Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165results about "Tensioning/braking arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for and method of processing billets in a rolling mill

A rolling mill has roughing, intermediate and finishing roll stands on a first side of a billet reheating furnace, and a breakdown mill on an opposite second side of the furnace. Billets are heated to an elevated rolling temperature in the furnace and are then ejected to the second side of the furnace for rolling in the breakdown mill before being directed back through the furnace for continued rolling into finished products at the first side of the furnace in the roughing, intermediate and finishing roll stands.

Owner:MORGAN CONSTR CO

Sheet metal scale removing water jet process

InactiveUS7077724B1Less complexEliminate scalingElectrostatic cleaningWork treatment devicesEngineeringHigh pressure

An apparatus and method of removing scale from the surfaces of processed sheet metal employs high pressure jets of water directed from nozzles positioned in close proximity to the sheet metal surfaces.

Owner:THE MATERIAL WORKS

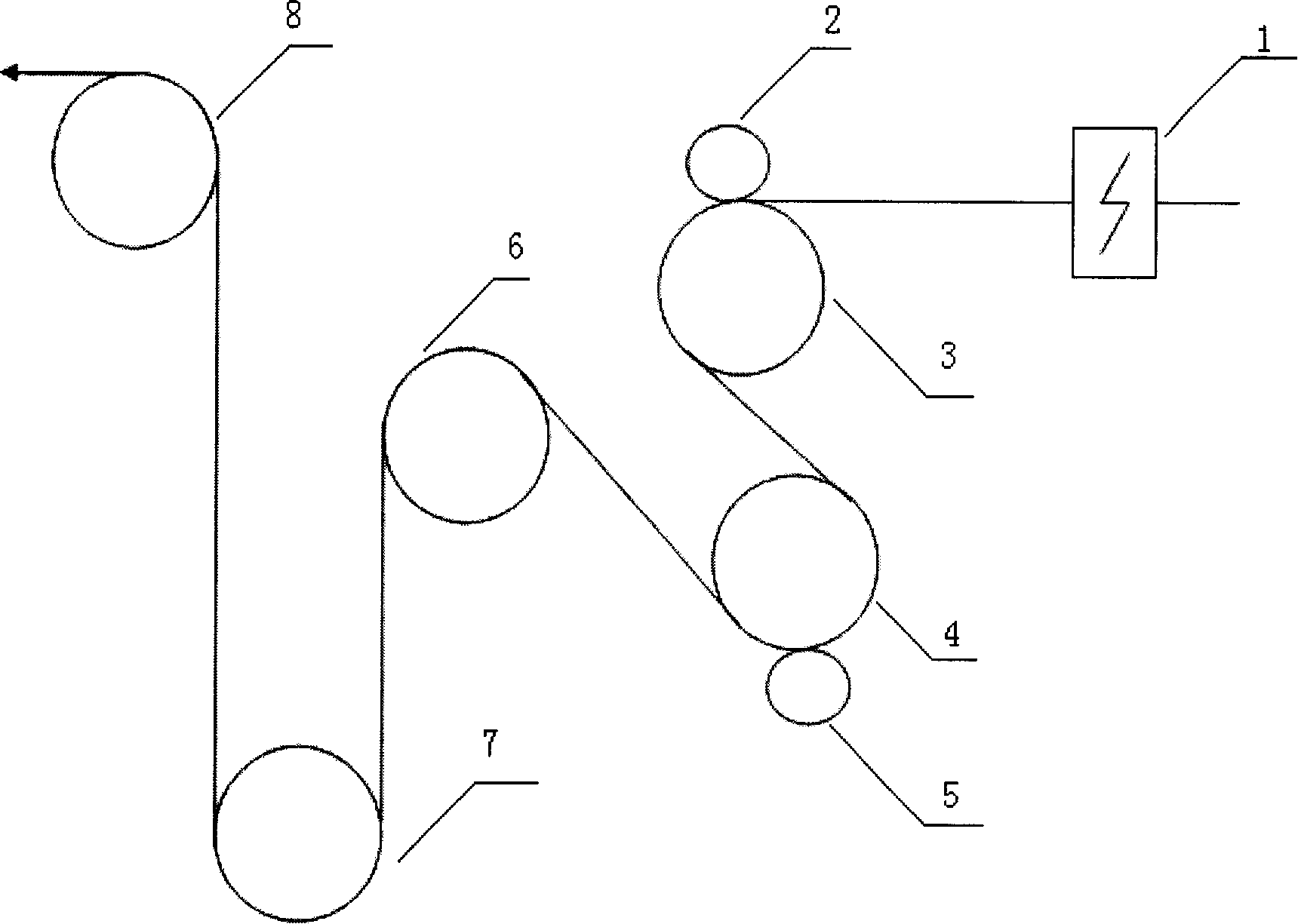

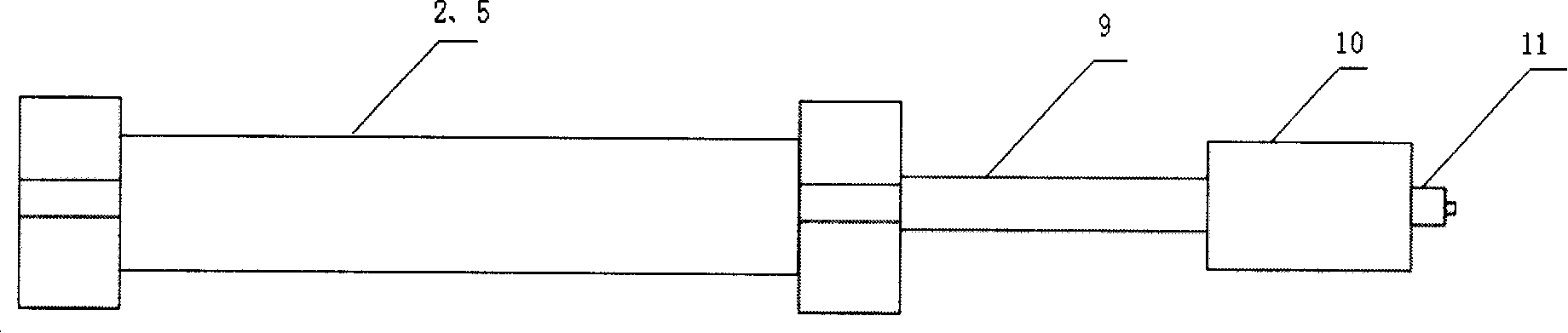

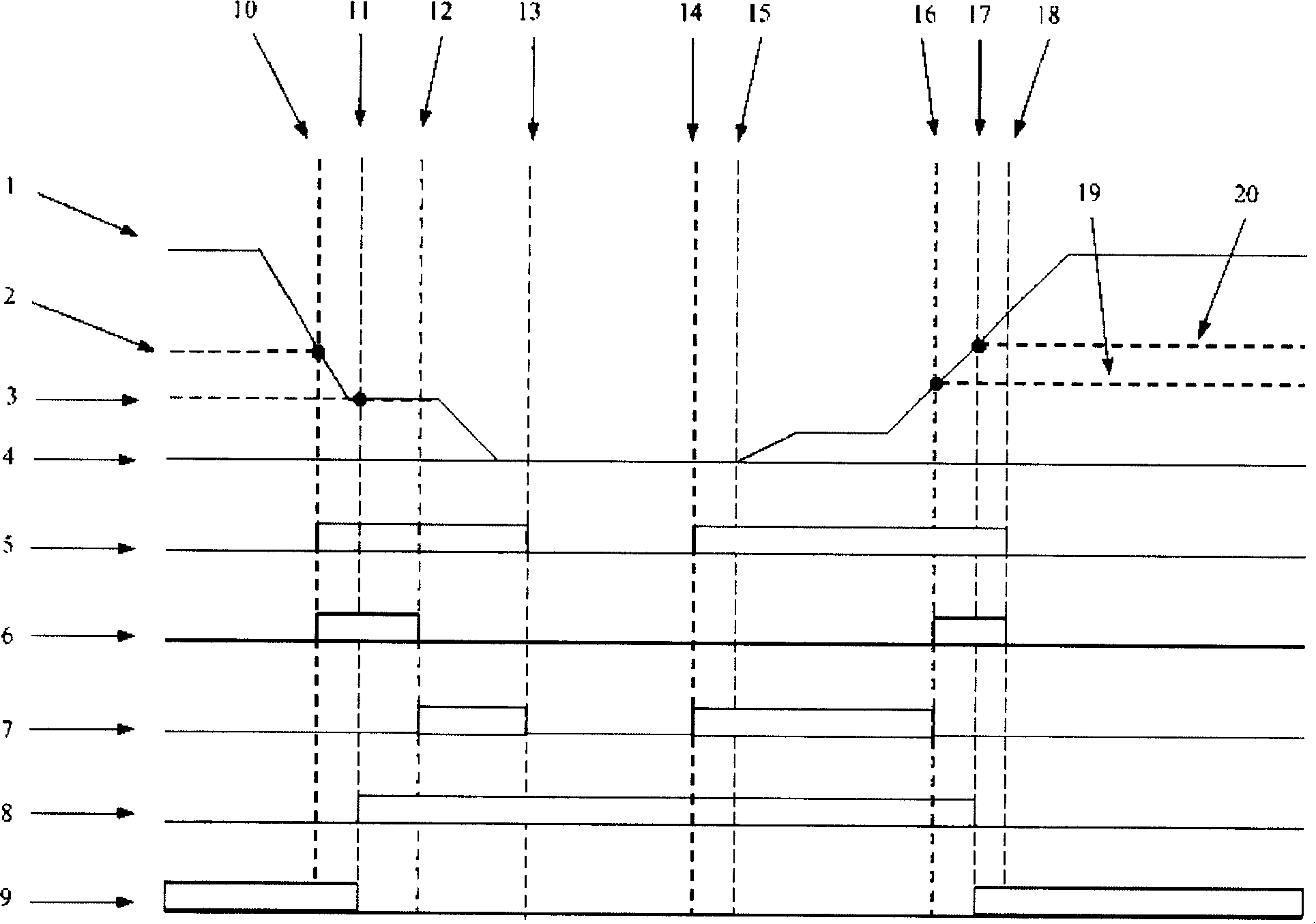

Control process for continuous skin pass operation for metal strip

InactiveUS6079242AEliminate disadvantagesRoll force/gap control deviceTensioning/braking arrangementsMechanical engineeringEngineering

A method of controlling a continuous skin-pass and reduction operation for a metal strip includes the steps of passing a strip through a gap between working rollers of at least two successive rolling stands, only an upstream one of the stands providing substantial thickness reduction of the strip; determining an extension rate of the strip provided by the upstream stand; determining a tension of the strip downstream of the upstream stand; adjusting the speed of the working rollers of the upstream stand compared to the speed of the working rollers of a downstream one of said stands according to the determination of the extension rate; and adjusting the squeezing force of the upstream stand according to the downstream tension determination. A response time to the step of adjustment of the squeezing force is longer than a response time to the step of adjusting the speed of the working rollers.

Owner:SOLLAC (SA)

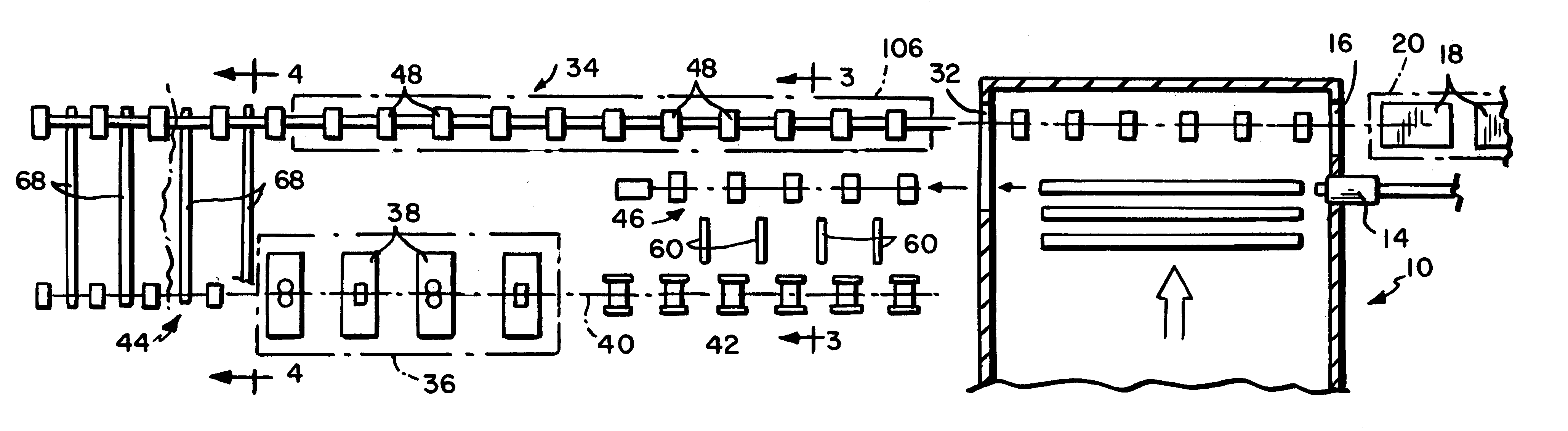

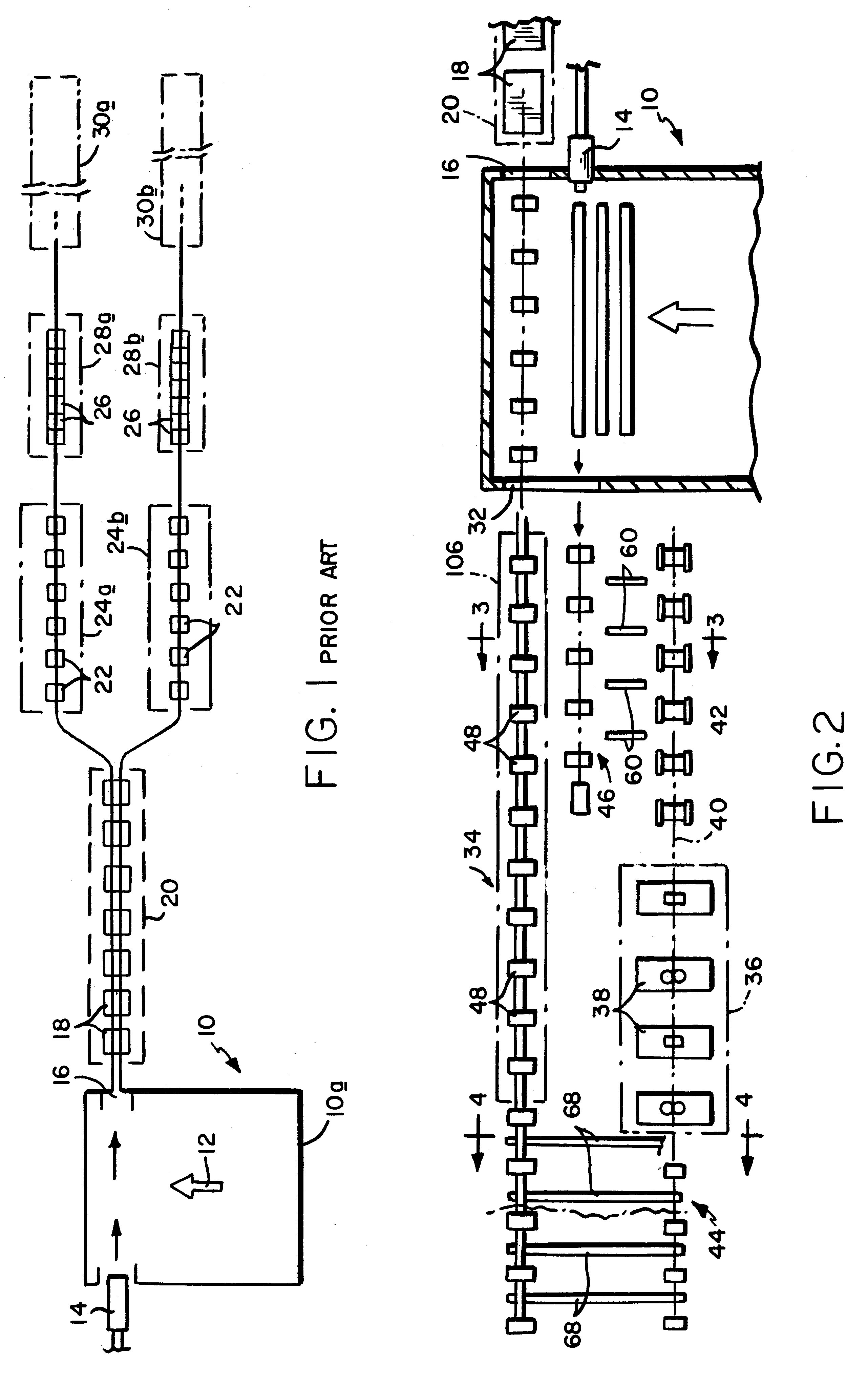

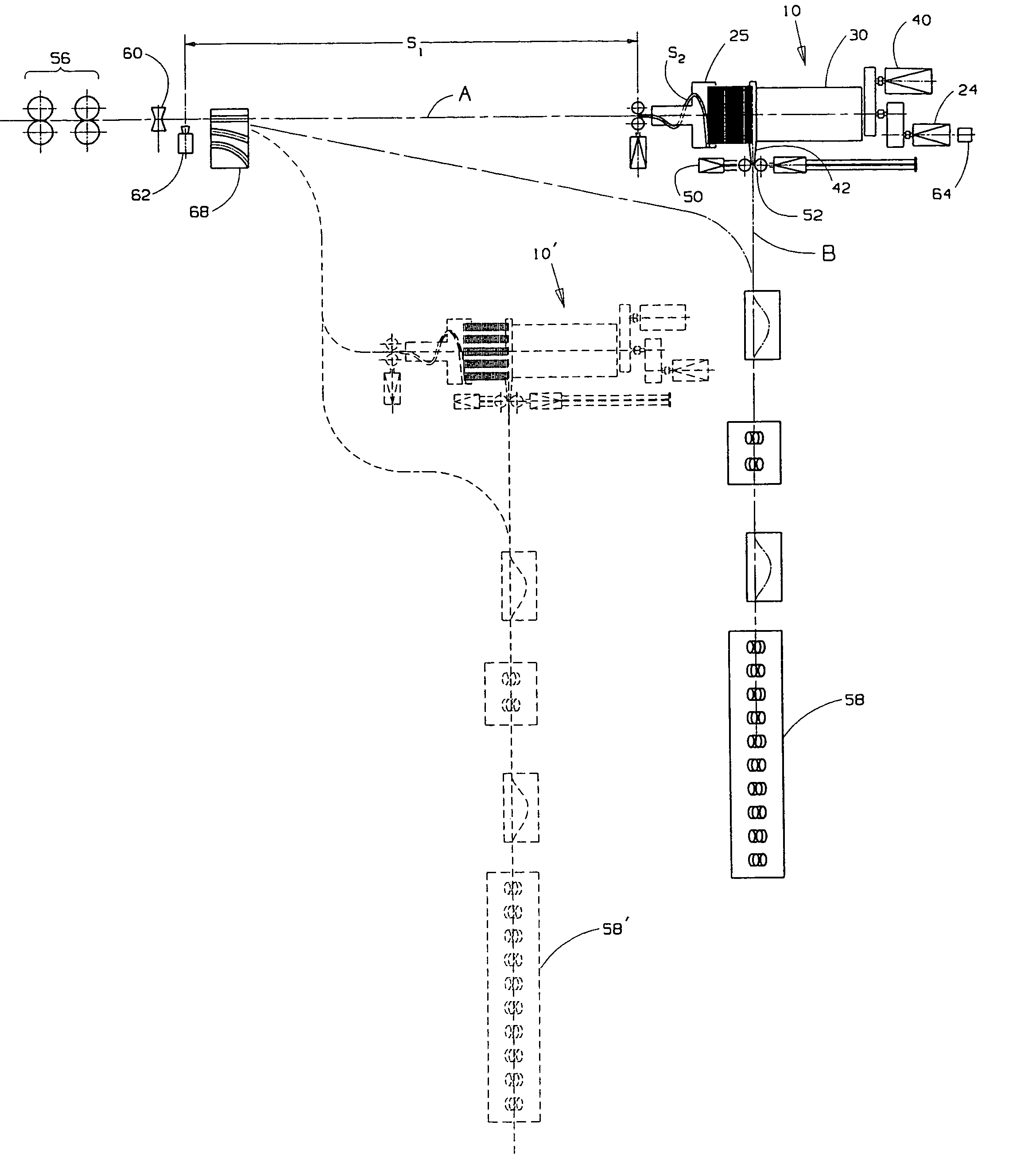

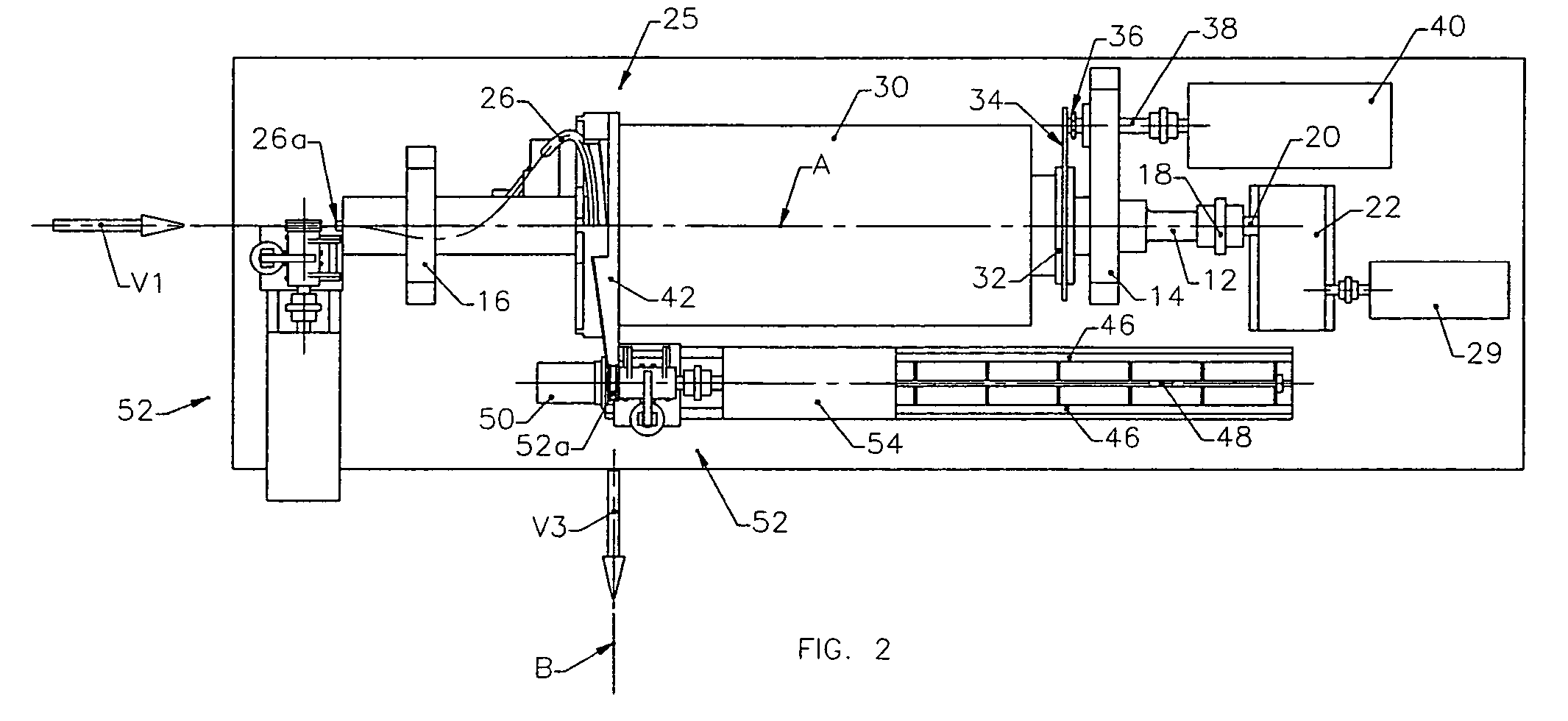

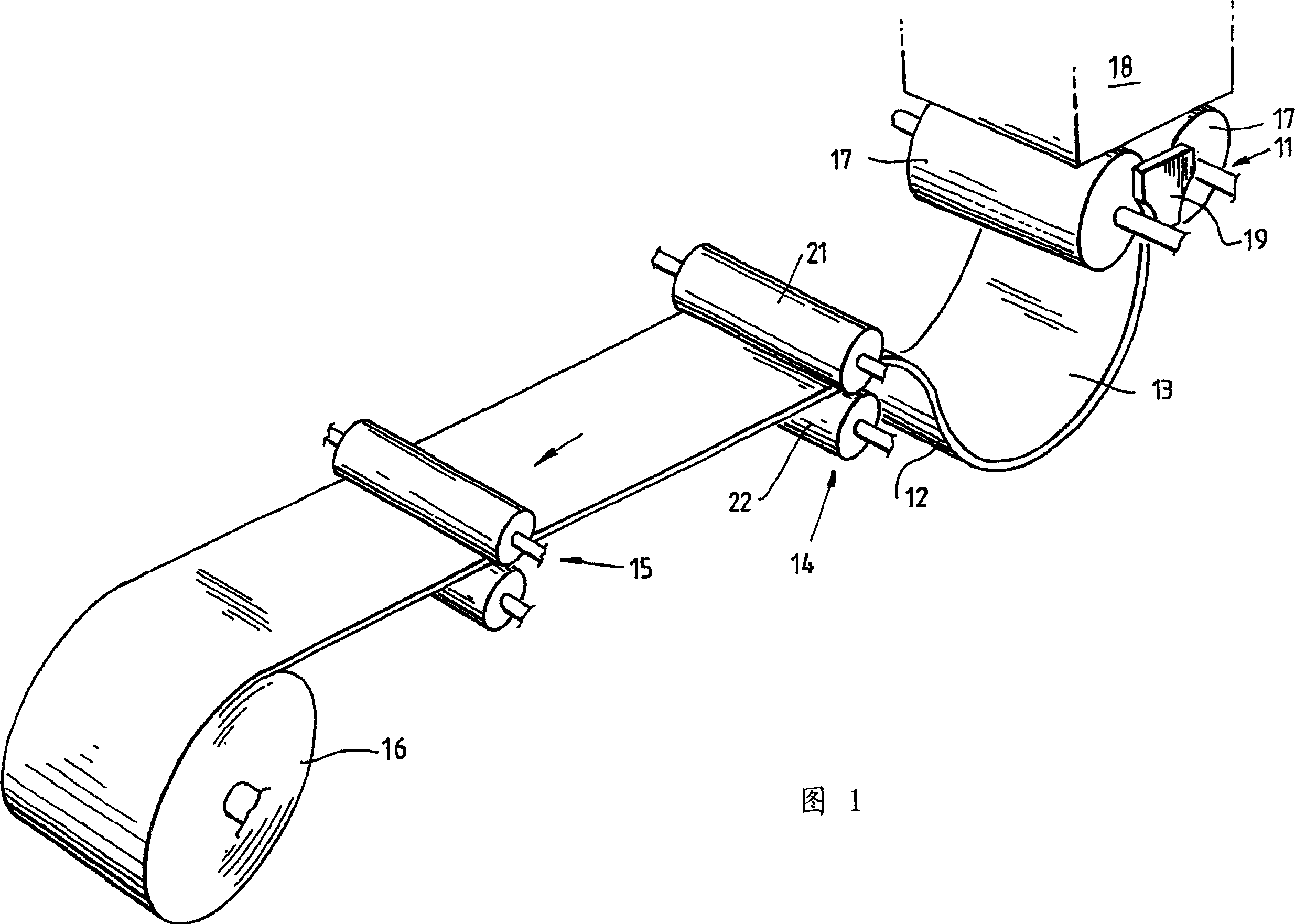

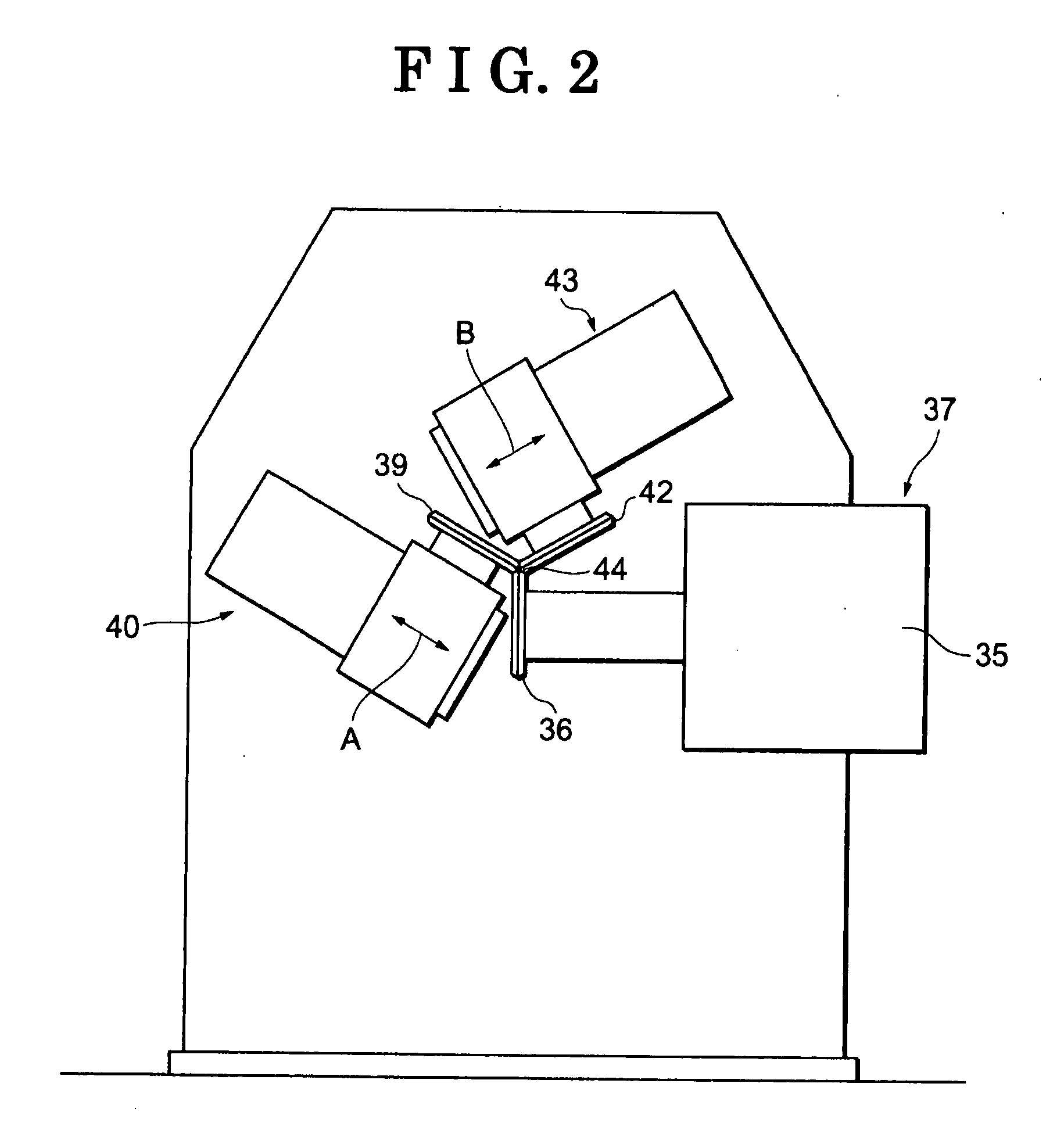

Method and apparatus for decelerating and temporarily accumulating a hot rolled product

InactiveUS7021103B2Guiding/positioning/aligning arrangementsFilament handlingEngineeringMechanical engineering

A method and apparatus is disclosed for decelerating and temporarily accumulating a hot rolled product moving longitudinally along a receiving axis at a first velocity V1. The product is directed through a curved guide having an entry end aligned with the receiving axis to receive the product, and an exit end spaced radially from the receiving axis and oriented to deliver the product in an exit direction transverse to the receiving axis. The curved guide is rotated about the receiving axis in a direction opposite to the exit direction of the product and at a speed at which the guide exit end has a velocity V2, thereby decelerating the product being delivered from the guide exit end to a reduced velocity V3 equal to V1−V2. The curvature of the guide and the orientation of its exit end is such as to form the delivered product into a helix deposited and temporarily accumulated on a cylindrical drum. The drum is rotated in a direction opposite to the direction of rotation of the curved guide to thereby unwind the product from the drum.

