Graphene aluminum composite material and preparation method thereof

An aluminum composite material, graphene technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of graphene and aluminum matrix cannot be uniformly mixed, long preparation period, etc., to achieve short preparation period , Simple operation, and the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention provides a kind of preparation method of graphene aluminum composite material, comprises the following steps:

[0029] S10, providing graphene airgel, forming an aluminum film on the surface of graphene airgel by vacuum evaporation;

[0030] S20, stirring the graphene airgel with the aluminum film on the surface to obtain the graphene powder with the aluminum film on the surface;

[0031] S30, using a stirring casting method to compound the graphene powder with the aluminum film on the surface and the aluminum matrix.

[0032] The preparation method of the graphene-aluminum composite material provided by the embodiment of the present invention adopts the vacuum evaporation method to form an aluminum film on the surface of the graphene airgel with a three-dimensional network structure, and then makes the overlapped graphene aerogels in the graphene aerogel by stirring Graphene flakes are dispersed to form graphene powder and stirr...

Embodiment 1

[0058] (1) Freeze-dry 100 mL of a graphene oxide aqueous solution with a concentration of 5 mg / ml, the freeze-drying temperature is -50 ° C, and the freeze-drying time is 20 h, and the prepared graphene oxide airgel is cut into 50 × 50 × 50 mm The small pieces were reduced in a vacuum environment at 2000°C for 2 hours to prepare graphene airgel.

[0059] (2) Put the graphene airgel prepared in step (1) into the vacuum coating equipment, vacuumize the vacuum chamber, and vacuum to 0.1Pa, carry out ion bombardment to the sample, the voltage is 200V, and the bombardment time is 30min. Turn on the diffusion pump to make the vacuum chamber into a high vacuum state with an air pressure of 5×10 -3 Pa, the graphene airgel is baked to further remove the gas in the graphene airgel. Preheat the evaporation source, adjust the voltage to make the temperature reach 700°C, melt the aluminum strip in the evaporation source to a molten state, adjust the power to 500W, adjust the temperature ...

Embodiment 2

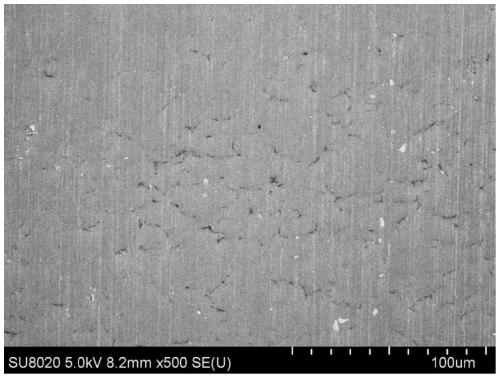

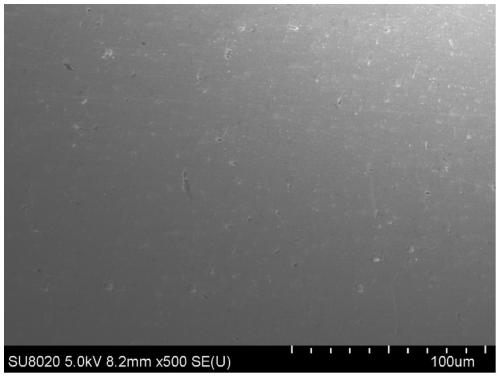

[0063] It is basically the same as Example 1, except that the concentration of the graphene oxide aqueous solution in step (1) is 3 mg / ml. The scanning electron micrographs of the graphene-aluminum composite material prepared in this example show that graphene can be evenly distributed in the aluminum metal phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com