Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82 results about "Force constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Force Constant. Force constants are the second derivatives of energy with respect to geometric displacements, ∂2E/∂2q, where differential q is the displacement of a vibrating atom with respect to the rest of the system (e.g., the other atom), for a diatomic molecule.

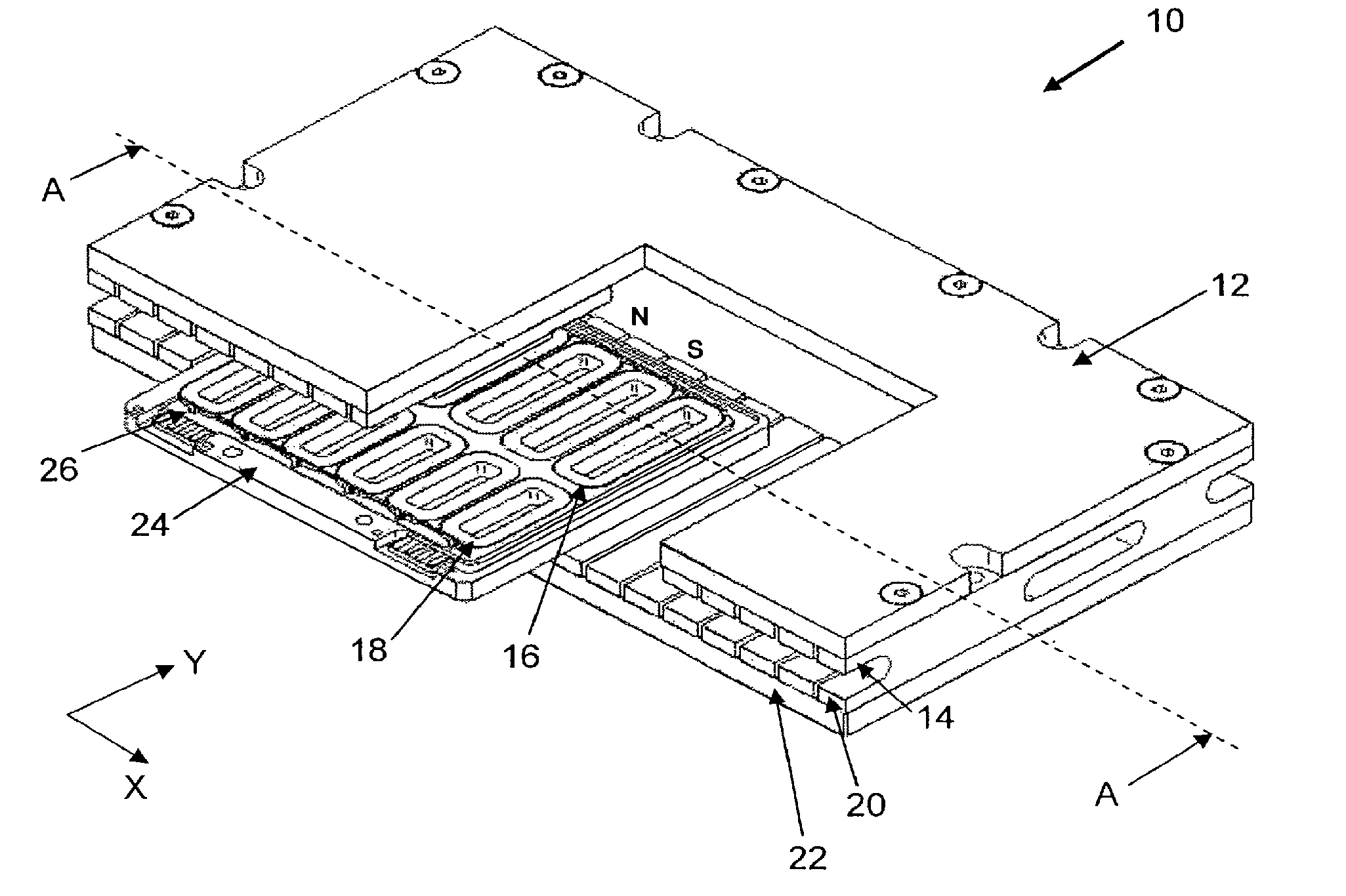

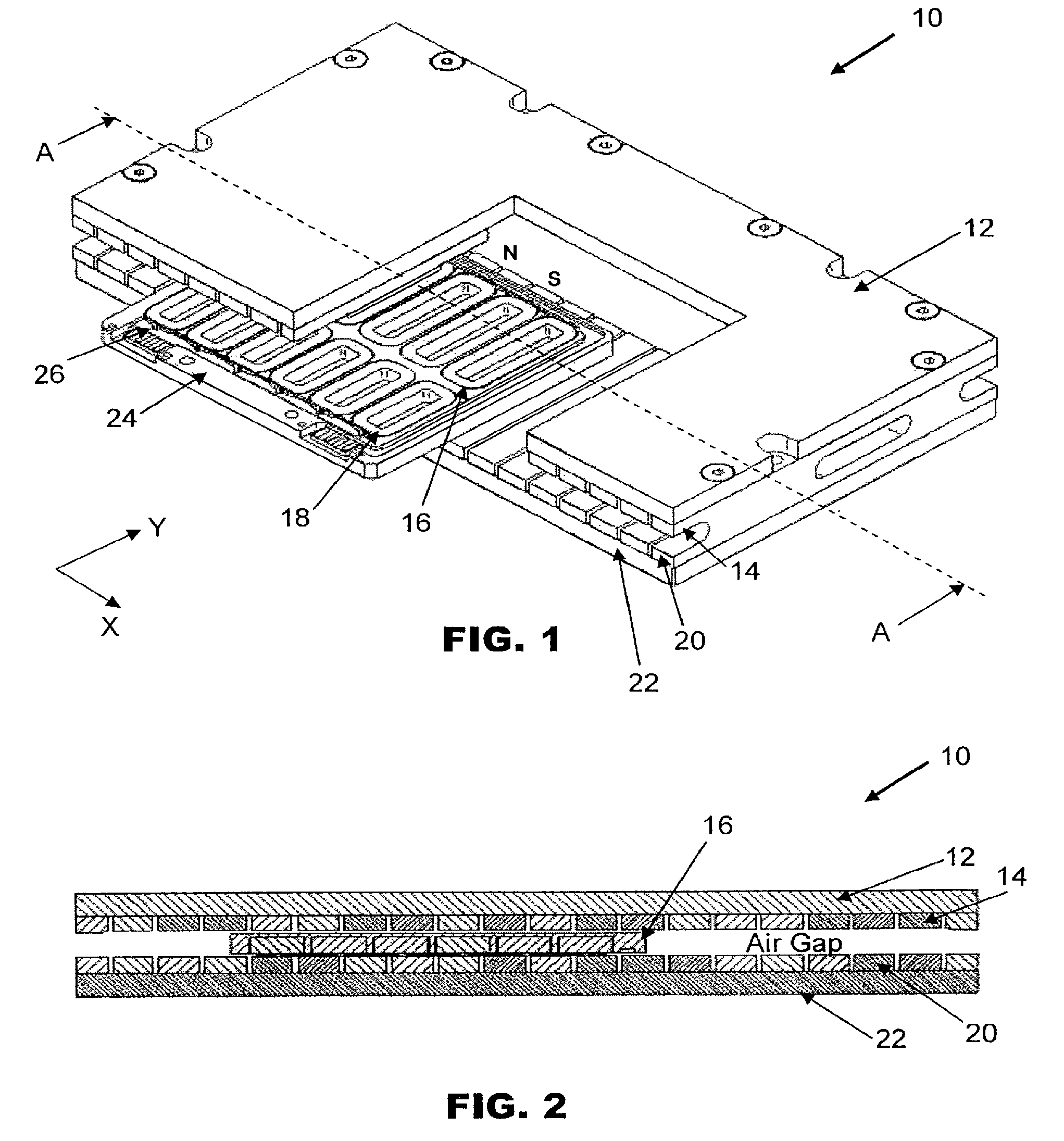

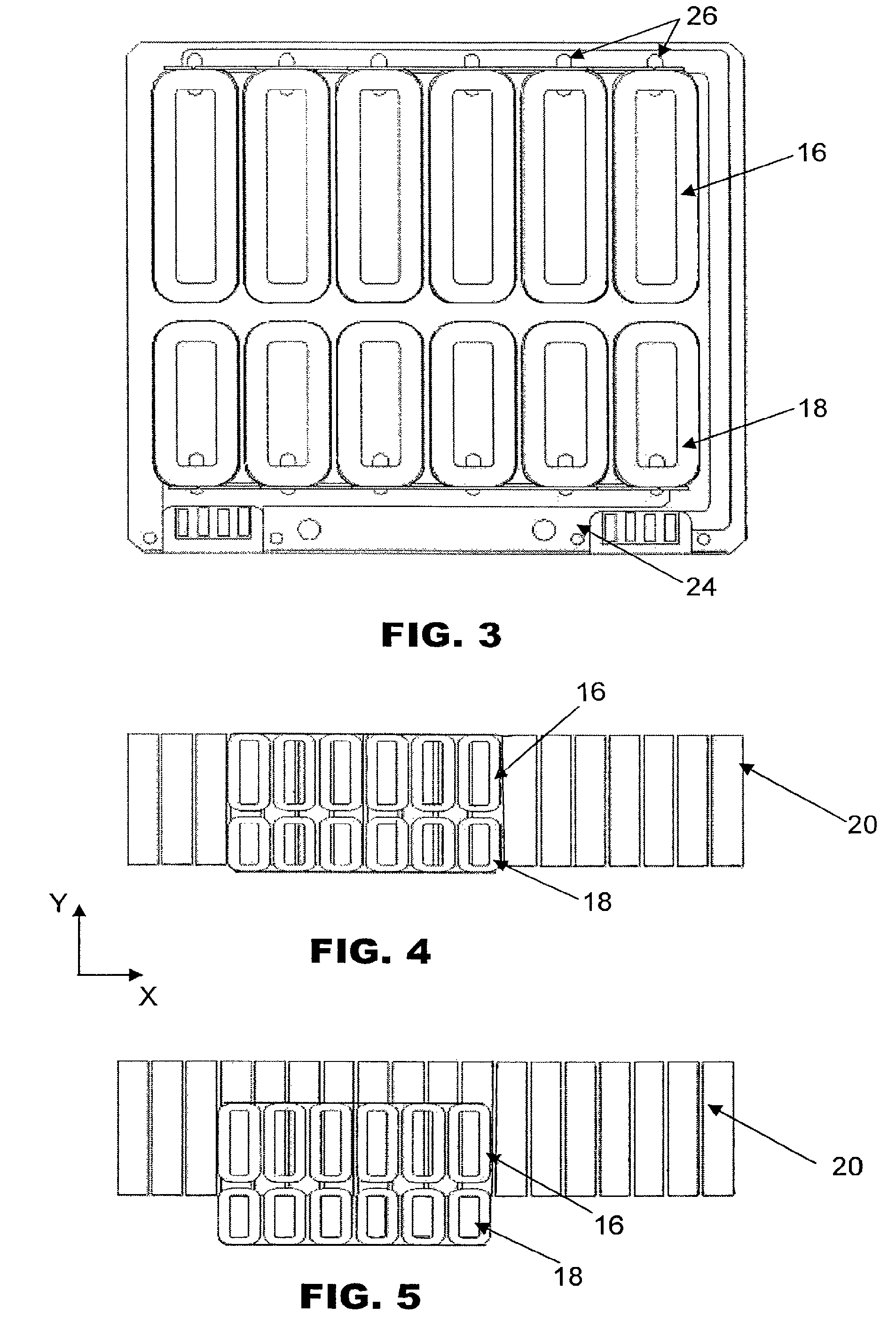

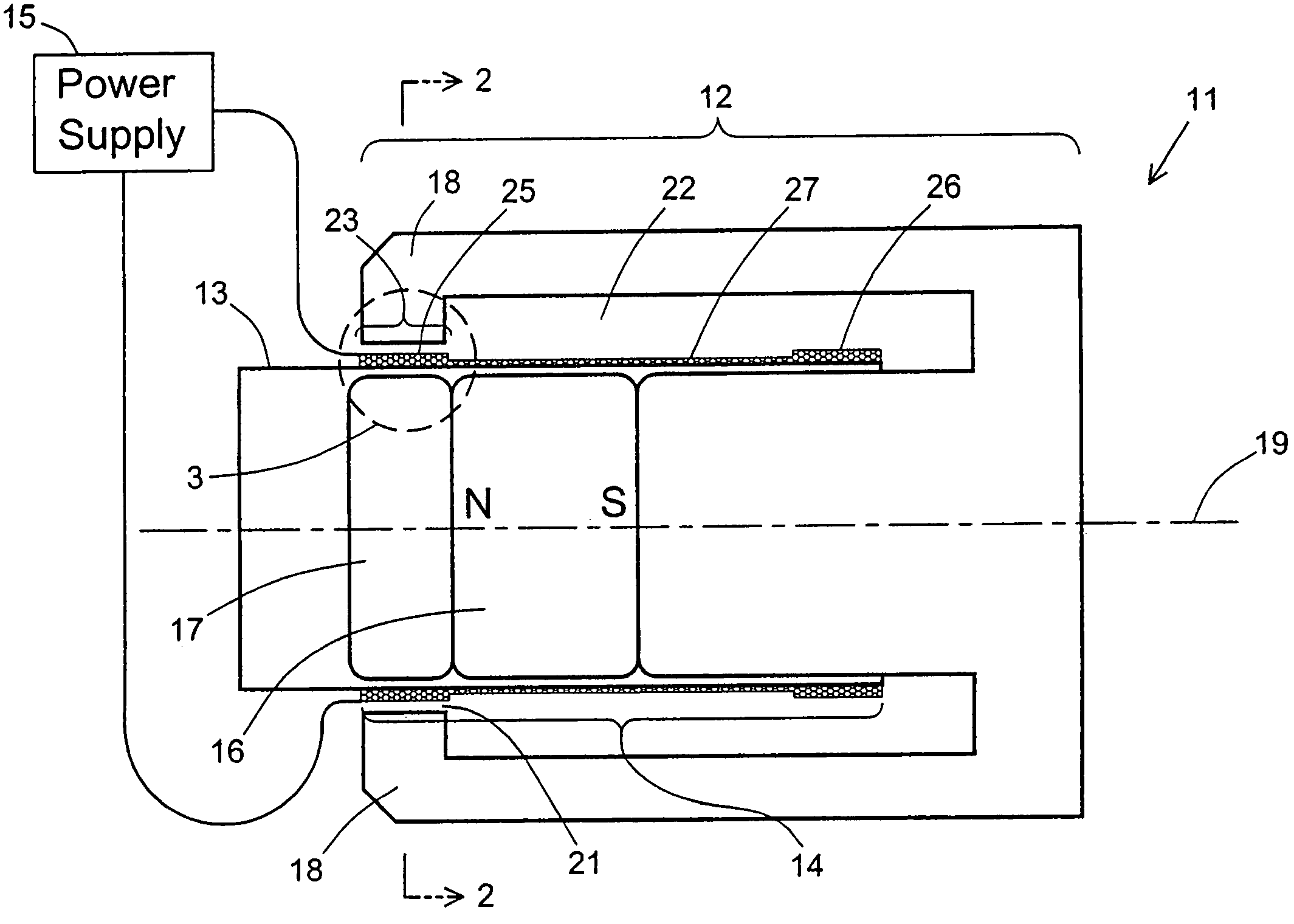

Dual-axis planar motor providing force constant and thermal stability

ActiveUS7808133B1Reducing thermal driftMinimize changesMagnetic circuitPropulsion systemsForce constantPlanar motor