Owner:PRIMETALS TECH USA

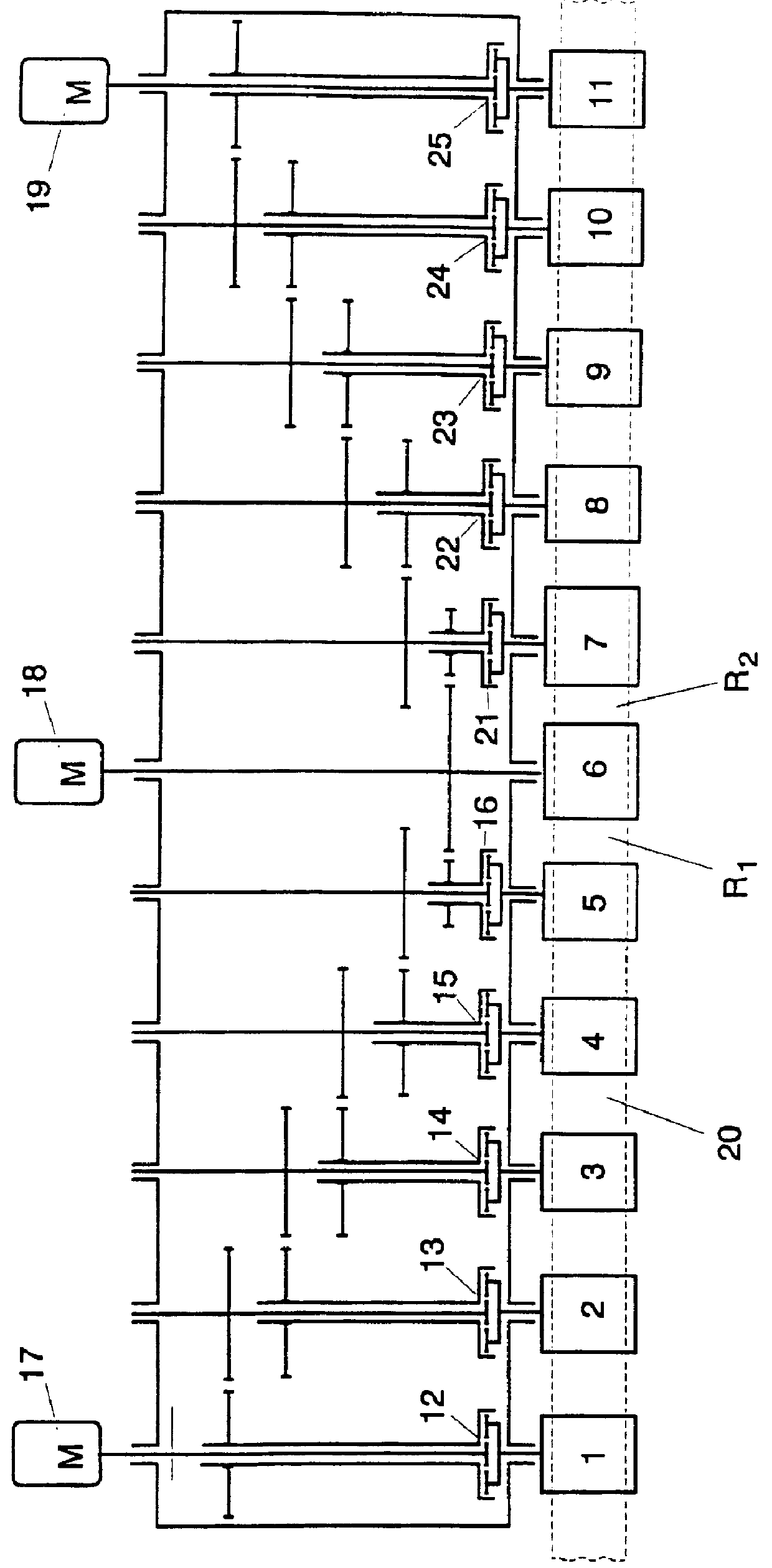

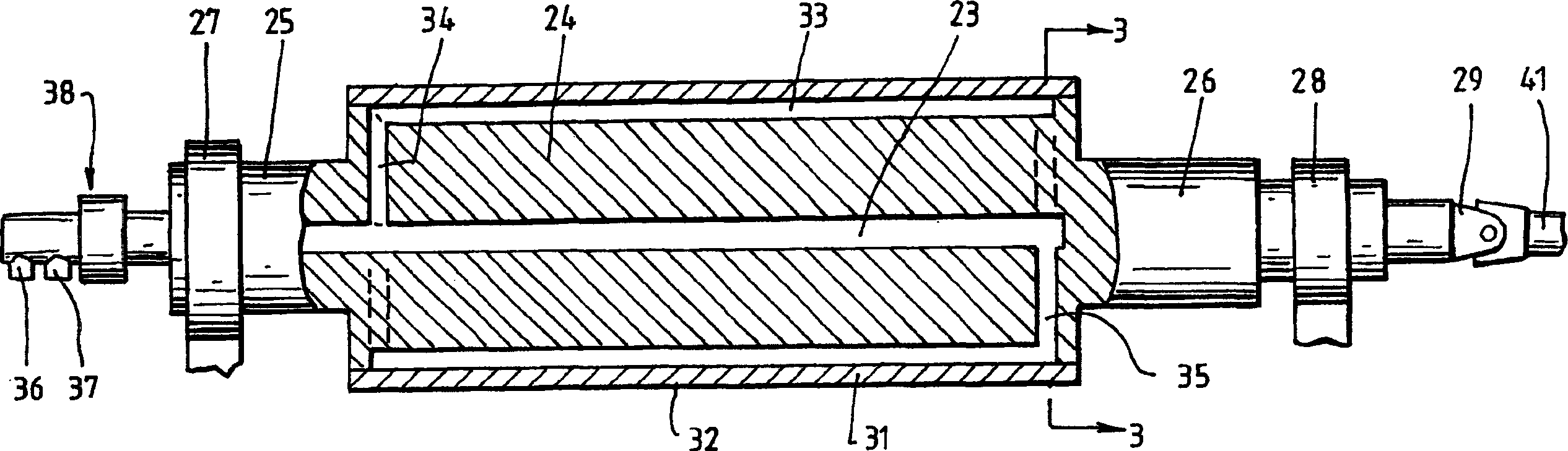

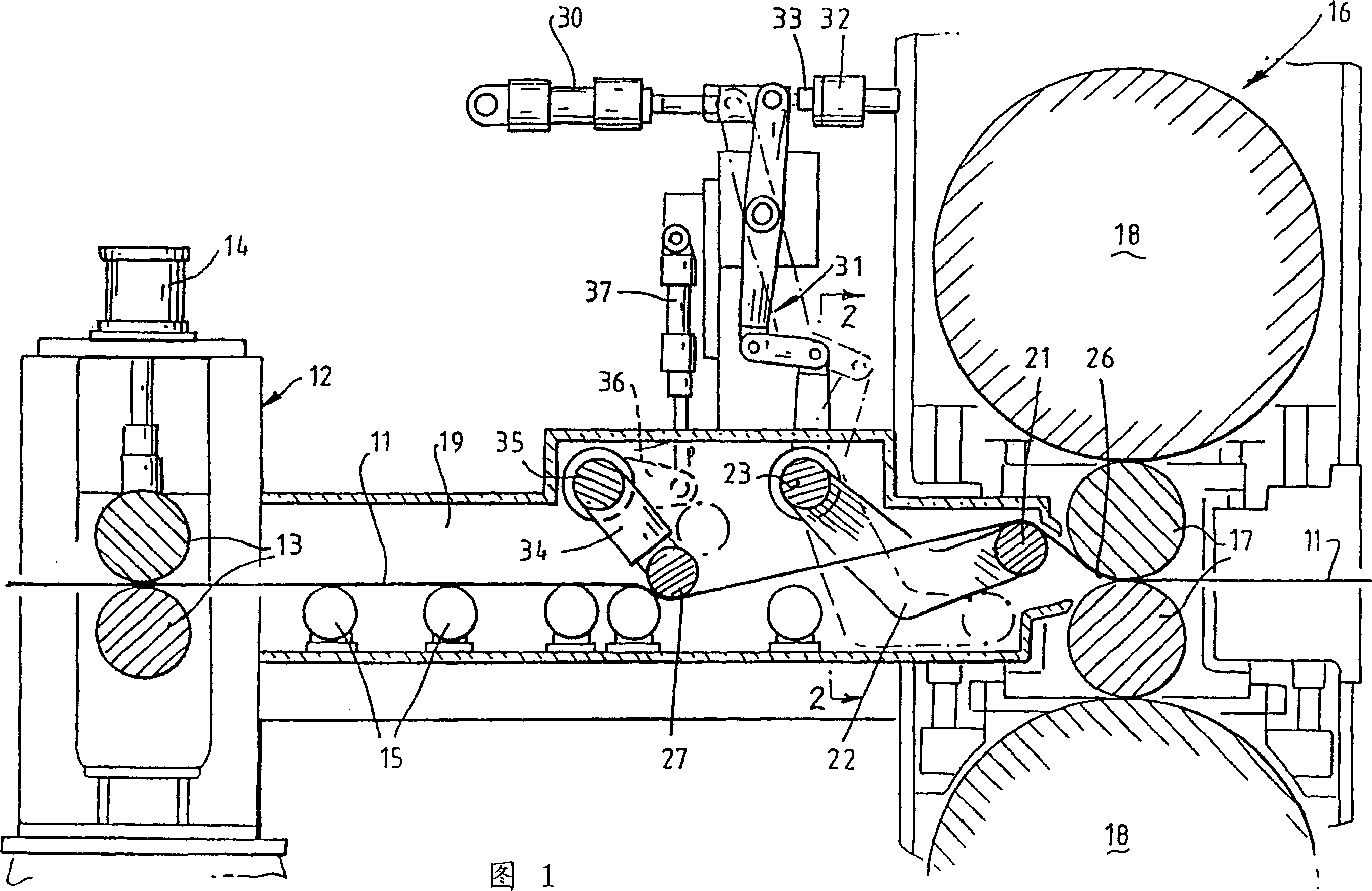

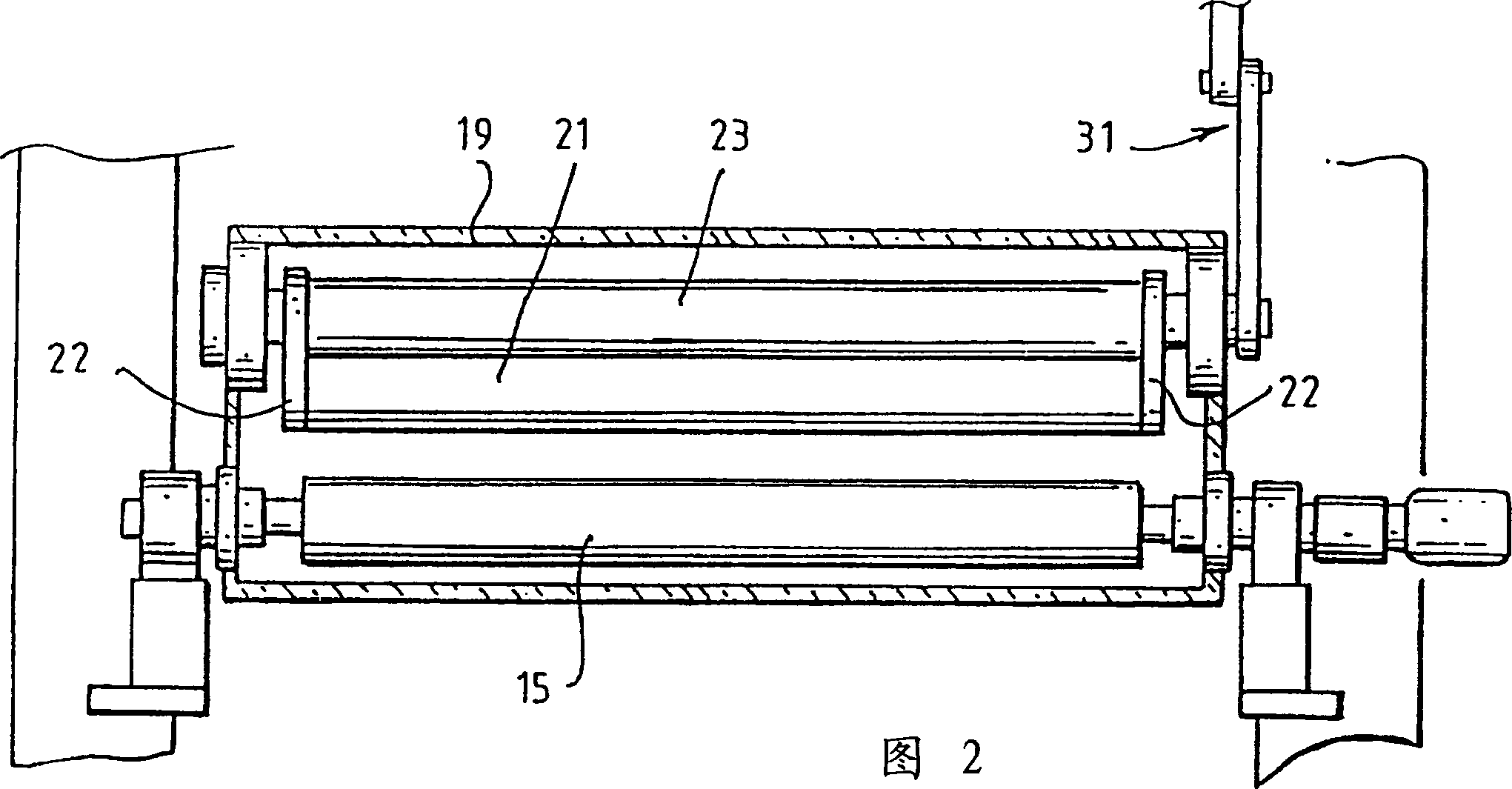

Device for stretching thin metal strips by traction

InactiveUS6109084AQuality improvementTensioning/braking arrangementsMetal rolling arrangementsDifferential transmissionEngineering

PCT No. PCT / EP97 / 05875 Sec. 371 Date Apr. 27, 1999 Sec. 102(e) Date Apr. 27, 1999 PCT Filed Oct. 24, 1997 PCT Pub. No. WO98 / 19804 PCT Pub. Date May 14, 1998An apparatus for stretch leveling thin metal strips, in particular aluminum strips between 0.1 and 0.5 mm thick, has a group of braking rollers that are interconnected via differential transmissions and controlled jointly with respect to speed to form a first leveling path with a downstream central speed-controlled leveling roller and that downstream a group of pulling rollers connected together by means of differential transmissions and controlled jointly with respect to speed form a second leveling path with the central leveling roller.

Owner:ERWIN KAMPF & MASCHFAB

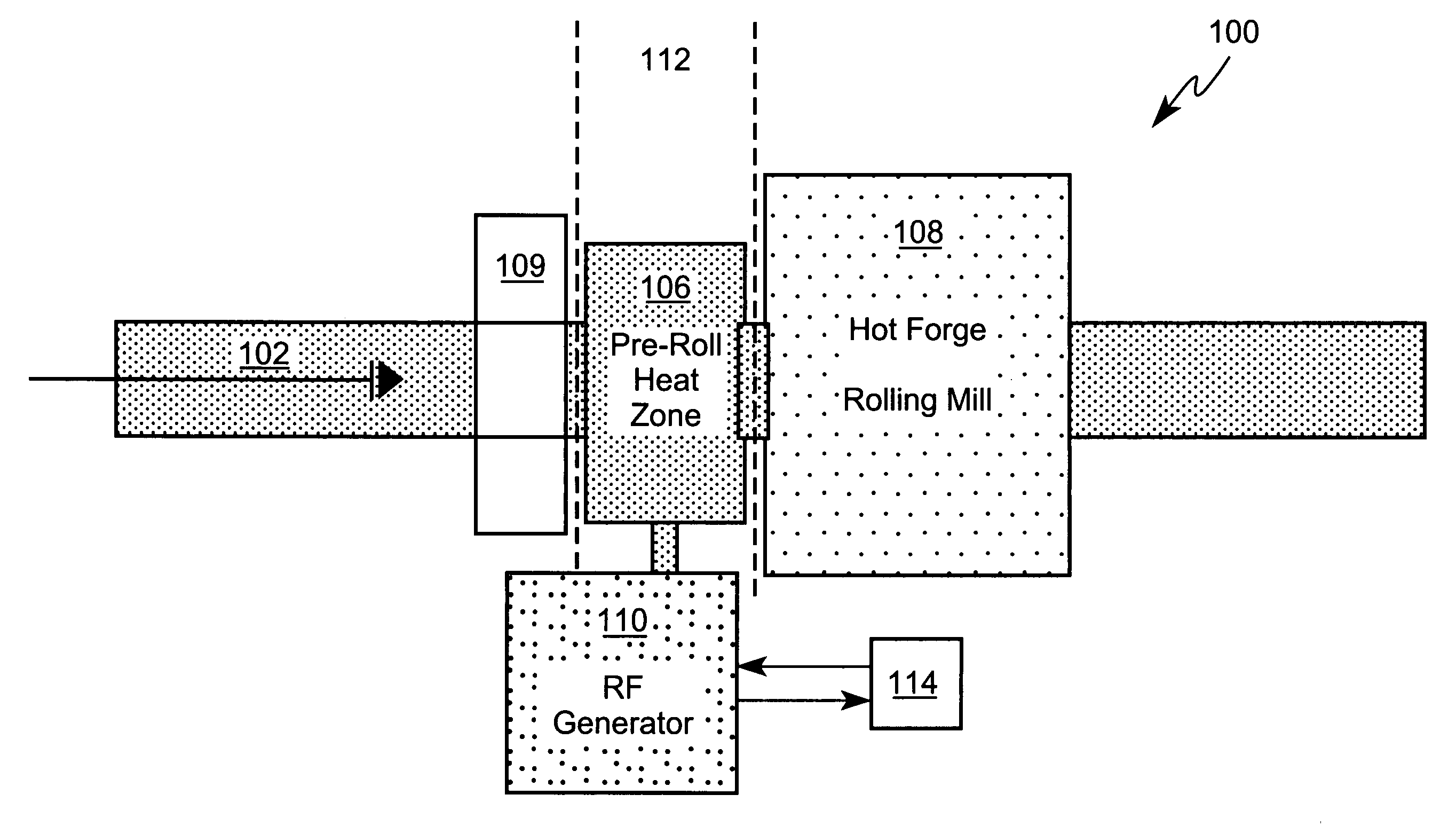

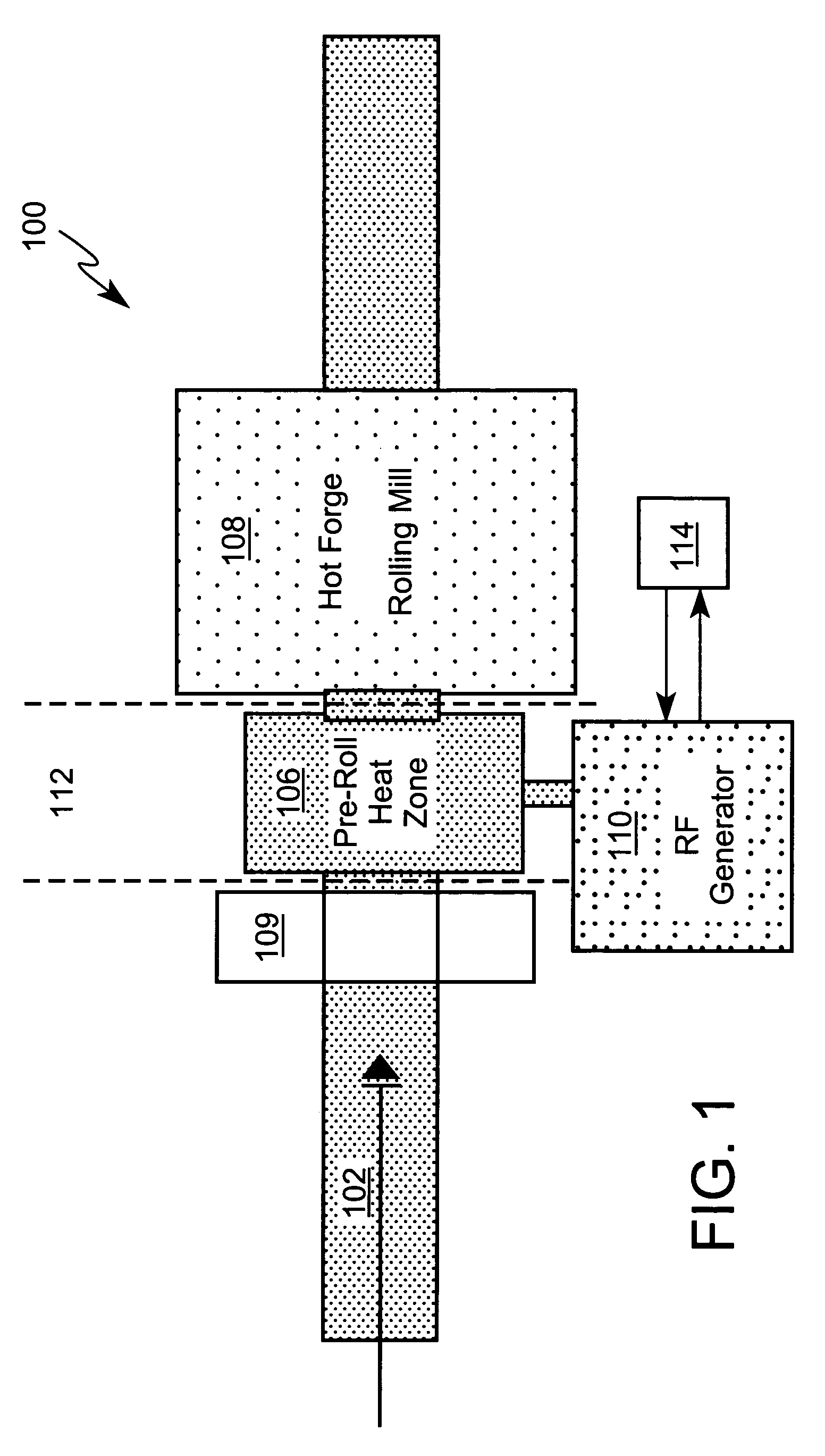

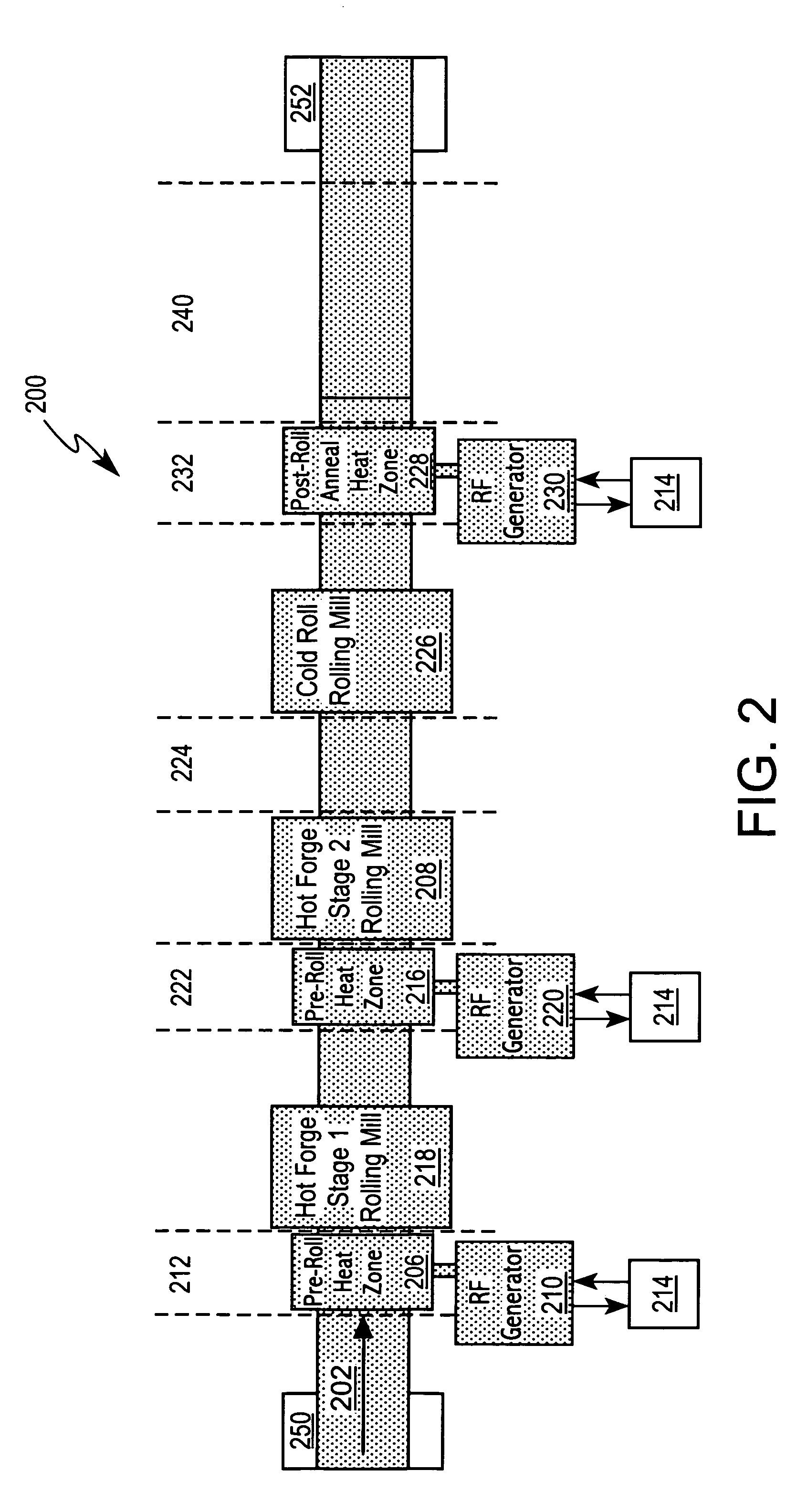

Continuous method of rolling a powder metallurgical metallic workpiece

InactiveUS7648596B2Minimize the numberMinimal thicknessIncreasing energy efficiencyFurnace typesDevice MonitorContinuous rolling

An apparatus for rolling of a powder metallurgical metallic workpiece is provided having a feeding device, a first induction heating apparatus in operable communication with a first RF generator and at least a first hot rolling mill. A process control device monitors at least one parameter of the first RF generator and outputs a signal. A method for continuous rolling of a metallic workpiece is also provided using the apparatus for rolling. The process control device signal can be used to monitor metallurgical properties of the workpiece and provide in-line evaluation of the workpiece.

Owner:PHILIP MORRIS USA INC

Tension control system for a continuous winding machine

InactiveUS7891597B1Wind to toleranceEasy to handleFilament handlingTensioning/braking arrangementsWinding machineControl system

A continuous winding machine uses embedded controllers to monitor and control the winding settings in maximum speed applications. Power is supplied to the embedded controllers from a main power source through a rotary transformer. The control system can be operated either through wired connections to a local computer or processor, or through a wireless system, or a combination of both, depending on the specific application. The machine uses a high speed, closed loop tensioning system that includes the filament supply spools and the mandrel supply and takeup spools. The control system menu includes the various winding operations useful to each user. The control system menu can be accessed remotely via computer, or by telephone.

