Method for improving performance of Mg/Al jointing interface

A technology for connecting interface and performance, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of poor interface bonding strength, complex production process, unstable product quality, etc. Improve the overall performance and improve the effect of casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

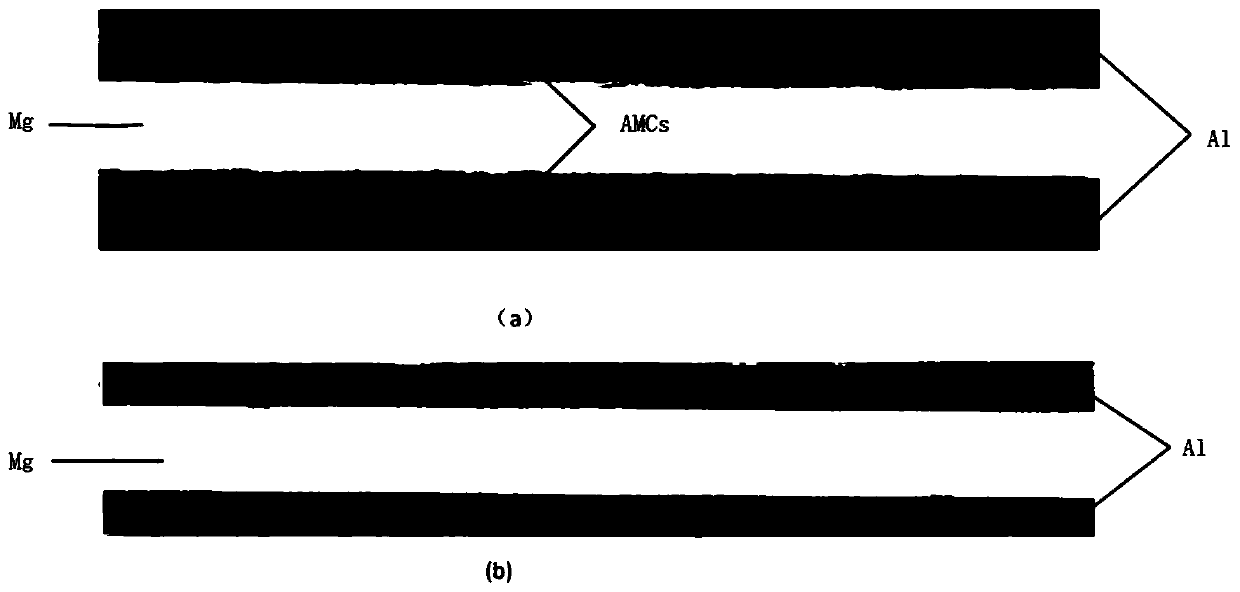

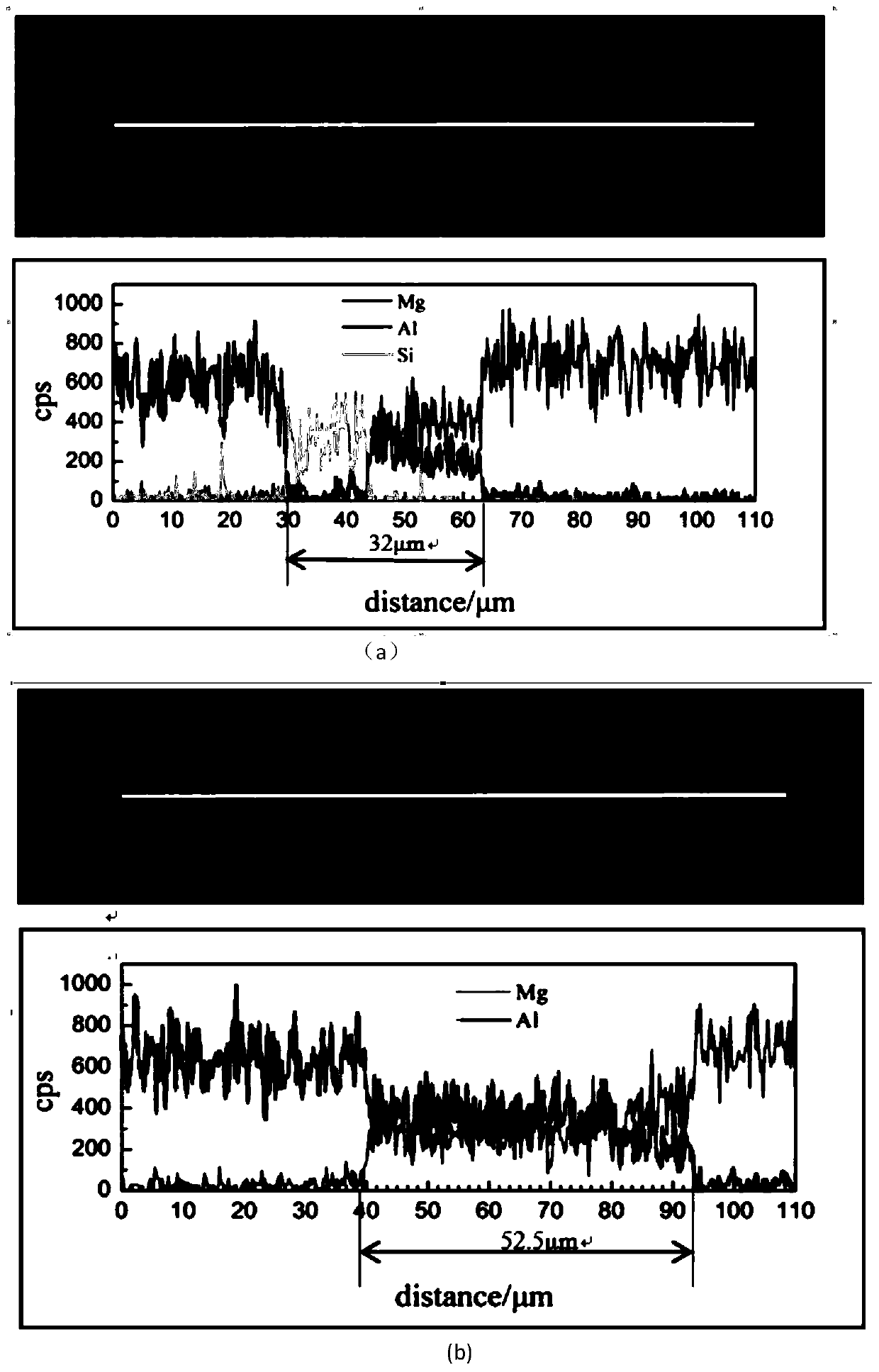

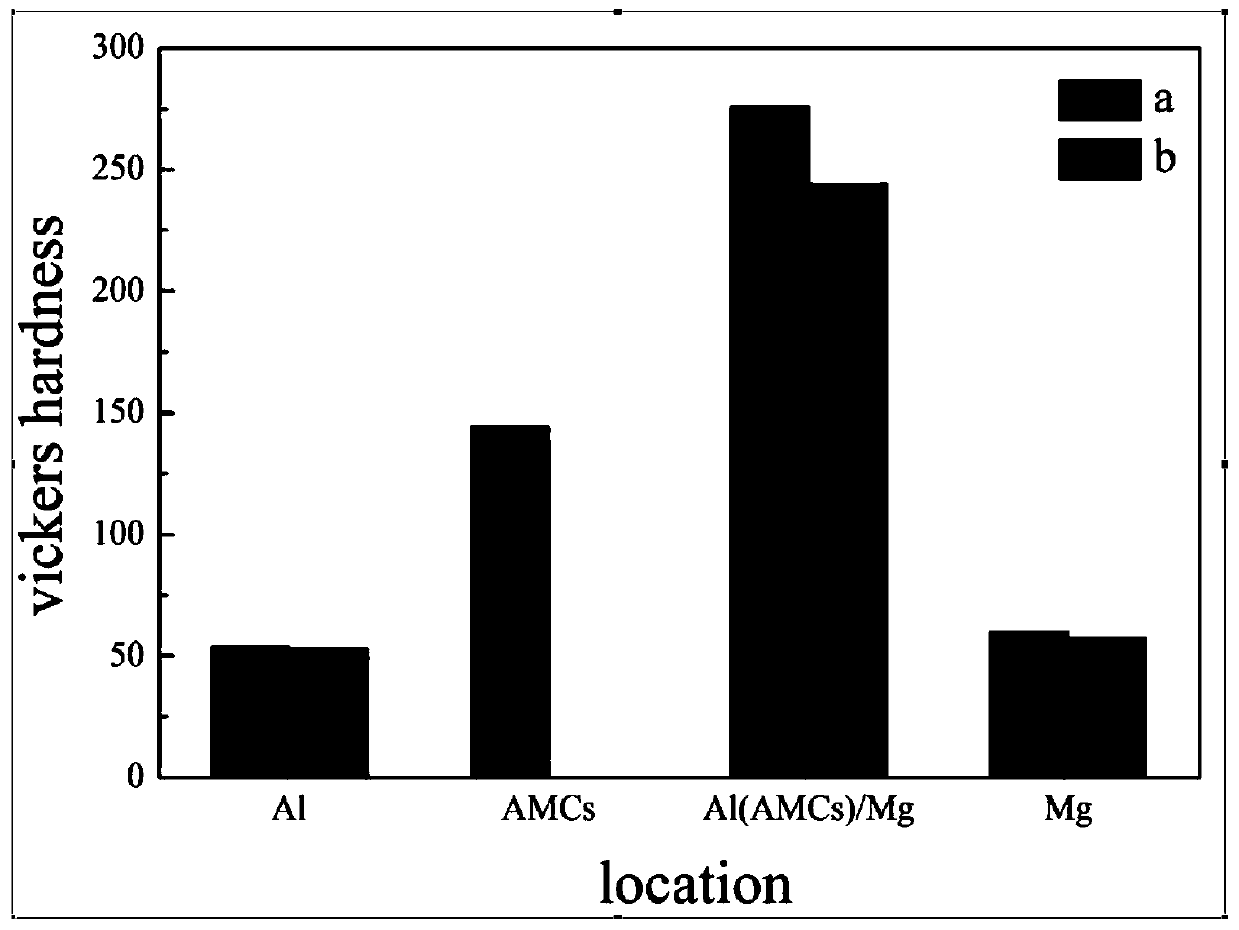

[0028] Specific Embodiment 1: This embodiment is a method for introducing a SiCp reinforcement phase to improve the interface of the Mg / Al layer, which is specifically carried out according to the following steps:

[0029] First, the preparation of SiCp / AMCs. The particle size of SiCp is 10 μm, and the particle volume fraction is 10%. Place the measured silicon carbide particles in a drying furnace, rise to 600° C. with the furnace and keep it warm for 2-3 hours. Preheat the die-casting mold to 150°C and brush with graphite oil, then preheat to 400°C and keep it warm for 1-3 hours. Before preparing AMCs, talcum powder and ZnO were evenly coated on the inner surface of the crucible to block the possible reaction between the crucible and the melt. AMCs were prepared by semi-solid stirring casting method. Before the aluminum alloy was completely melted, the Ar+CO2 mixed gas was introduced, and the aluminum alloy was kept at about 100°C (760°C) above the melting point of the alum...

specific Embodiment approach 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume fraction of spherical SiCp described in step 1 is 5%, and the others are the same as Embodiment 1.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the volume fraction of spherical SiCp described in step 1 is 15%, and the others are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com