Anticorrosive layered double-hydroxy composite metal hydroxide film and preparation method thereof

A double-hydroxy compound and layered double-hydroxy technology, which is applied in coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., can solve the problems of unfriendly environment and toxic corrosion inhibitors, and achieve improved corrosion resistance and good protection Function, the effect of excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

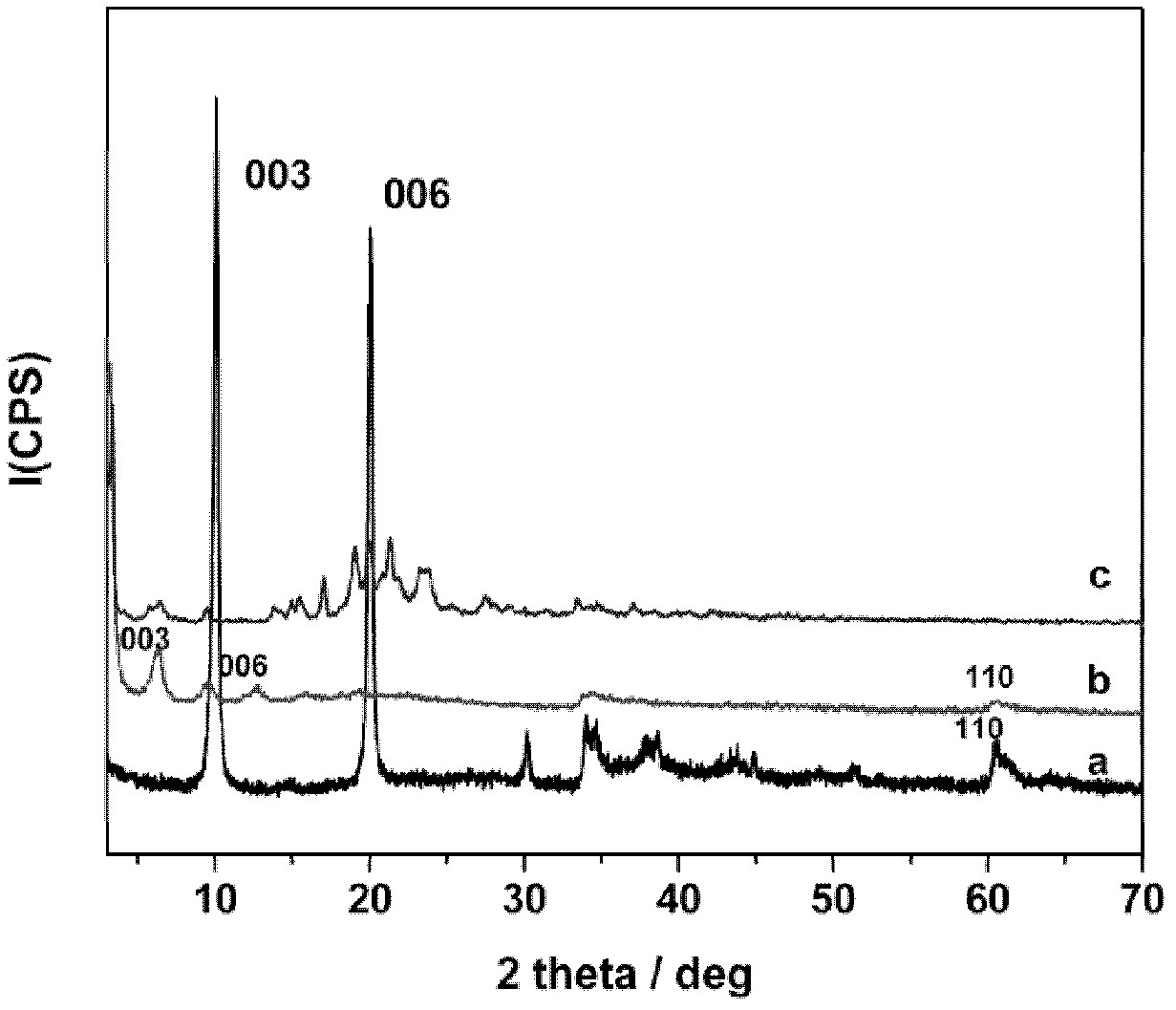

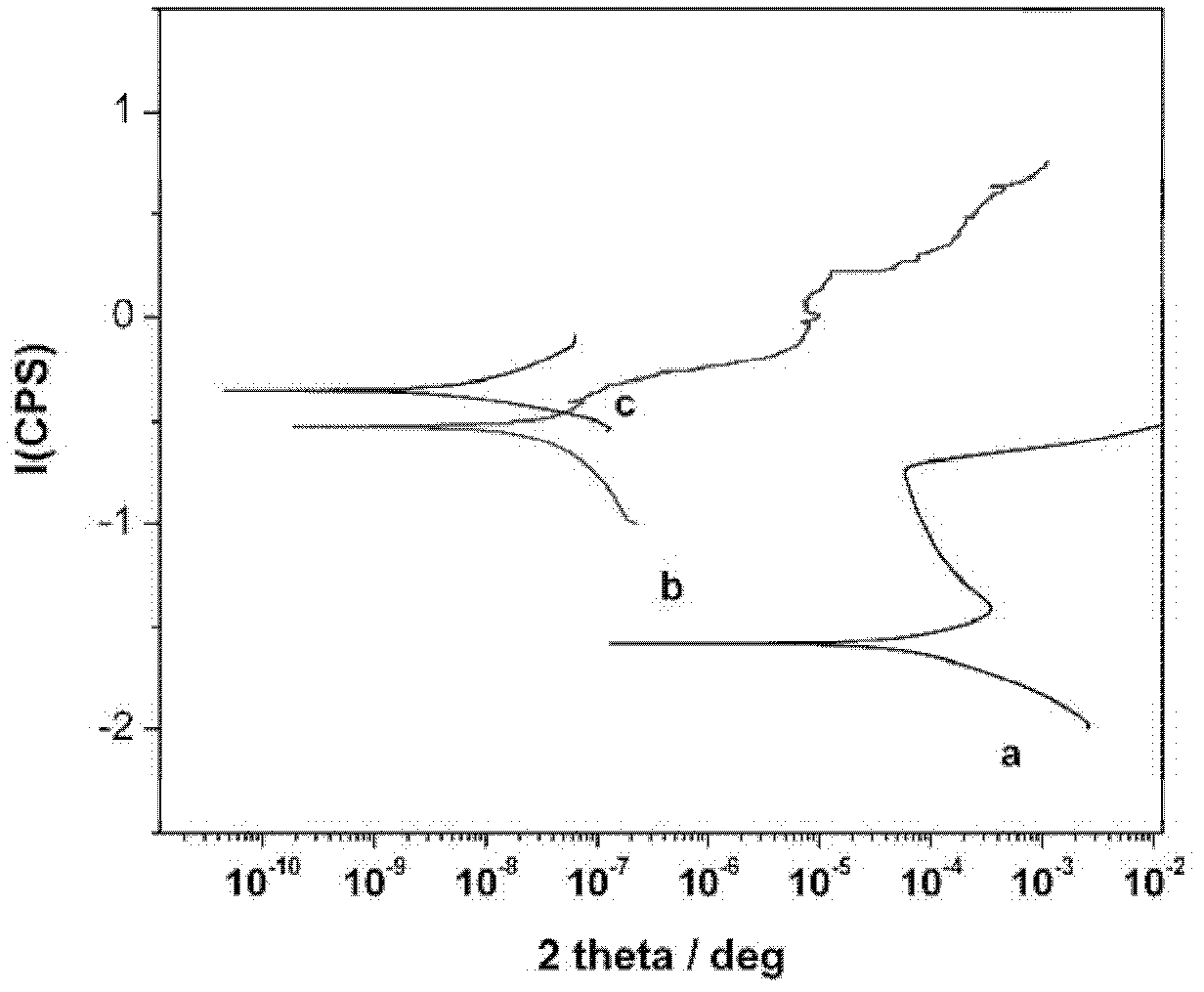

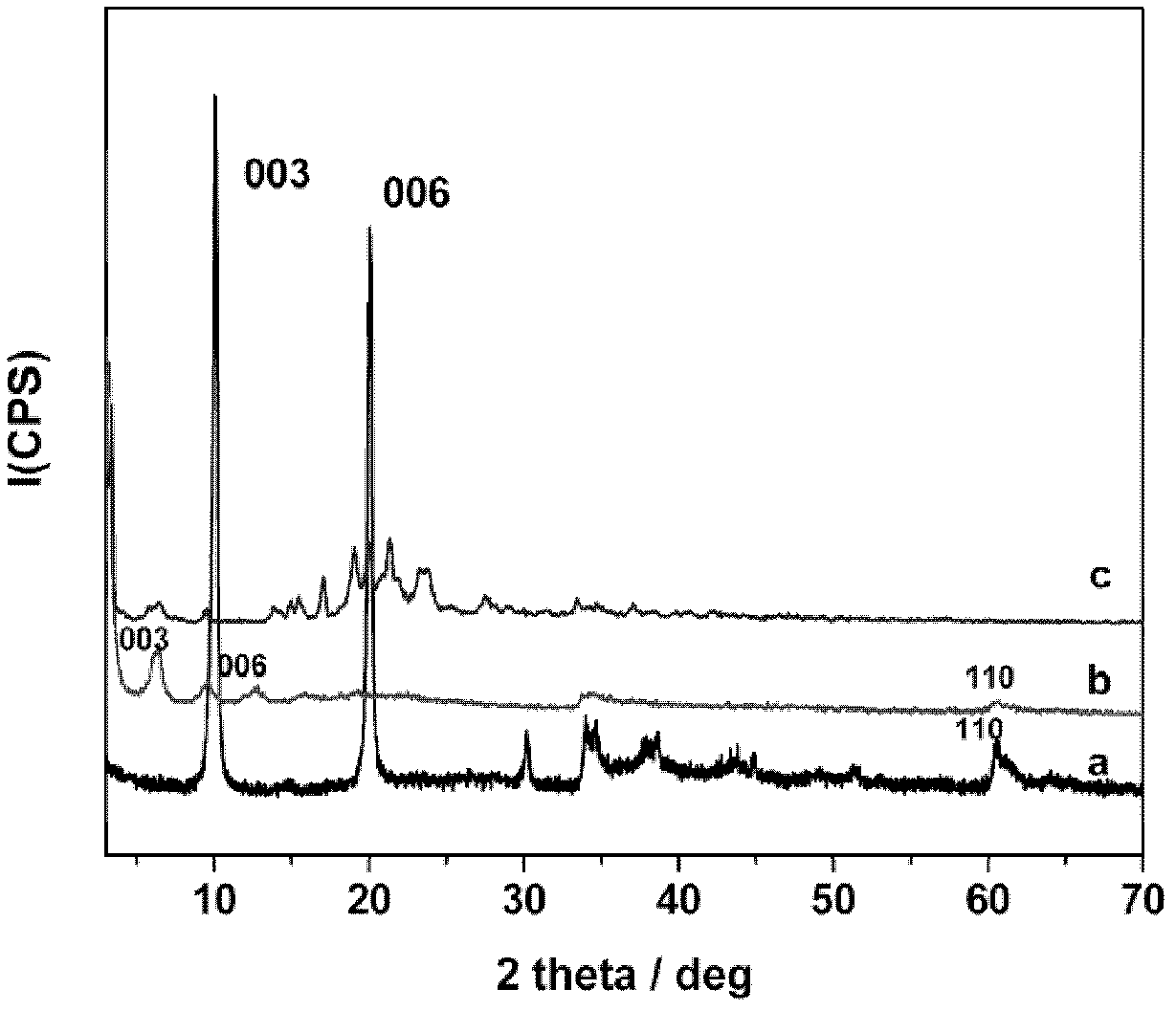

Image

Examples

Embodiment 1

[0027] A. Ultrasonic cleaning the aluminum sheet with a purity of 99.99wt% with deionized water and acetone for 5 minutes to remove impurities and oil stains on the surface, then ultrasonically cleaning it with 1% sodium hydroxide solution for 2 minutes, and then cleaning it with deionized water Clean it up and oxidize it in an anodizing device. The aluminum sheet is used as the anode, the lead plate is used as the cathode, the electrolyte is 1mol / L sulfuric acid solution, and the oxidation voltage is 2V / cm 2 The aluminum sheet is taken out after anodizing for 60 minutes, and the electrolyte solution is washed away with deionized water to obtain an anodized aluminum sheet on the surface for use;