Owner:HENSON TECH LLC

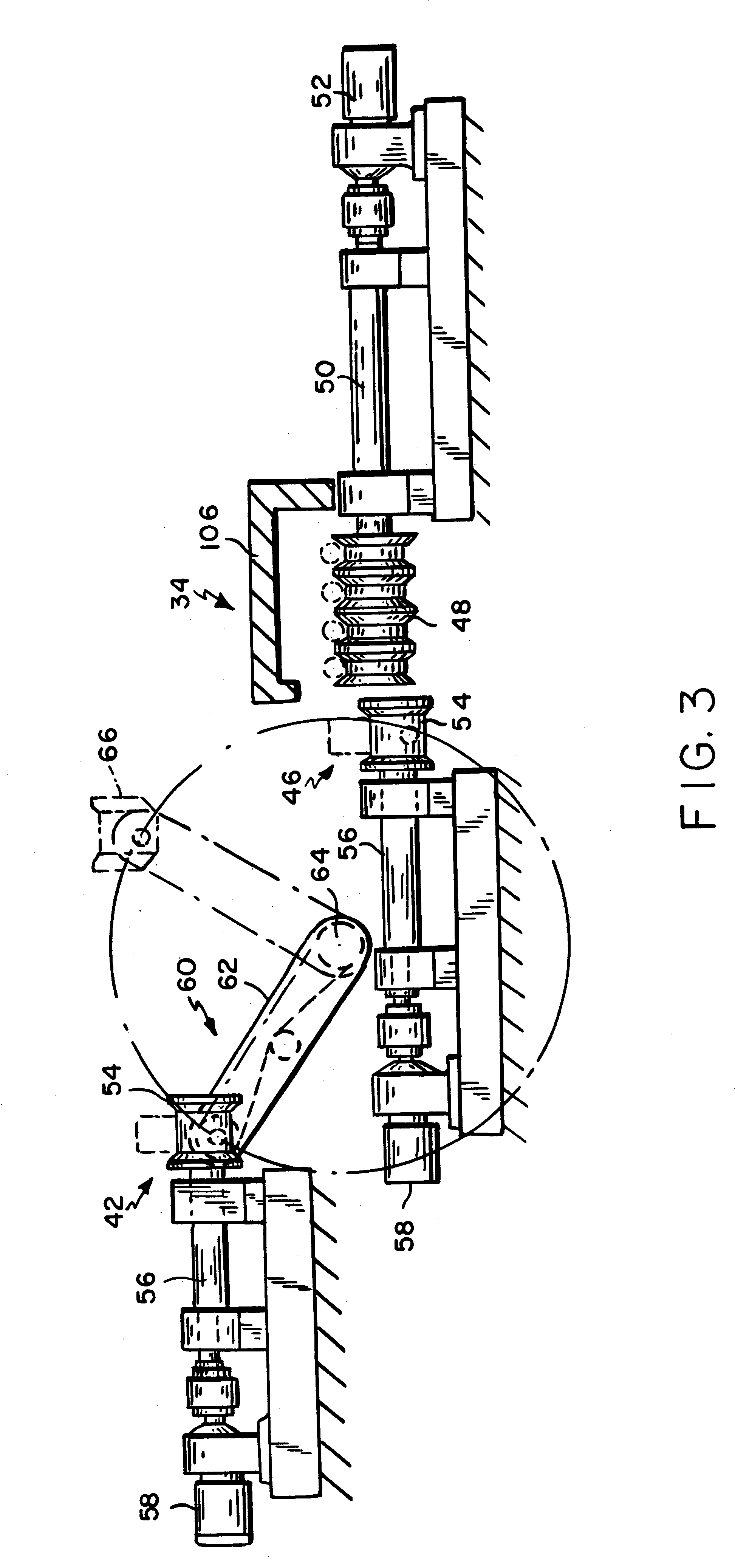

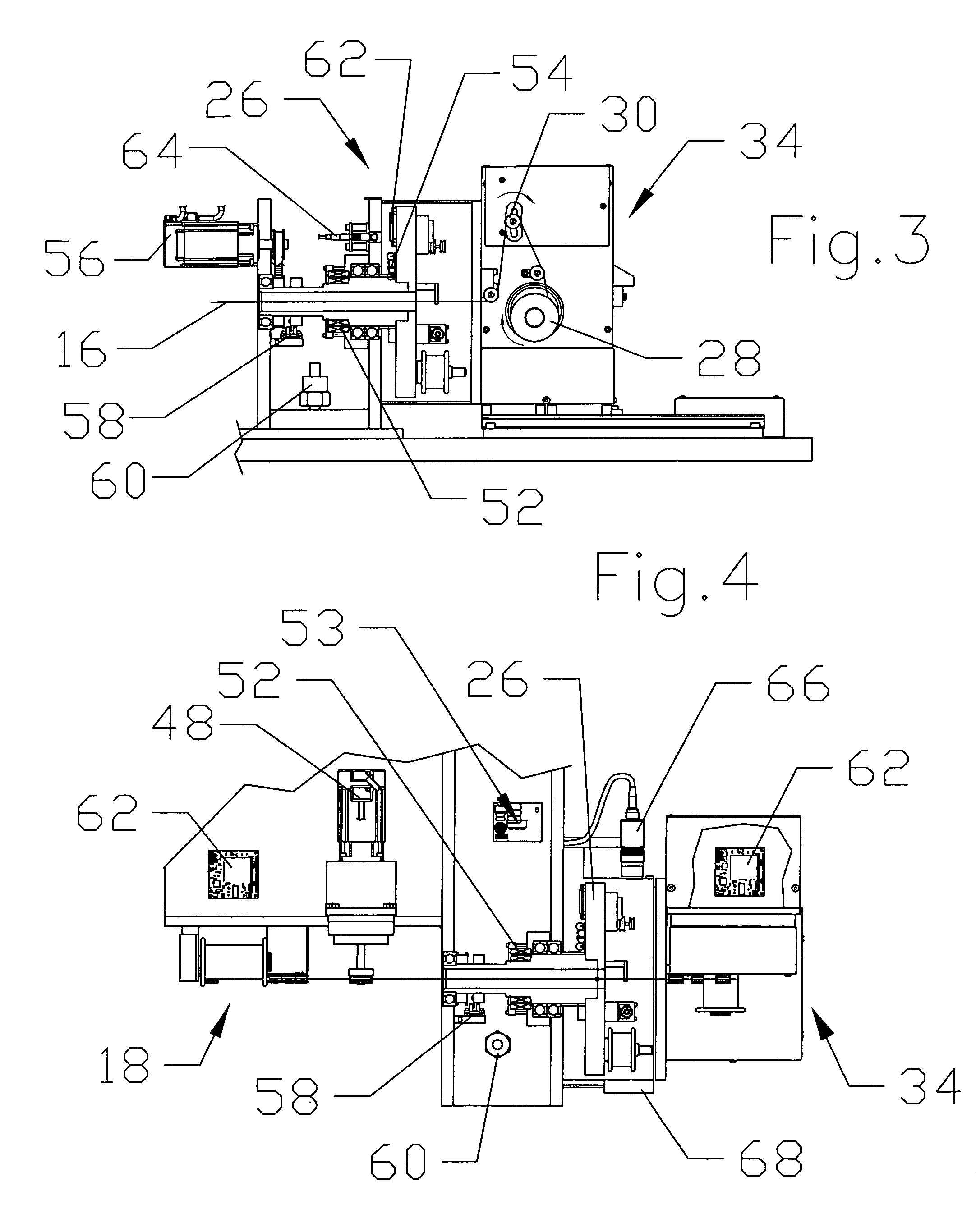

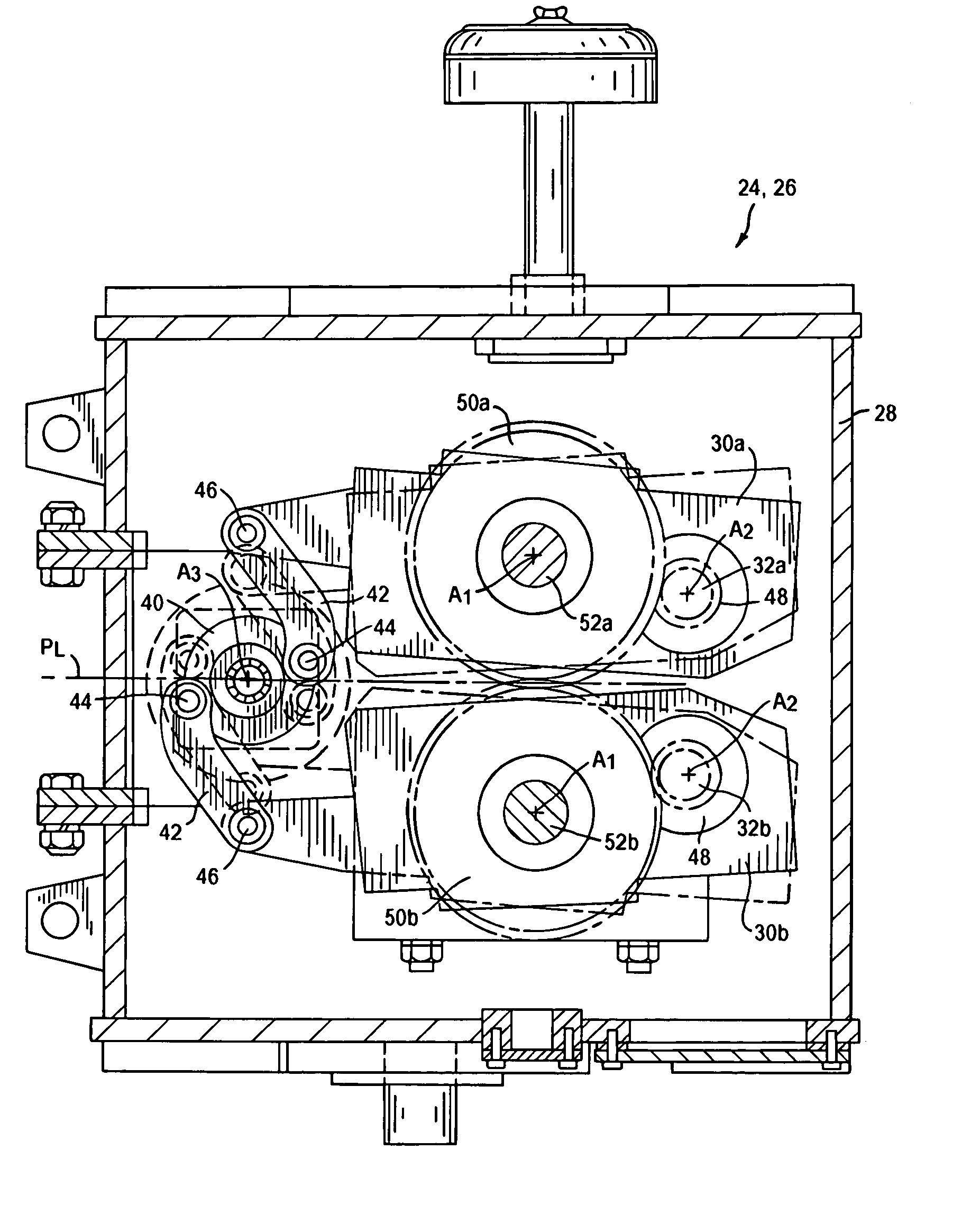

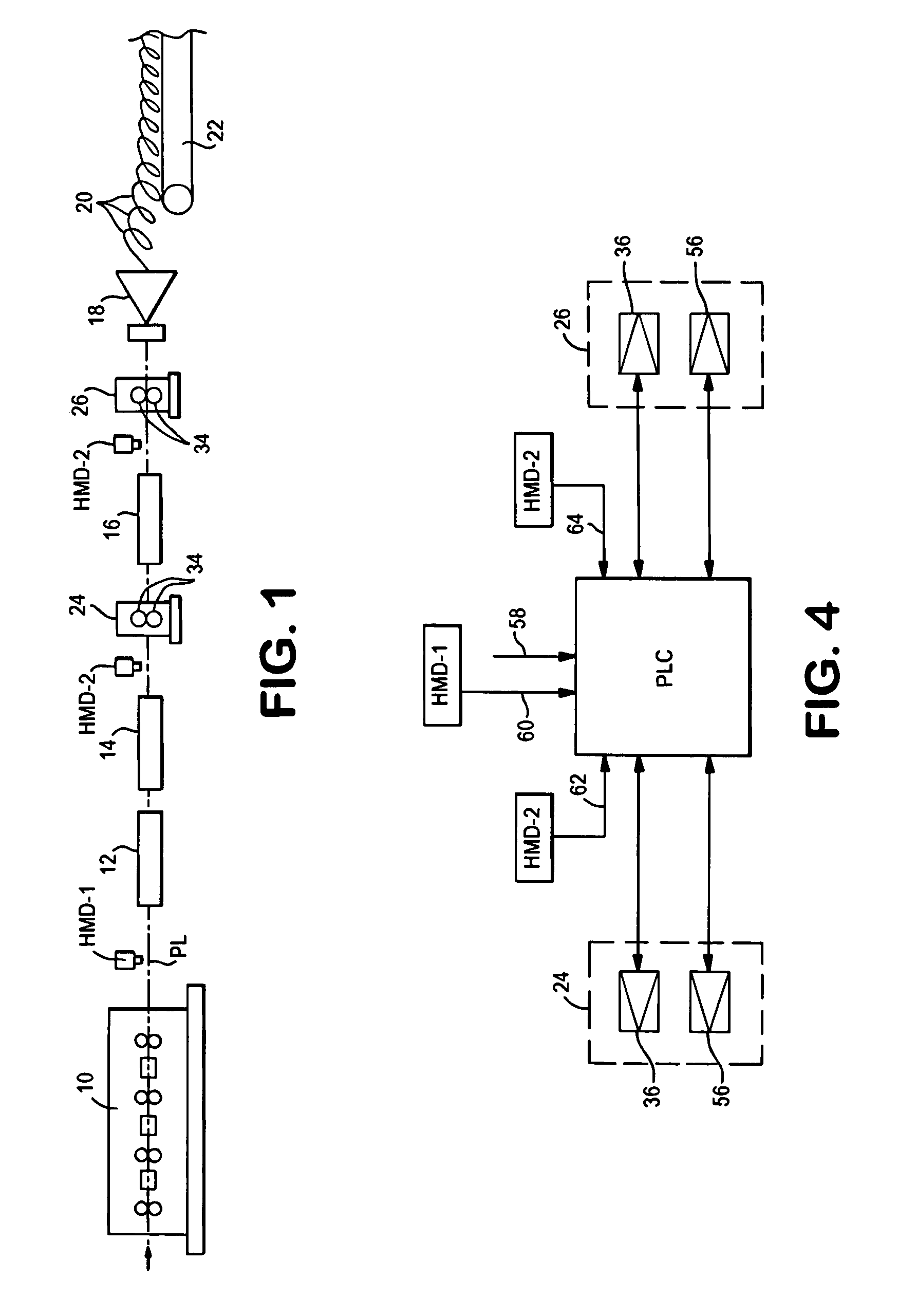

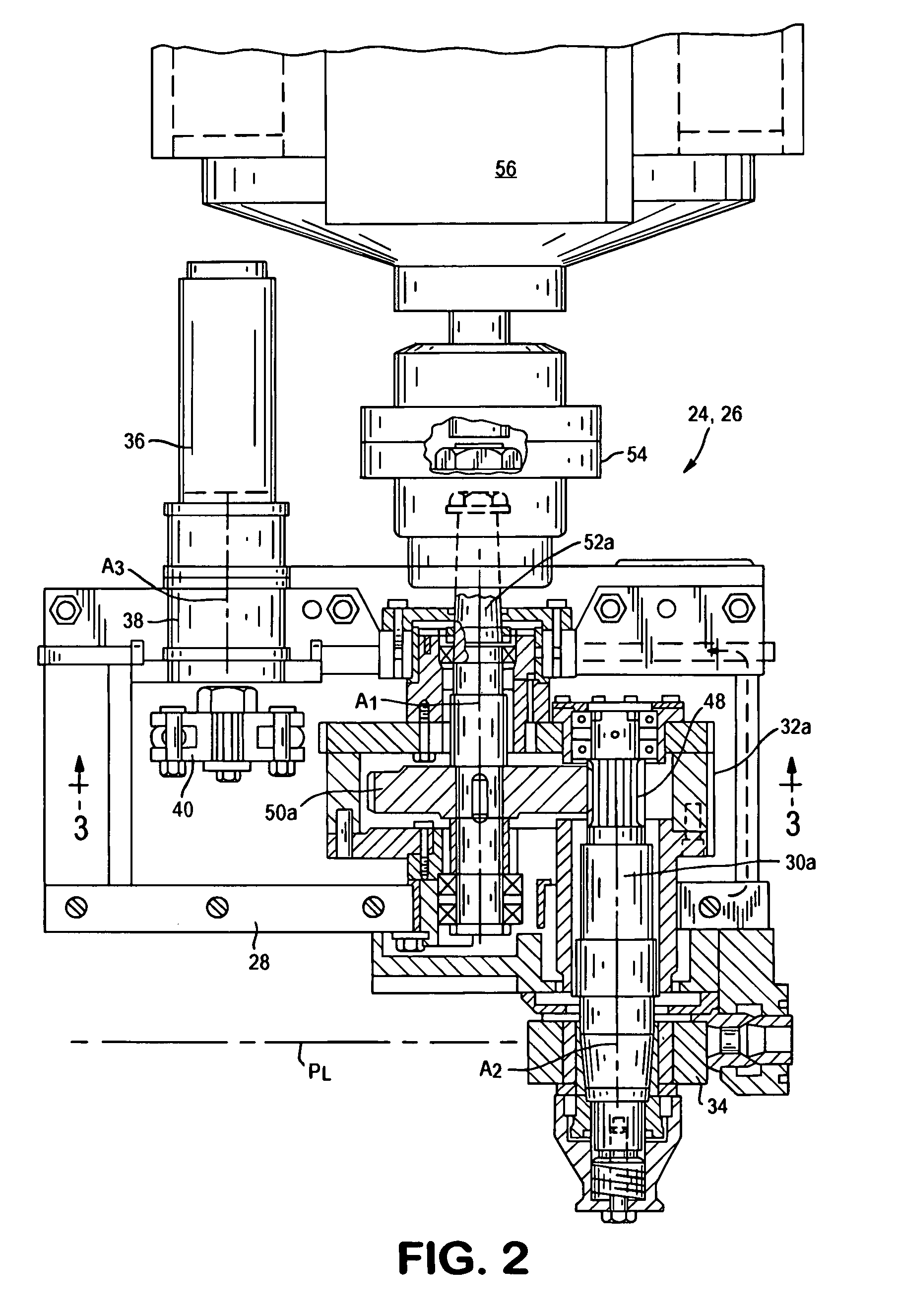

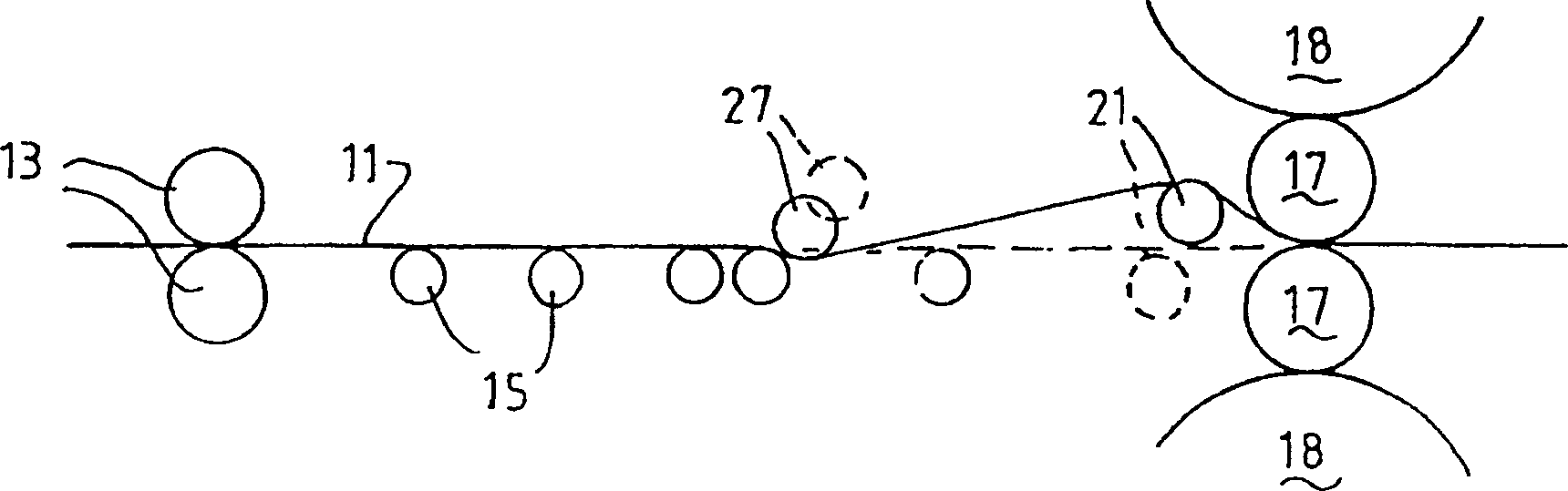

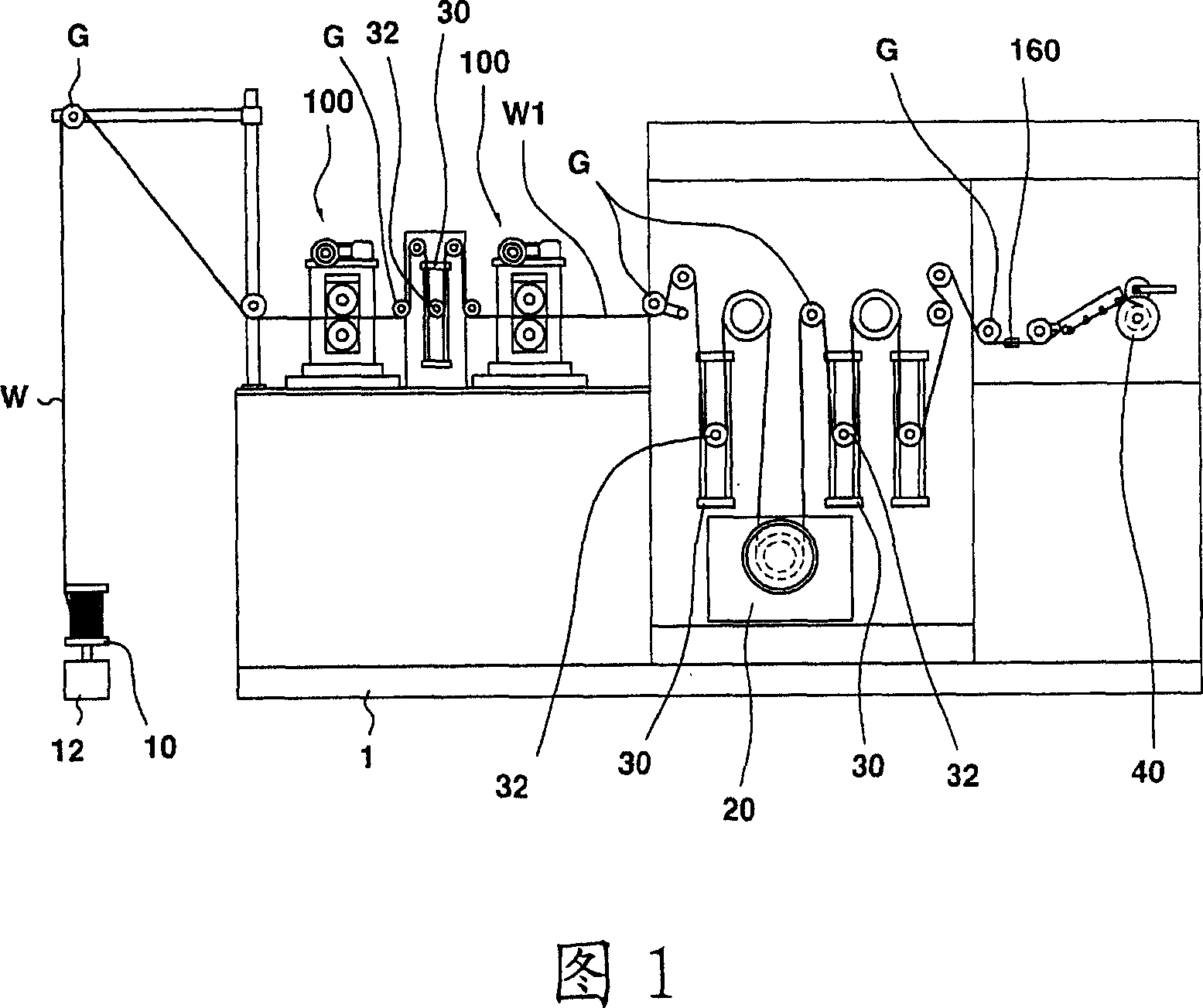

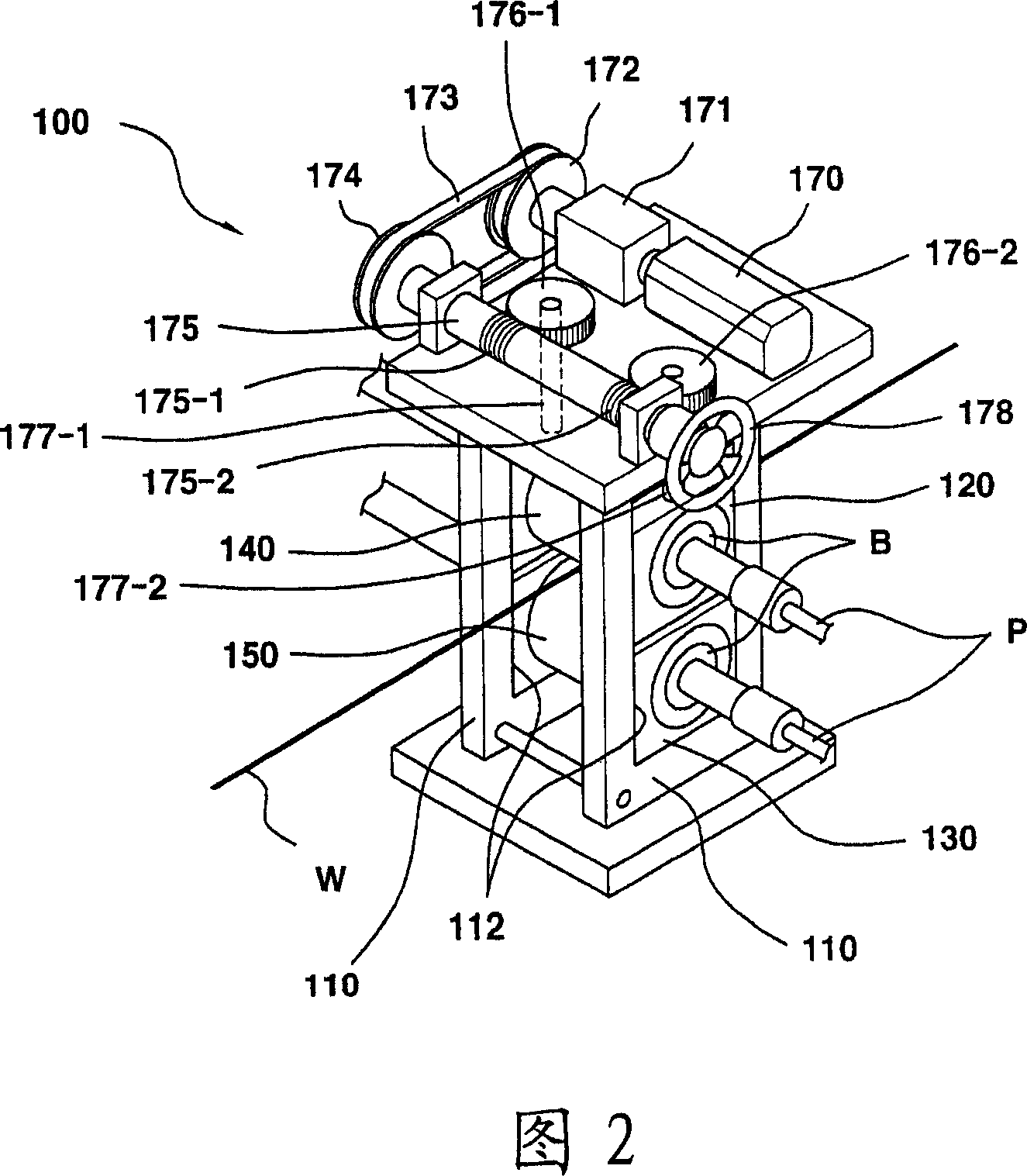

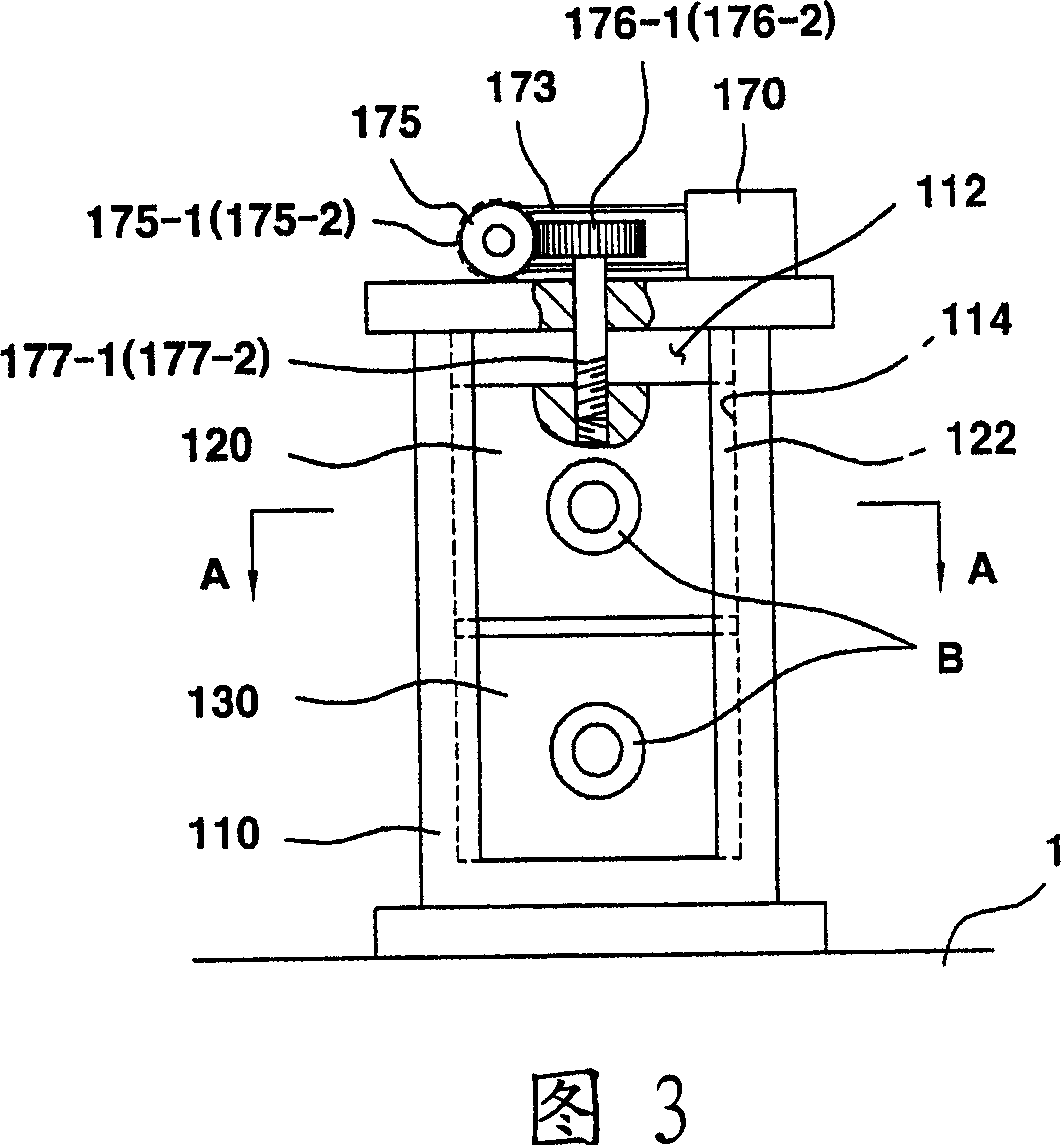

Pinch roll unit

A pinch roll unit for either propelling or retarding a product moving along the pass line of a rolling mill comprises a pair of levers mounted for rotation about parallel first axes. Roll shafts are carried by the levers with each roll shaft being journalled for rotation about a second axis parallel to the first axis of its respective lever. Pinch rolls are carried by the roll shafts and are positioned to define a gap therebetween for receiving the product. An electrically powered first motor operates via a linkage to rotate the levers about the first axes and to move the pinch rolls between open positions spaced from the product, and closed positions contacting and gripping the product therebetween. An electrically powered second motor rotatably drives the pinch rolls.

