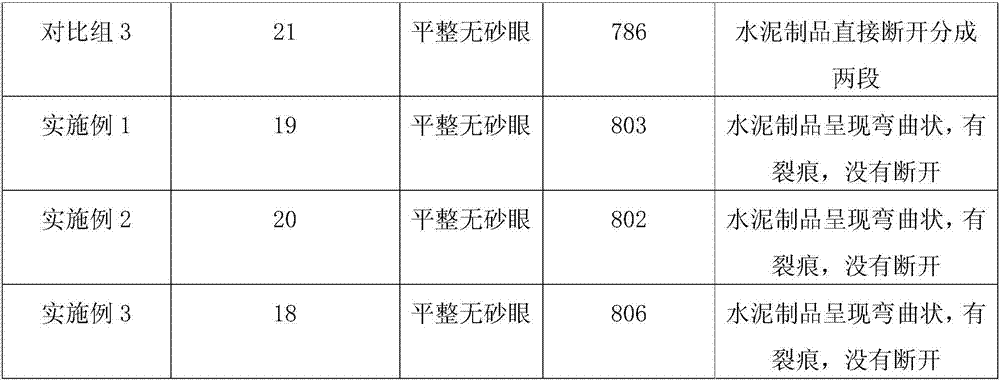

Examples

Embodiment 1

[0021] A kind of preparation method of cement product, comprises the following steps:

[0022] (1) Put the raw materials of cement products and water into the mixer according to the mass ratio of 1:1.8, mix and stir evenly, and then pour the mixture into the mold;

[0023] (2) Put the un-demolded cement product into the curing room for a curing. During the curing process, keep the pressure in the curing room at 0.3MPa, the temperature at 60°C, and the humidity at 70%. The time for the curing is 2 hours , Spray the reinforcing agent on the cement products during a curing process, and use microwaves to accelerate the coagulation of the cement products throughout the process, and demould after the first curing;

[0024] (3) Spray reinforcing agent again on the cement products after demoulding, and then carry out secondary curing. During the secondary curing, the pressure in the curing room is maintained at normal pressure, the temperature is 35°C, and the humidity is 40%. The ti...

Embodiment 2

[0030] A kind of preparation method of cement product, comprises the following steps:

[0031] (1) Put the raw materials of cement products and water into the mixer according to the mass ratio of 1:2, mix and stir evenly, and then pour the mixture into the mold;

[0032](2) Put the cement product without demoulding into the curing room for a curing, keep the pressure of the curing room at 0.4MPa, the temperature at 70°C, and the humidity at 75% during the curing process, and the curing time is 3 hours , Spray the reinforcing agent on the cement products during a curing process, and use microwaves to accelerate the coagulation of the cement products throughout the process, and demould after the first curing;

[0033] (3) Spray reinforcing agent again on the cement product after demolding, and then carry out secondary curing. During the secondary curing, the pressure in the curing room is maintained at normal pressure, the temperature is 40°C, and the humidity is 45%. The time ...

Embodiment 3

[0039] A kind of preparation method of cement product, comprises the following steps:

[0040] (1) Put the raw materials of cement products and water into the mixer according to the mass ratio of 1:2.3, mix and stir evenly, and then pour the mixture into the mold;

[0041] (2) Put the un-demolded cement product into the curing room for a curing. During the curing process, keep the pressure of the curing room at 0.5MPa, the temperature at 80°C, and the humidity at 80%. The time for the curing is 4 hours , Spray the reinforcing agent on the cement products during a curing process, and use microwaves to accelerate the coagulation of the cement products throughout the process, and demould after the first curing;

[0042] (3) Spray reinforcing agent again on the cement product after the demoulding, then carry out secondary curing, keep the pressure of curing room to be normal pressure in the secondary curing process, temperature is 45 ℃, humidity is 50%, the time of secondary curin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com