[0028] B. Weigh 0.595g of zinc nitrate and 0.96g of ammonium nitrate, dissolve them in 200ml deionized water, and prepare NH 4 + : Zn 2+ Molar ratio is 200ml of the reaction solution of 6, wherein Zn 2+ The molar concentration is 0.01mol / L, and the pH is adjusted to 6.5 with 1wt% am...

Embodiment 2

[0038] A. Ultrasonic cleaning the aluminum sheet with a purity of 99.99wt% with deionized water and acetone for 6 minutes to remove impurities and oil stains on the surface, then ultrasonically cleaning it with a sodium hydroxide solution with a mass fraction of 1wt% for 3 minutes, and then cleaning it with deionized water Clean it up and oxidize it in an anodizing device. The aluminum sheet is used as the anode, the lead plate is used as the cathode, the electrolyte is 1mol / L sulfuric acid solution, and the oxidation voltage is 2V / cm 2 The aluminum sheet is taken out after anodizing for 60 minutes, and the electrolyte solution is washed away with deionized water to obtain an anodized aluminum sheet on the surface for use;

[0039] B. Weigh 2.975g of zinc nitrate and 4.8g of ammonium nitrate, dissolve them in 200ml deionized water, and prepare NH 4 + : Zn 2+ Molar ratio is 200ml of the reaction solution of 6, wherein Zn 2+ The molar concentration is 0.05mol / L, and the pH is...

Embodiment 3

[0045] A. Ultrasonic cleaning the aluminum sheet with a purity of 99.99wt% with deionized water and acetone for 8 minutes to remove impurities and oil stains on the surface, then ultrasonically cleaning it with 3% sodium hydroxide solution for 2 minutes, and then cleaning it with deionized water Clean it up and put it into an anodizing device for oxidation, in which the aluminum sheet is used as the anode, the lead plate or stainless steel plate is used as the cathode, the electrolyte is 1.0mol / L sulfuric acid solution, and the oxidation voltage is 2V / cm 2 Aluminum sheet, after anodizing the aluminum sheet for 60 minutes, take it out, rinse off the electrolyte with deionized water, and obtain an anodized aluminum sheet on the surface for use;

[0046] B. Weigh 2.975g of zinc nitrate and 6.4g of ammonium nitrate, dissolve them in 200ml deionized water, and prepare NH 4 + : Zn 2+ Molar ratio is 8 reaction solution 200ml, wherein Zn 2+ The molar concentration is 0.05mol / L, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com