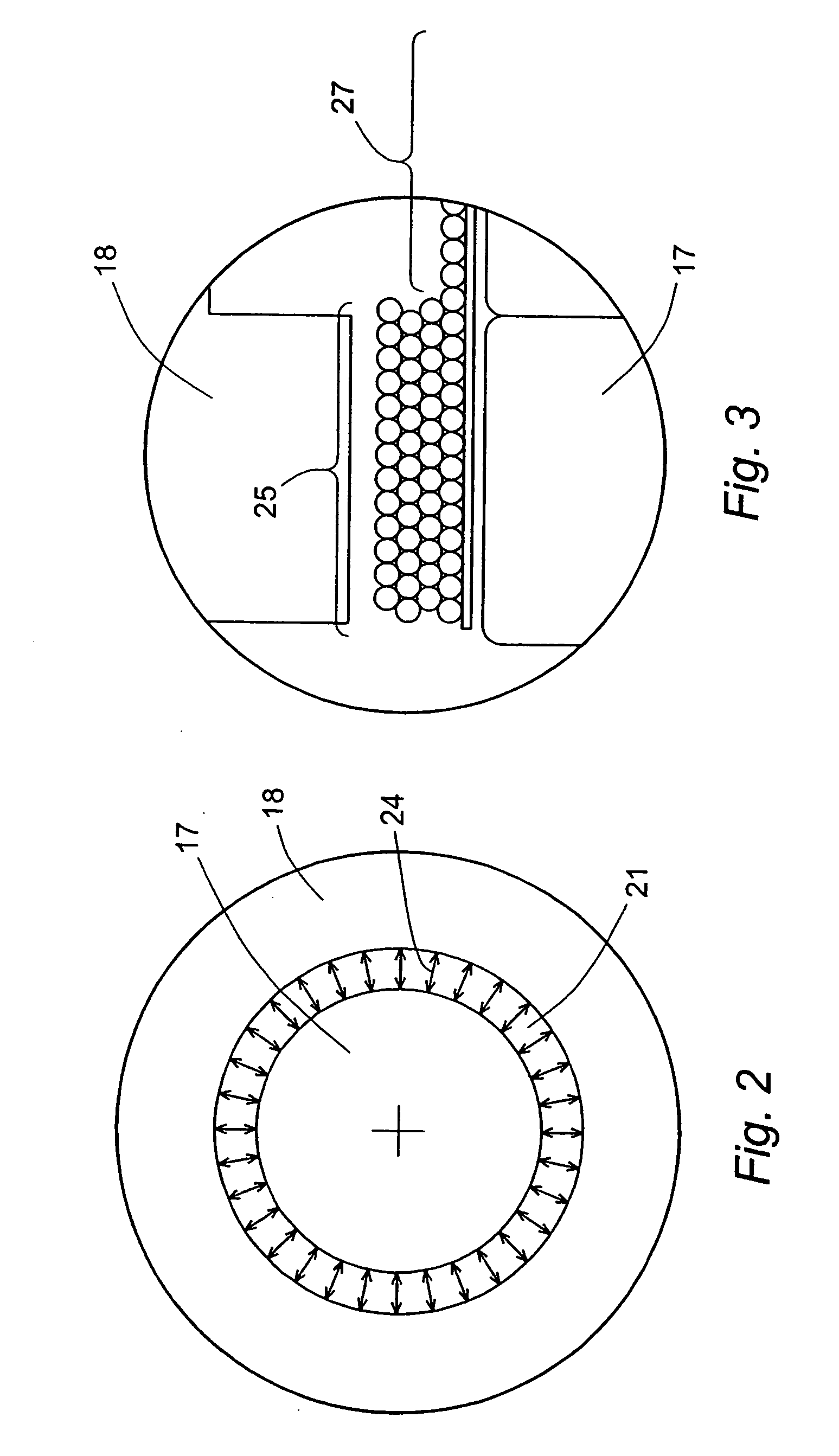

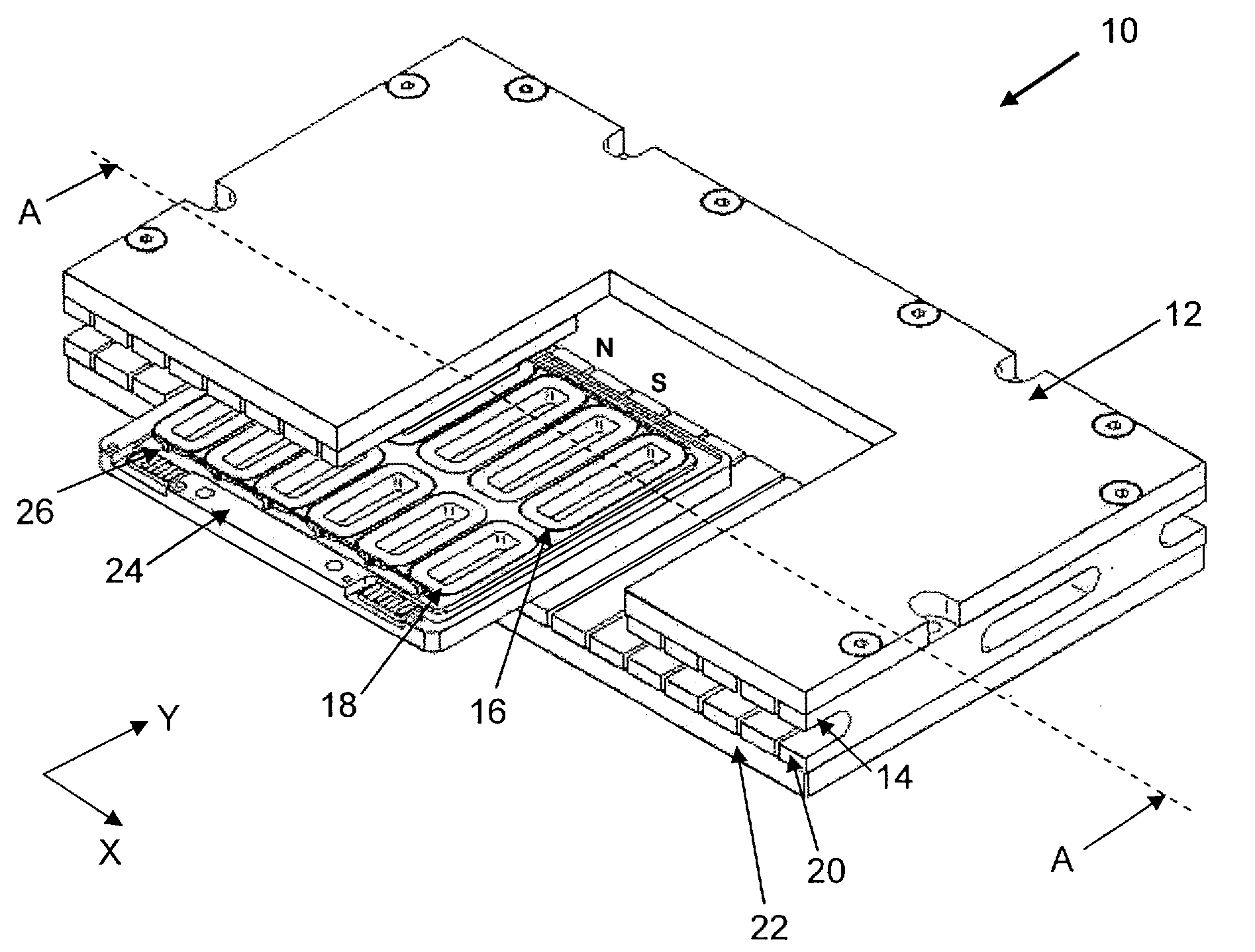

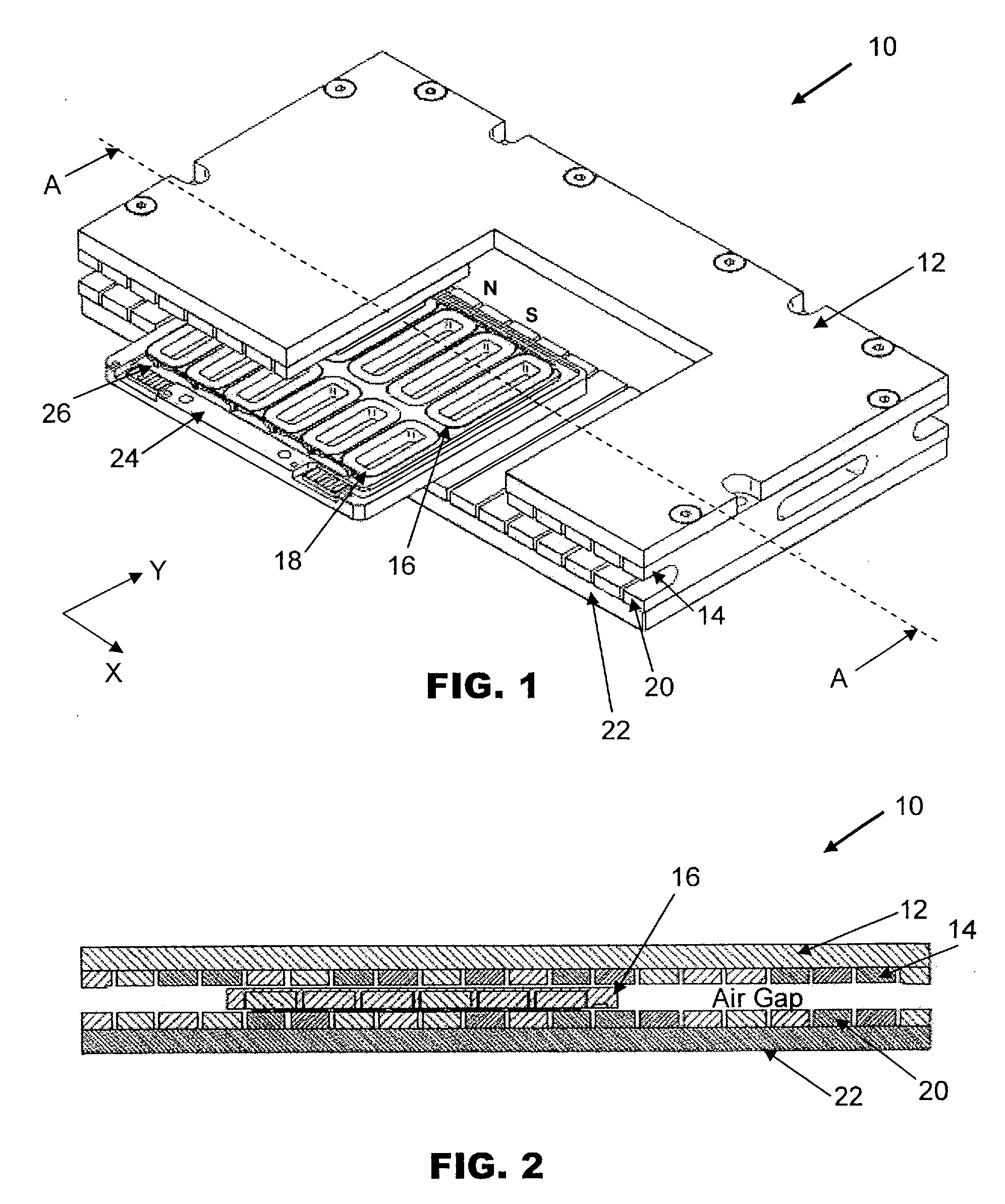

A motor is provided comprising a magnet assembly having two rows of magnets arranged along a first axis, which are separated by a gap for generating magnetic flux lines between the rows of magnets. The motor further comprises a coil bracket which is located within the gap between the two rows of magnets. The coil bracket includes a first set of coils arranged along the first axis that are operative to drive movement of the coil bracket relative to the magnet assembly along the first axis. A second set of coils arranged along the first axis are operative to drive movement of the coil bracket relative to the magnet assembly along a second axis which is orthogonal to the first axis between a first end position and a second end position along the second axis. The first set of coils is fully located within the flux lines generated by the magnet assembly at both the first and second end positions of the coil bracket and the second set of coils is located at least partially outside the flux lines generated by the magnet assembly at the second end position of the coil bracket.