Owner:PRIMETALS TECH USA

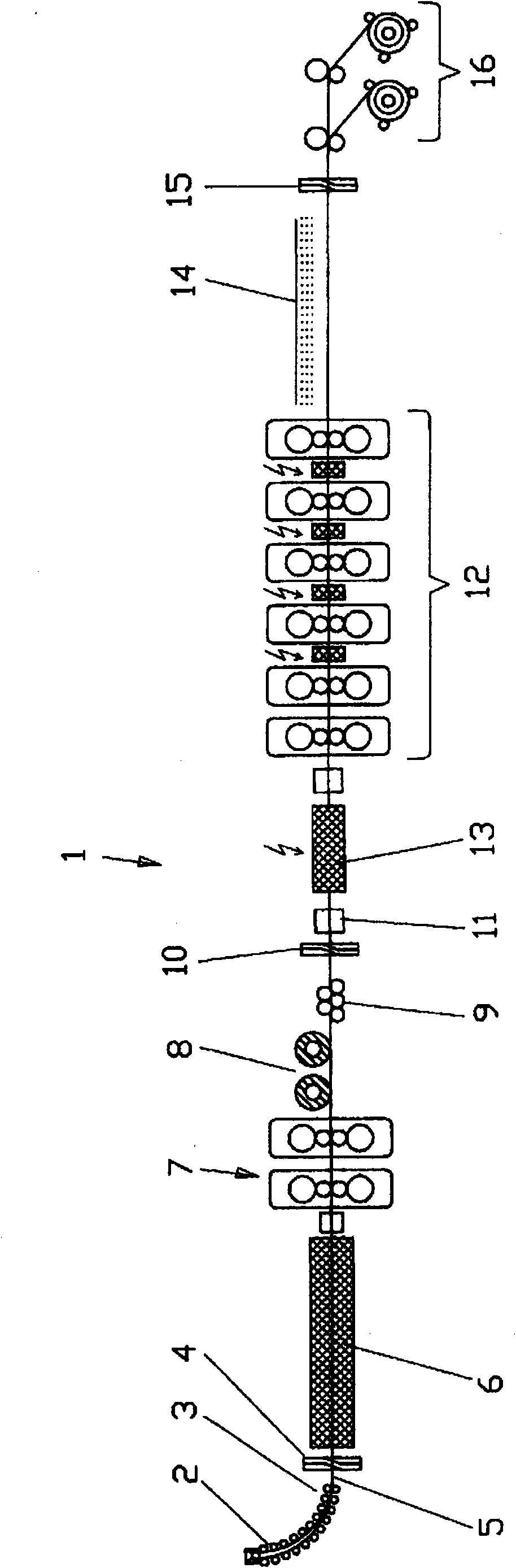

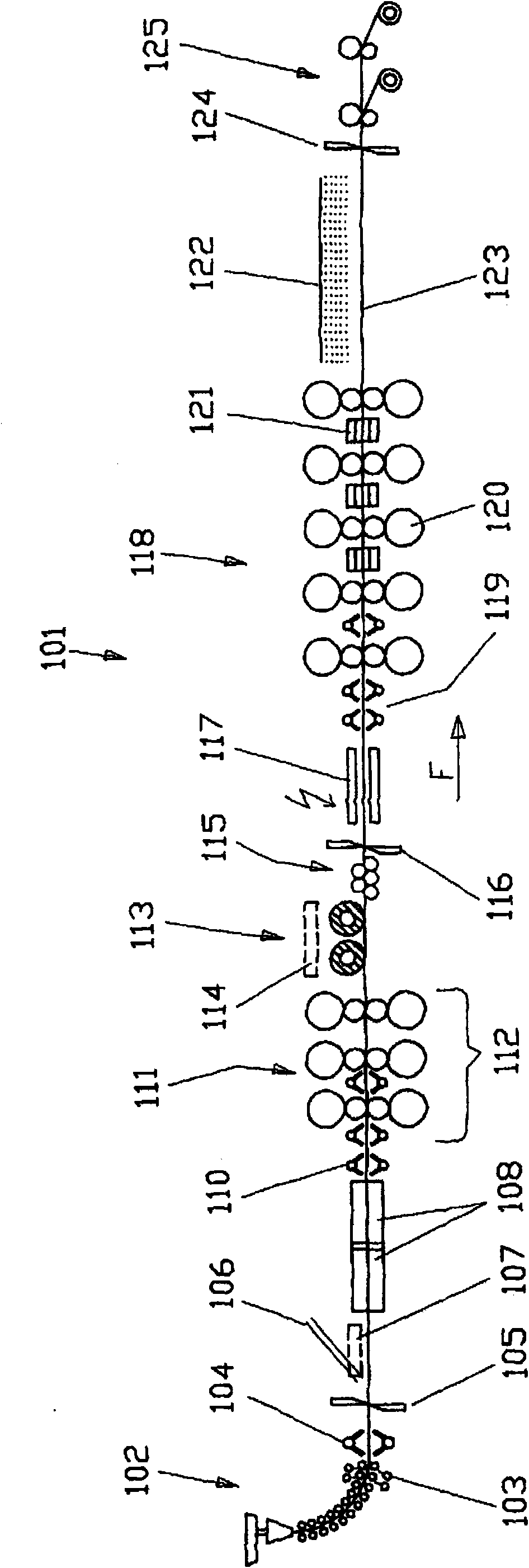

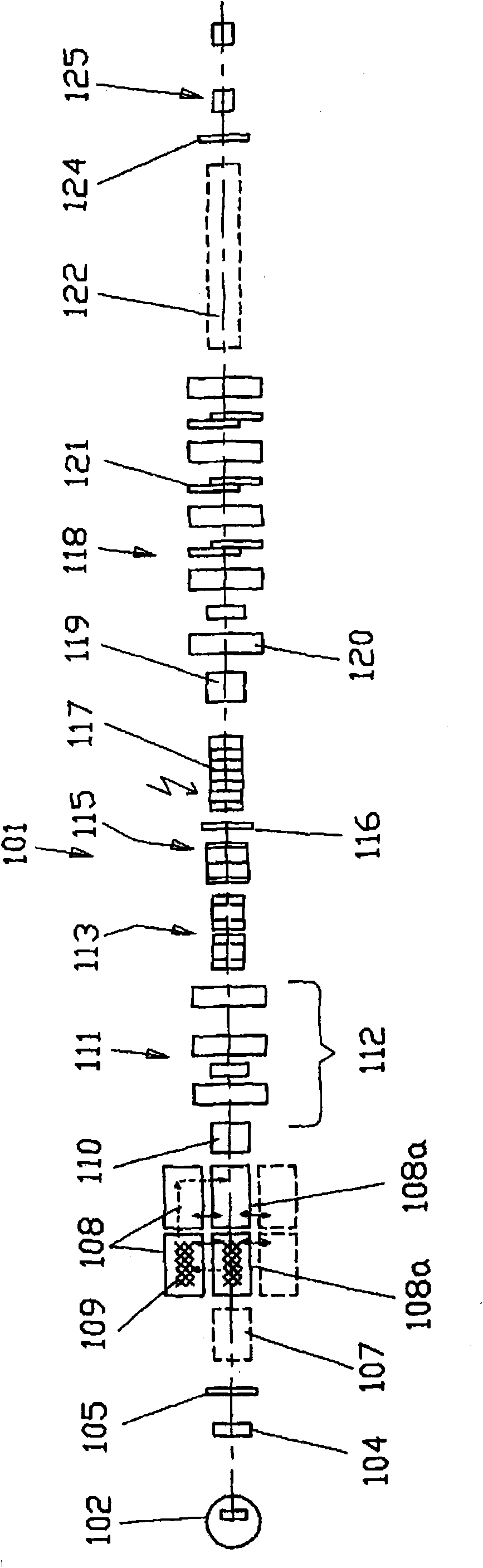

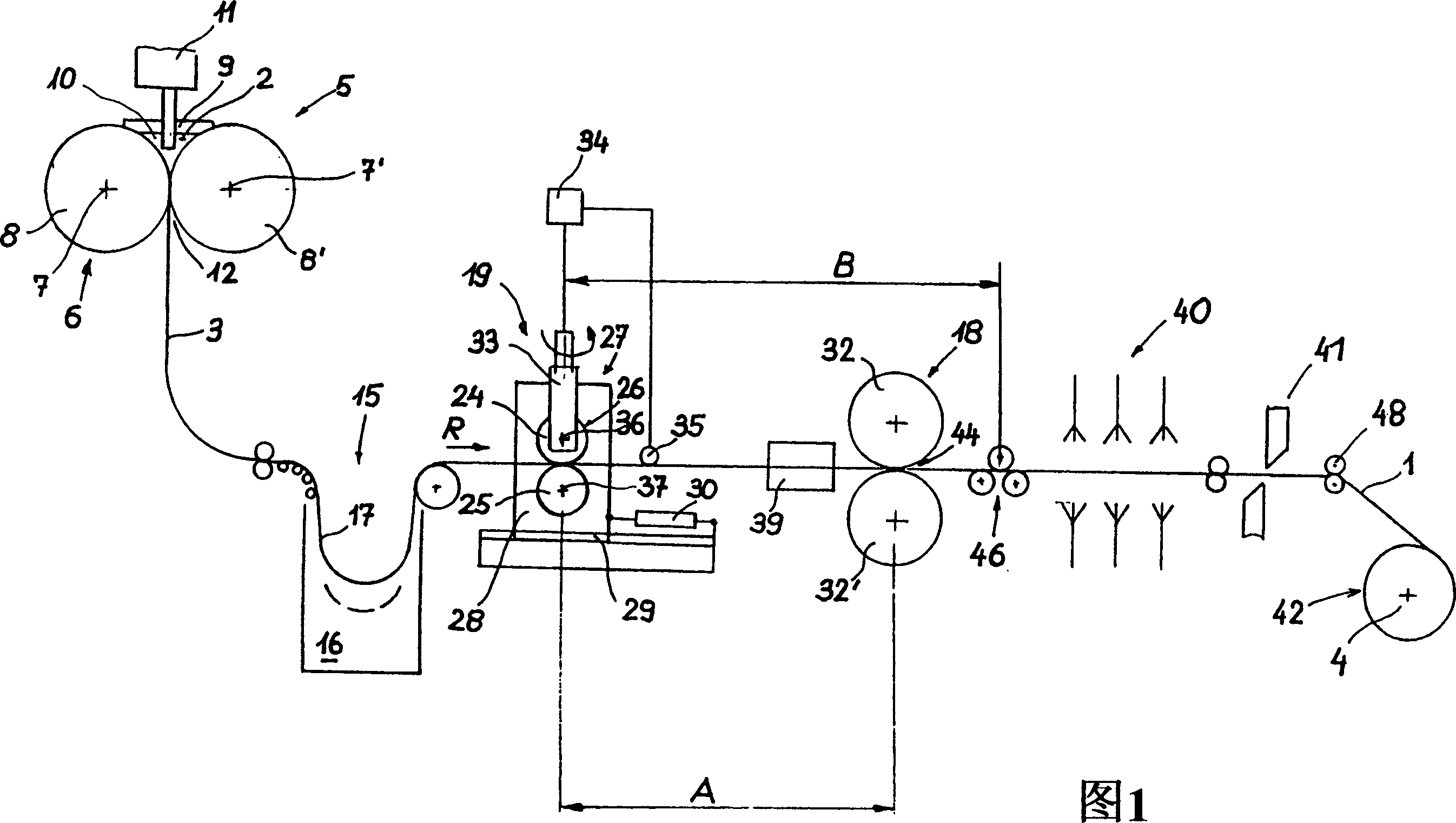

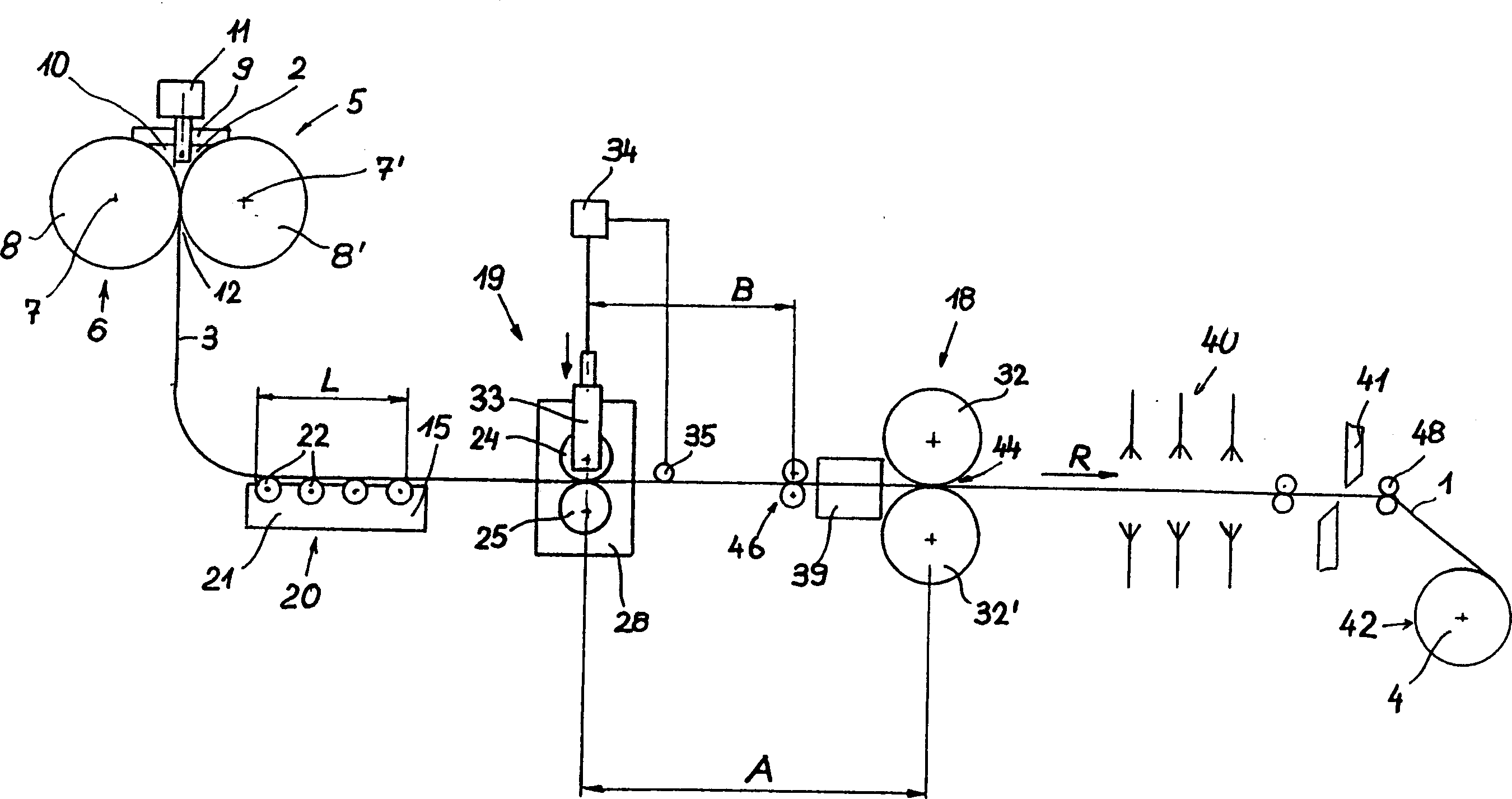

Compact, flexible CSP facility for continuous, semi-continuous and batch operation

InactiveCN101848776AMetal rolling stand detailsTensioning/braking arrangementsBatch operationEngineering

The invention relates to a compact, flexible CSP facility (1,101,201,301,401) for continuous, semi-continuous and batch operation, comprising a casting machine, a roughing stand group (7,111,211) and a finishing stand group (12,118,218), wherein a coil store (8,113,213,501) which stores the rough strip or slab coming from the roughing stand is integrated in the roller table for batch or semi-continuous operation, wherein the coil store is deactivated in continuous operation. The coil store (8,113,213,501) is designed to hold an increased quantity of rough strips or slabs in such a way that two, three or more rough strips or slabs can be wound onto a coil to form jumbo coils.

Owner:SMS DEMAG AG

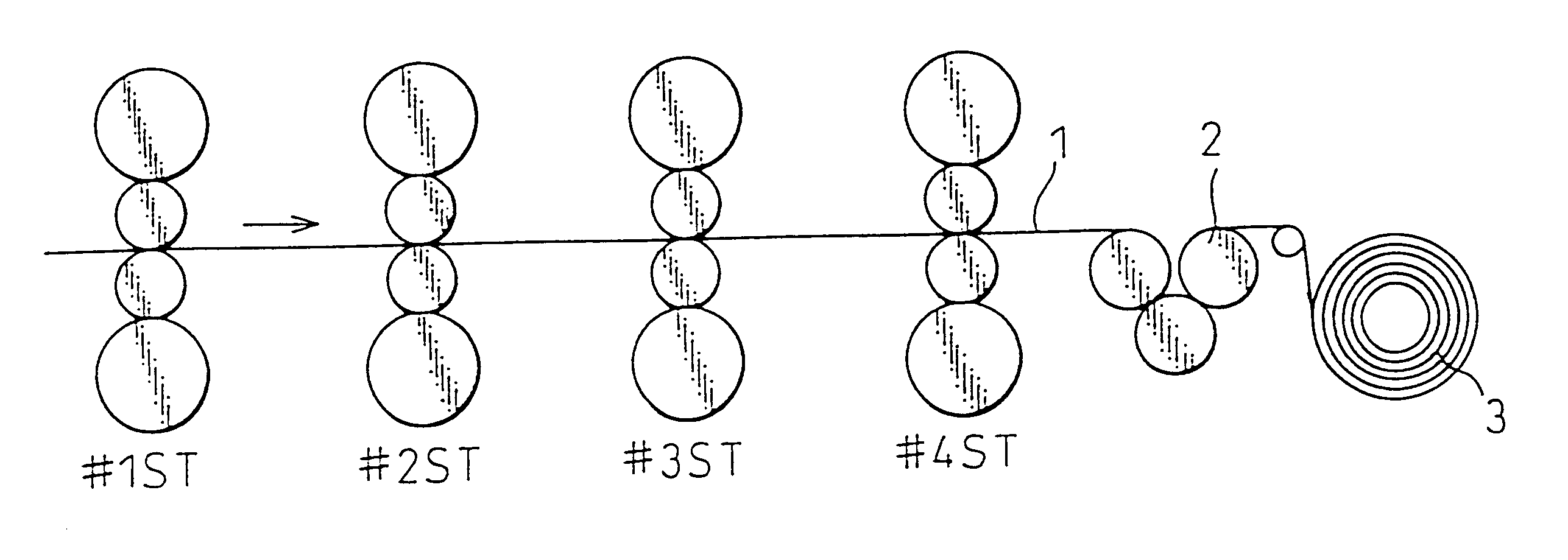

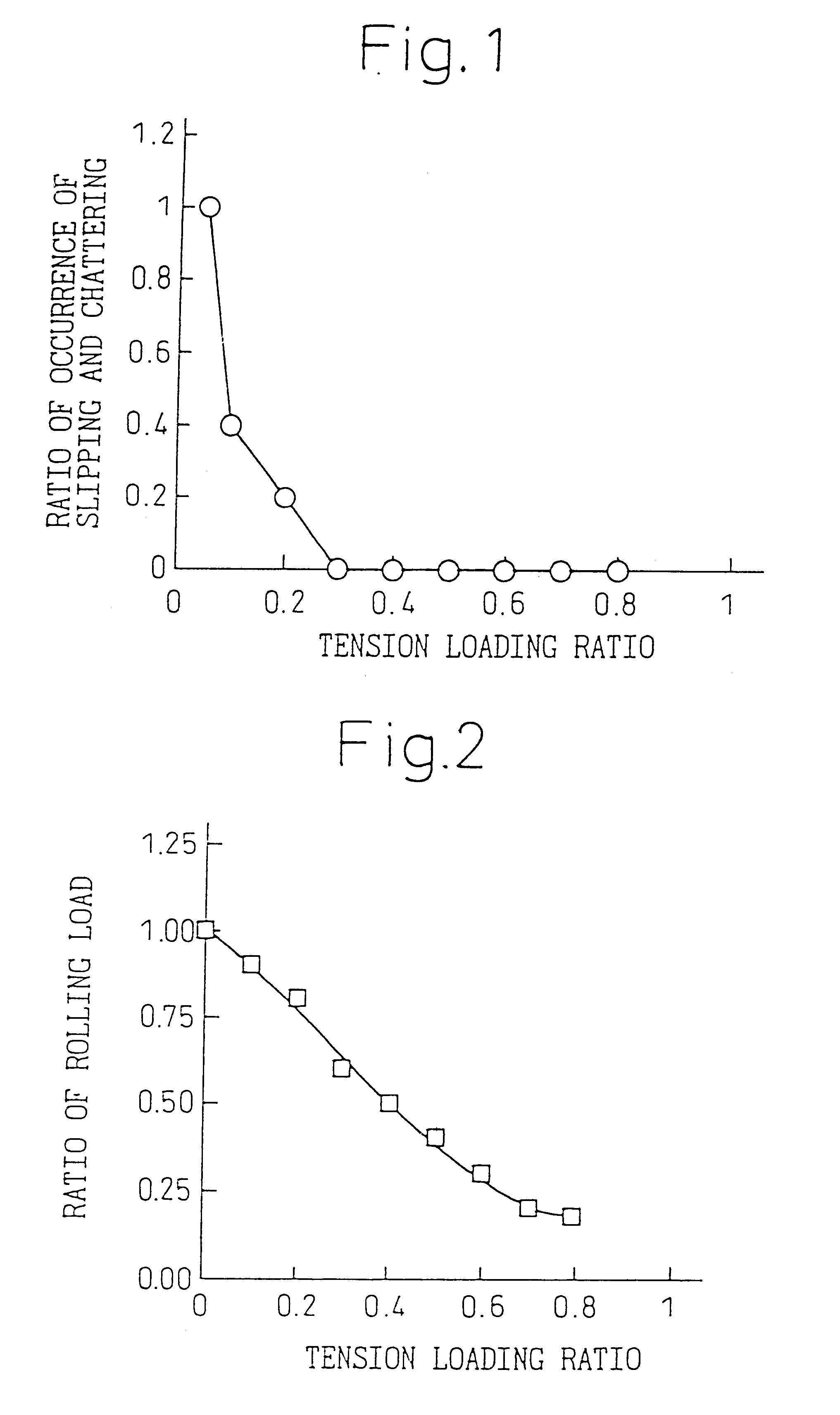

Cold tandem rolling method and cold tandem rolling mill

InactiveUS6269668B1Increase production costGood effectTensioning/braking arrangementsTension/compression control deviceElectric machineryUltimate tensile strength

The present invention is to provide a tandem cold rolling method conducted by a tandem cold rolling mill, the number of rolling stands of which is not less than 4, wherein a rolling tension, the intensity of which is not lower than 30%, preferably not lower than 40% of the deformation resistance of material to be rolled, is given at least by the final rolling stand. The present invention is also to provide a tandem cold rolling mill satisfying the inequality of JC>=(0.375{overscore (h)}+0.275)JM, wherein the average thickness of a product sheet on the delivery side of the final rolling mill is {overscore (h)}, and an output of one coiler arranged on the delivery side of the tandem cold rolling mill, or a sum of an output of one coiler on the delivery side and an output of the bridle roller on the delivery side is JC, and an output of the main motor of the final rolling stand of the tandem cold rolling mill is JM.

Owner:NIPPON STEEL CORP

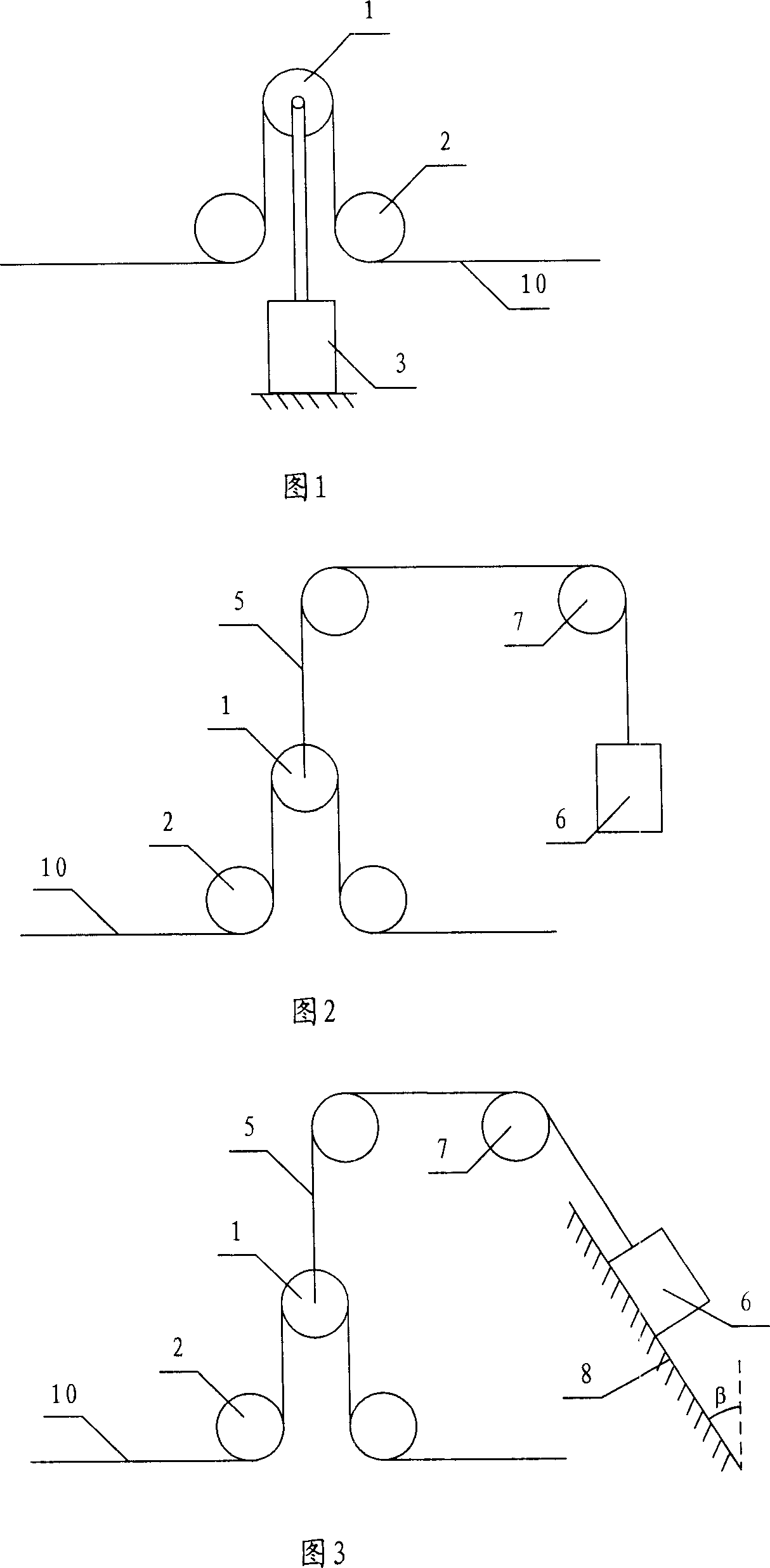

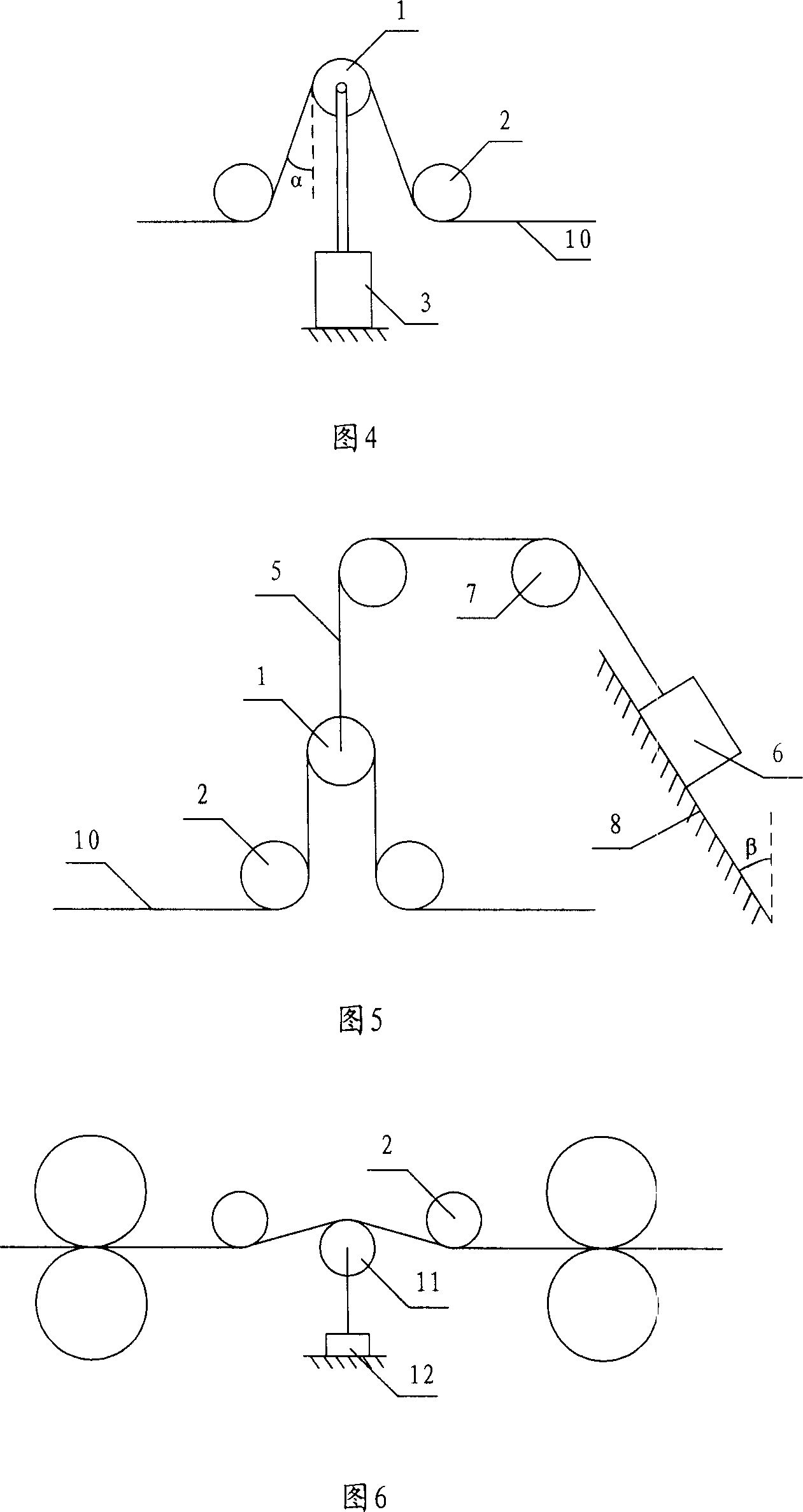

Tension equipment of continuous mill system

InactiveCN101007321AEnsure constant tensionHigh control precisionTensioning/braking arrangementsTension/compression control devicePull forceForce constant

The invention involves a tension device of tandem rolling system. It includes two guide rollers guiding rolling pieces move, floating roller is equipped between said two guide rollers and supports rolling pieces with constant force and makes the rolling pieces stretching force constant through moving up and down, the rolling pieces between said floating roller and said two guide rollers is vertical. Said floating roller can be connected with a hydraulic means which has constant support force, also can be connected with a counterweight body with constant stretching force through hanger rope. The invention proposes a technology program which ensures rolling pieces stretching force constant in rolling plant through changing storage rolling pieces length in rolling mill plant, has characteristics of simple structure, separately adjustment, fast dynamic response and high control precision, etc, it effectively solves the enormous puzzle and technical difficulty stopping tandem rolling technique development for years and years.