Owner:ASM ASSEMBLY AUTOMATION LTD

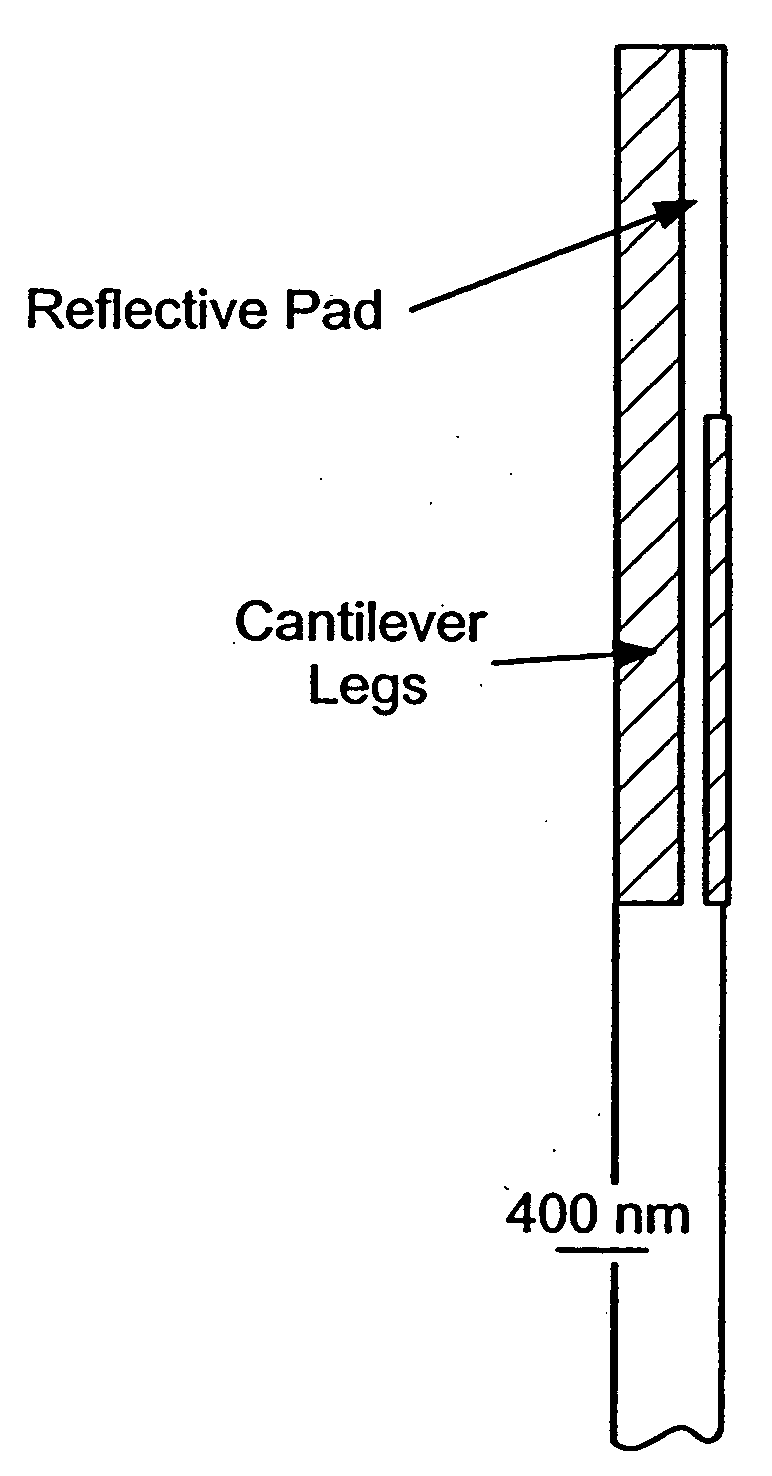

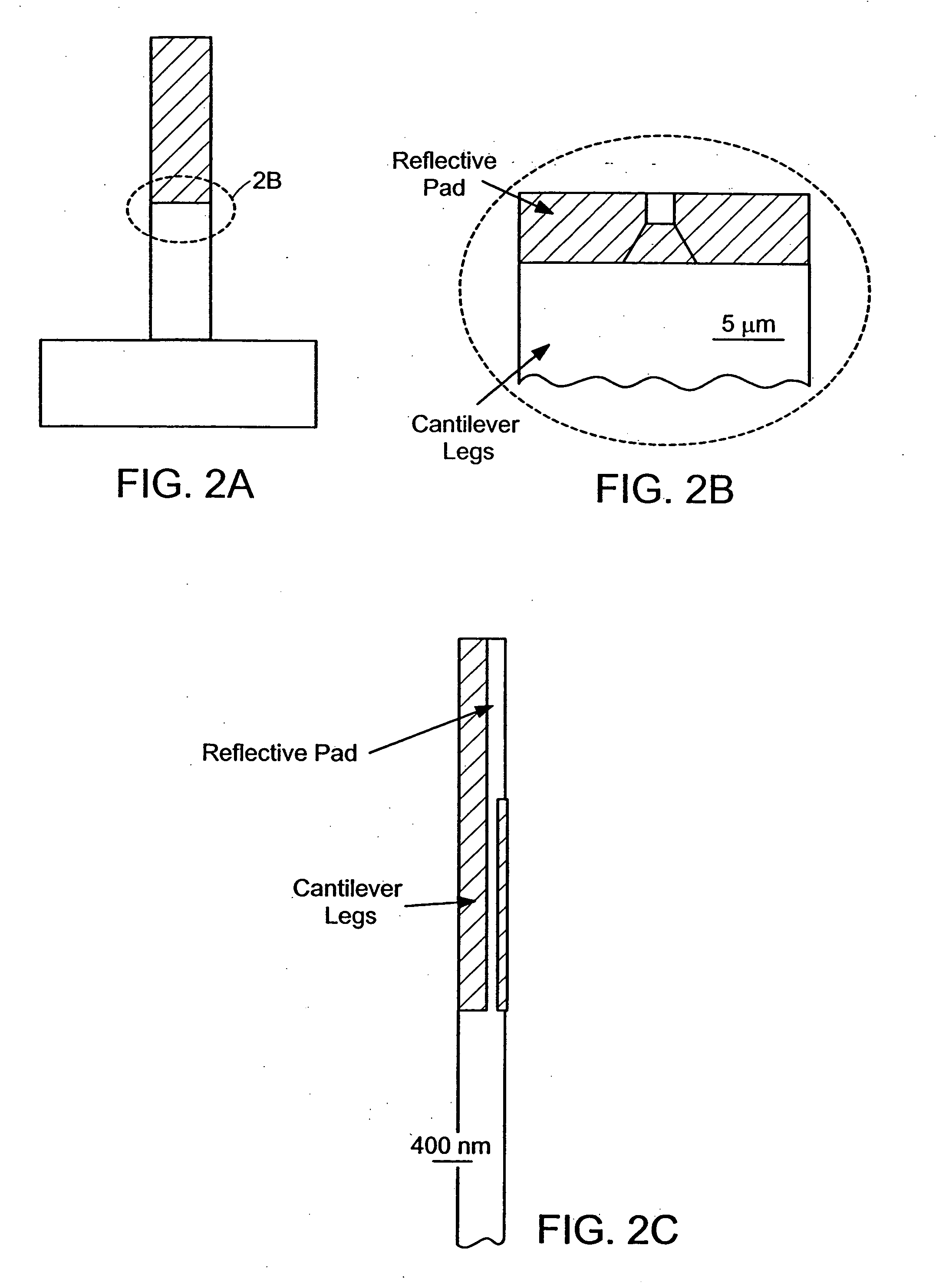

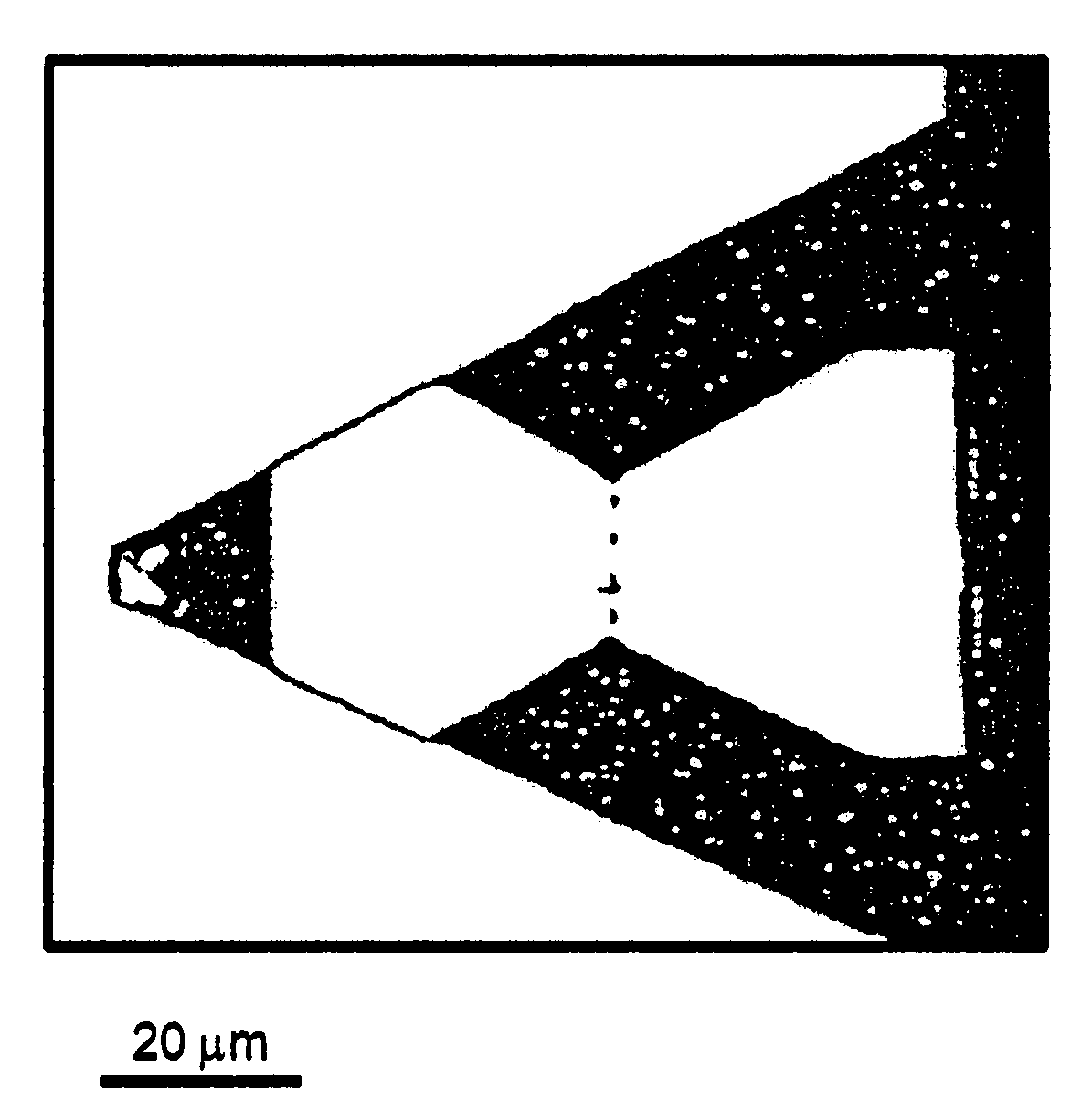

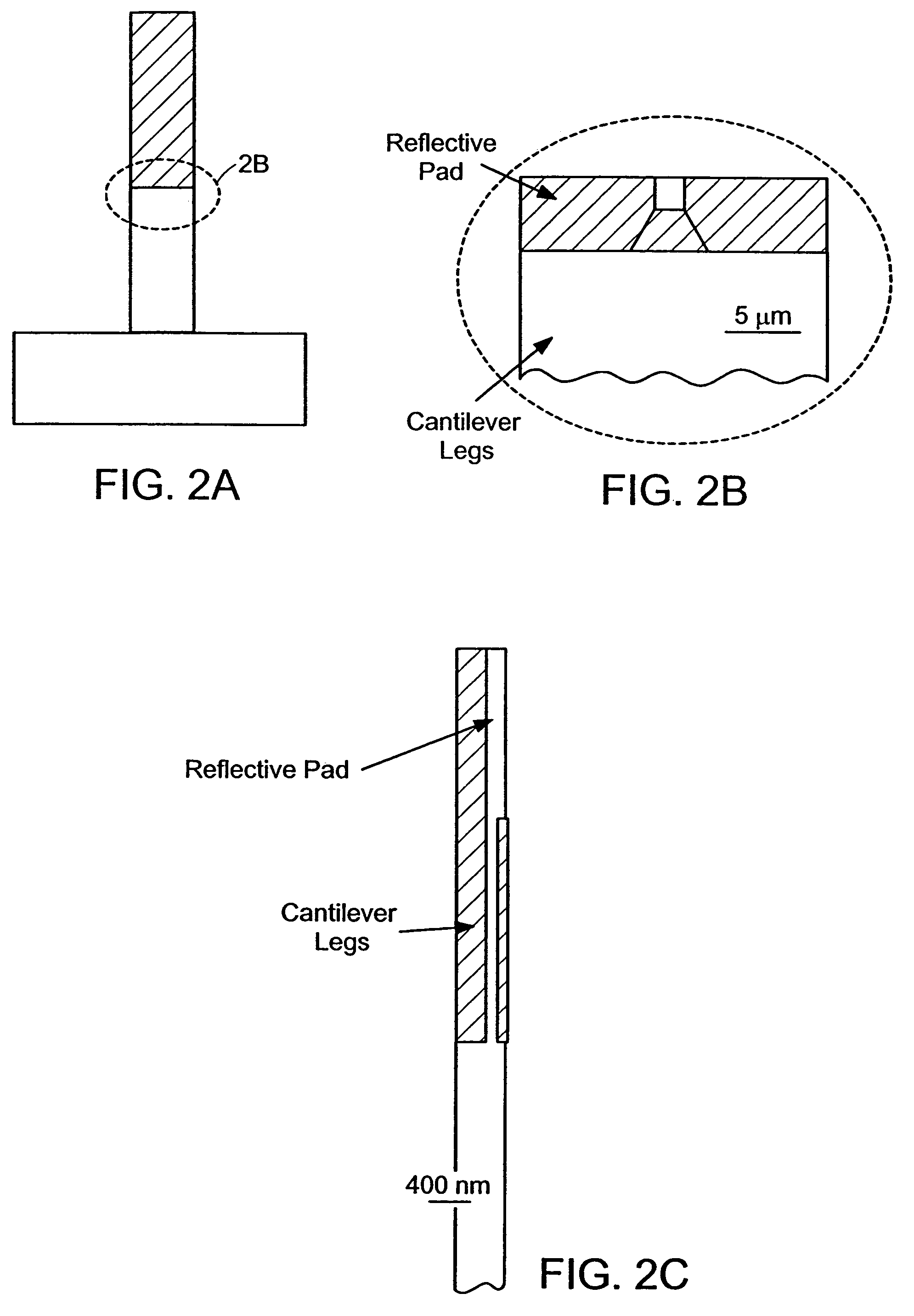

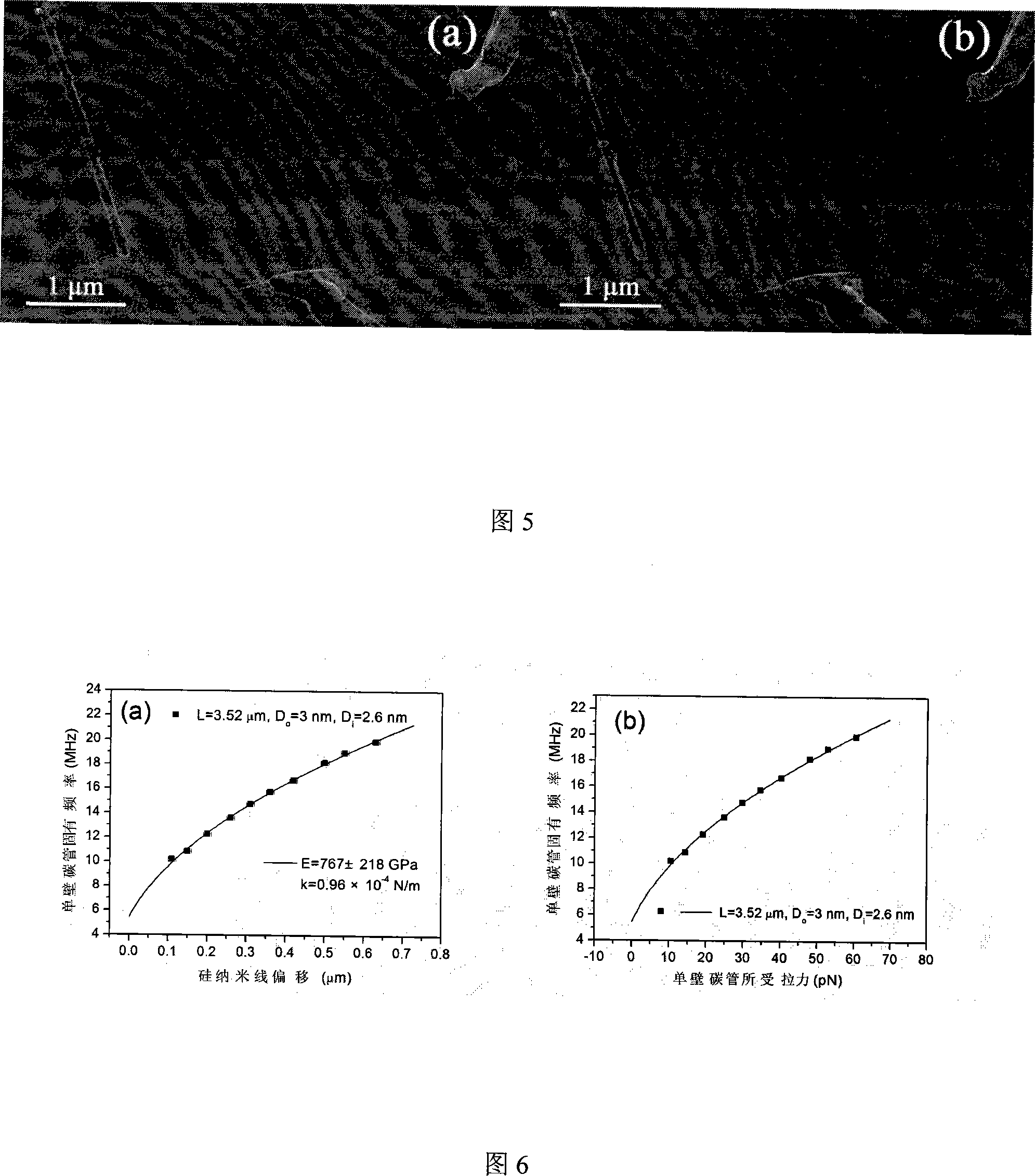

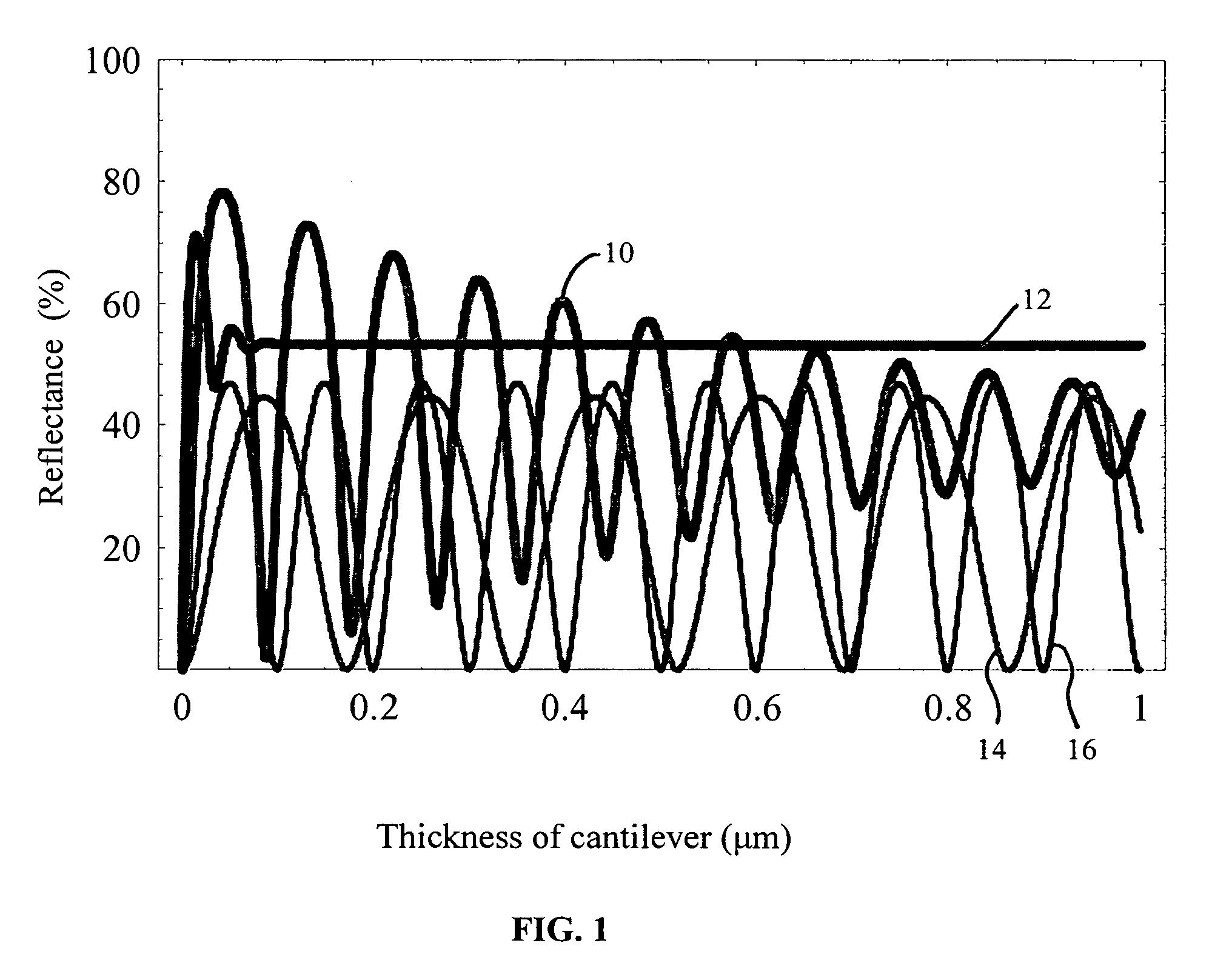

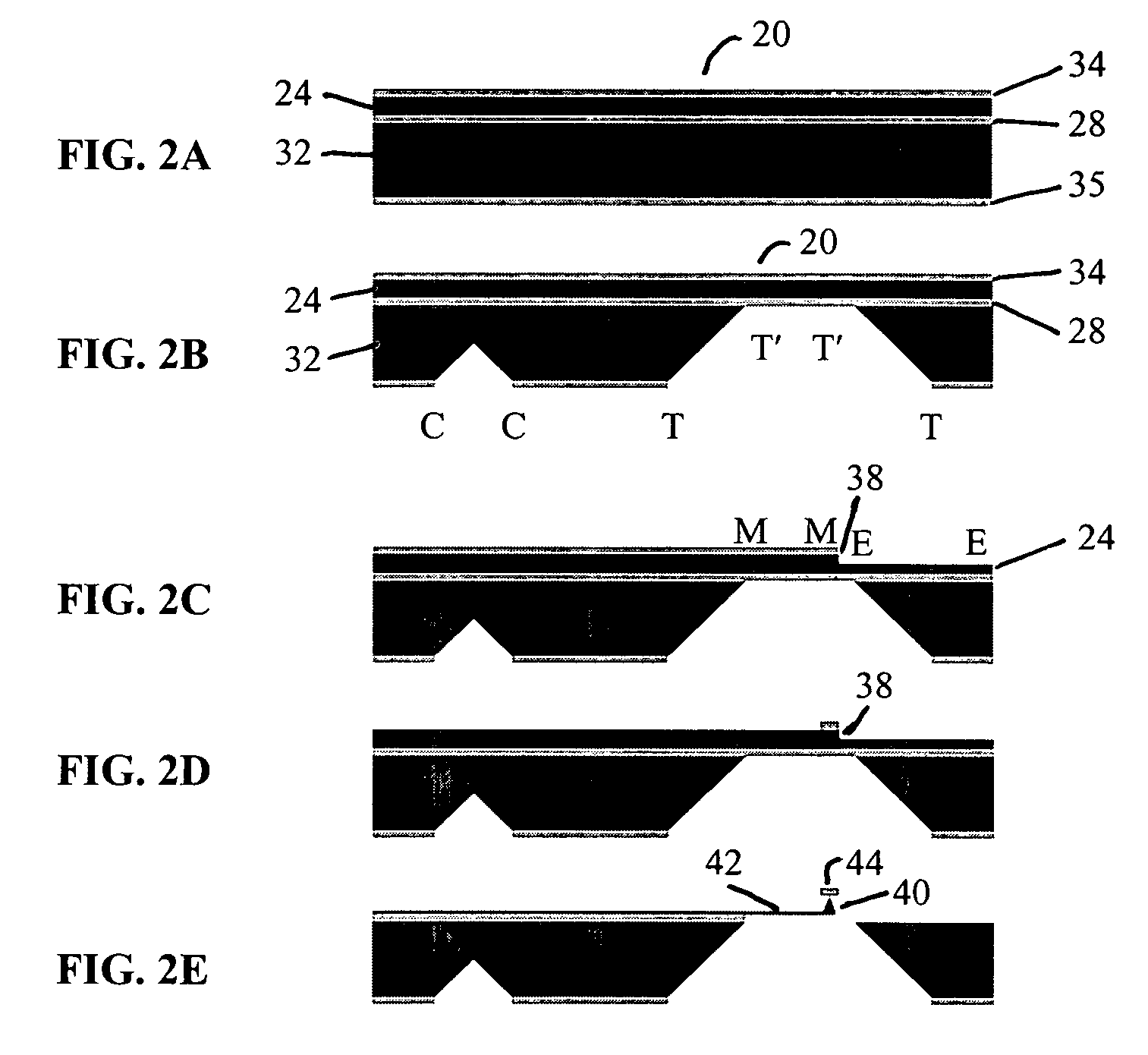

Afm cantilevers and methods for making and using same

InactiveUS20050011256A1Improve performanceNanostructure manufactureSurface/boundary effectTemporal resolutionForce constant

The invention provides high performance cantilevers with optimal combinations of high resonant frequency and low force constant. In one aspect, AFM cantilevers with spring constants in the range 1-10−6 N / m with (fundamental) resonant frequencies in aqueous solutions of 0.1-100 MHz are provided. A high performance cantilever may be made by focused ion beam milling or electron deposition. The high performance cantilevers allow faster scanning, increase the temporal resolution of force measurement, improve measurement sensitivity by reducing cantilever noise, and improve sensitivity by reducing cantilever spring constant.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

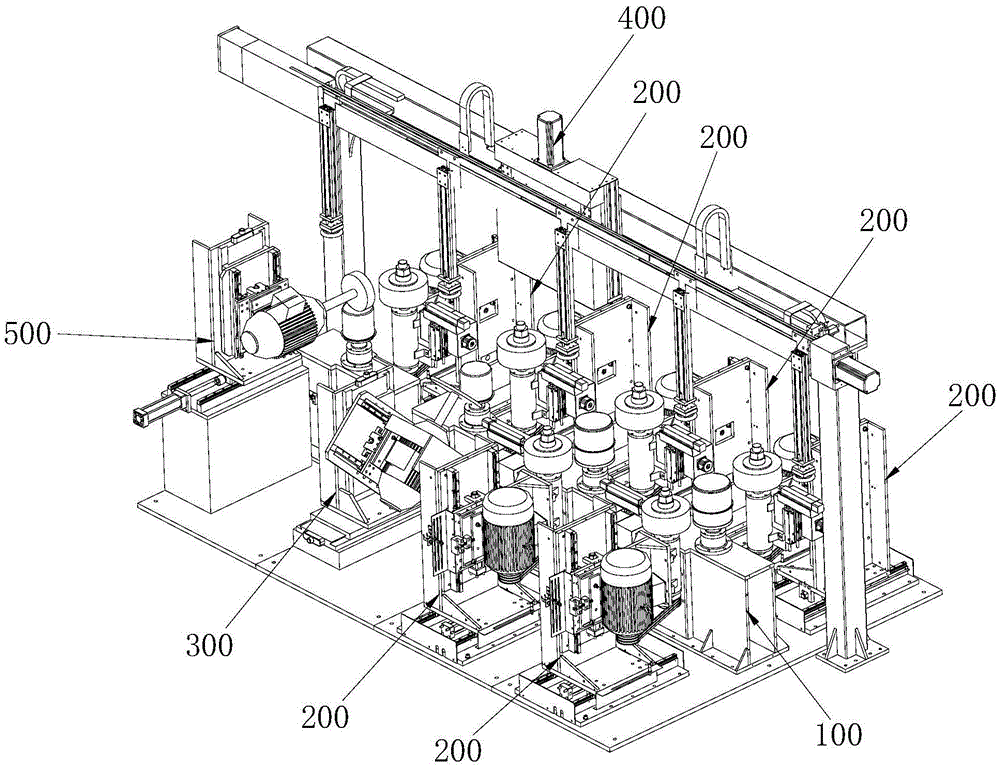

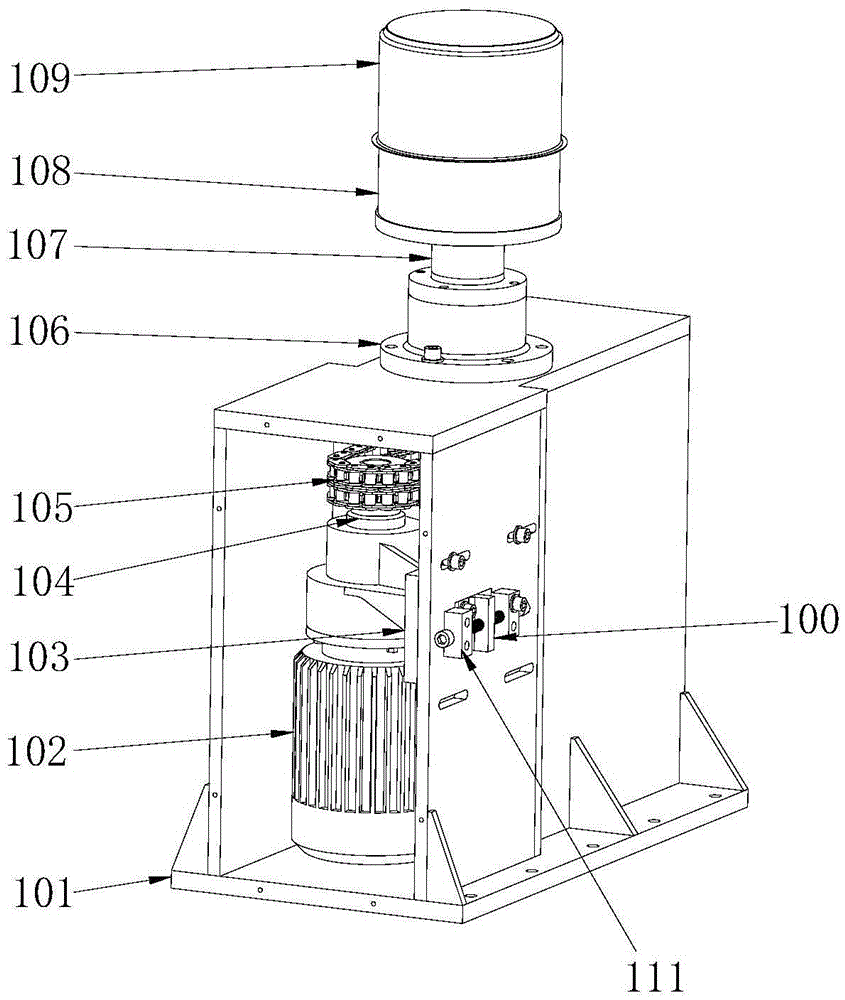

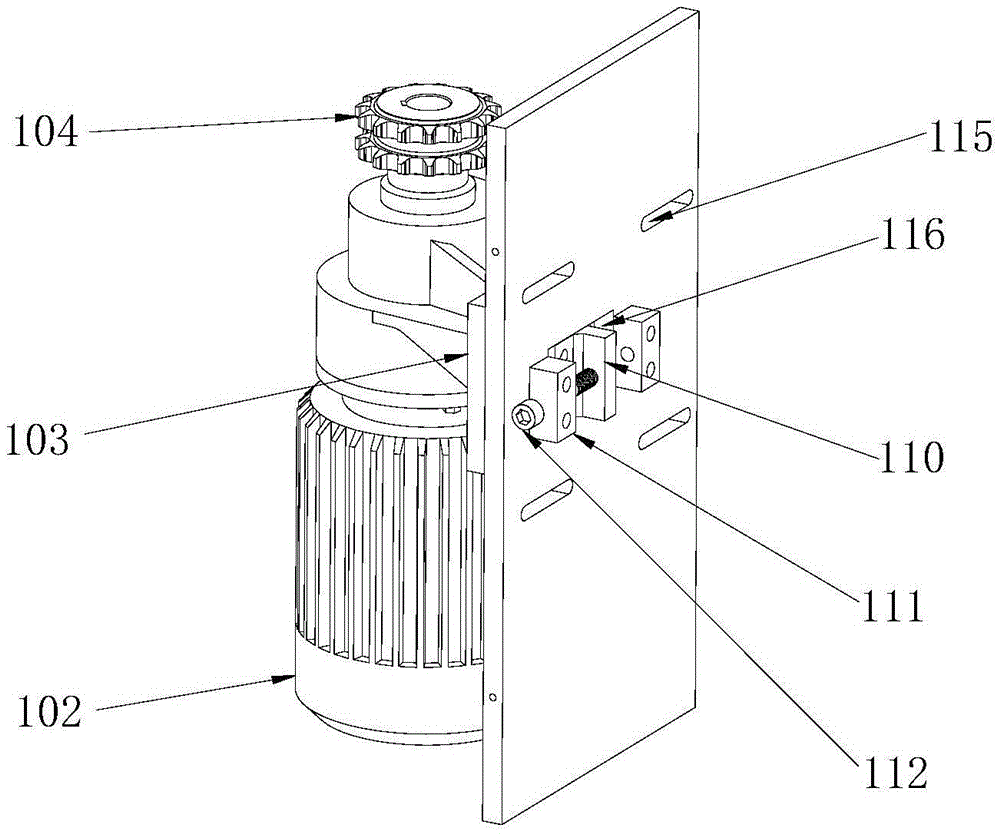

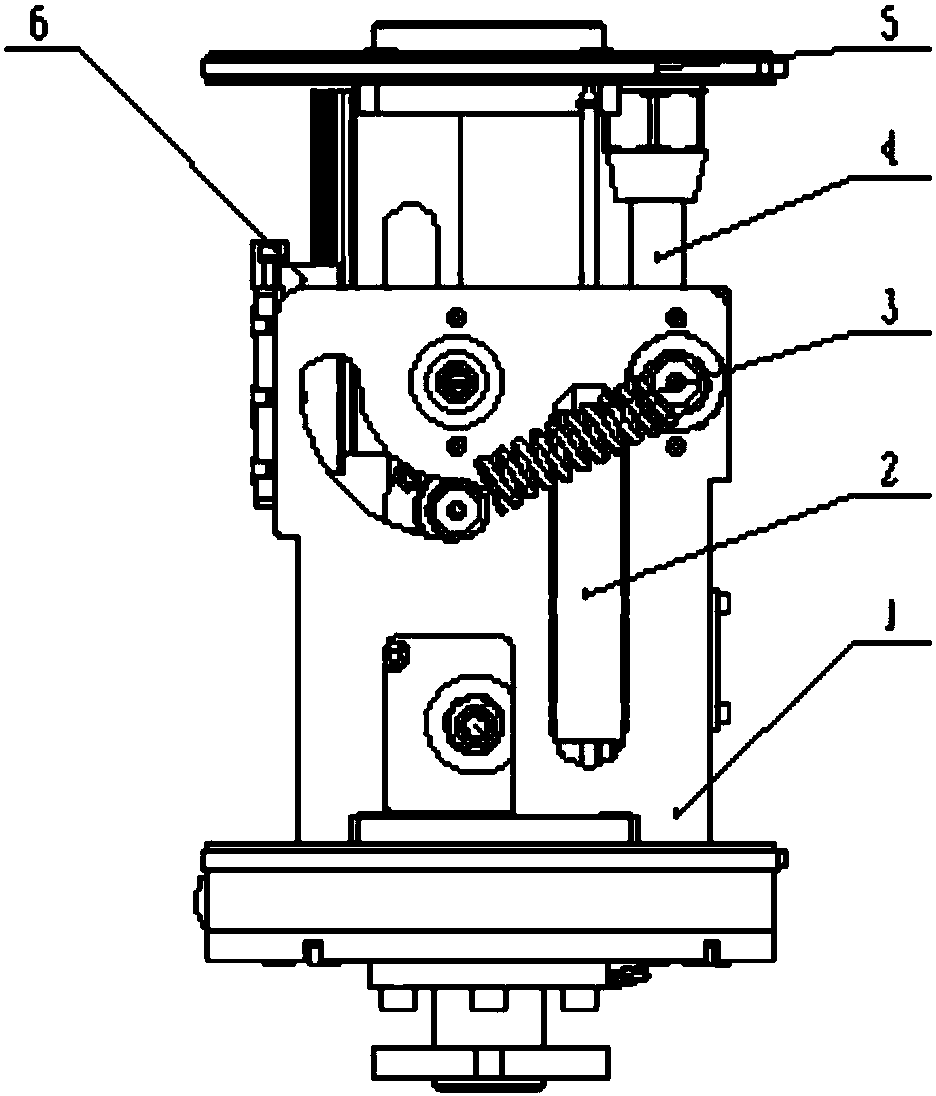

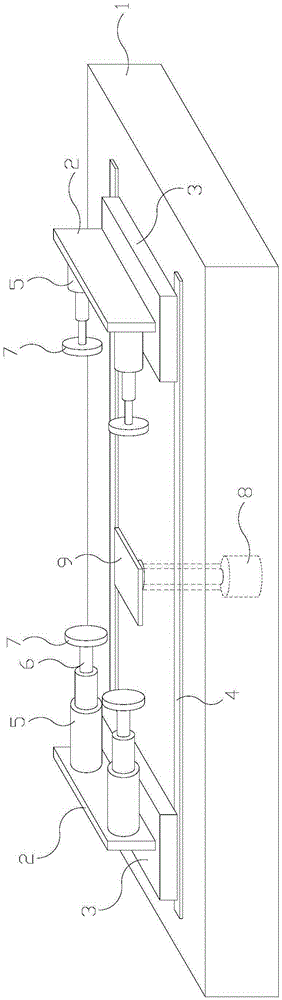

Multi-station linear polisher system

ActiveCN105598804AAutomatically compensates for wearAutomatic loss compensationGrinding carriagesPolishing machinesWaxForce constant

The invention discloses a multi-station linear polisher system which comprises a die head rotating mechanism, a polisher main body mechanism, a linear multi-station polisher system, an automatic waxing mechanism and a conveying manipulator mechanism, wherein the die head rotating mechanism comprises a rotating die head and is used for adsorbing a to-be-processed stainless steel kettle onto the rotating die head; the polisher main body mechanism is provided with a plurality of polisher sets; the linear multi-station polisher system is formed by freely combining the plurality of polisher sets; the automatic waxing mechanism is used for automatically complementing the abrasion of a polishing wheel and solid wax strips during a working process; the conveying manipulator mechanism is positioned above each station and used for taking and putting the stainless steel kettle among different stations. According to the system, three types of polisher sets are freely combined to form modularization of multiple stations, the structure is simple and compact, and the flexibility is quite high; the system is capable of complementing the abrasion of the polishing wheel and the solid wax strips during the working process, keeping polishing force constant and keeping the polishing effect; during a polishing process, manpower is not needed, and the automation degree is high.