Owner:郑红专 +1

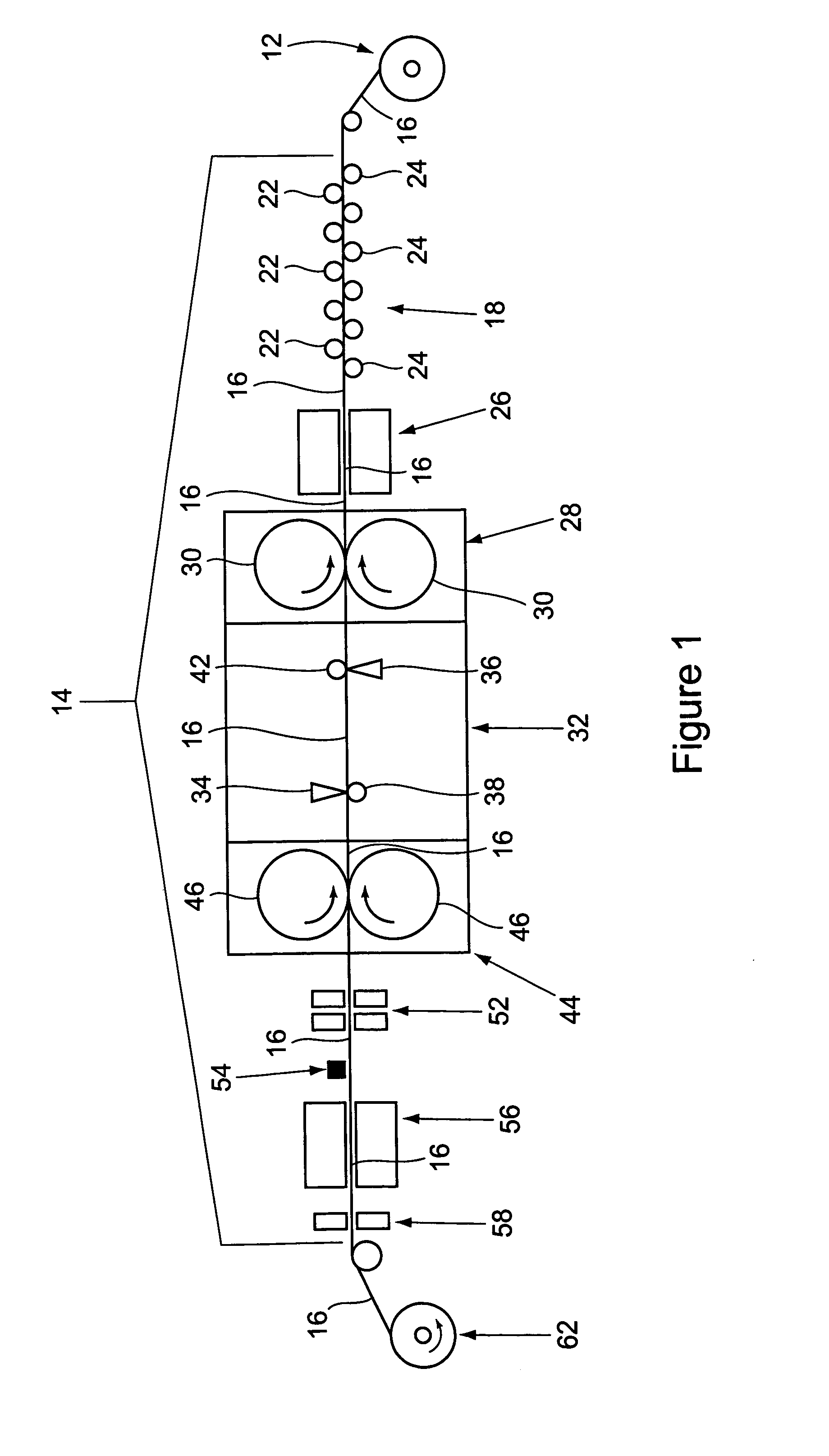

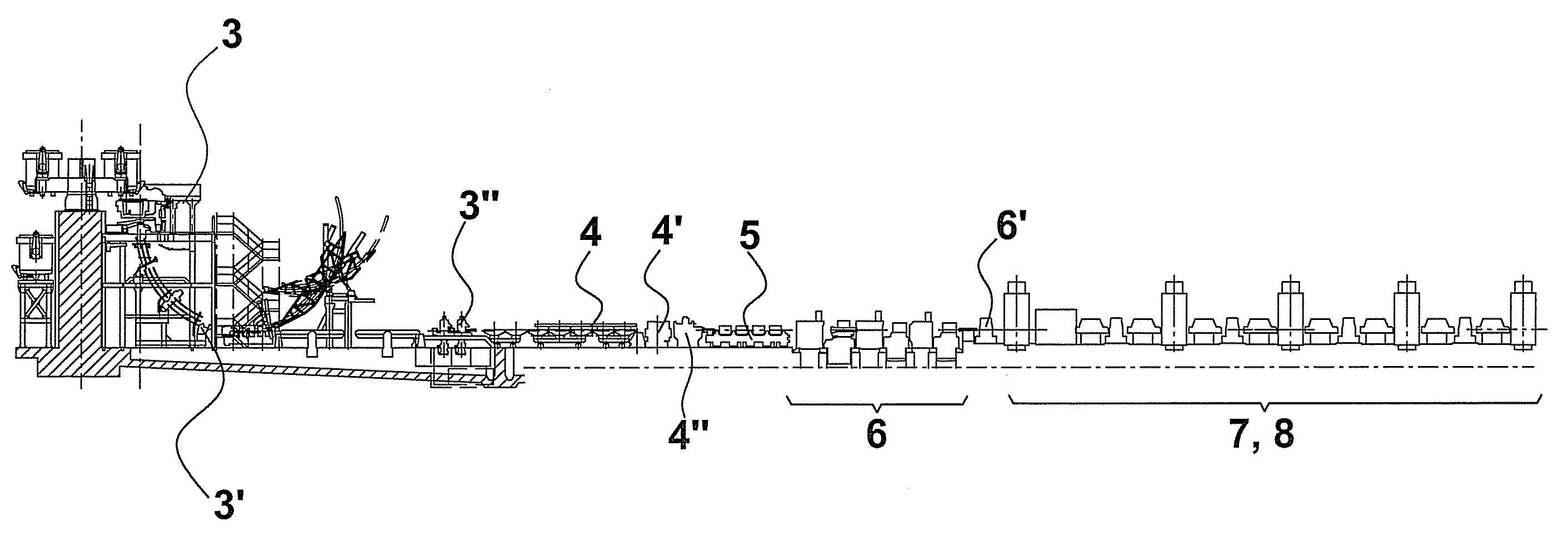

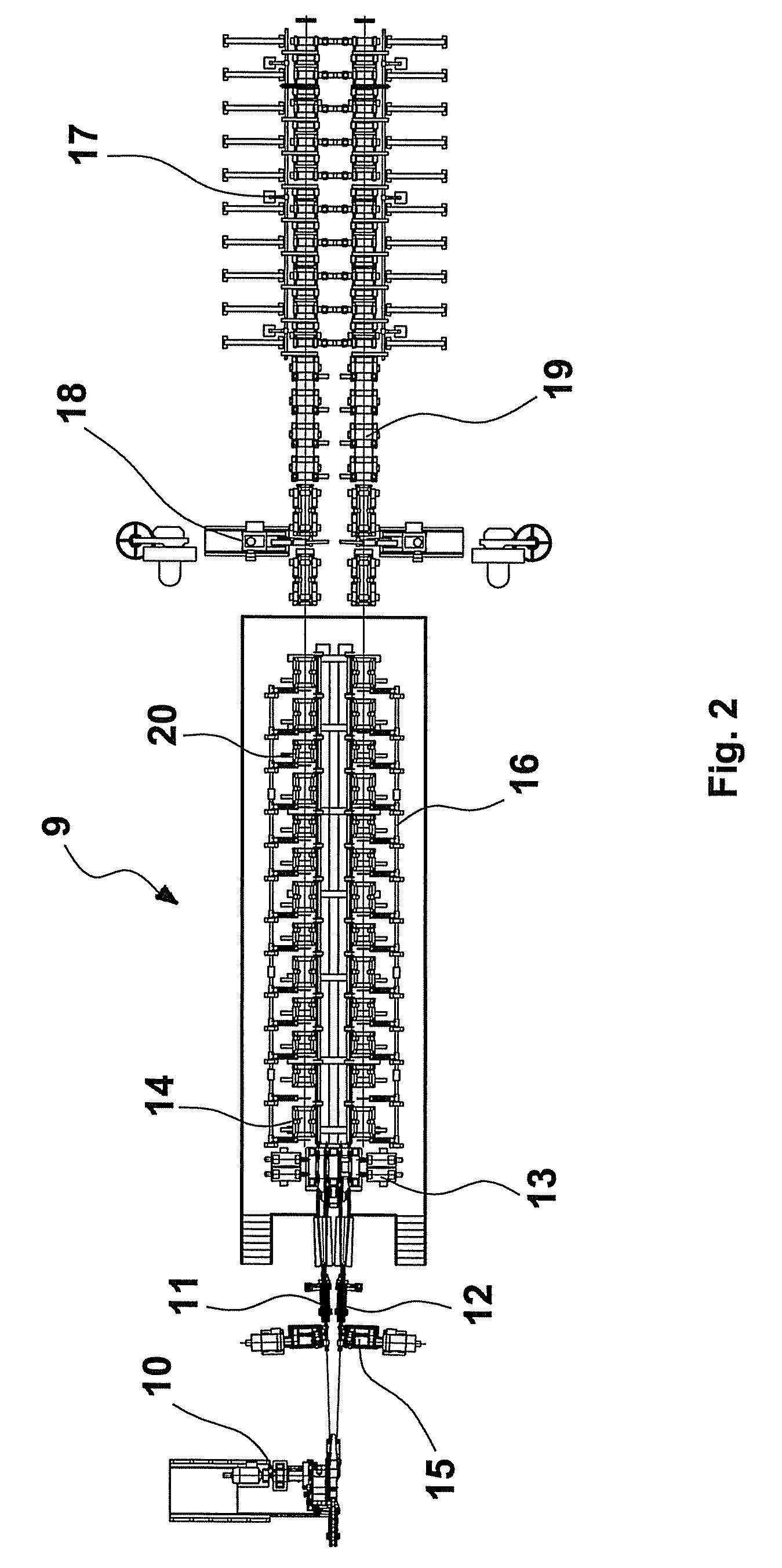

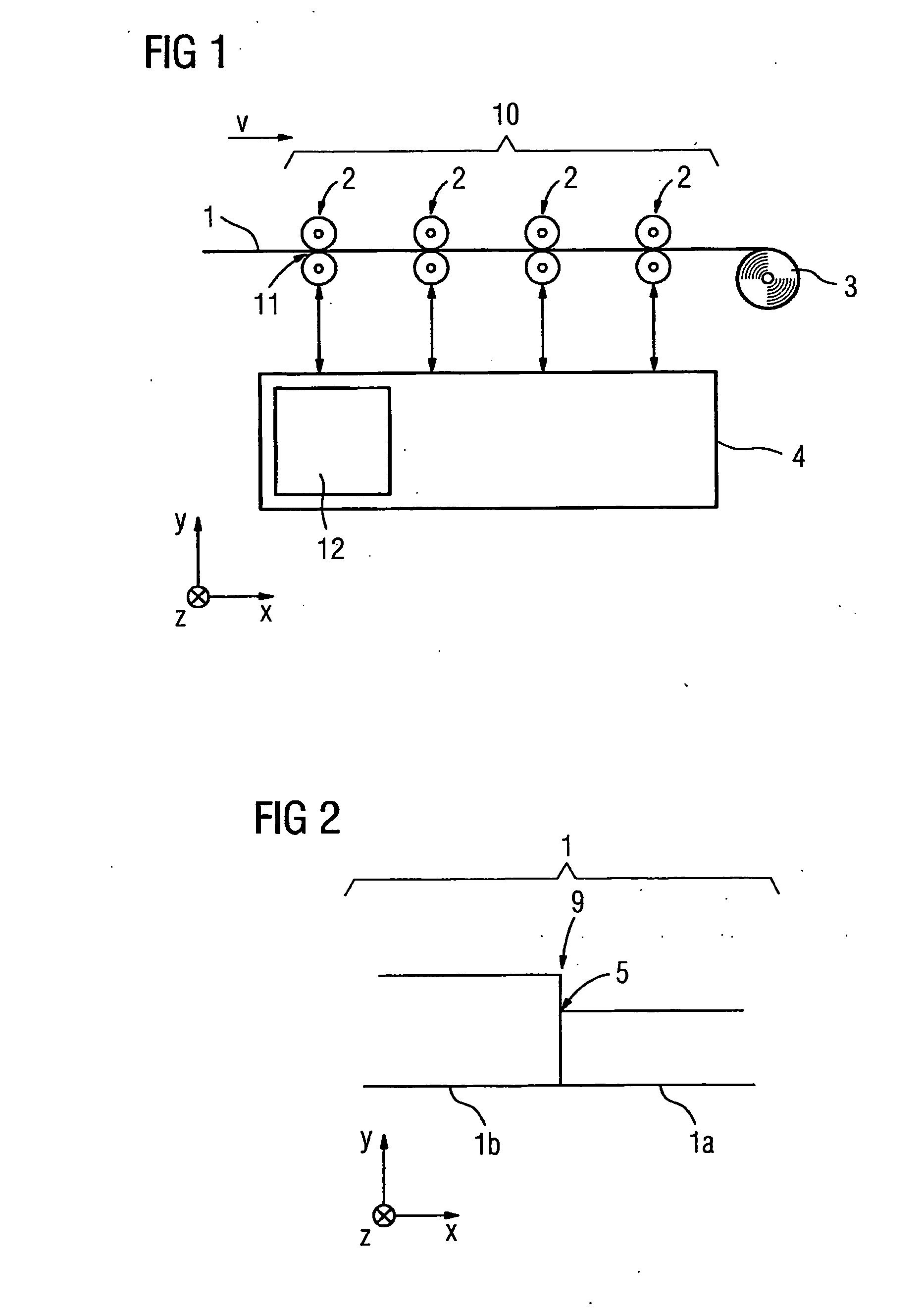

Compact Plant for Continuous Production of Bars and/or Profiles

ActiveUS20080196236A1Low investment costShorten production timeMetal rolling stand detailsGuiding/positioning/aligning arrangementsTO-18Rebar

Compact plant for making steel bars and profiles with which, starting from the scrap, it is possible to obtain the finished product, for example bars with commercial length from 6 to 18 meters, pre-packed, packaged and ready for sale, with all the stations placed in line and operating continuously. All the stations are arranged in reduced spaces, thereby reducing both investment costs and plant management costs, and decreasing production times. Advantageously, the plant of the invention incorporates an extremely compact bar packaging apparatus which, through an innovative arrangement and innovative operating method of the components thereof, allows a further reduction in length.

Owner:DANIELI & C OFF MEC SPA

Method for Rolling Rolling Stock Having a Transitional Region

InactiveUS20080060403A1Avoid disadvantagesRoll force/gap control deviceWork manipulationCritical transitionTransitional Region

The invention relates to a method for rolling a product in a rolling train comprising at least two roll stands having a roll gap, the product to be rolled comprising a transition region. If a critical transition region crosses the rolling train, the roll gaps of the roll stands are successively opened and closed according to the position of the transition region moving at speed through the rolling train, in the direction of the direction of travel of the conveyor. The opening of the roll gaps occurs parallel to the position of the critical transition region when the product is displaced. A transition region is critical when the structure requires the roll gaps to be opened. The inventive opening of the roll gaps, when the device is moving, enables the controlled transition of a product to be rolled with extreme variations in dimensions and / or hardness, for a shorter length.

Owner:SIEMENS AG

Feeding strip material

A pinch roll assembly that may be used for feeding hot metal strip comprises a pair of parallel pinch rolls. At least one of the rolls comprises a copper or copper alloy tube providing the external peripheral roll surface and internal water cooling passages to cool the cylindrical tube by flowing water through the passages. The copper or copper alloy tube is fitted to a cylindrical arbor formed with end shafts for mounting the roll in journal bearings. Shaft is provided with a rotary drive coupling and shaft is fitted with a rotary water coupling for flow of cooling water to the water flow passages.

Owner:CASTRIP

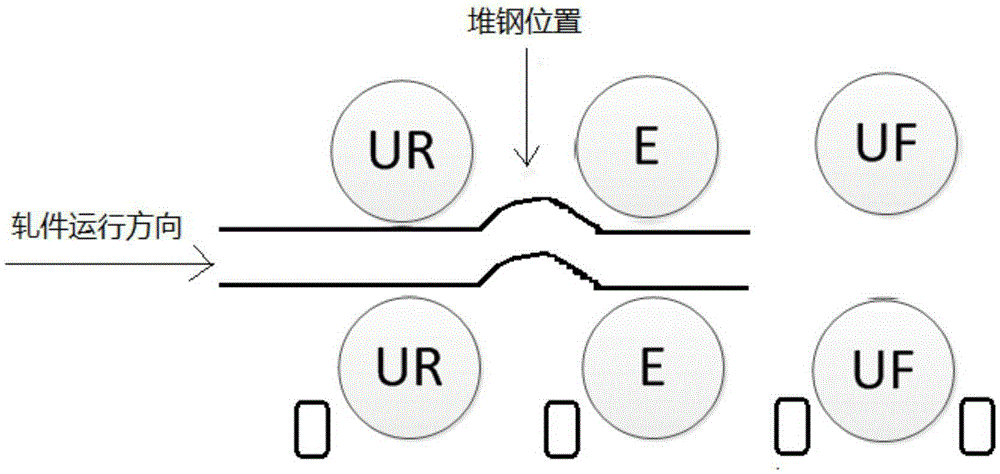

Steel pilling-up protective method for serial type rolling mill

InactiveCN105234184AAvoid harmRealize security protectionMeasuring devicesTensioning/braking arrangementsAutomatic controlStrip mill

The invention discloses a steel pilling-up protective method for a serial type rolling mill, belongs to the technical field of an automatic control method for a rolling mill and aims to provide the steel pilling-up protective method for the serial type rolling mill by which steel pilling-up in the rolling process of a rolled piece can be accurately judged in time, an alarm is given in time, and the rolling mill stops operating. According to the steel pilling-up protective method for the serial type rolling mill, hot metal detection elements are installed at a rolled piece inlet side and a rolled piece outlet side of each rack of the serial type rolling mill respectively and used for detecting whether the end of the rolled piece reaches the current position. When the system judges that the end of the rolled piece enters from the rolled piece inlet side and does not reach the rolled piece outlet side within a preset time, an alarming module is started. The steel pilling-up protective method for the serial type rolling mill is suitable for the serial type rolling mill to roll various rolled pieces, and especially suitable for steel pilling-up protection control over heavy steel rails and other rolled pieces prone to having a steel pilling-up phenomenon in the same class.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

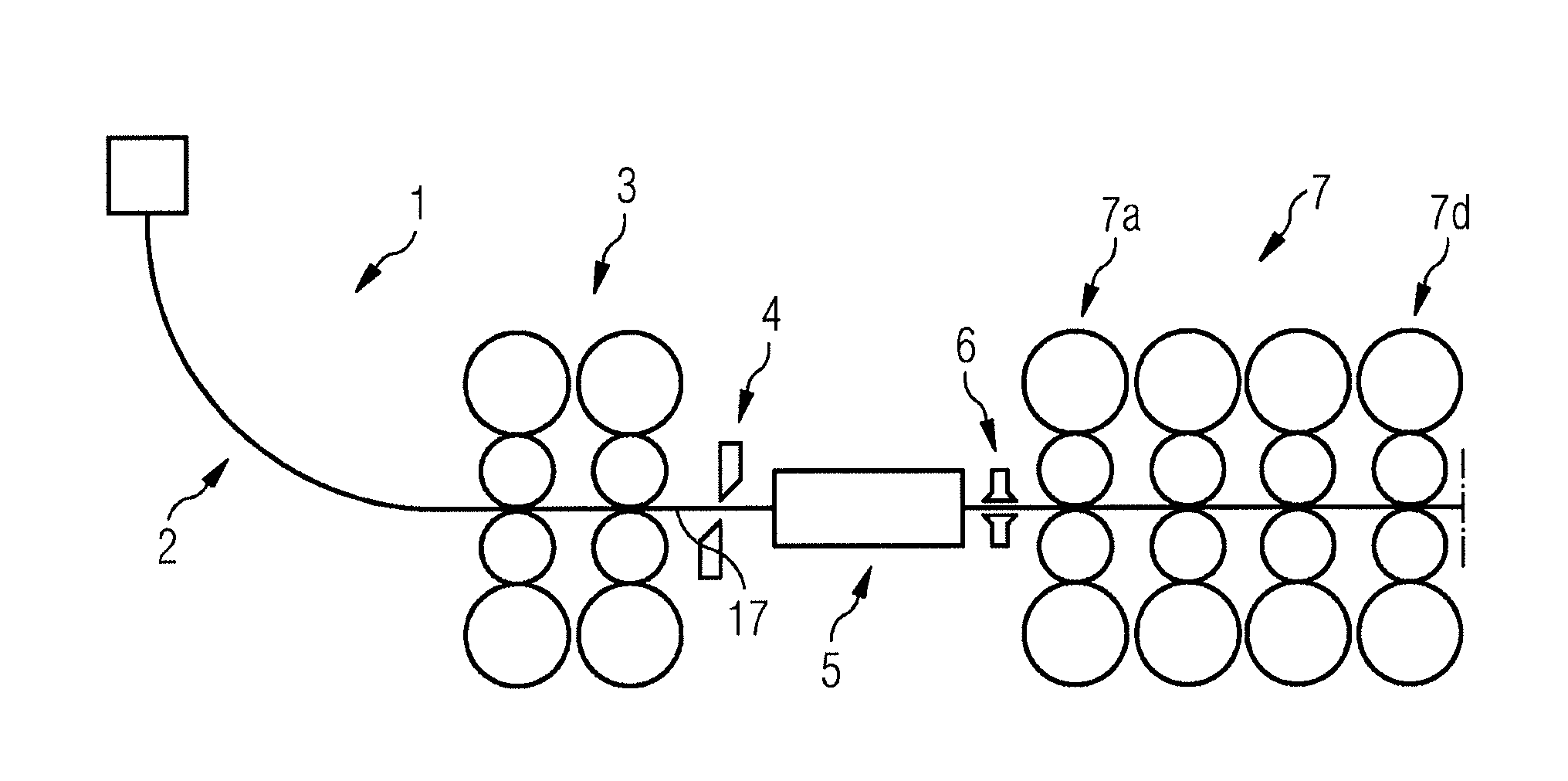

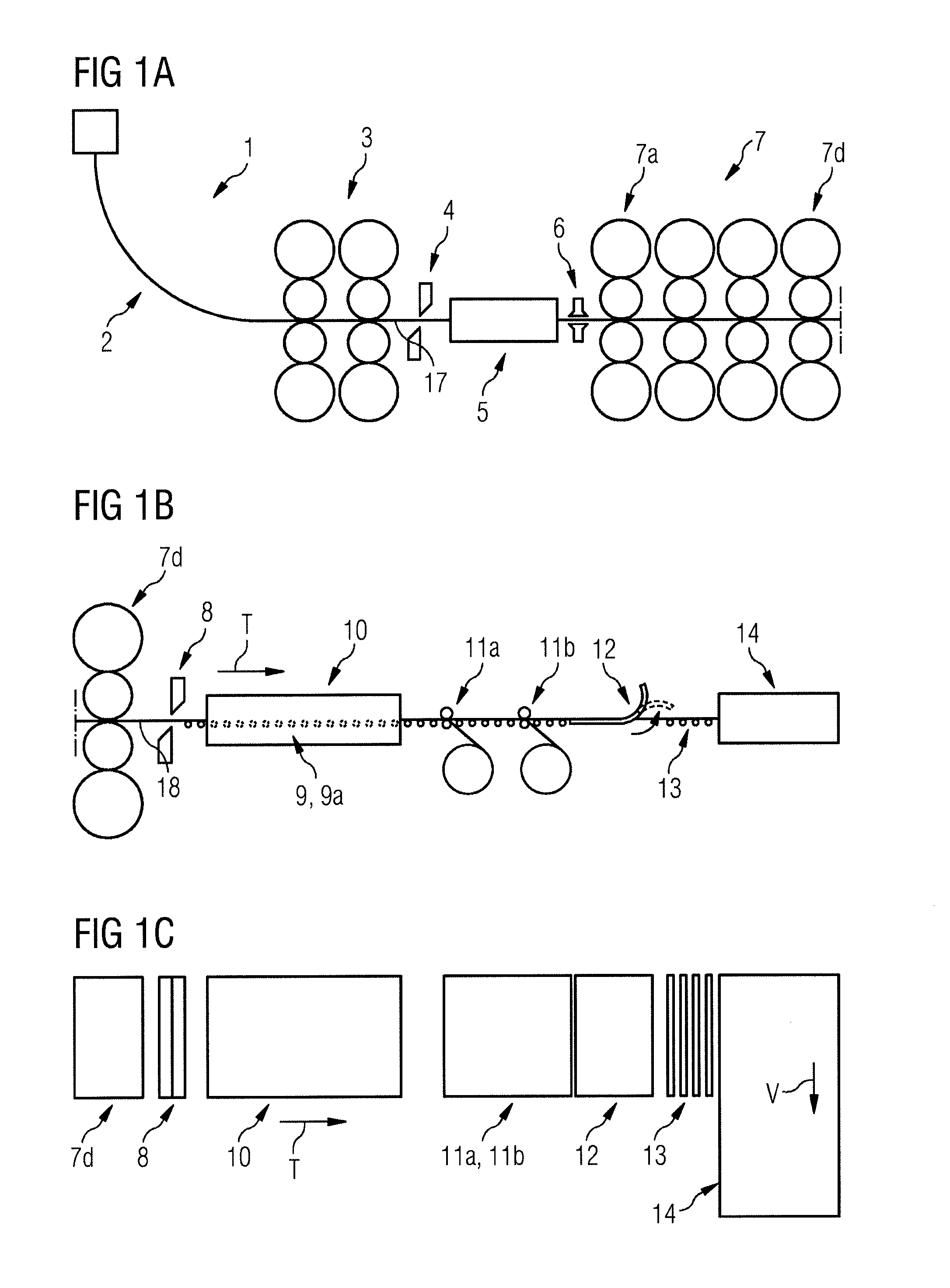

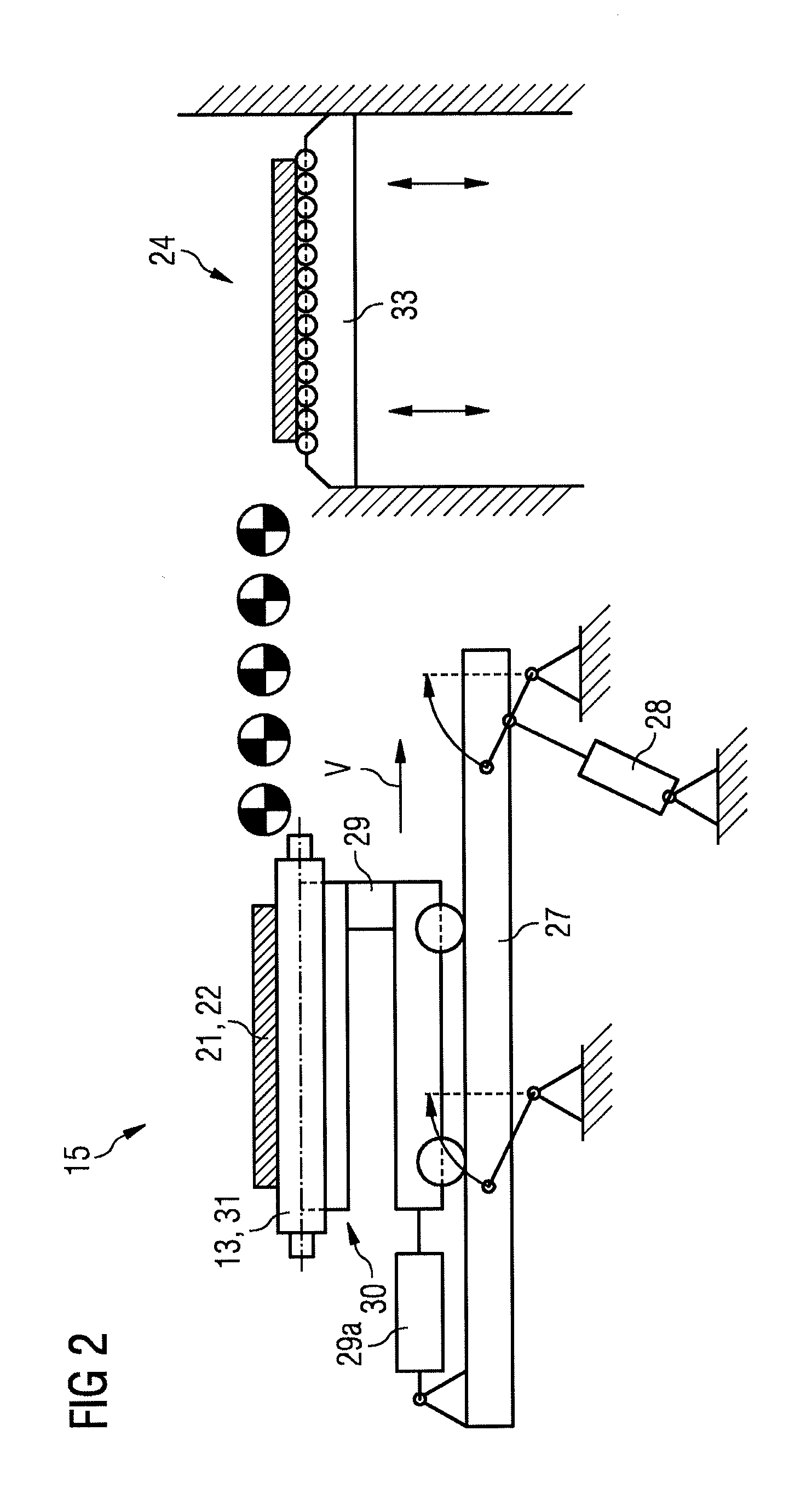

Method and apparatus for the rapid delivery of heavy plates from a rolling mill

InactiveUS20160101450A1Safe storageIncrease speedTemperature control deviceMetal rolling stand detailsThick plateStrip mill

A method and device for rapid discharging of metallic plates (21, 22) particularly thick plates, from a rolling mill, to enable secure discharge of relatively short plates (21, 22) from the rolling mill at high velocity and low cycle times by transporting a first plate (21) on a roller bed (9, 13) in the transport direction (T), and preferably the first plate (21) is accelerated in the transport direction (T); depositing the first plate (21) on the roller bed (9, 13); transporting a second plate (22) on the roller bed (9, 13) in the transport direction (T); depositing the second plate (22) in the transport direction before the first plate (21) on the roller bed (9, 13); and discharging the first and the second plates (21, 22) from the roller bed (9, 13) onto a storage (24), wherein the discharging occurs crosswise to the transport direction (T).