Owner:XINXING XIANFENG STAINLESS STEEL PROD MFGR CO LTD

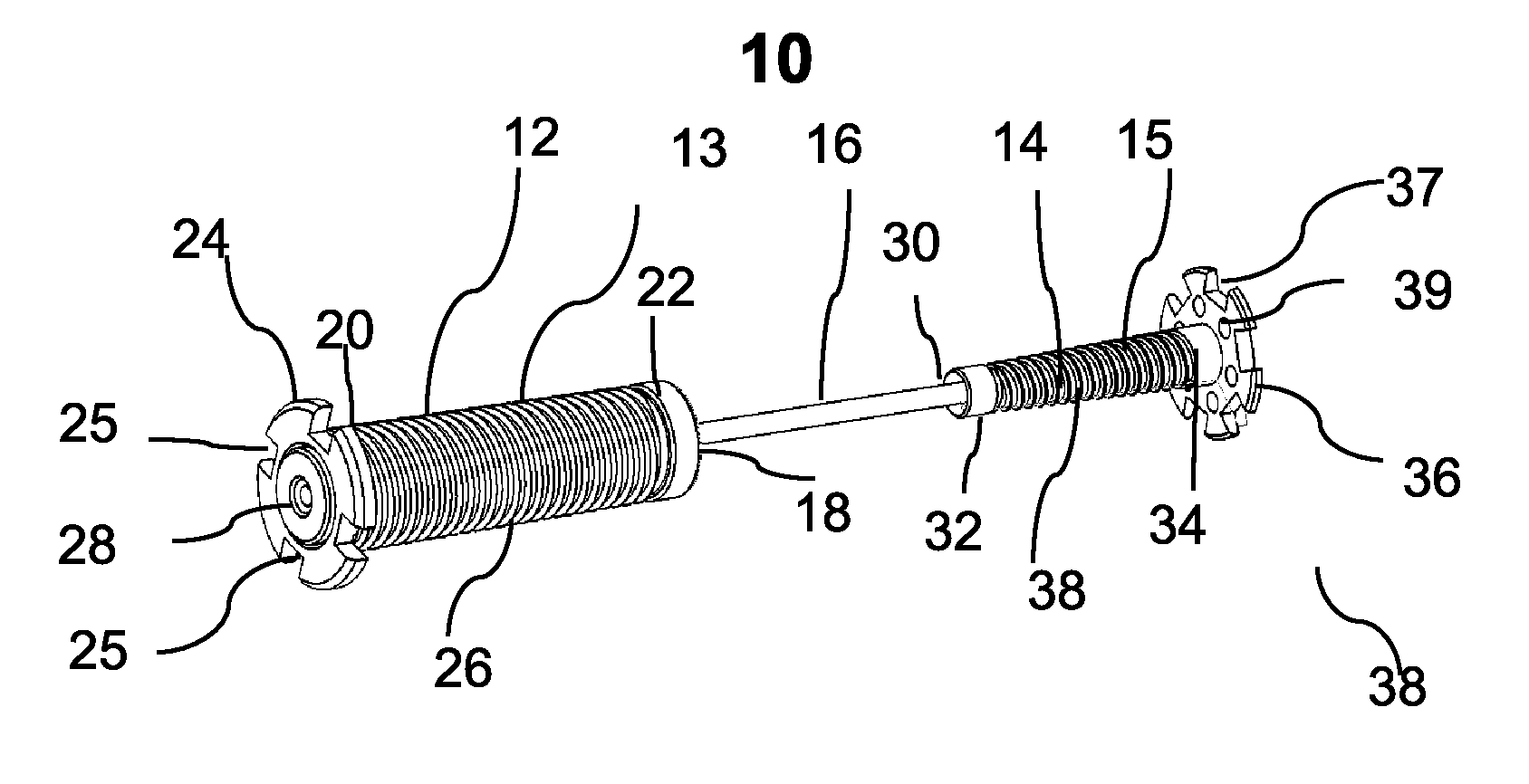

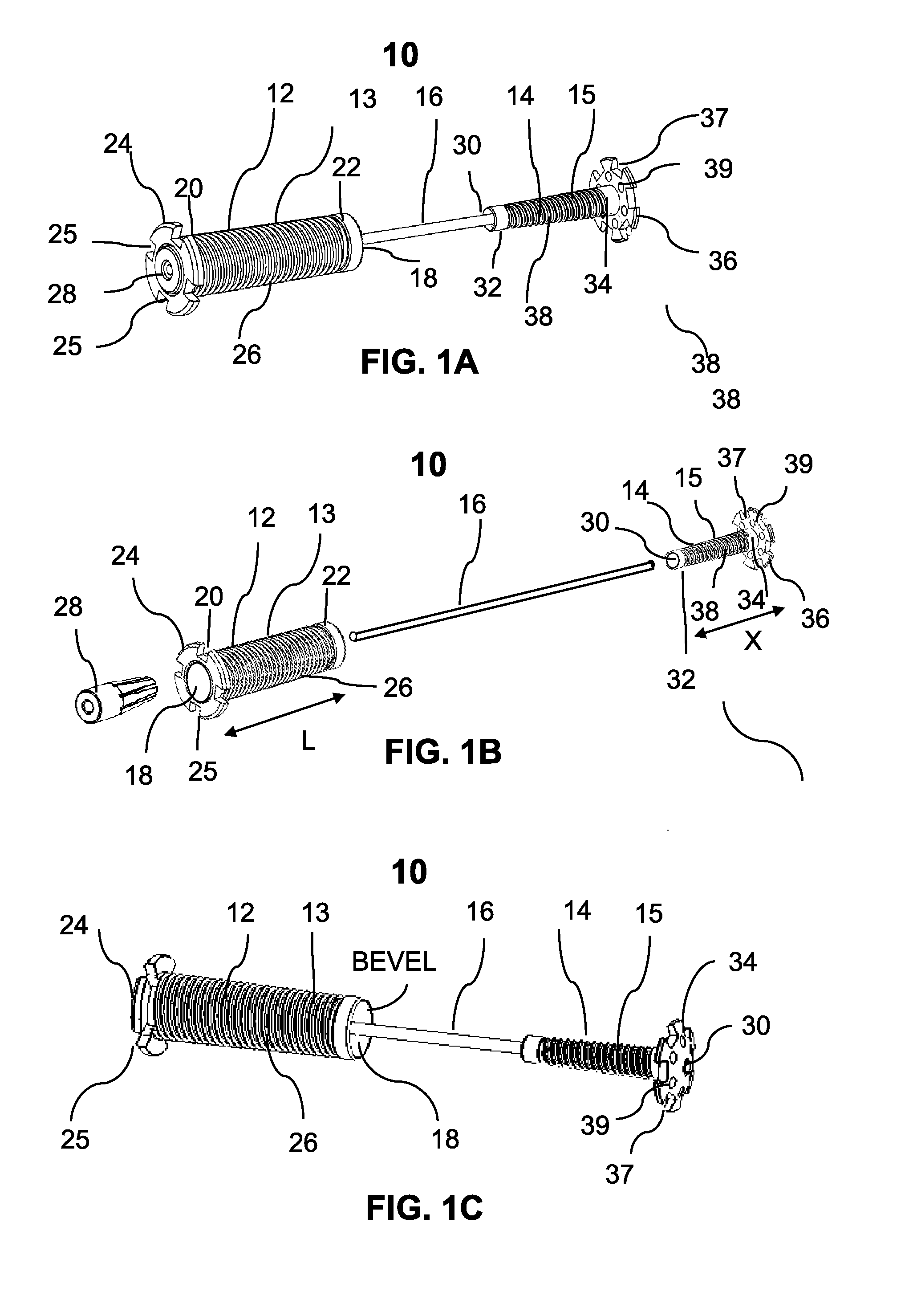

Devices and methods for bone anchoring

InactiveUS20160038186A1Successfully addressSuture equipmentsInternal osteosythesisForce constantBone tissue

A device for fixation of bone tissue and methods of using same are provided. The device includes a first anchor positionable within a first bone region, a second anchor positionable within a second bone region and a wire interconnecting the first and second anchors. The wire is attached to the first anchor via an elastically deformable element having a force constant (K) of 20-80 N / mm along a longitudinal axis of the first anchor.

Owner:CYCLA ORTHOPEDICS

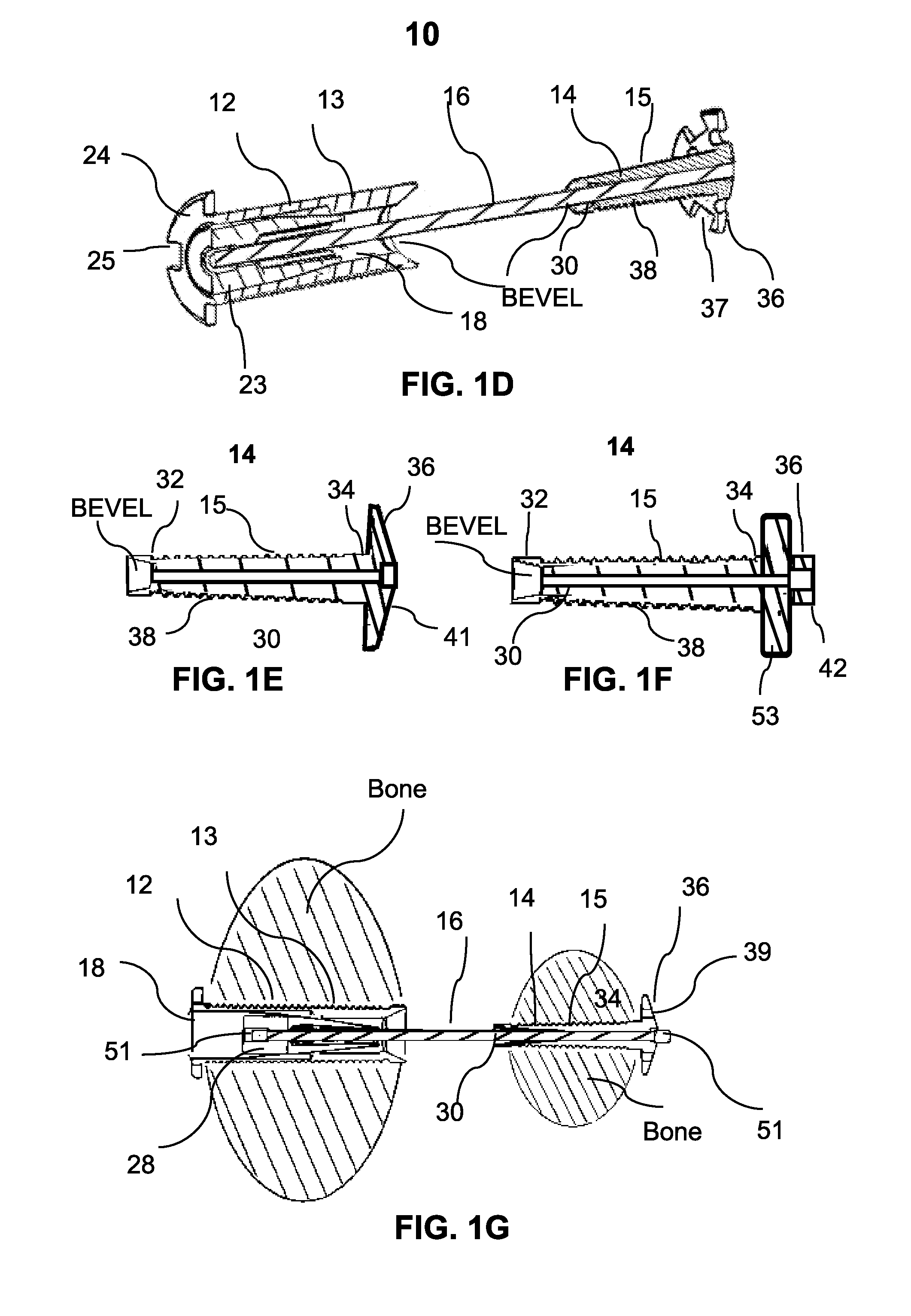

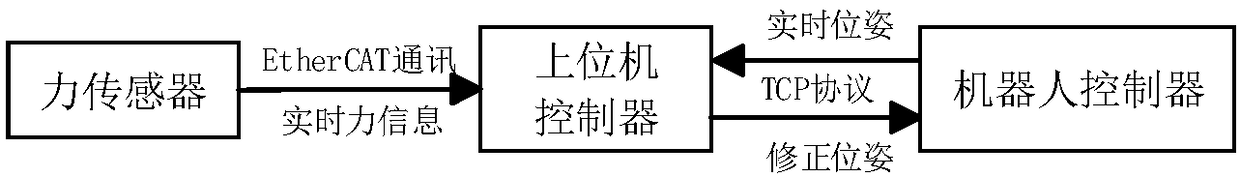

Mechanical arm collision detection and response method based on six-dimensional force sensor

InactiveCN104626171AImprove detection accuracyQuick responseManipulatorCollision detectionForce constant

The invention discloses a mechanical arm collision detection and response method based on a six-dimensional force sensor. The six-dimensional force sensor is arranged between a flange at the tail end of a mechanical arm and a load, and the measurement data of the sensor are continuously acquired according to set sampling frequency; a control system of the mechanical arm obtains the force (see the specification for the symbol) and moment (see the specification for the symbol) on the load of the mechanical arm under external action through gravity compensation of the load; collision detection is conducted according to a preset force constant threshold value Fs and a preset moment constant threshold value Ms when the mechanical arm drives the load to make translation movement or rotation movement, and corresponding motions are controlled according to the relative directions of the preset linear velocity / angular velocity of the mechanical arm and external force / moment. By adopting the six-dimensional force sensor for collision detection, detection precision is high, and respond speed is high; by eliminating the influences of load gravity and load posture, sensitive collision detection can still be conducted on heavy loads; motions making collision worse can be stopped instantly once collision occurs, motions in the opposite directions are allowed, and the method is reasonable and practical.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

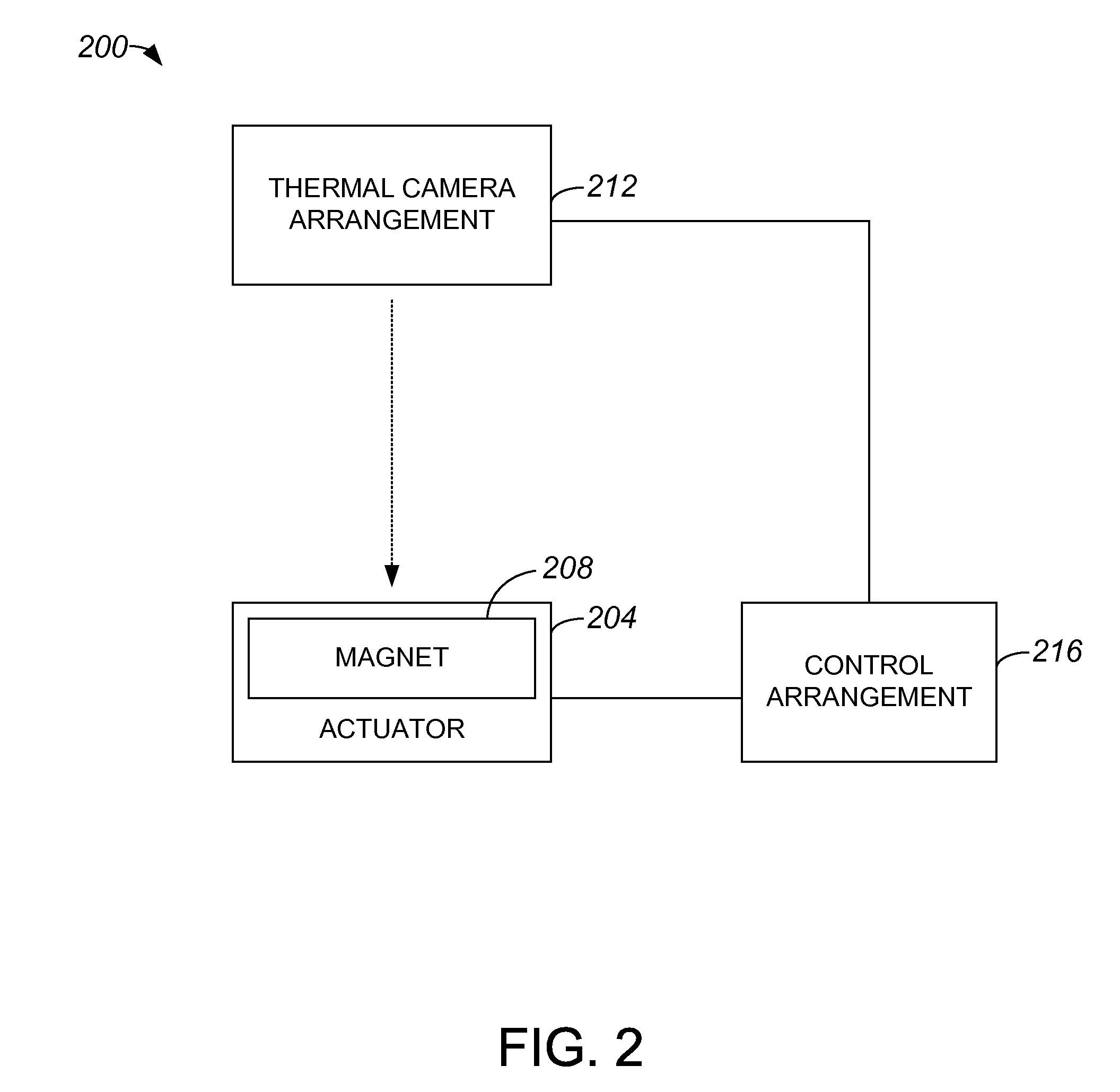

Compensating Temperature Effects in Magnetic Actuators

Methods and apparatus for adjusting the amount of current provided to a magnetic actuator to compensate for a temperature change associated with the magnetic actuator are disclosed. According to one aspect of the present invention, an apparatus includes an actuator, which has at least one magnet and an associated force constant. The apparatus also includes a temperature sensing arrangement and a control arrangement, the temperature sensing arrangement being arranged to determine or measure a temperature of the magnet. The control arrangement adjusts the current provided to the actuator based on the temperature of the magnet. The current is adjusted to maintain a correct or desired force in light of temperature-induced variations to a force constant.

Owner:NIKON CORP

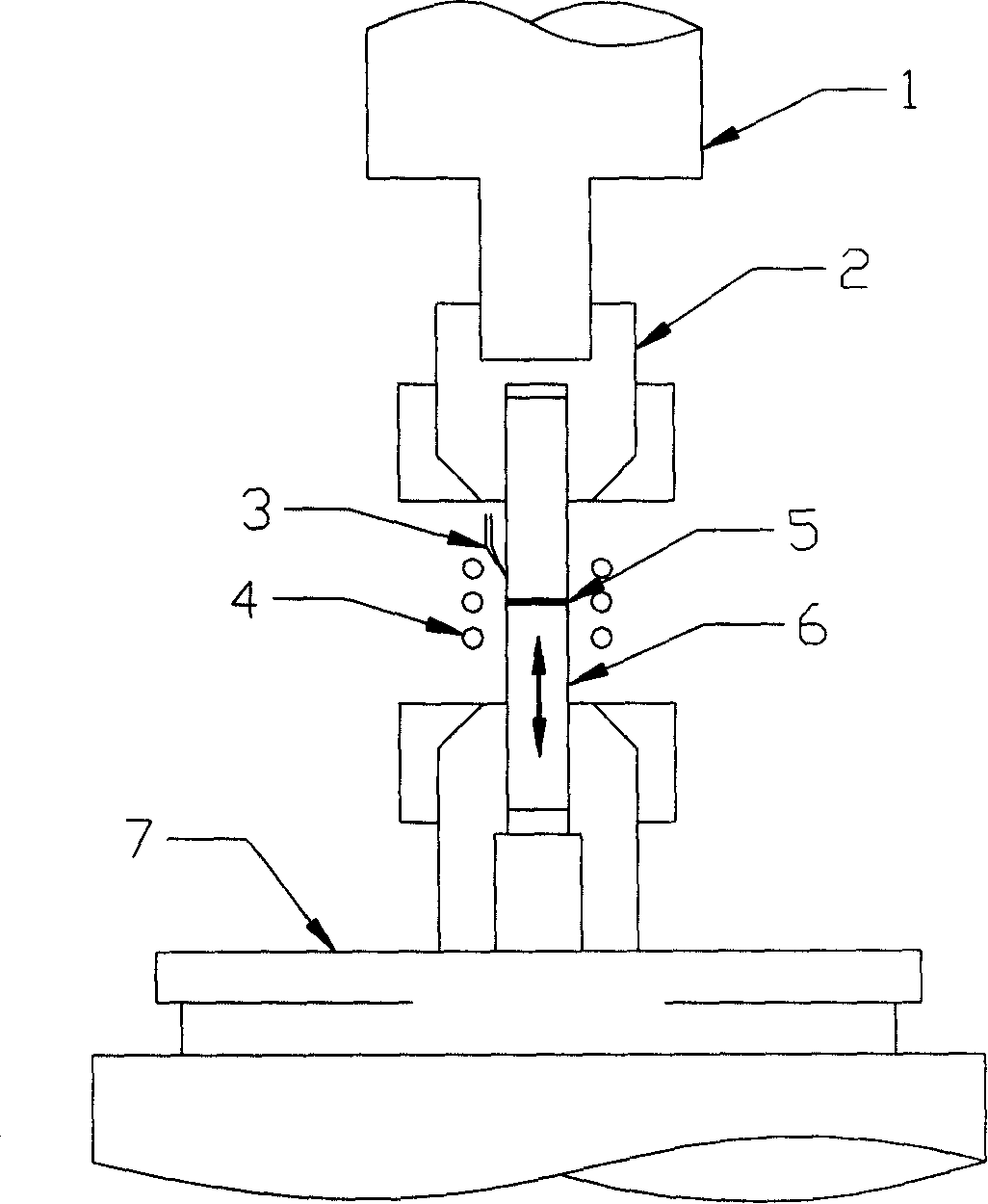

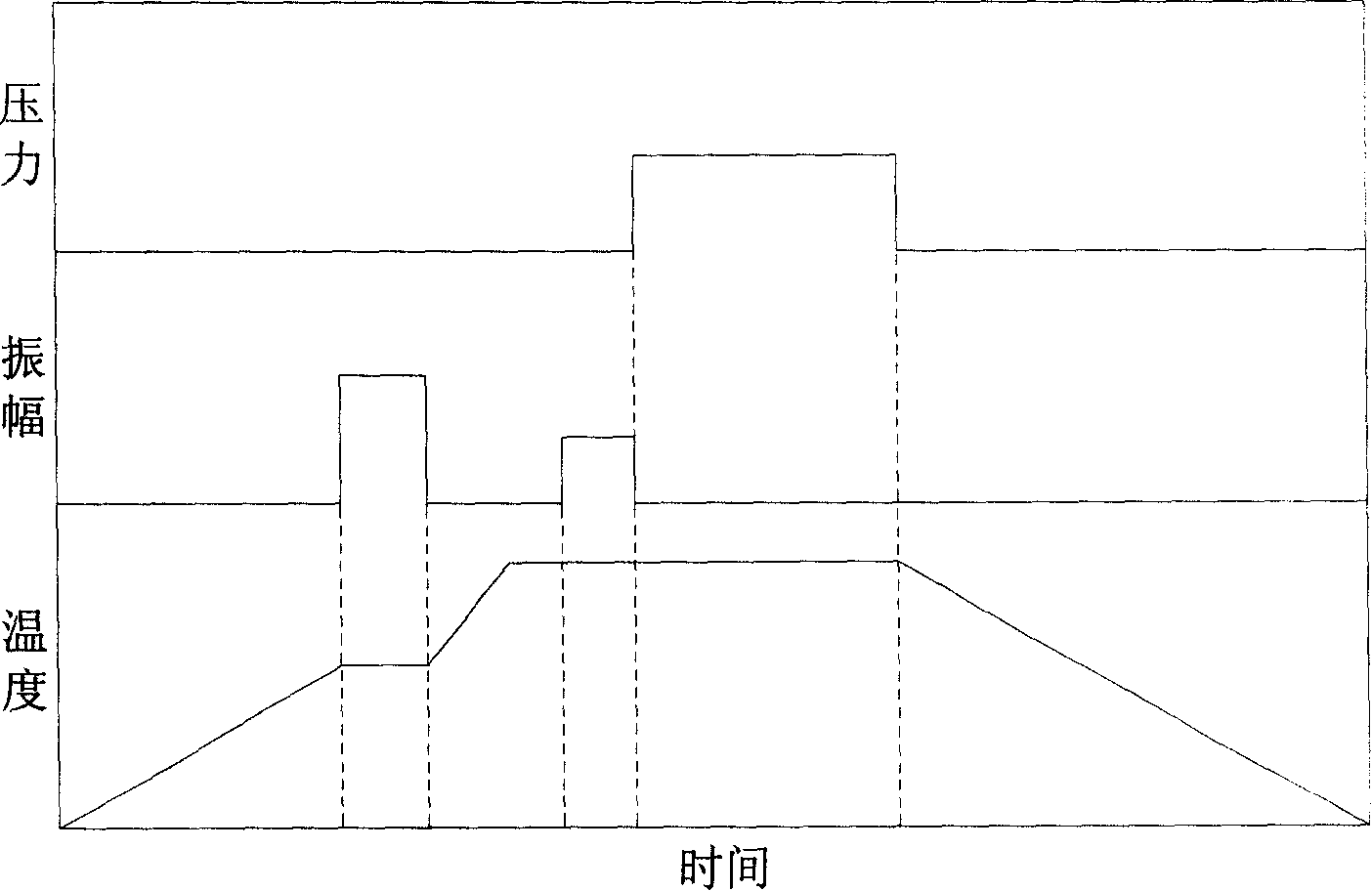

Aluminum alloy and its composite material non-vacuum semi-solid state vibration-rheological connection method

InactiveCN1876302AAchieve weldingShort welding cycleSoldering apparatusNon-electric welding apparatusForce constantSemi solid

The invention provides a method for anti-vacuum vibrating theological connecting aluminum alloy and its complex material. The invention is characterized in that: clamping aluminum alloy or complex material weldment on chucking appliance and placing medium temperature welding material on two pre-welding surface, heating weldment with temperature being 380-400 Deg. C, starting vibrating device after welding material fusion, the amplitude is 0.1-0.5 mm. The temperature during vibrating process is the same, and the vibrating time is 10-300 seconds. The temperature is increased to 450-520 Deg. C after vibration, and it is kept for 1-5 minutes. Then starting vibrating device again, the amplitude is 0.1-1 mm, stopping after 3-60 seconds, forcing constant pressure with pressure range being between 0.1-2 Mpa, keeping temperature for 5-30 minutes, and cooling. The invention is characterized by low cost, high efficiency and quality.

Owner:HARBIN INST OF TECH

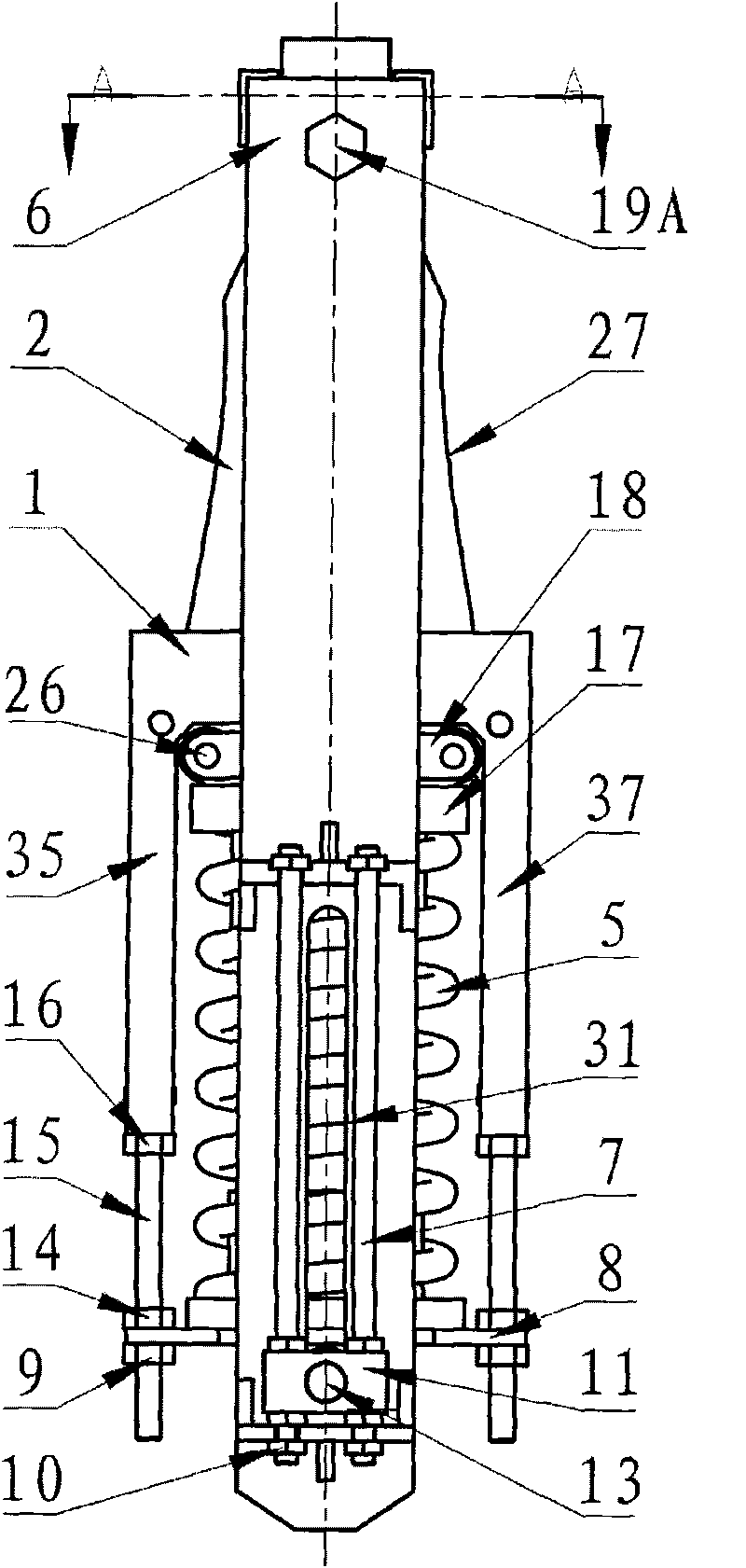

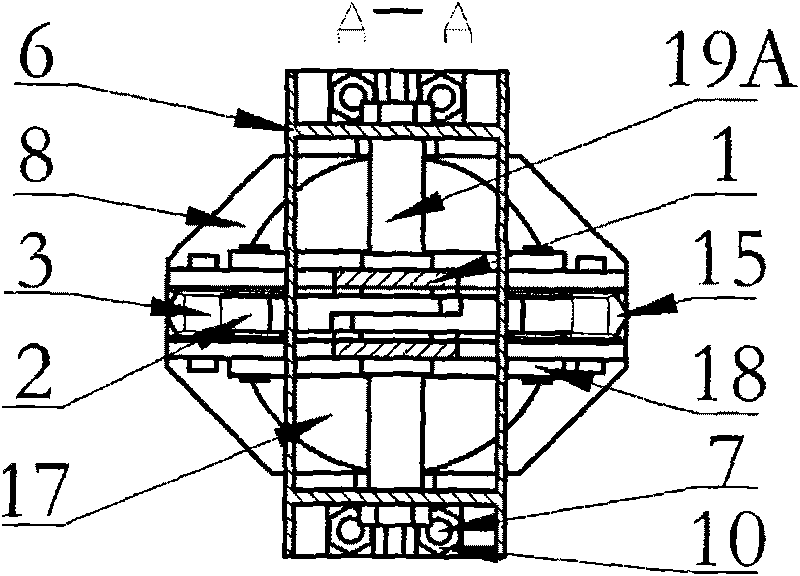

Constant force spring support hanger frame whose supporting and hanging forces and displacement do not change and loading force can be regulated

InactiveCN1367333AConstant bearing forceStable working conditionPipe supportsInstrument housingCouplingFixed frame

The constant pressure spring support hanger frame is mainly formed from fixed frame, load coupling component, load force-transfer component and spring energy-storing component. One end of the described load coupling component is connected with spring energy-storing component. Besides, it also includes a displacement plate fixed in the fixed frame by means of motion pair, and said displacement plate is equipped with load force-transfer component and curve contour capable of retaining loading direction and acting force constant, said curve contour is connected with another end of load coupling component.

Owner:帖德顺

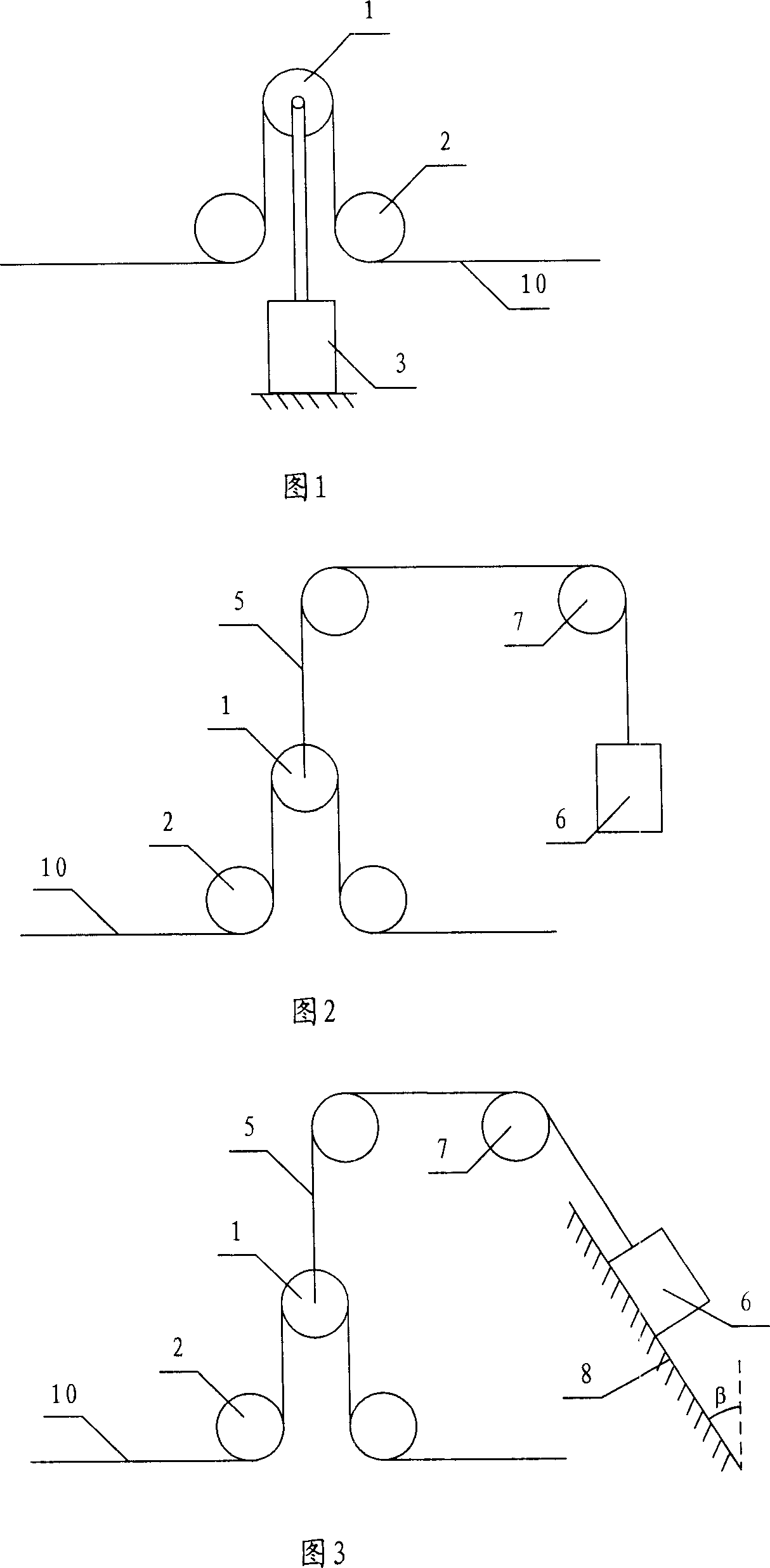

Tension equipment of continuous mill system

InactiveCN101007321AEnsure constant tensionHigh control precisionTensioning/braking arrangementsTension/compression control devicePull forceForce constant

The invention involves a tension device of tandem rolling system. It includes two guide rollers guiding rolling pieces move, floating roller is equipped between said two guide rollers and supports rolling pieces with constant force and makes the rolling pieces stretching force constant through moving up and down, the rolling pieces between said floating roller and said two guide rollers is vertical. Said floating roller can be connected with a hydraulic means which has constant support force, also can be connected with a counterweight body with constant stretching force through hanger rope. The invention proposes a technology program which ensures rolling pieces stretching force constant in rolling plant through changing storage rolling pieces length in rolling mill plant, has characteristics of simple structure, separately adjustment, fast dynamic response and high control precision, etc, it effectively solves the enormous puzzle and technical difficulty stopping tandem rolling technique development for years and years.

Owner:郑红专 +1

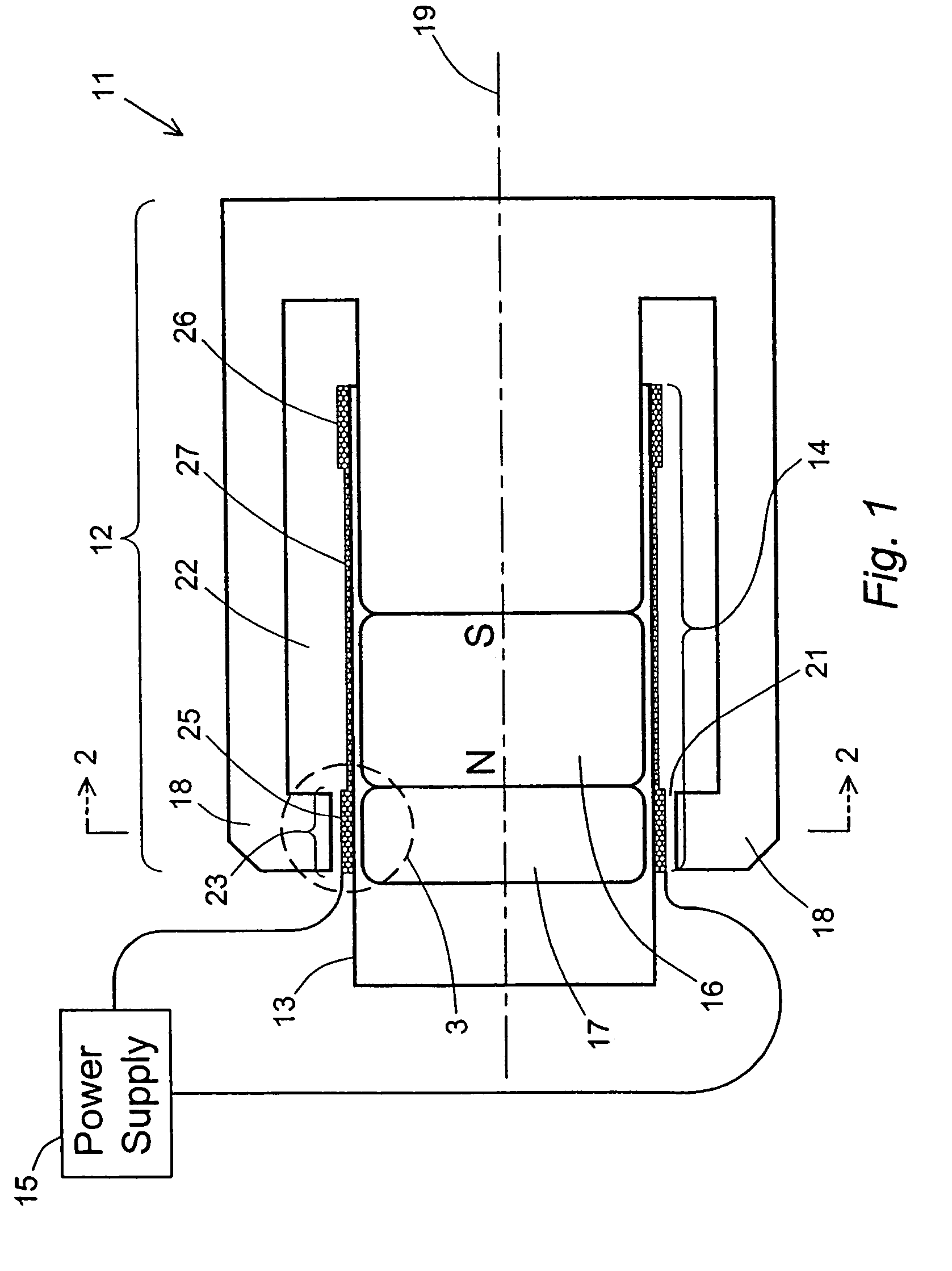

Moving coil actuator for reciprocating motion with controlled force distribution

InactiveUS7279814B2Large forceLower coil resistancePropulsion systemsElectrical conductorReciprocating motion

A moving coil actuator that moves in a rapid back-and-forth motion is constructed with a magnet assembly that concentrates the magnetic flux in a region of limited length and with a coiled electric conductor that includes two separated regions of densely wound coil, the assembly and conductor arranged such that only one of the coil regions resides in a concentrated flux region at either end of the actuator stroke. This is achieved with either a single region of concentrated flux or two spatially separated regions of concentrated flux. In either case, the force constant, i.e., the motor force generated in each coil per unit of current through the coil, is non-linear, with a maximal force at each end of the stroke and a minimal force at the stroke mid-point. The result is an efficient use of the electric current and relatively small amounts of materials of construction, and accordingly less weight for the actuator to carry during its travel and its changes of direction.