Owner:PRIMETALS TECH AUSTRIA GMBH

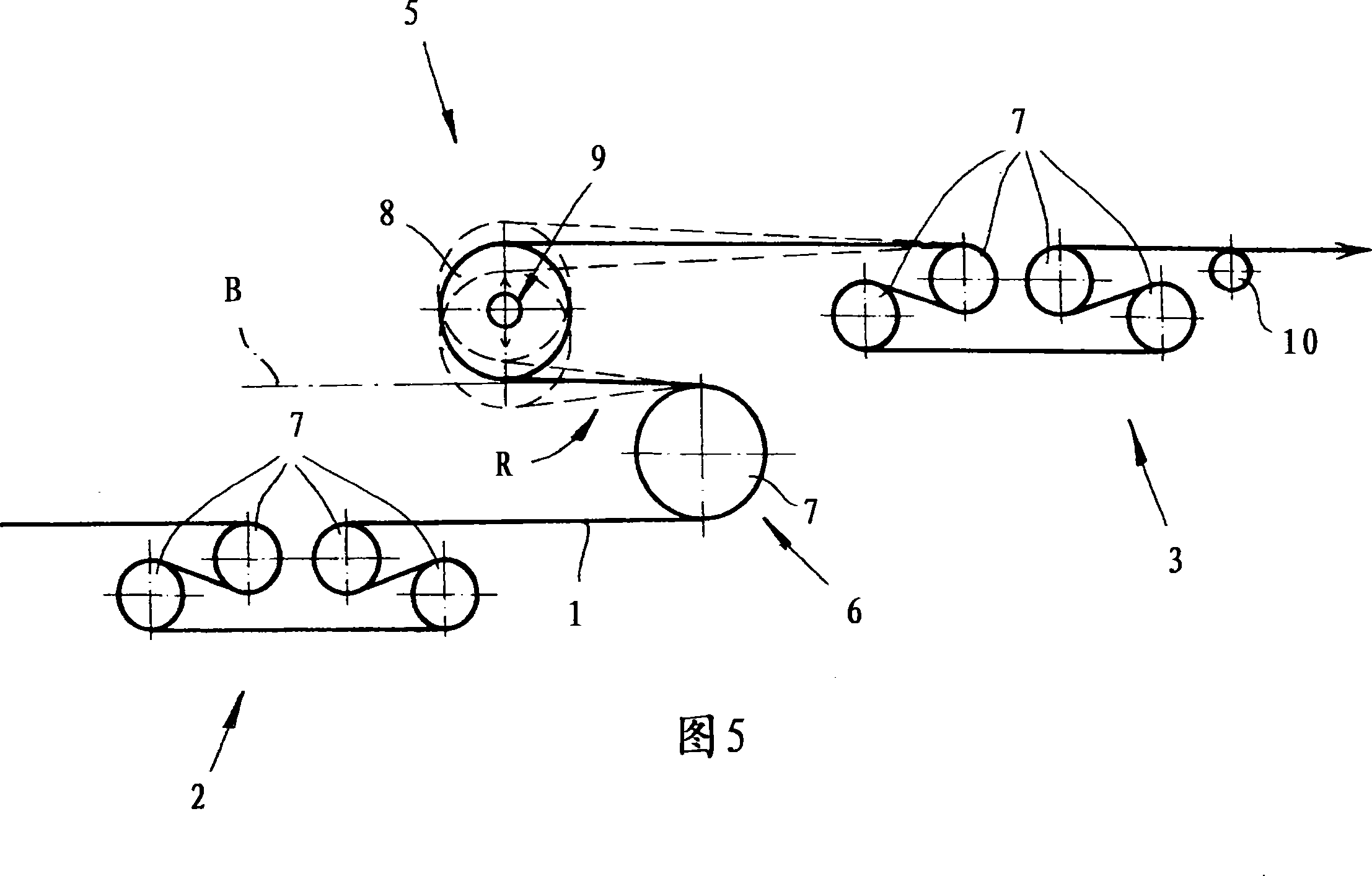

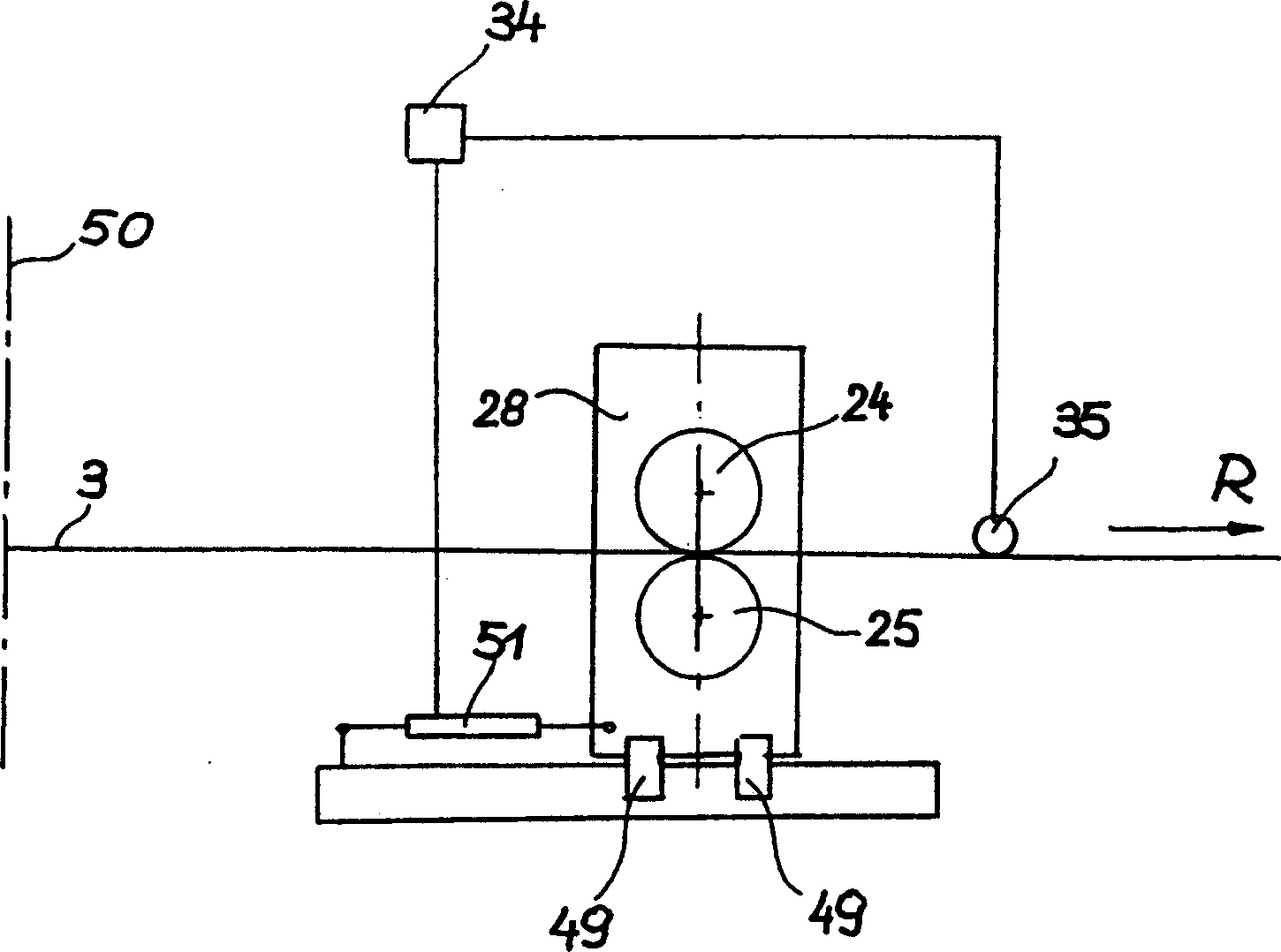

Method for controlling and/or regulating slipping motion of roller relative to strip, controller and/or regulator, machine-readable program code, storage medium and industrial plant

ActiveCN102131596ASave resourcesImprove reliabilityFunction indicatorsTensioning/braking arrangementsInterconnectionControl theory

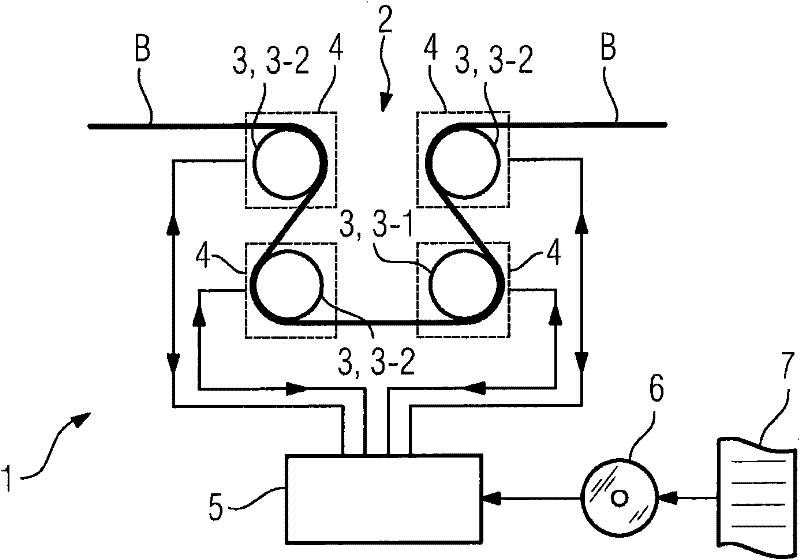

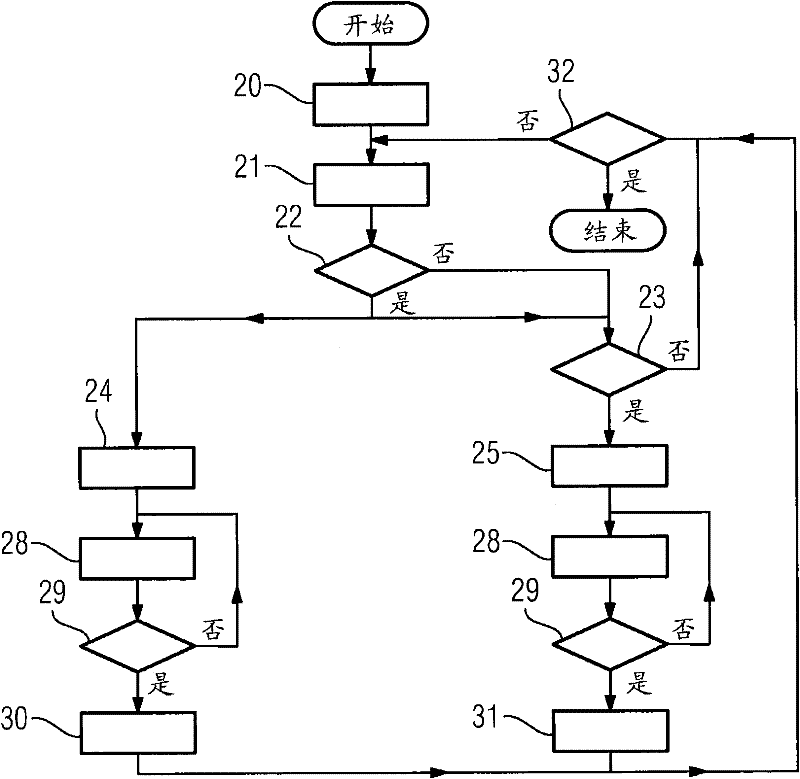

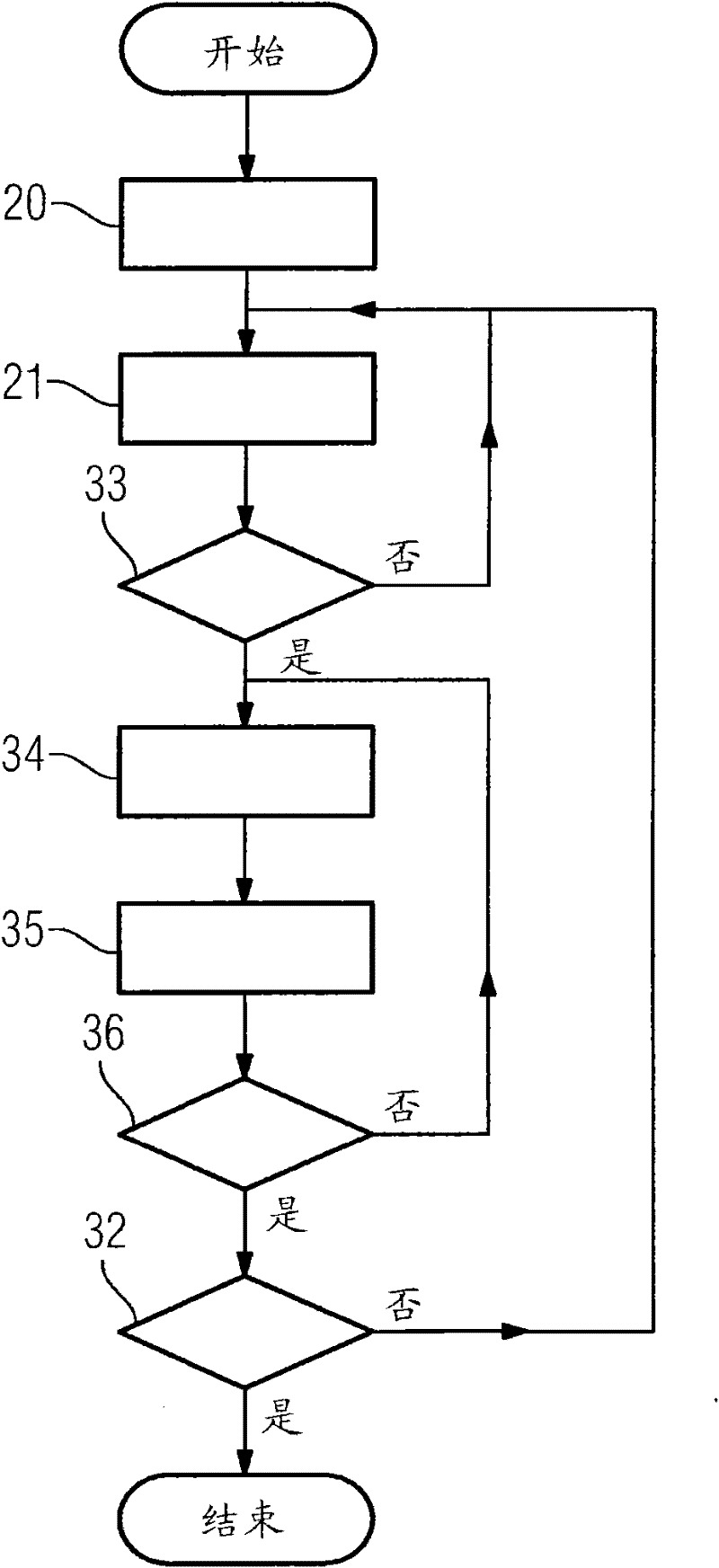

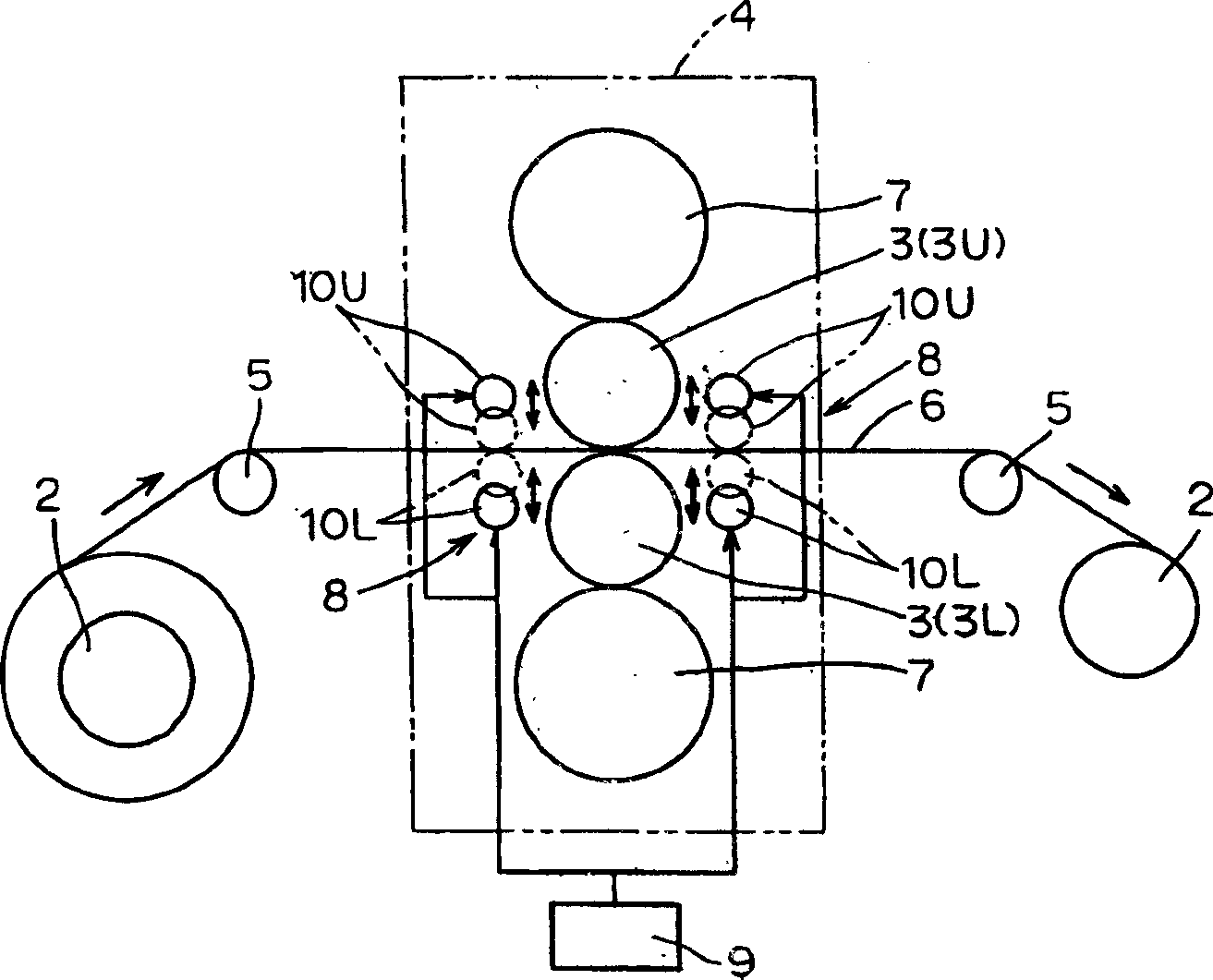

The invention relates to an industrial plant (1), to a controller and / or regulator (5), to a machine-readable program code (7), to a storage medium (6), and to a method for controlling and / or regulating a slipping motion of a roller (3, 3-1, 3-2) relative to a strip (B), particularly a cold strip to be processed in a metal processing unit, said strip being guided through a roller interconnection (2) comprising the roller (3, 3-1, 3-2) and at least one further roller (3, 3-1, 3-2) at an adjustable strip speed. By monitoring (21) the occurrence of the slipping motion by means of detecting at least one technical operating variable of the roller (3, 3-1, 3-2), and due to the fact that with the occurrence of a slipping motion of the roller (3, 3-1, 3-2), a current circumferential speed of the roller (3, 3-1, 3-2) and / or of at least one of the at least one further roller (3, 3-1, 3-2) and / or of the strip speed is changed (24, 25, 26, 27, 34) such that the current circumferential speed of the slipping roller (3, 3-1, 3-2) and the strip speed approach each other, it becomes possible to detect a slipping of a strip relative to a roller in a system, and to reduce or remedy the same, particularly during the operation of the plant.

Owner:PRIMETALS TECH GERMANY

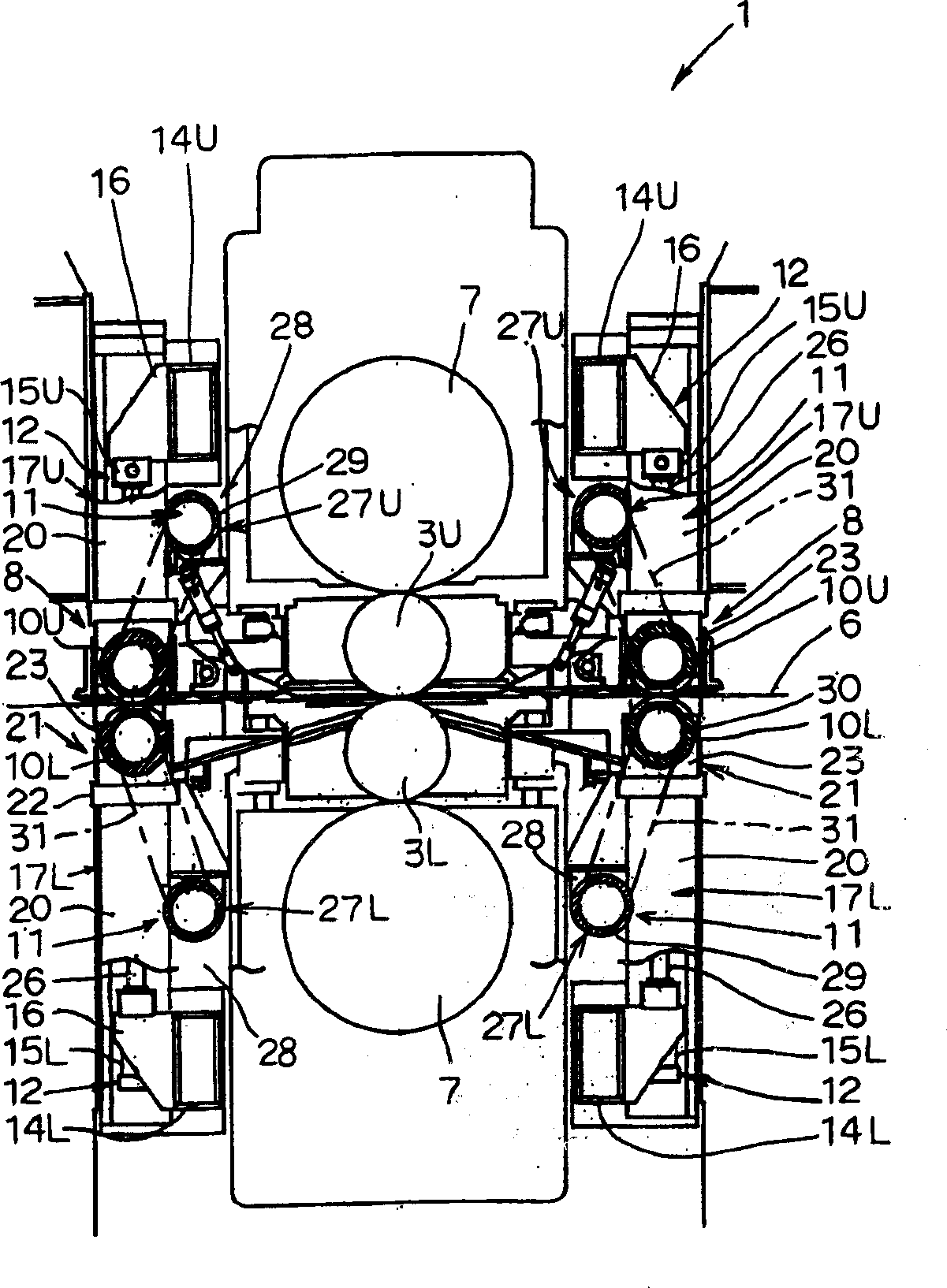

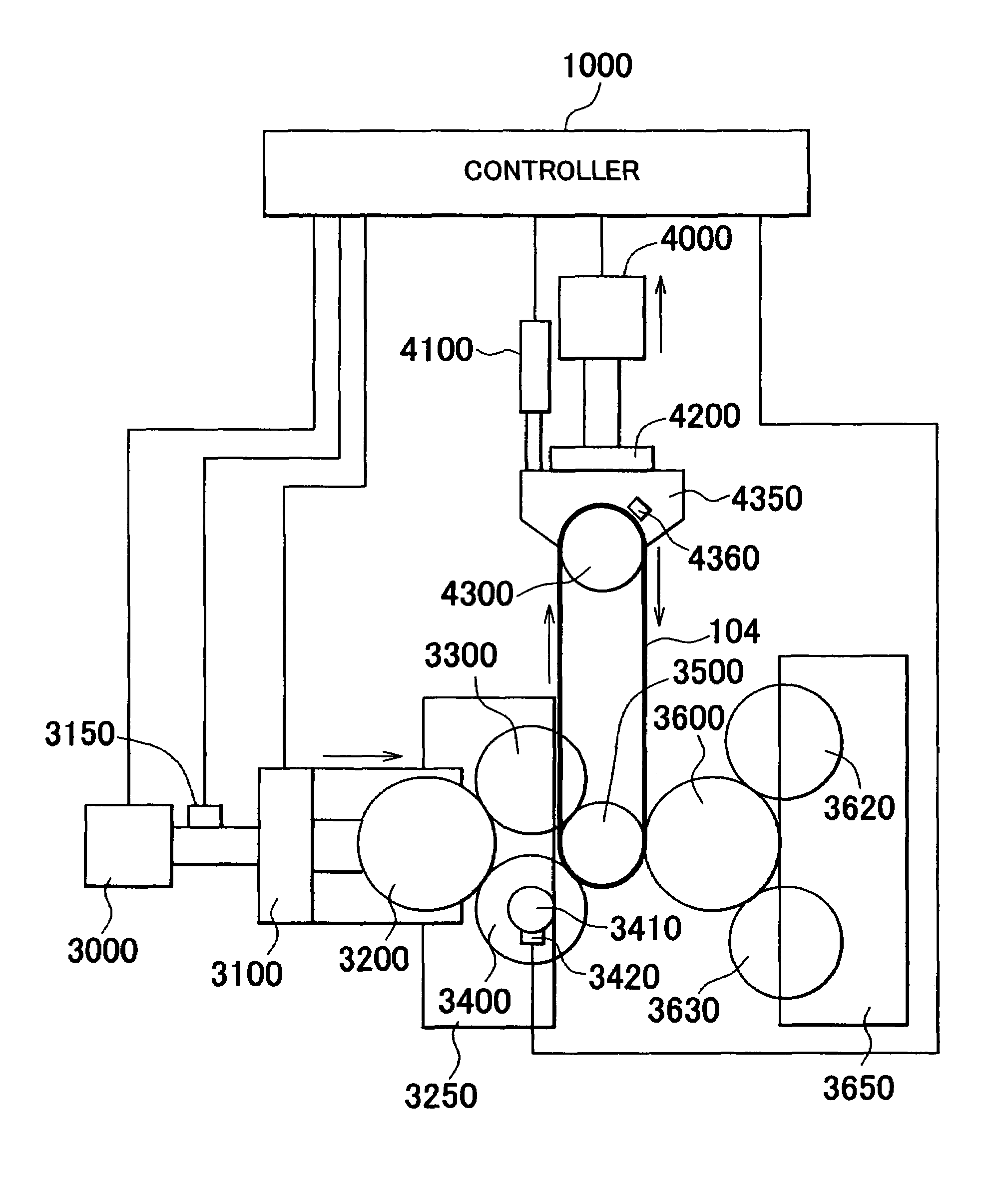

Rolling machine

InactiveCN1593800ANo defectsMetal rolling stand detailsTensioning/braking arrangementsEngineeringRolling mill