Owner:BIO RAD LAB INC

Dual-axis planar motor providing force constant and thermal stability

ActiveUS20100264755A1Reducing thermal driftMinimize changesMagnetic circuitPropulsion systemsForce constantPlanar motor

A motor is provided comprising a magnet assembly having two rows of magnets arranged along a first axis, which are separated by a gap for generating magnetic flux lines between the rows of magnets. The motor further comprises a coil bracket which is located within the gap between the two rows of magnets. The coil bracket includes a first set of coils arranged along the first axis that are operative to drive movement of the coil bracket relative to the magnet assembly along the first axis. A second set of coils arranged along the first axis are operative to drive movement of the coil bracket relative to the magnet assembly along a second axis which is orthogonal to the first axis between a first end position and a second end position along the second axis. The first set of coils is fully located within the flux lines generated by the magnet assembly at both the first and second end positions of the coil bracket and the second set of coils is located at least partially outside the flux lines generated by the magnet assembly at the second end position of the coil bracket.

Owner:ASM ASSEMBLY AUTOMATION LTD

AFM cantilevers and methods for making and using same

InactiveUS7441444B2Surface/boundary effectSemiconductor/solid-state device manufacturingTemporal resolutionForce constant

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

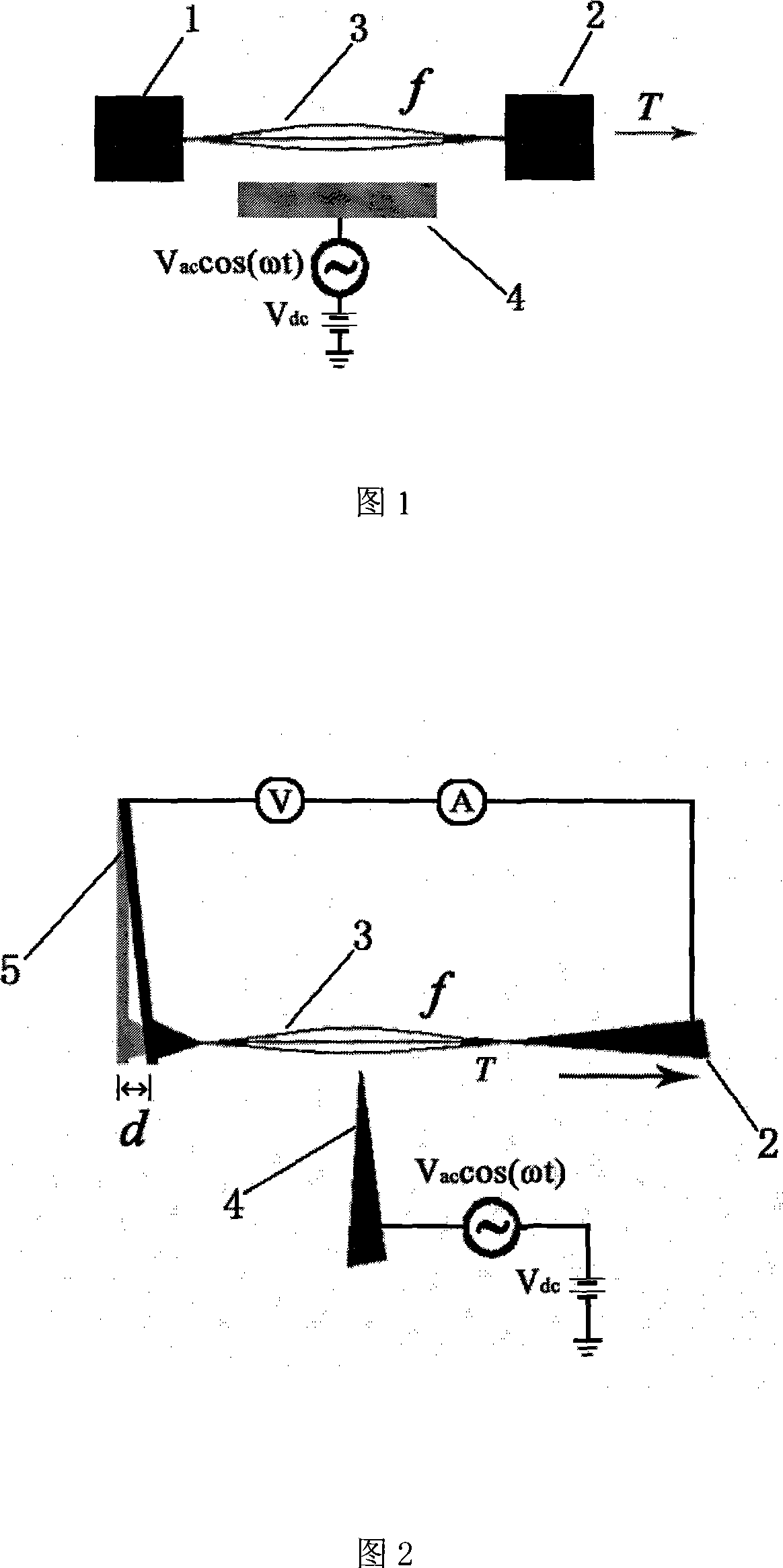

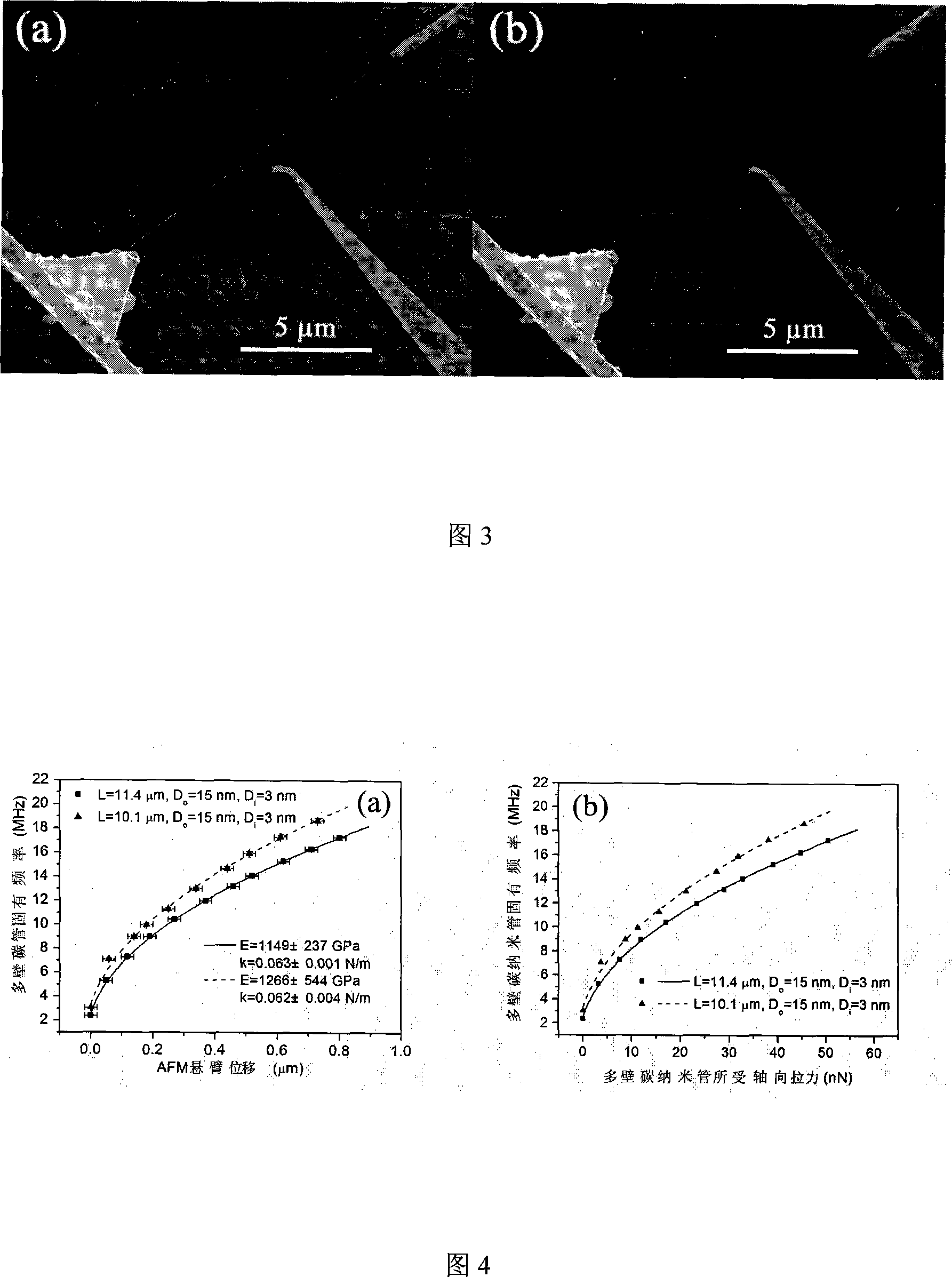

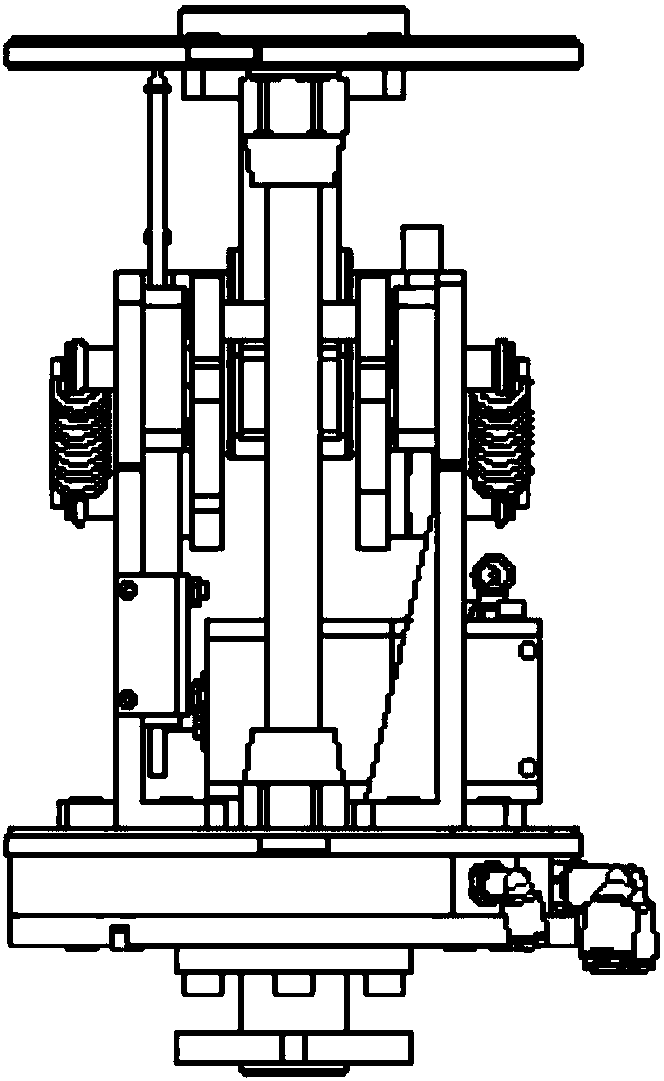

Method for accurately measuring micro-force and measuring micro-cantilever force constant

InactiveCN101183033AAccurate measurementForce measurement by measuring frquency variationsPull forceResonance

The invention provides a method for accurately measuring a tiny force and a force constant of a micro-cantilever, belonging to the field of nanometer measurement. In this method, the two ends of a nanomaterial are fixed on two fulcrums, and a small axial pulling force T is applied to the nanomaterial; on the side of the nanomaterial, an electrode is placed in the middle of the nanomaterial, and a The alternating voltage excites the nanomaterial to make it resonate, and the natural frequency f of the nanomaterial is measured; according to the material characteristics and geometric characteristics of the nanomaterial and the boundary conditions of the nanomaterial, the natural frequency of the nanomaterial is calculated from the vibration equation. The relationship between the axial tensile force received, that is, the f-T curve of the nanomaterial; according to the natural frequency f measured above, the magnitude of the micro tensile force T is obtained. The method is further used to measure the micro-deflection force of the micro-cantilever when it is deflected, and the force constant of the micro-cantilever is measured in combination with the measurement of the deflection displacement. The invention can be used to develop an instrument for accurately measuring tiny forces of the order of pico-newtons or even flying newtons.

Owner:PEKING UNIV

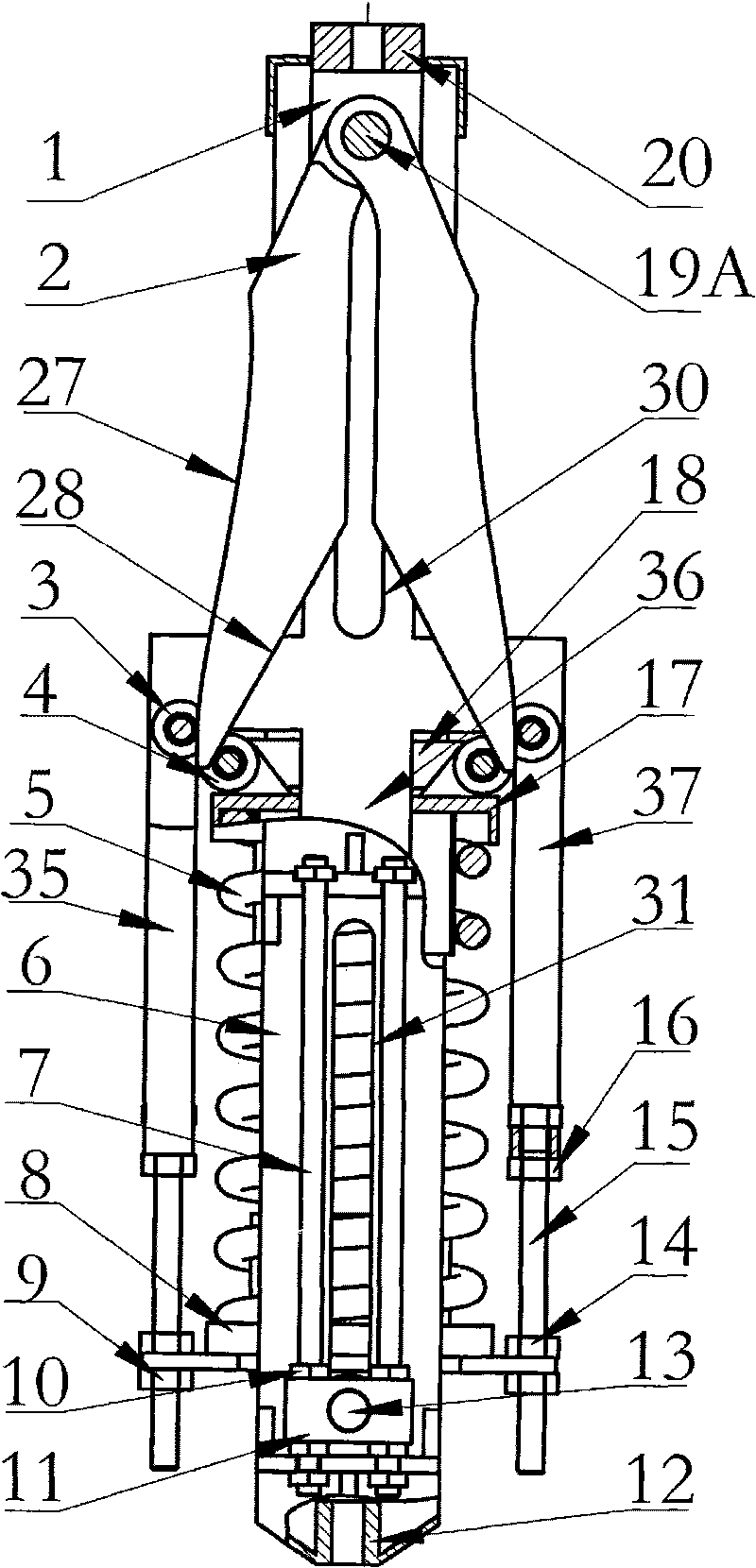

Force control joint device capable of keeping output force constant

The invention discloses a force control joint device. The force control joint device comprises a base, elastic mechanism assemblies, a pneumatic muscle structure assembly, a displacement sensor assembly and an output end. The force control joint device is characterized in that the two symmetrically-arranged elastic mechanism assemblies output thrust, the pneumatic muscle structure assembly outputstensile force, and the resultant force of the thrust and the tensile force is used for controlling output force of a joint jointly. The displacement sensor assembly is used for monitoring the currentreal-time deformation quantity of the joint so as to facilitate subsequent data processing and real-time control over the output force of the joint. The force control joint device is used for controlling pressure, and through special structural design, when the joint carries a grinding tool head, under interference of the uneven work surface condition, the contact pressure of the grinding tool head and the surface of a workpiece can be kept to be constant.