Owner:KOBE STEEL LTD

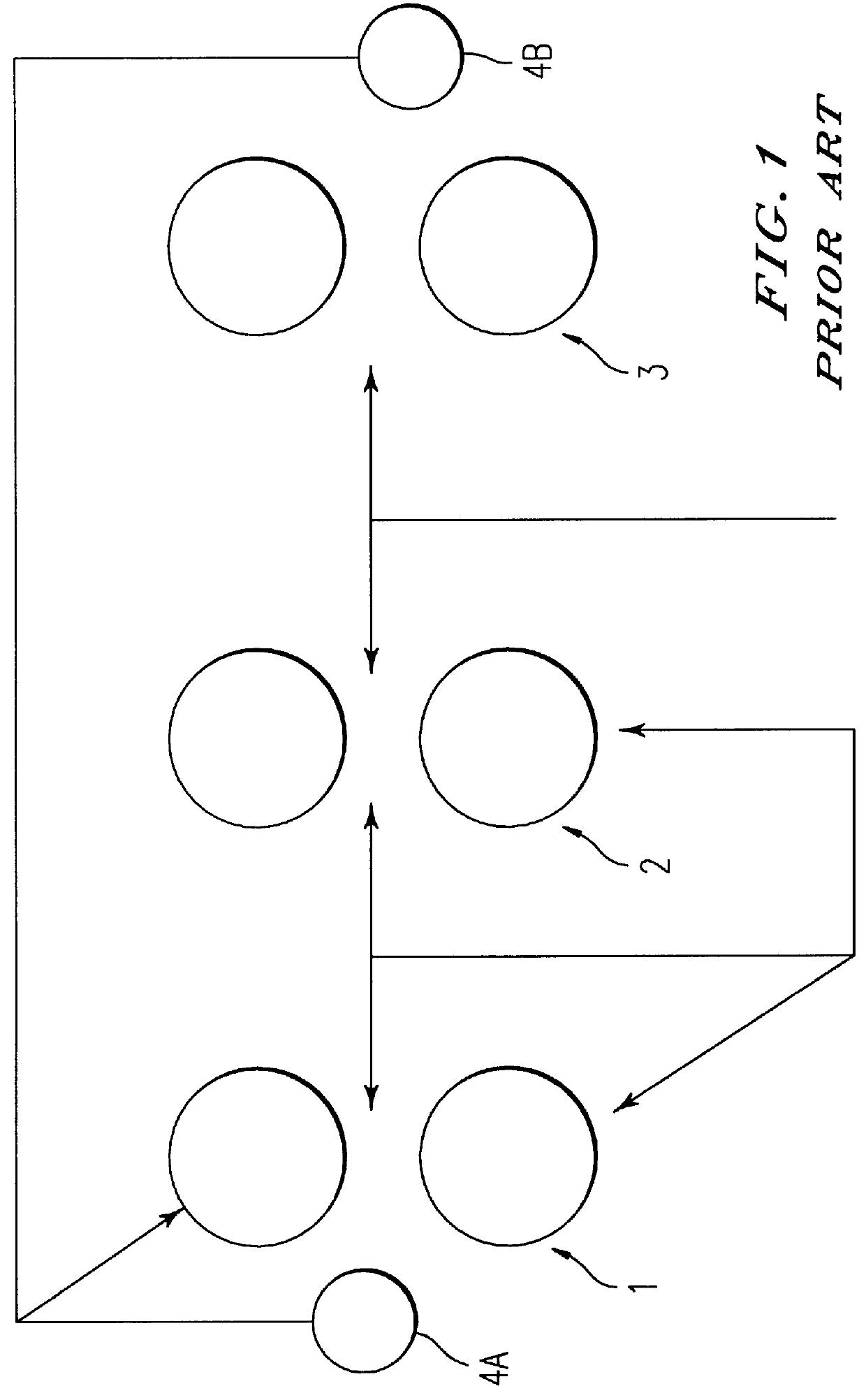

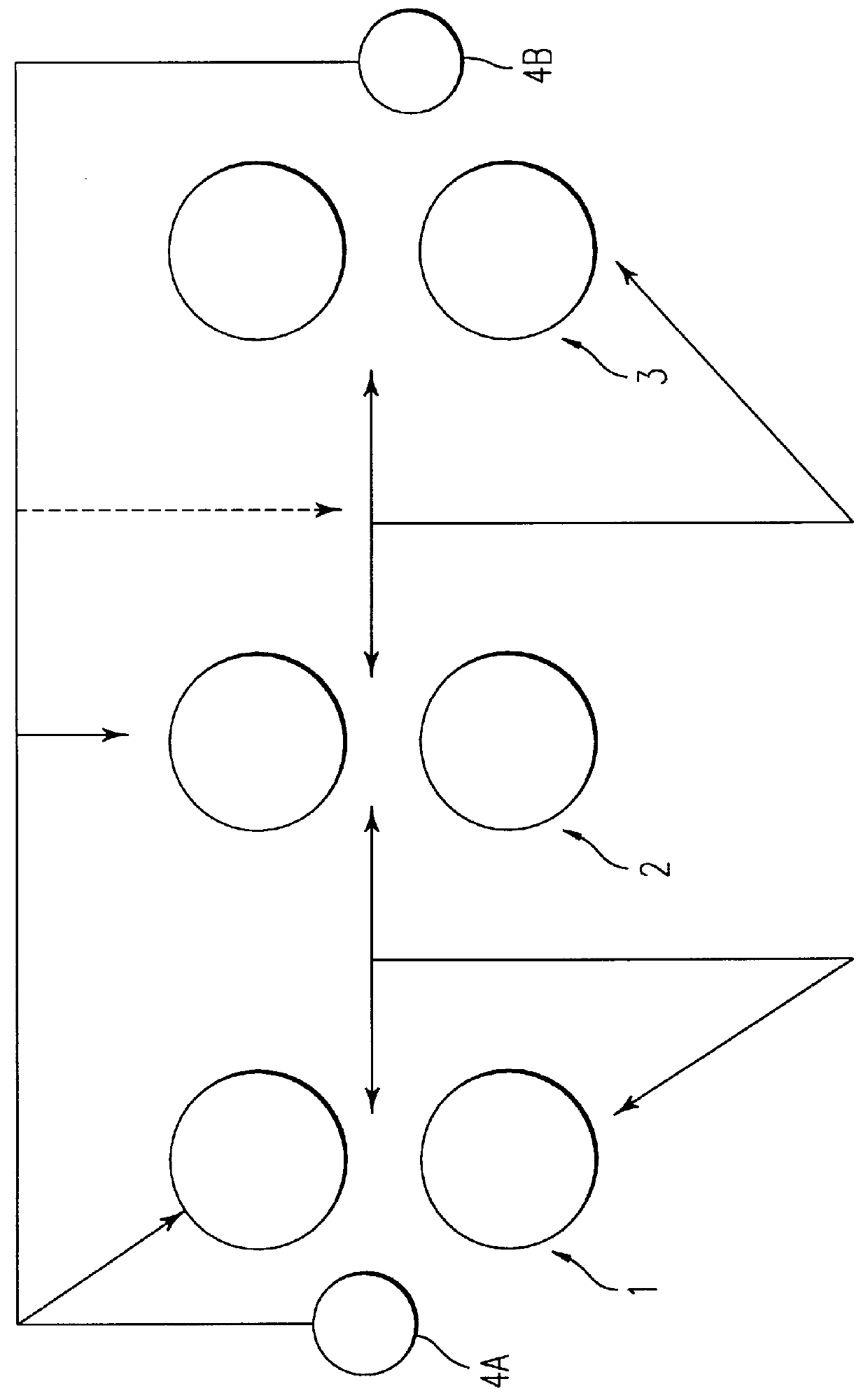

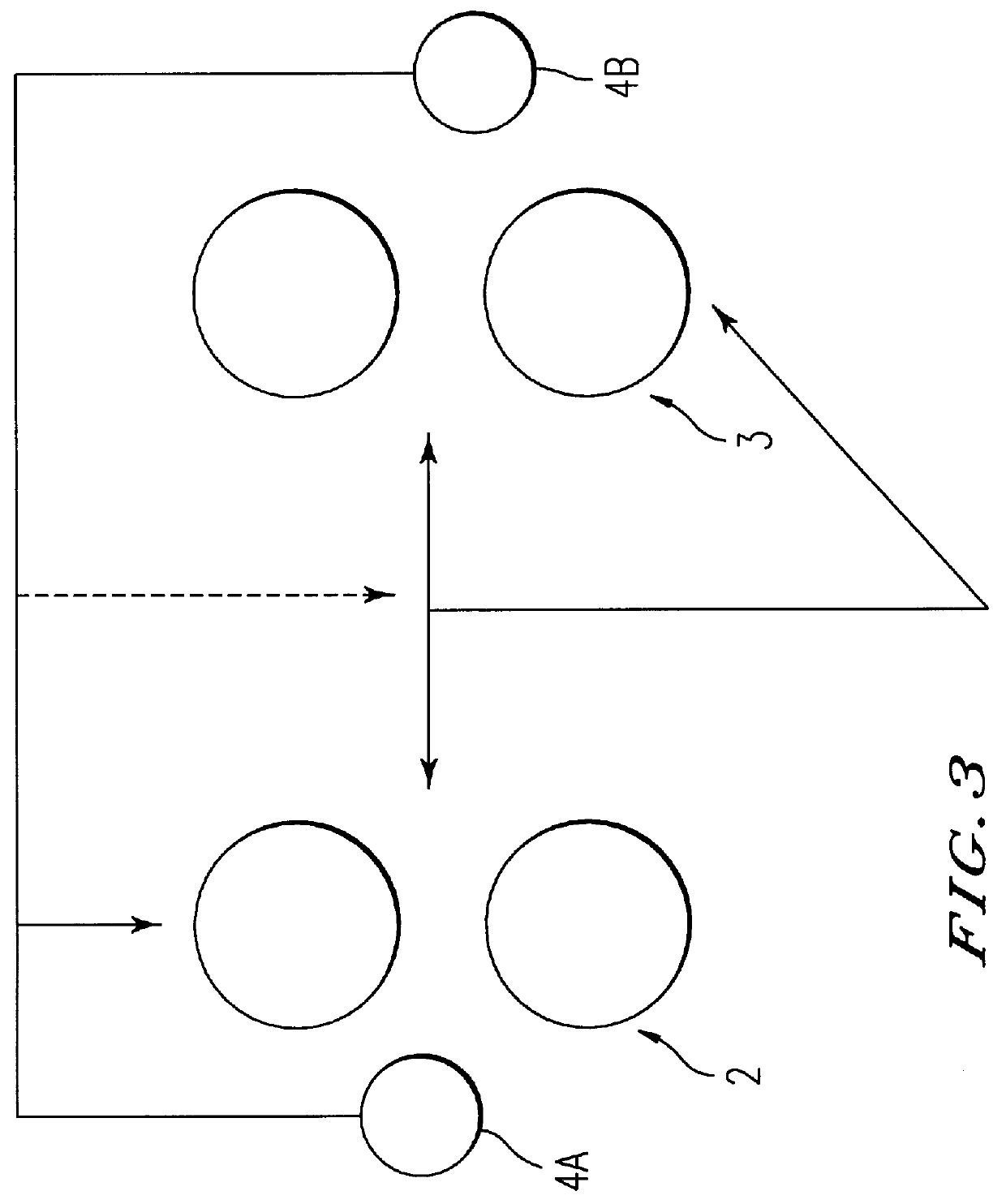

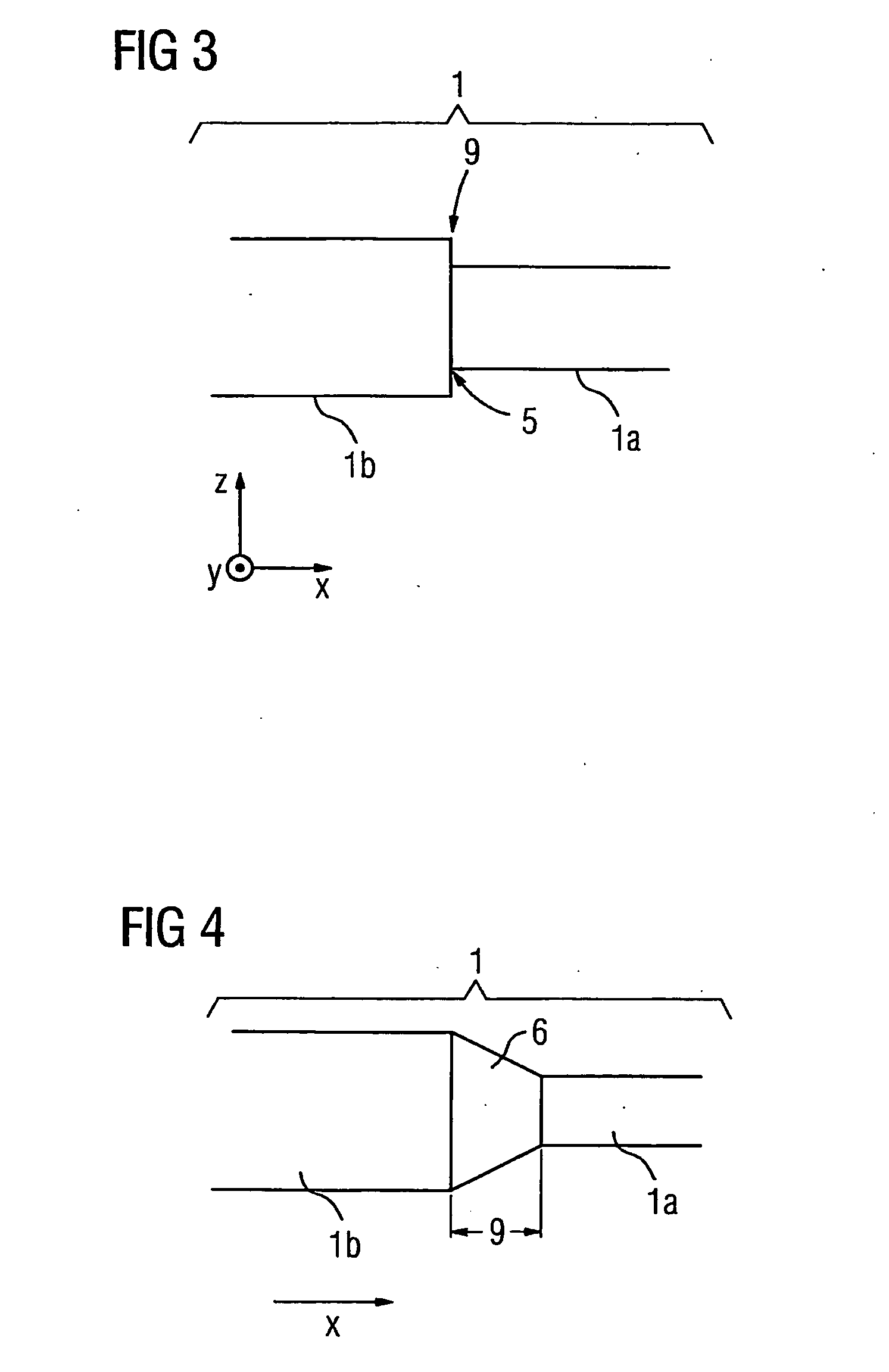

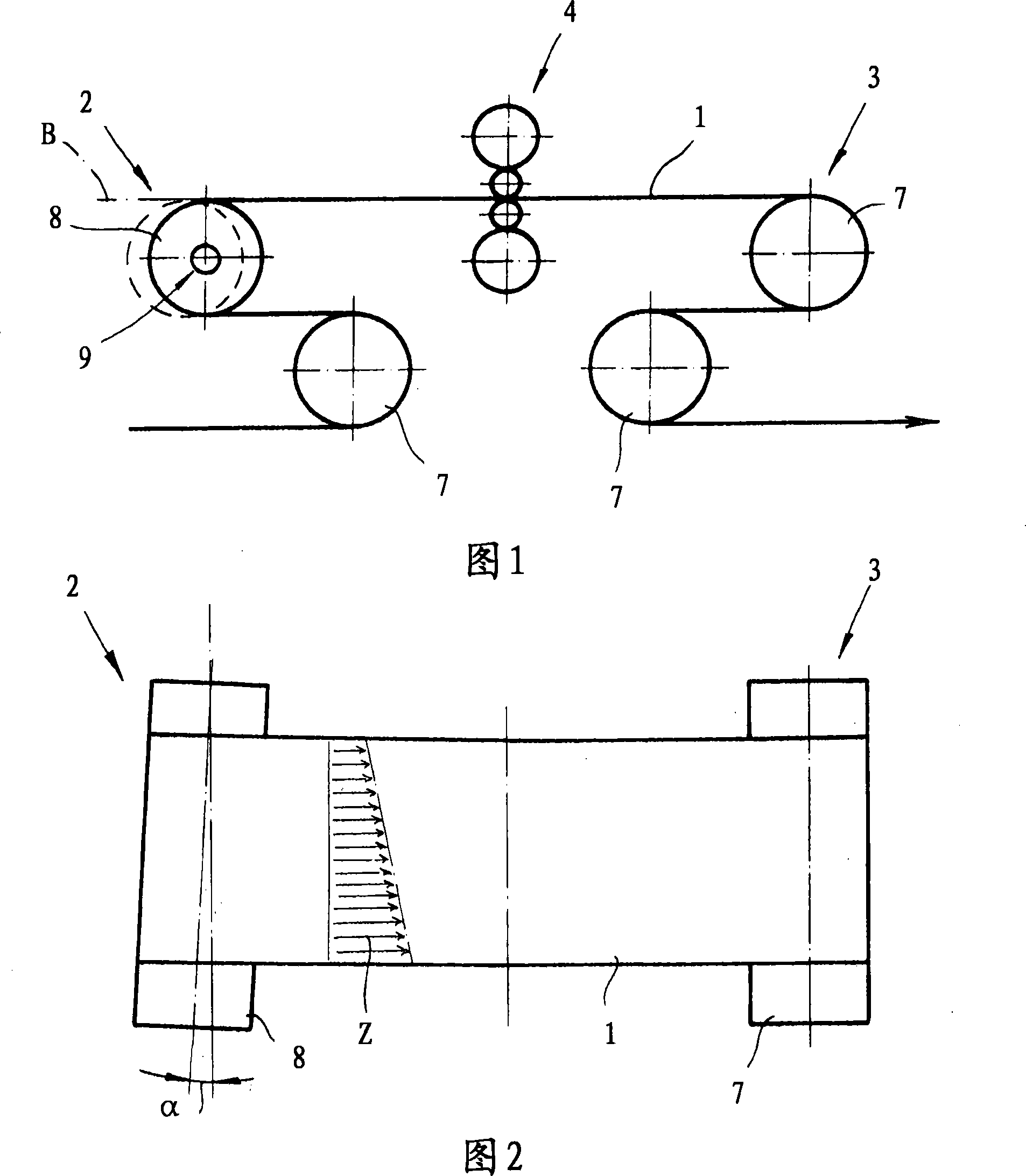

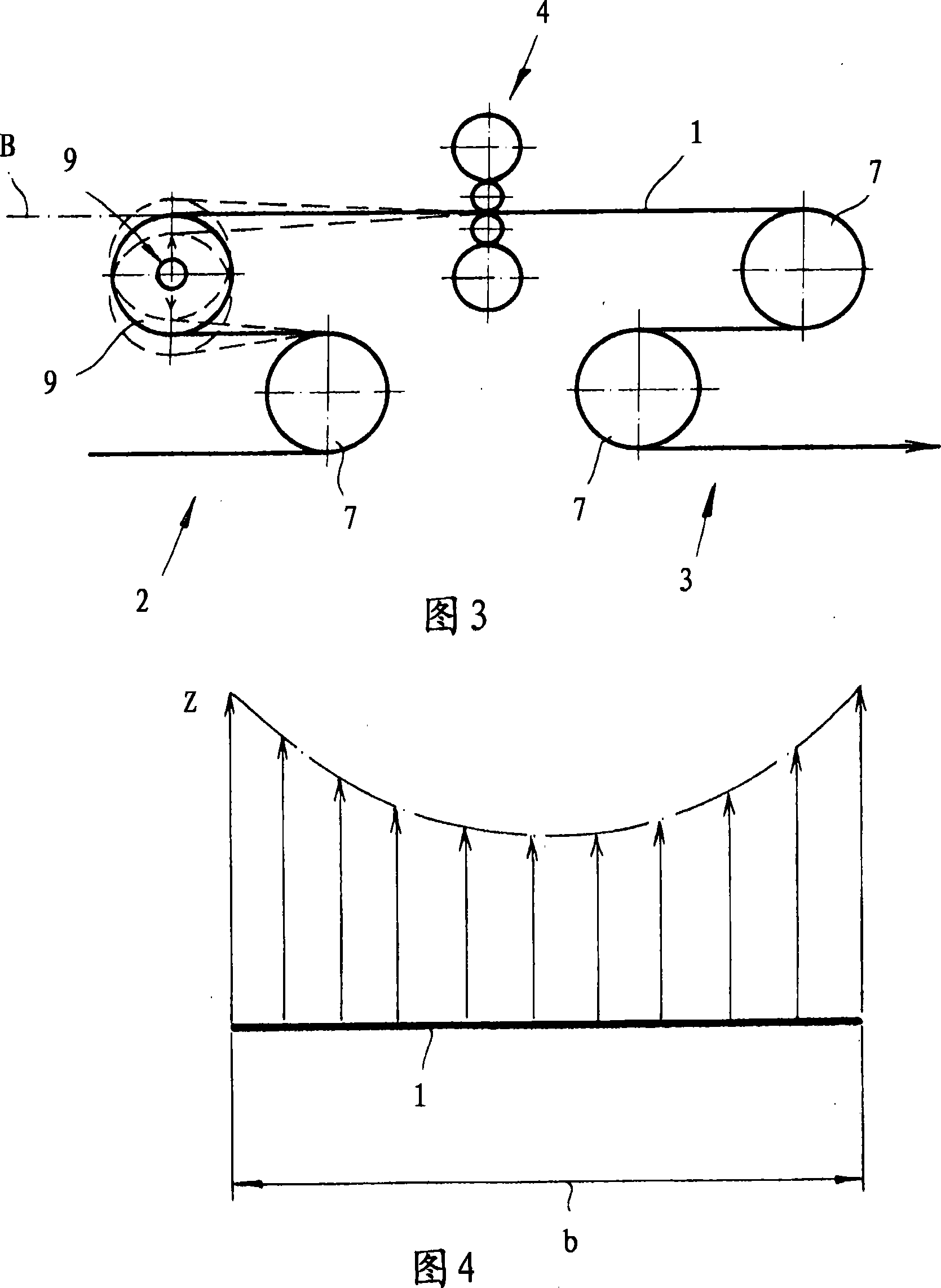

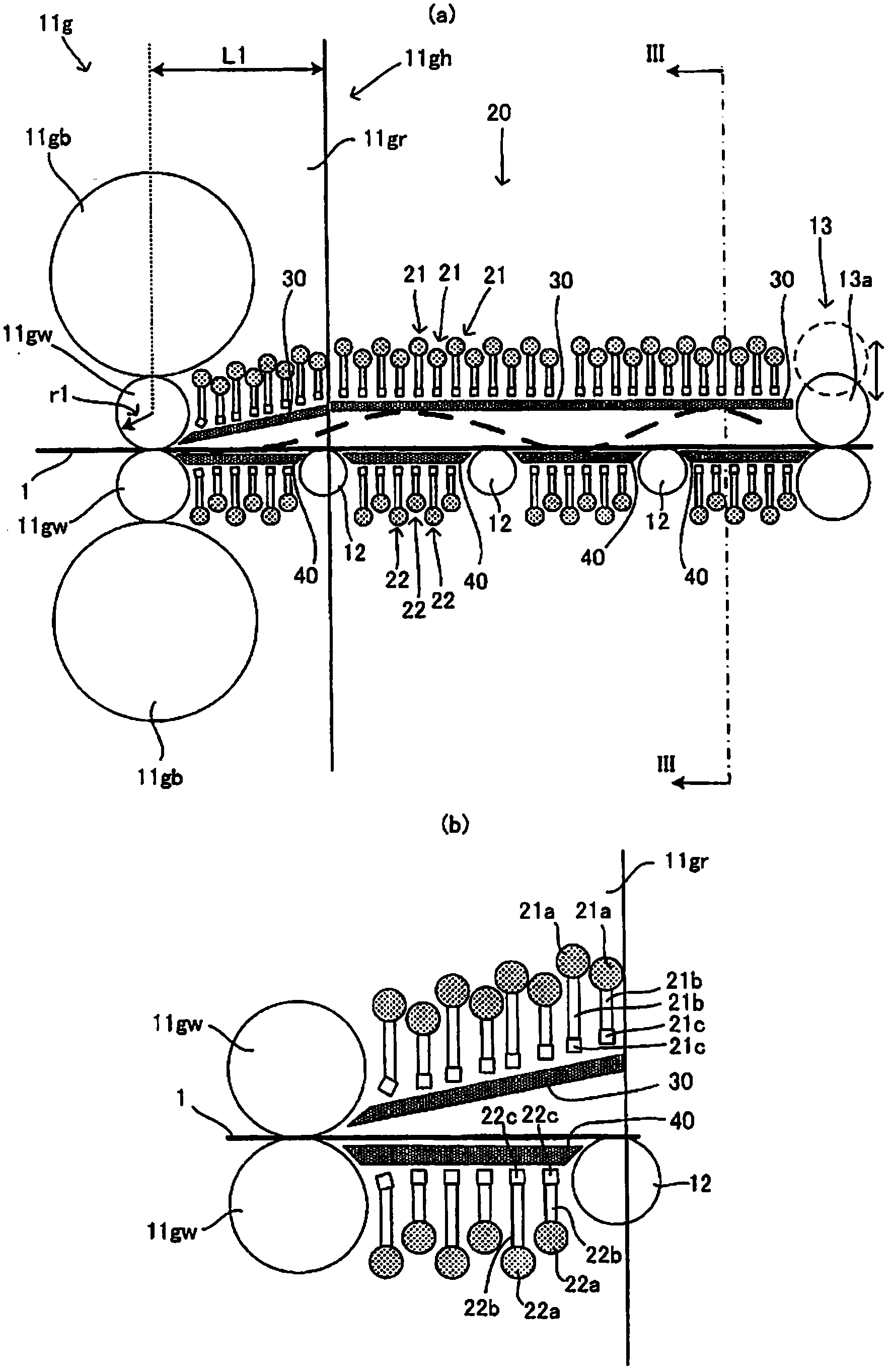

Device and method for leveling metal strips

InactiveCN101239356AEliminate plane errorsMetal-working feeding devicesTensioning/braking arrangementsMetal stripsStructural engineering

Sets of tightening rollers form a feeder set (2) of tightening rollers and a delivery set (3) of tightening rollers. The feeder set of tightening rollers increases pulling action. The delivery set of tightening rollers decreases pulling action. Between the feeder set of tightening rollers and the delivery set of tightening rollers there can be a band-treatment device, e.g. rollers (4) / stretching devices. An independent claim is also included for a method for planishing / smoothing metal bands during rolling, aligning and / or stretching.

Owner:BWG BERGWERK & WALZWERK MASCHINENBAU GMBH

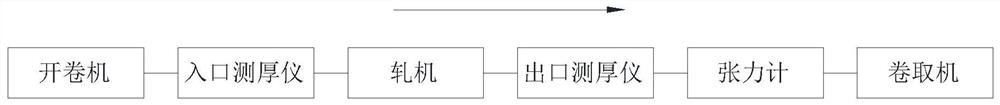

Continuous rolling mill entrance region tight rolls system and control method thereof

ActiveCN101229566APrevent slidingReduce scratchesRare end control deviceTensioning/braking arrangementsControl systemEngineering

The invention discloses a tension roll group system at entrance of a continuous rolling mill and a control method thereof. The tension roll group system consist of a tension roll, a press roll and an auto control system used for controlling the tension roll group system at the entrance of the continuous rolling mill. The press roll is connected with a power device. The invention changes the press roll of the tension roll into belt drive control and controls the tension roll system through the control method which is to adjust speed and torque of the press roll according to the speed, loop tension and the working status of the equipment at the entrance of a continuous rolling mill, prevent strip from sliding at the tension roll group and protect the surface quality of the strip and the surface of the tension roll, thereby reducing scratching of the strip tail.

Owner:BAOSHAN IRON & STEEL CO LTD

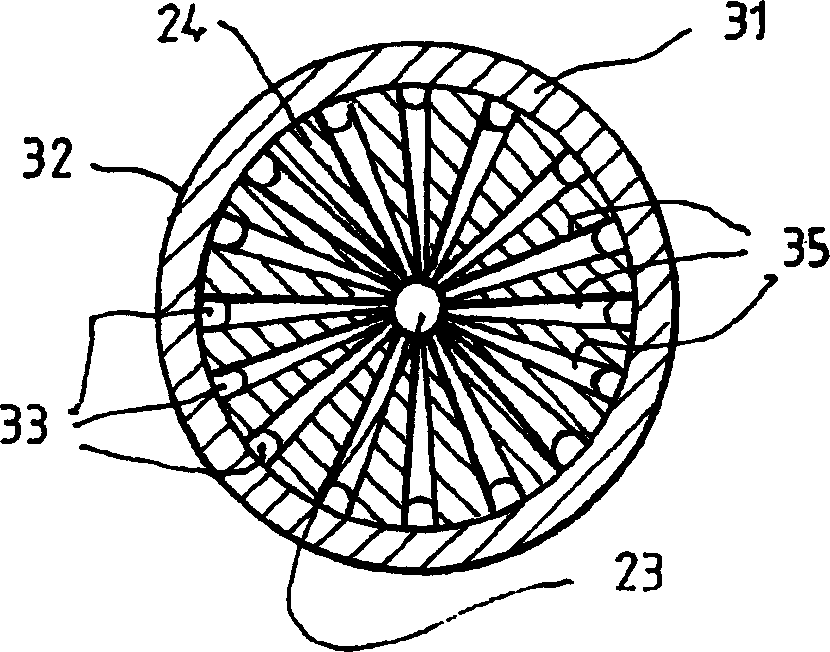

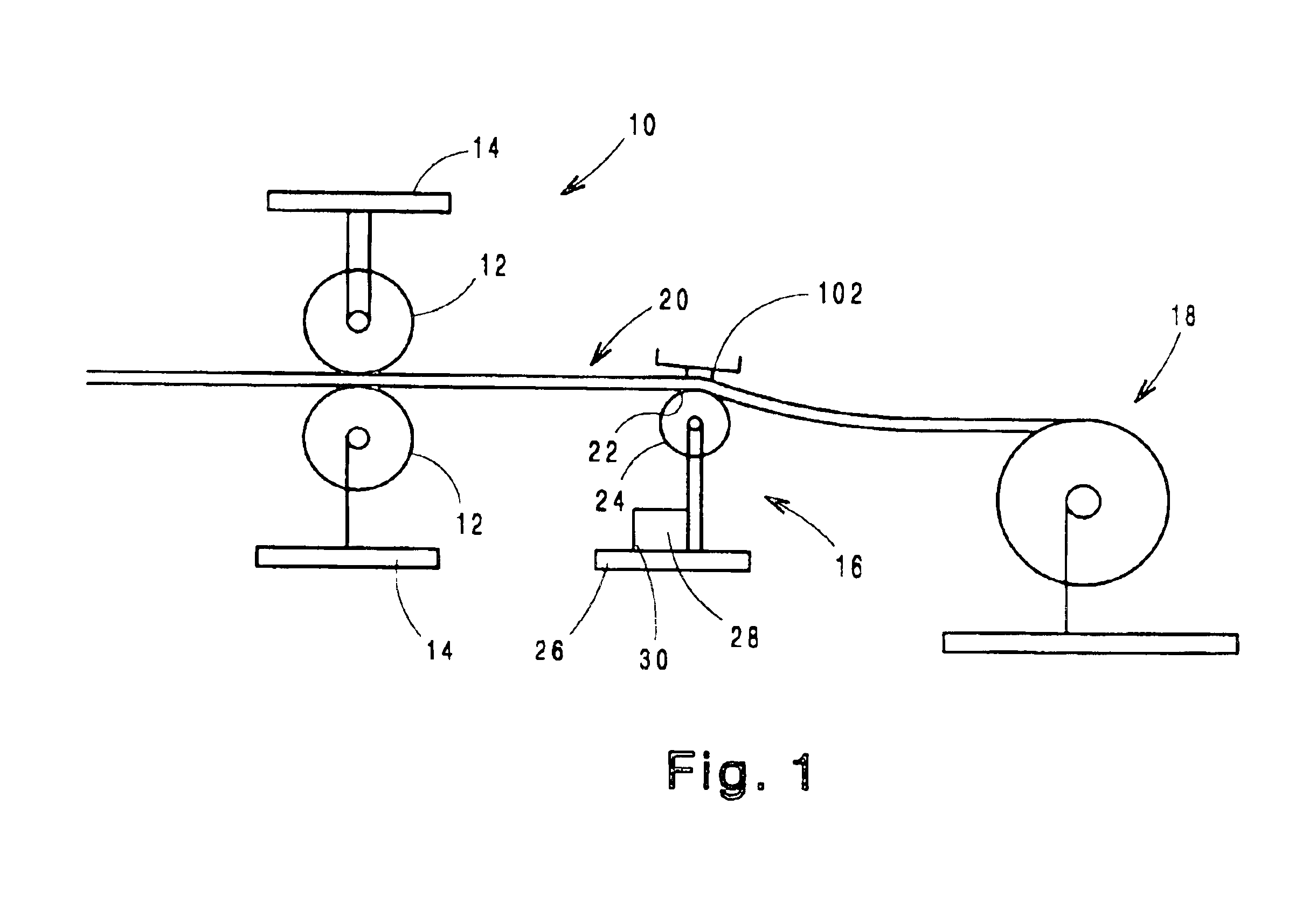

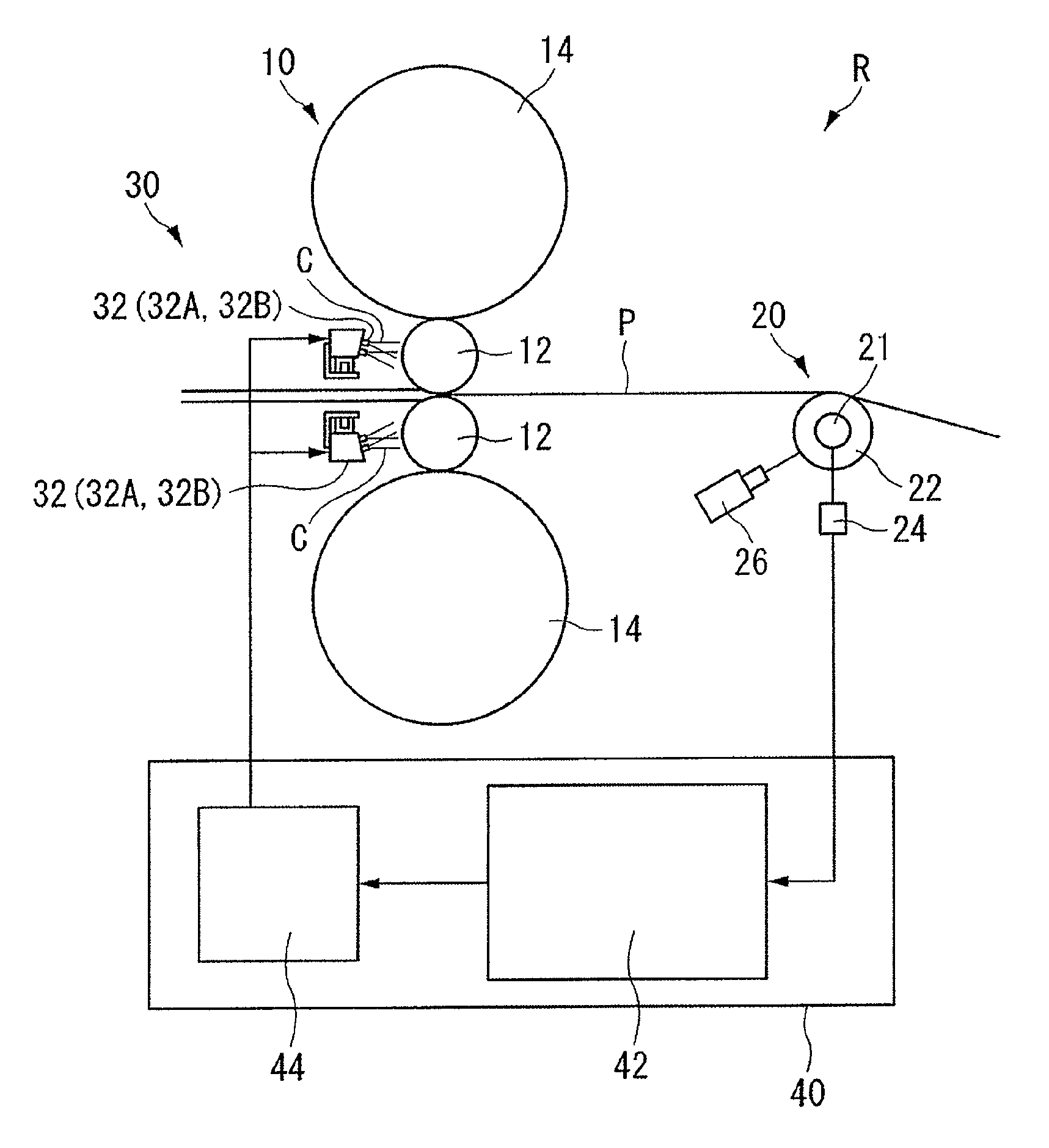

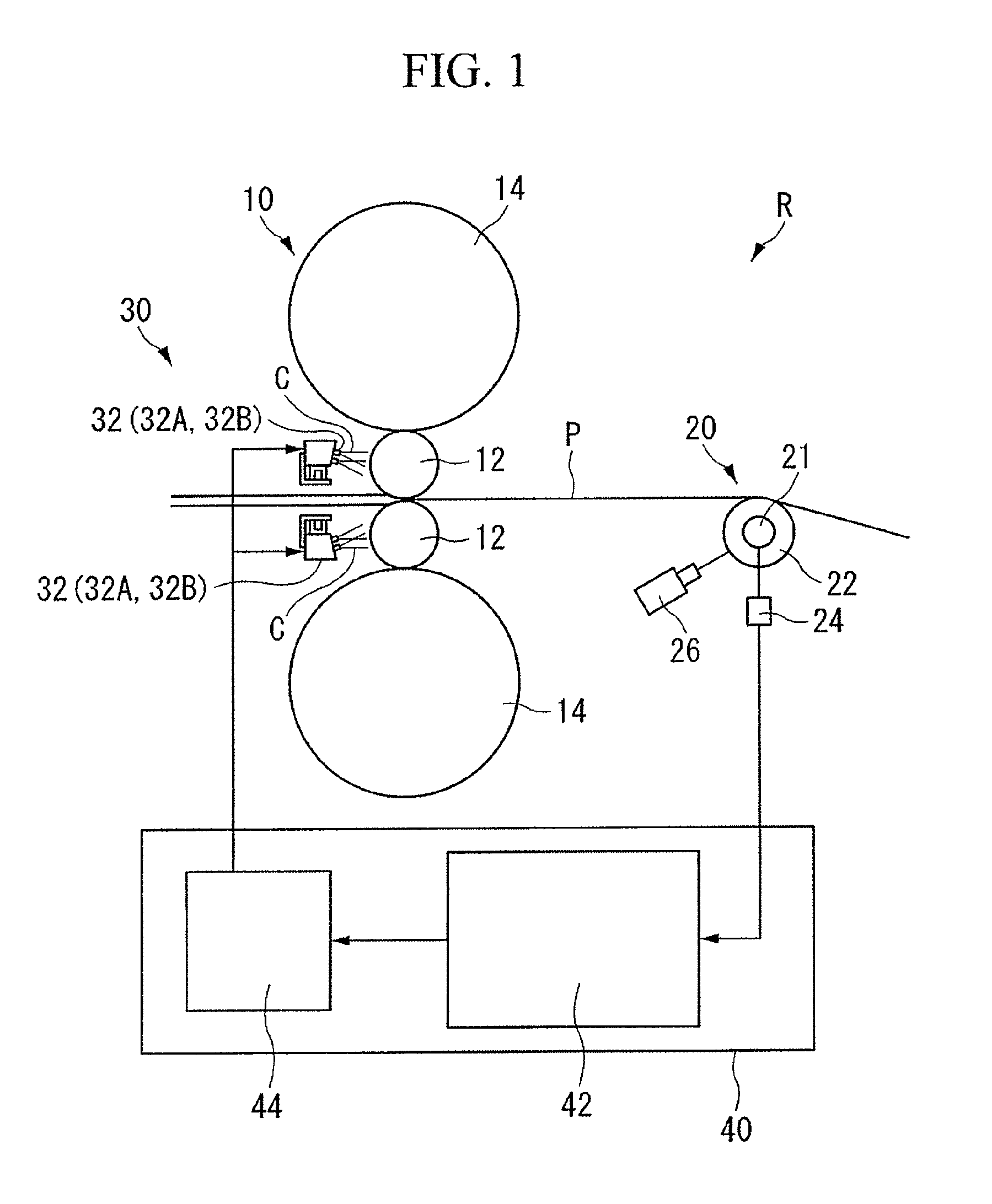

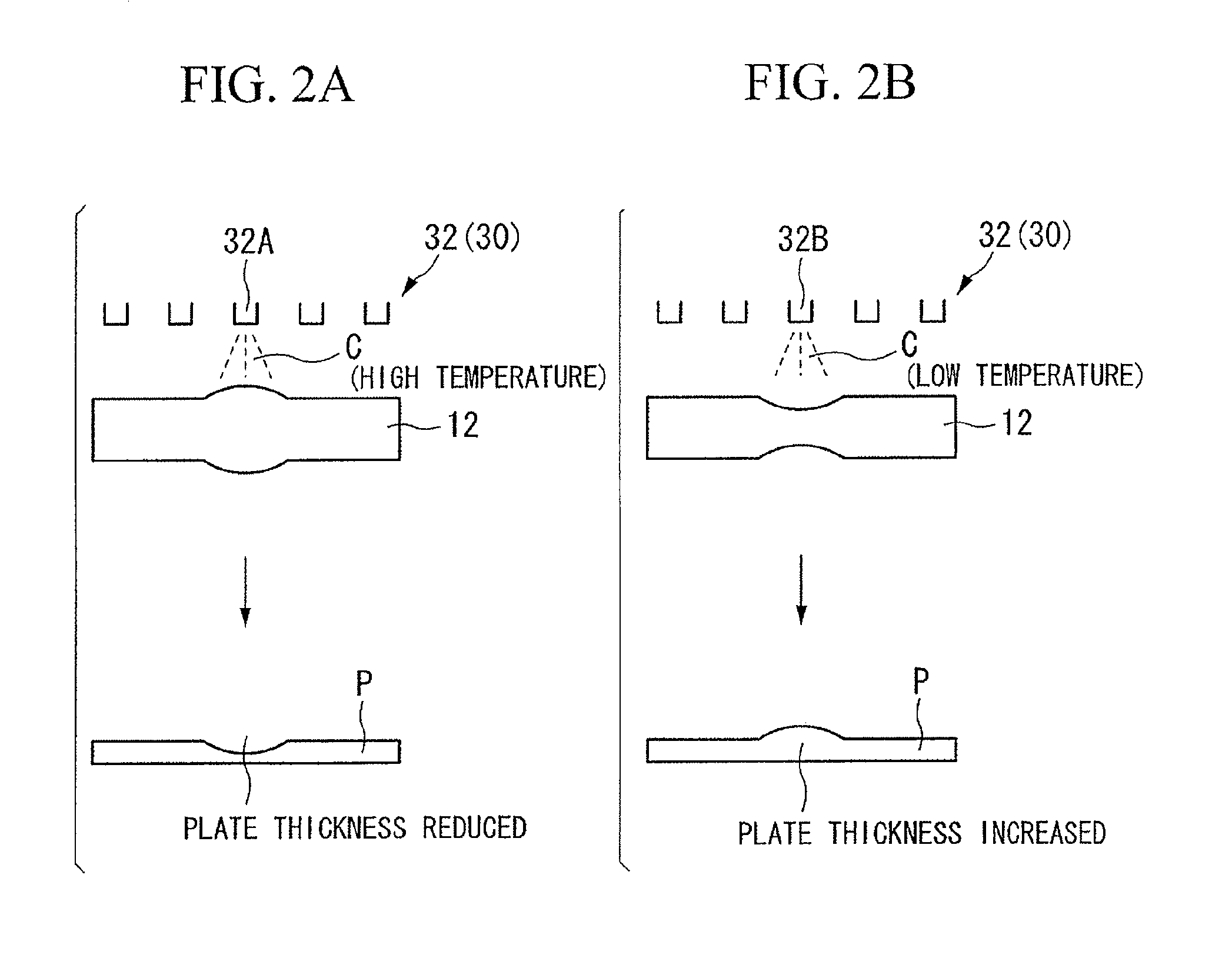

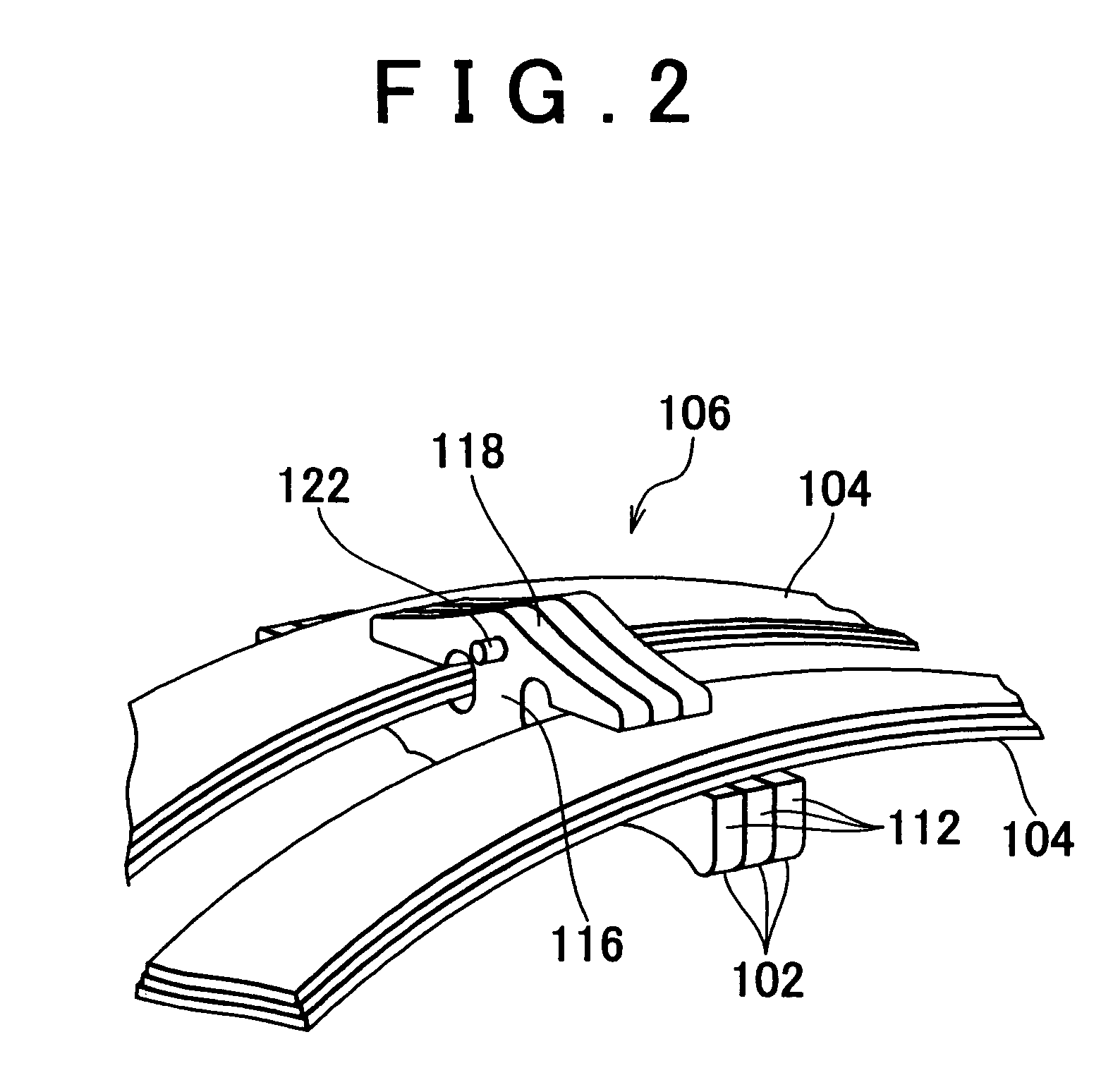

Rolling mill apparatus and method of shape control of rolled strip and plate

This invention relates to a rolling mill apparatus and a method of shape control of a rolled strip which enables satisfactory shape control even in extremely thin rolling. A rolling mill apparatus of this invention has a rolling mill, which rolls a rolled strip P between upper and lower work rolls; a shape detecting portion, which detects the degree of flatness of the rolled strip in the width direction of rolled strip which has been rolled by the rolling mill; a spray portion, having a plurality of spray nozzles arranged along the length direction of the upper and lower work rolls, which sprays the upper and lower work rolls with coolant C; and, a shape control portion, which adjusts the spray amount and / or temperature of the coolant C sprayed from the spray portion based on detected information from the shape detecting portion, to control the shape of the rolled strip P. The shape control portion has two control modes, in which the relationship of the detected information of the shape detecting portion and the spray amount and / or temperature of the coolant C sprayed from the spray portion are inversely proportional, and switches between these two control modes based on the strip thickness of the rolled strip P.

Owner:IHI CORP

Method for handling stacked steel due to strip breakage on rolling mill

ActiveCN103191933AEnsure safetyReduce downtimeMetal rolling stand detailsTensioning/braking arrangementsWind componentWork roll

The invention provides a method for handling stacked steel due to strip breakage on a rolling mill and is applied to the technical field of production and processing of rolling mills. Strip steel of the rolling mill is wound through a winding component after being rolled out of gaps between working rolls. The handling steps for stacked steel due to strip breakage include that: when steel stacking due to strip breakage occurs to the rolling mill, the gap of each working roll assembly is controlled to clamp stacked steel; the working rolls of the rolling mill are controlled to rotate reversely, and the working rolls which clamp the stacked steel pour back the strip steel in the direction opposite to the rolling direction; and the working roll assemblies drive the stacked steel to quit a steel rolling port to finish handling of the stacked steel due to strip breakage. By means of the method, time for handling strip breakage can be saved, the production efficiency can be improved, the safety of operators and devices in an accident handling process can be guaranteed, and the labor intensity and operating time of the operators can be reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Hot rolling thin strip

A thin steel strip is passed through a pinch roll stand comprising pinch rolls to a hot rolling mill comprising work rolls and backing rolls. In advance of rolling mill, the strip passes over support rolls. An anti-crimping guide roll located immediately in advance of the rolling mill is mounted on a pair of rocker structures so as to be rasiable from a lower inoperative position to lift the strip out of a straight line path so as to pass around the anti-crimping roll and to be wrapped about the upper work roll, that roll supports the strip and resists buckling of the strip and the generation of crimping defects.

Owner:CASTRIP

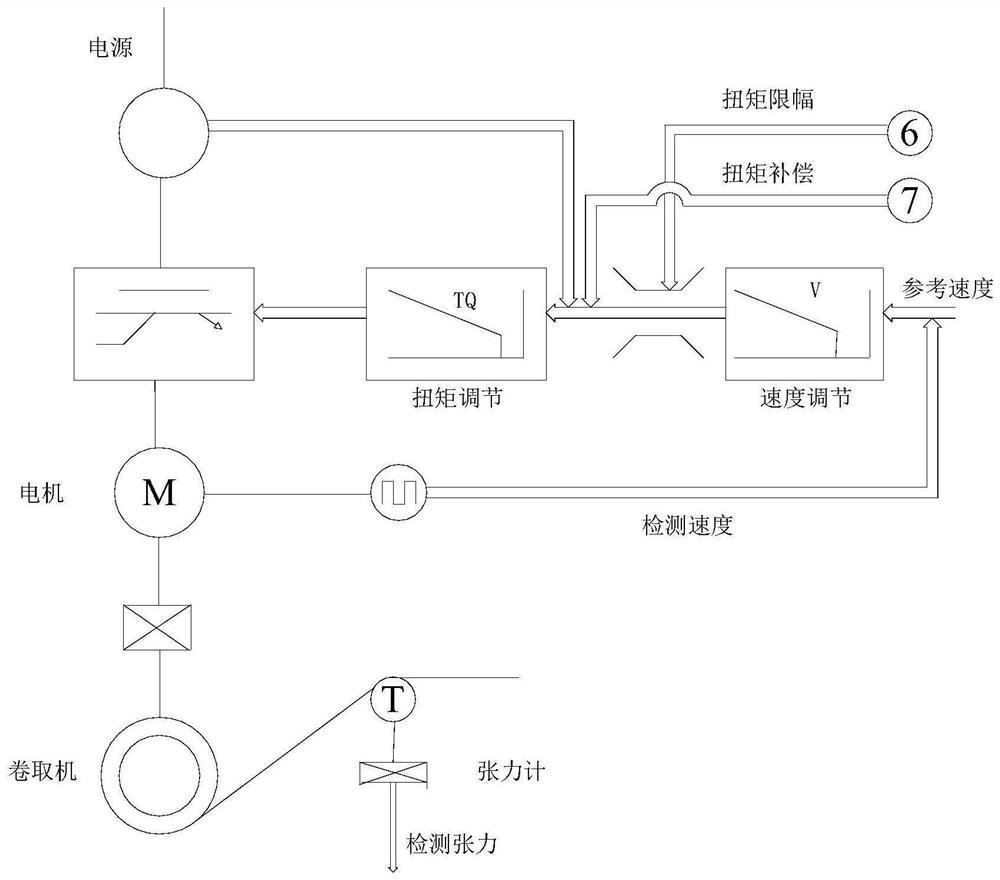

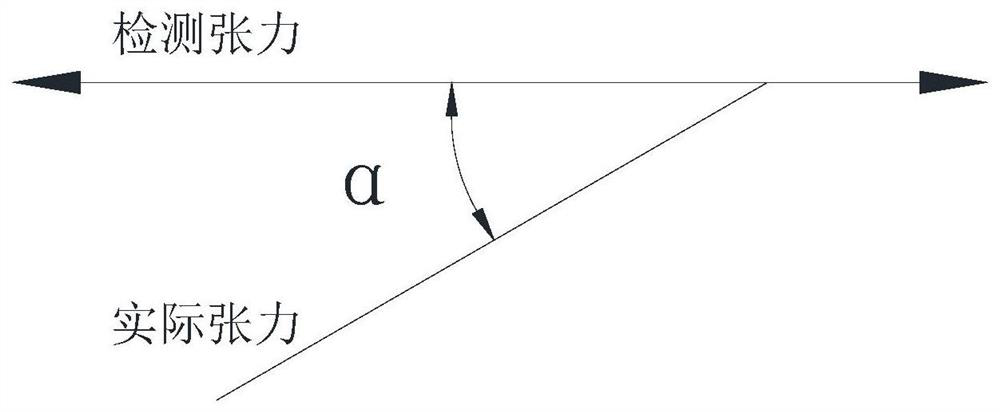

Ultra-thin steel strip coiling tension control method

ActiveCN113042540AGuaranteed tightGuaranteed to rollTensioning/braking arrangementsTension/compression control deviceFriction torqueLoad torque

The invention relates to an ultra-thin steel strip coiling tension control method. The technical problem that tension is difficult to control in the ultra-thin steel strip rolling process is solved. The tension control method comprises the following steps that firstly, static tension is established for an uncoiler and a coiler before a steel rolling unit operates; secondly, after the steel rolling unit operates, a tension value of a steel belt is detected, and a detection result is used for adjusting the output torque of a motor of the coiler; and thirdly, in the ultra-thin steel strip rolling process, torque compensation is conducted on the coiler, the tension of the steel strip is made to be constant, and the load torque MZ of the coiler comprises the steel strip tension torque MF, the rotational inertia torque MD, the steel strip bending torque Mw and the transmission system friction torque Mf. According to the technical scheme provided by the invention, strip drawing and strip breakage are avoided in the ultra-thin steel strip coiling process, so that a steel coil can be tightly and neatly coiled, the performance requirement of a product is met, and the production efficiency is also improved.

Owner:SHANXI TAIGANG STAINLESS STEEL PRECISION STRIP CO LTD

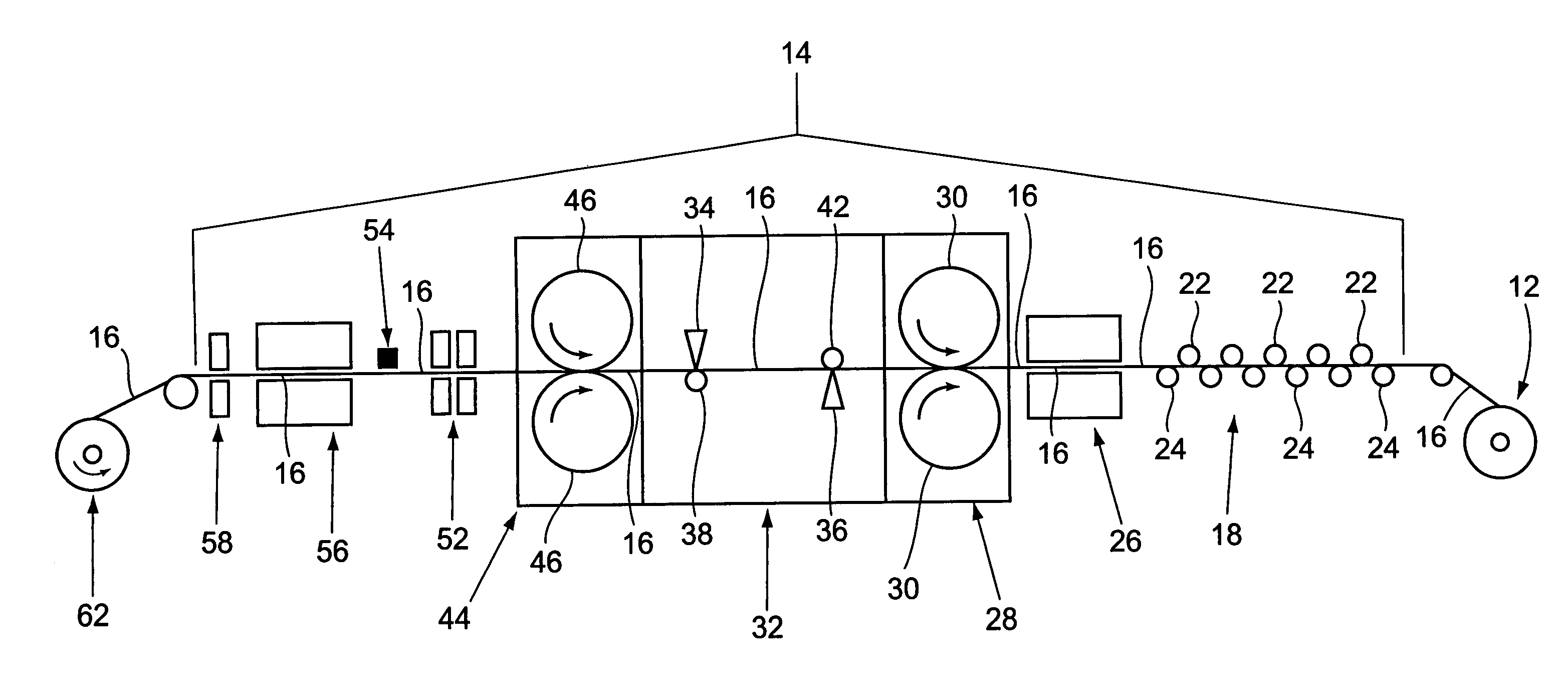

Rolling apparatus and rolling method

InactiveUS7140218B2High dimensional accuracyReduce distortionV-beltsTemperature control deviceEngineeringMechanical engineering

A rolling apparatus includes a pair of small rolling roller and a large rolling roller which hold a ring with the ring being sandwiched therebetween, and which roll the ring, and a tension roller; a temperature sensor which measures a temperature of the ring before rolling; a storing portion which stores, in advance, a relation between the temperature of the ring and a temperature correction coefficient for correcting a condition for rolling; and a controller which changes the condition for rolling based on the measured temperature of the ring and the stored relation so as to perform rolling processing.

Owner:TOYOTA JIDOSHA KK

Method and equipment for continuous production of rolled metal plate from molten metal

InactiveCN1575212AMetal rolling stand detailsGuiding/positioning/aligning arrangementsMetal stripsStrip casting

The invention relates to a method and to a device for producing a rolled metal strip from a molten metal by producing a cast metal strip in a strip casting device (5) and then rolling the undivided metal strip in a roll stand (18) to the final thickness of the strip. For controlling the course of the strip, strip guiding devices (19) are provided, especially upstream of the roll stand. In order to guarantee, with little components required, a stable insertion of the metal strip into the roll stand at the input side of the roll stand or at the site of rolling in accordance with the strip dimensions, the strip guidance interferes or is carried out at a distance of 1.0 to 10.0 times the strip width, preferably at a distance of 1.5 to 5.0 times the strip width, upstream of the roll stand.

Owner:VOEST ALPINE AG

Rolling mill for copper wire

InactiveCN1974033AAutomatically adjusts the rolling widthRoll force/gap control deviceMetal rolling stand detailsCopper wireRolling mill

Disclosed is a rolling mill for copper wire. The rolling width of the mill roller can be automatically and accurately regulated by using the signal from the thickness measurement sensor, so that a copper wire with precise size can be obtained all the time. In addition, the copper wire can be kept tension by means of a plurality of tension regulation device, and then can be winded equably by the precise measure of the thickness of the copper wire.

Owner:WORLDBC

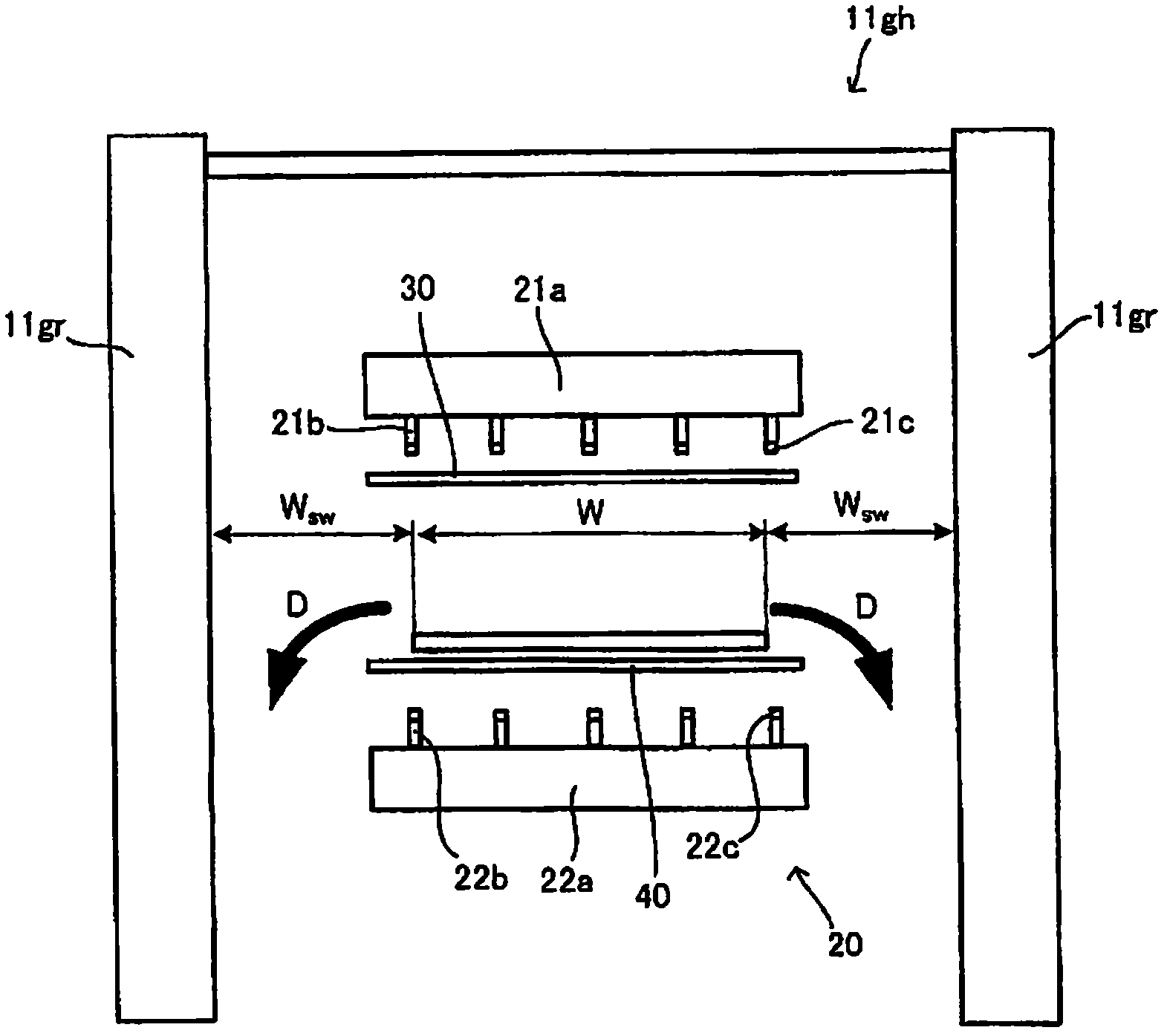

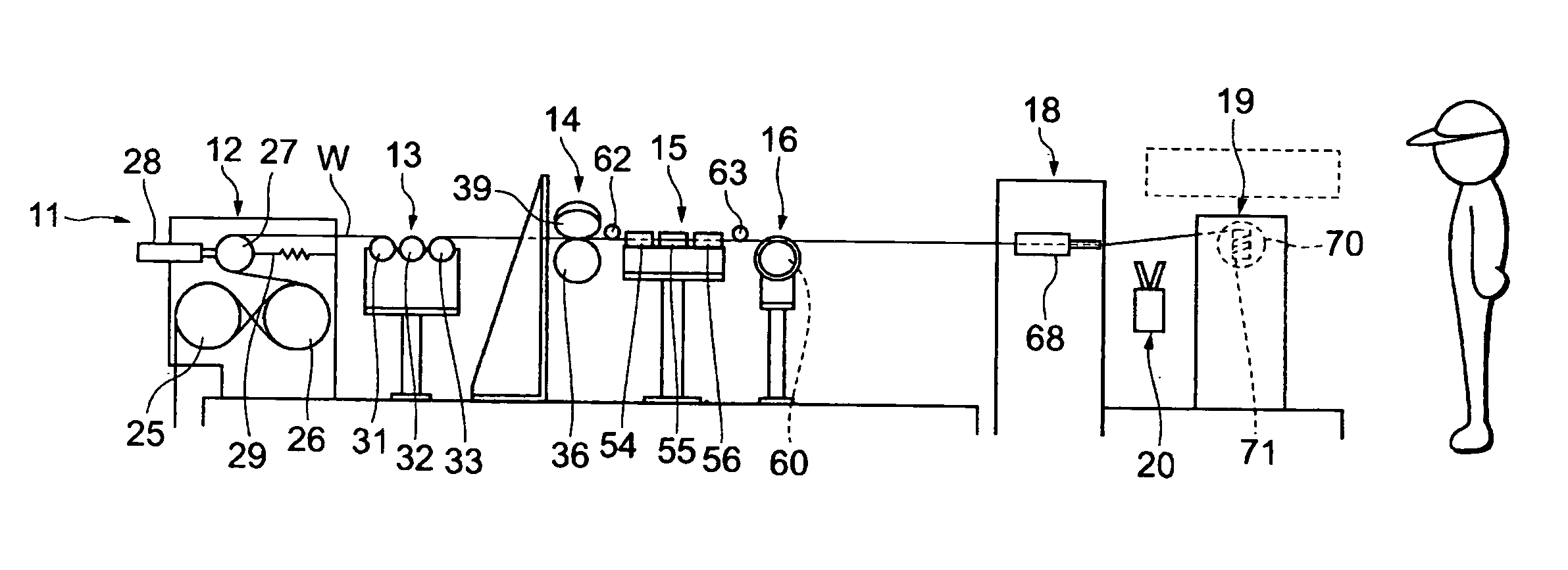

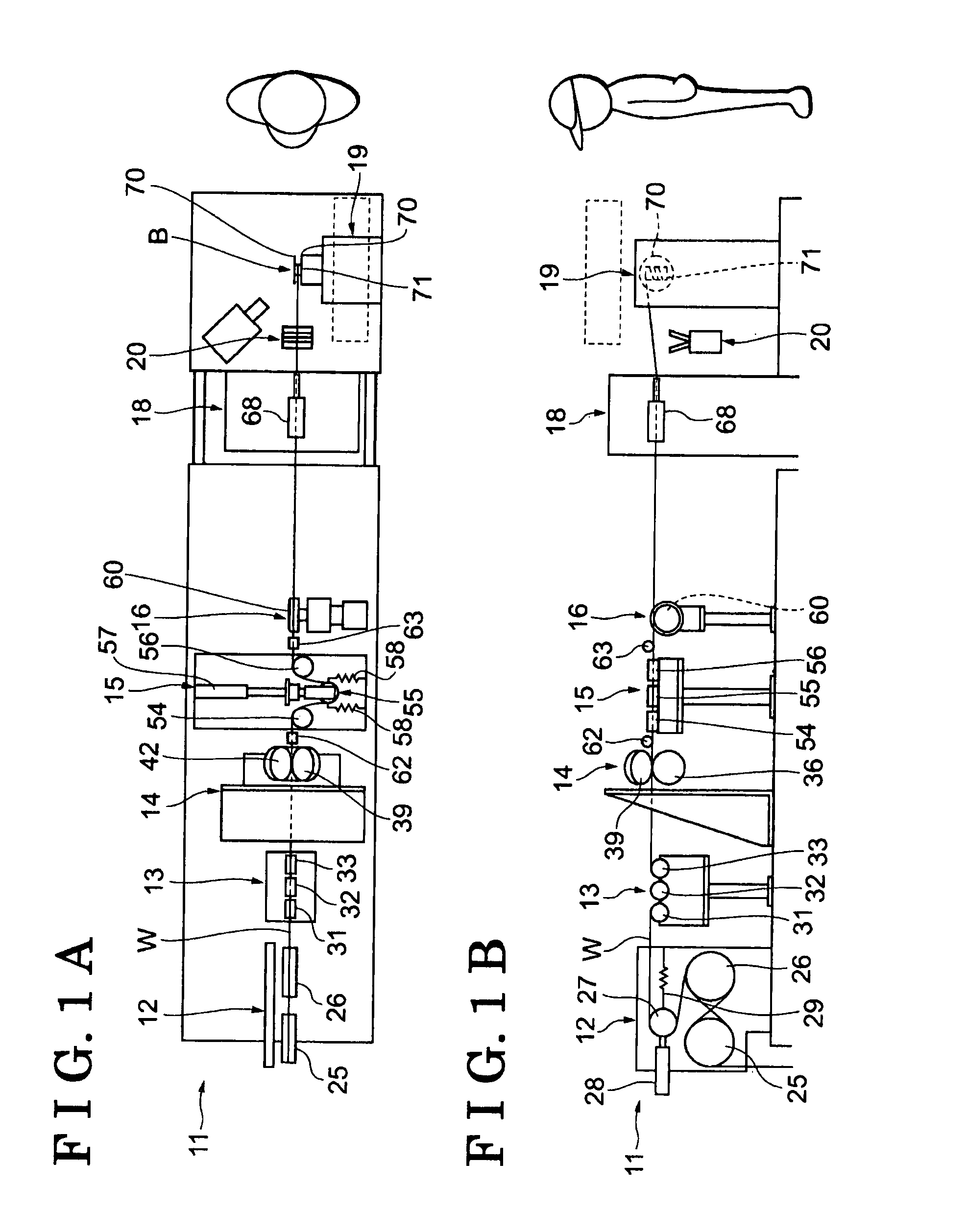

Manufacturing apparatus for hot-rolled steel plate and manufacturing method for steel plate

ActiveCN102421545AImprove mechanical propertiesGood drainageGuiding/positioning/aligning arrangementsTensioning/braking arrangementsSurface coolingProduction line

Provided are a manufacturing apparatus with high drainability for a hot-rolled steel plate and a manufacturing method for a steel plate, in a hot-rolled steel plate production line. In a manufacturing apparatus for a hot-rolled steel plate, a last stand thereof has a pair of raised portions in a housing, and a cooling device has a plurality of upper surface cooling nozzle arrays which are arranged in a transfer direction and which inject a cooling water onto an upper surface of a steel plate, a plurality of lower surface cooling nozzle arrays which are arranged along the transfer direction and which inject the cooling water onto the lower surface of the steel plate, and an upper surface guide on the upper surface side of the steel plate. The end of the cooling device on the last stand side is arranged between the raised portions. When the uniform cooling width is (W), the average gap distance between the ends of the uniform cooling width and the raised portions is (Wsw), the gravitational acceleration is (g), the average water rate density at the uniform cooling width is (Qq), and the value determined from (Wsw) and the average distance (h) between the upper surface guide and the upper surface of the steel plate is (C), a predetermined relationship is satisfied.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com