Owner:BEIHANG UNIV

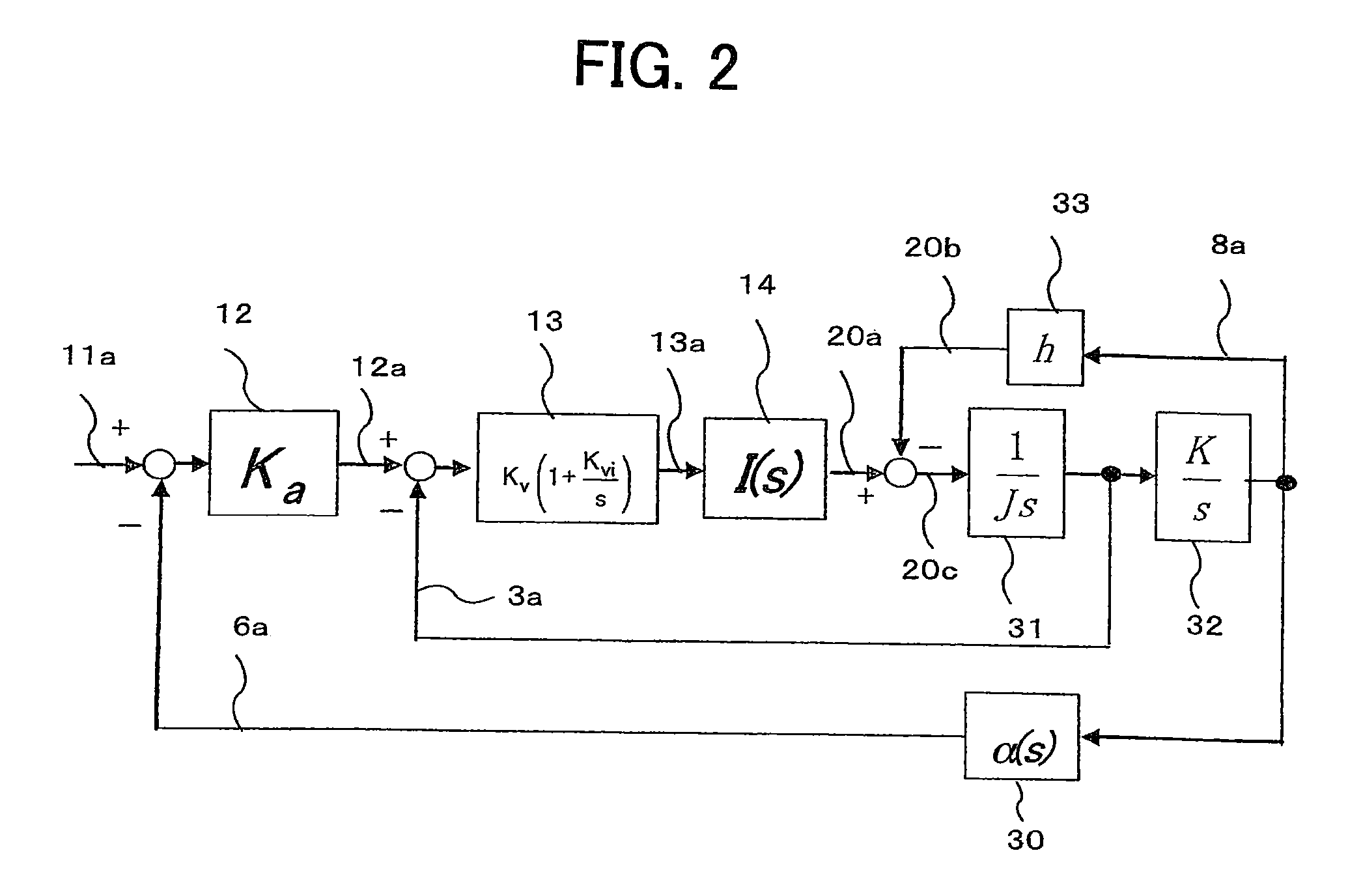

Motor control device

InactiveUS8860355B2Improve controlEnsure controlElectric motor controlTemperatue controlMotor speedForce constant

Owner:MITSUBISHI ELECTRIC CORP

Self-compensating constant-force spring hanger

The invention relates to a self-compensating constant-force spring hanger, which mainly comprises a static frame, a dynamic frame, a cam, a spring, upper and lower spring end covers and static and dynamic idler wheels. The cam hinged on the dynamic frame by a cam shaft is provided with two inner and outer working curves which ensure a supporting and hanging force constant and are matched with the dynamic and static idler wheels arranged on the upper spring end cover and the static frame respectively. The spring and the upper and lower spring end covers are sleeved on a middle arm of the static frame. The lower spring end cover is connected with the static frame by an adjusting nut and an adjusting screw. The dynamic frame is provided with a locking support plate which can lock an indicating pin fixedly connected on the static frame after being matched with a locking device. The self-compensating constant-force spring hanger can be used for supporting and hanging pipelines with cold and thermal displacement in the industries, such as the power industry, the petrochemical industry and the like, and also can be used in the occasions that contact lines and the like of electrified railways needs the constant tensile force.

Owner:高永峰

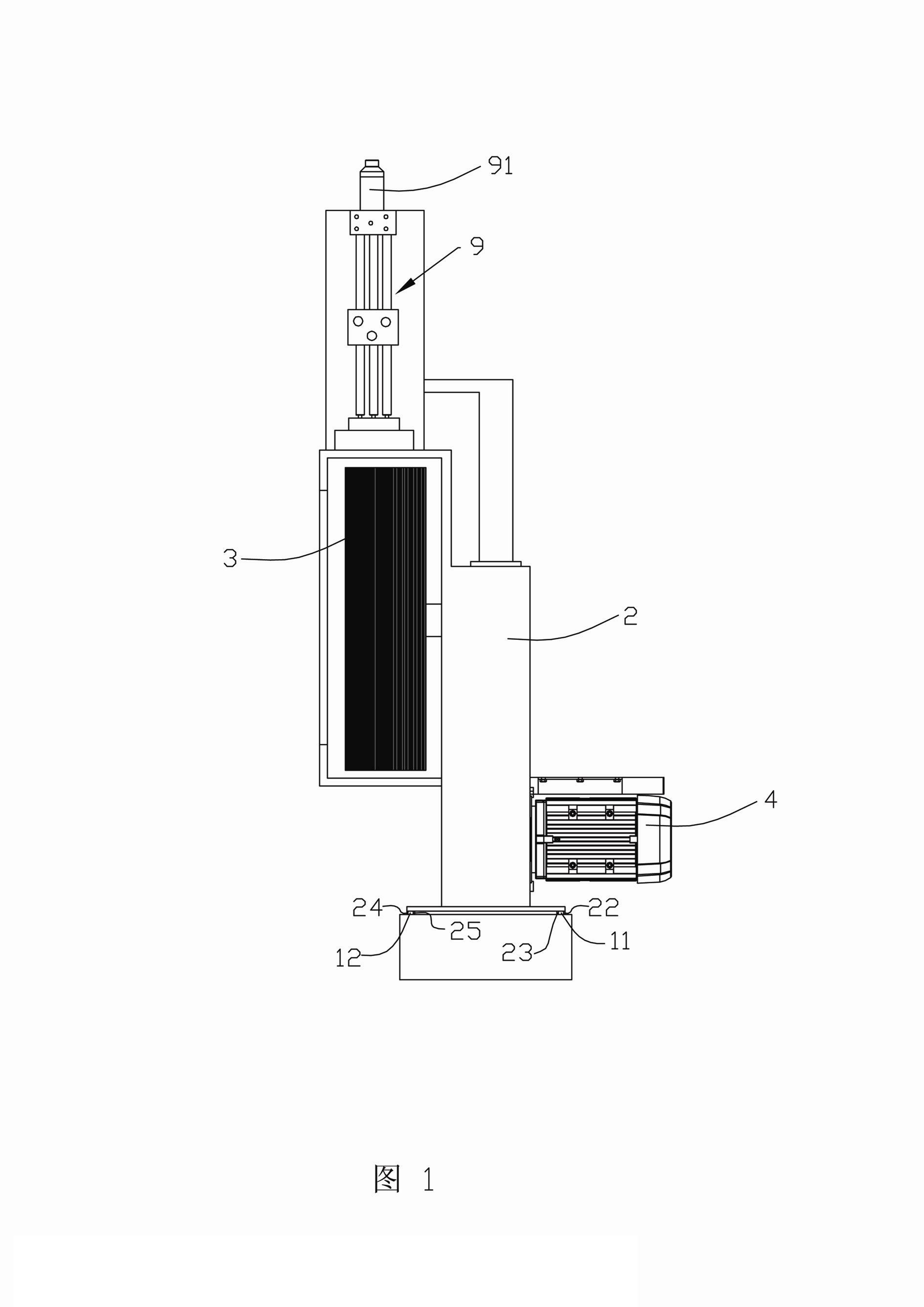

Method and equipment for controlling constant polishing force of buffing machine

ActiveCN102145473ANovel ideaSimple structurePolishing machinesAutomatic grinding controlMotor driveForce constant

The invention relates to a method for controlling the constant polishing force of a buffing machine, comprising the following steps of: setting control parameters by a control system; acquiring the working current of a drive motor through a frequency converter; acquiring the working radius of a buffing wheel through a servo motor; and analyzing and controlling a driver so that the servo motor drives a machine body connected with the buffing wheel to radially and horizontally move front and back along the buffing wheel. The invention also provides the buffing machine capable of keeping the polishing force constant, comprising the machine body, the buffing wheel, the drive motor and the servo motor, wherein the machine body is connected with a base; the buffing wheel is arranged on the machine body; the drive motor is connected with the buffing wheel and drives the buffing wheel to rotate; the servo motor is arranged on the base and connected with the machine body and drives the machinebody to radially and horizontally move front and back along the buffing wheel; the drive motor is connected with the frequency converter for controlling the drive motor; the servo motor is connected with the driver for controlling the servo motor; and the frequency converter and the driver are both connected with an PLC (Programmable Logic Controller) control system. The buffing machine can keep the polishing force constant, enables the surface polishing of a product to be more reliable and has scientific design and advanced conception.

Owner:FUJIAN CHANGJIANG IND

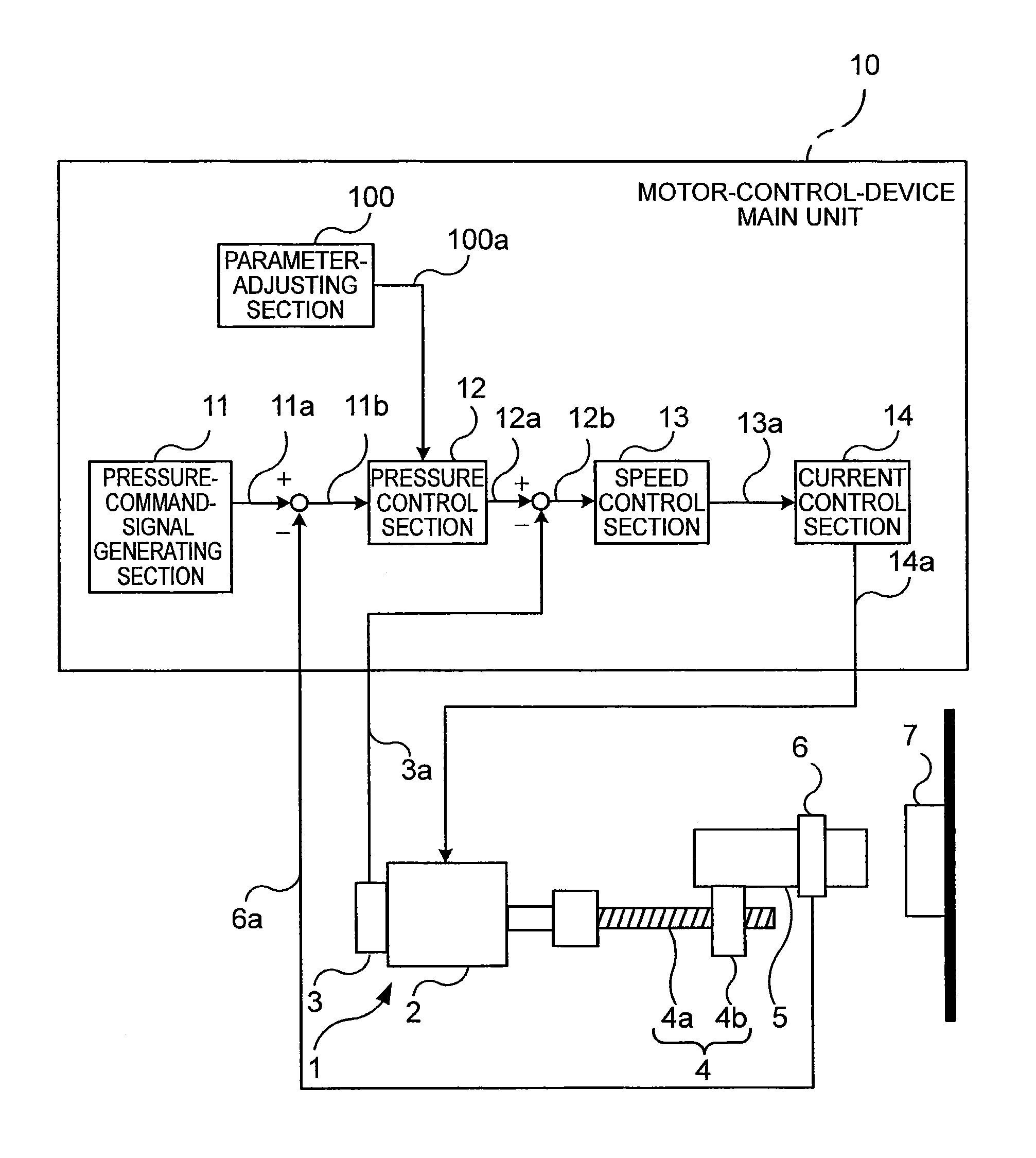

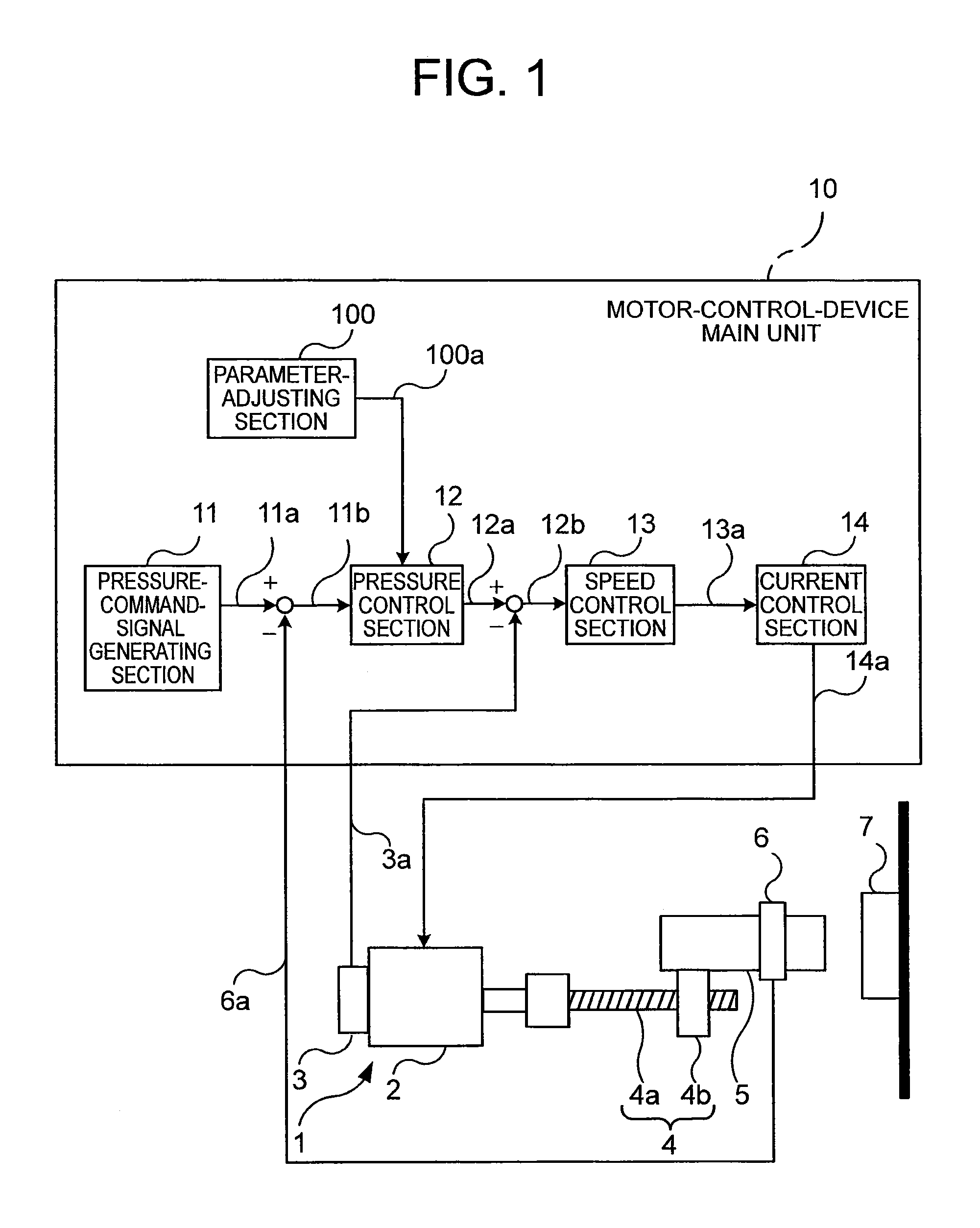

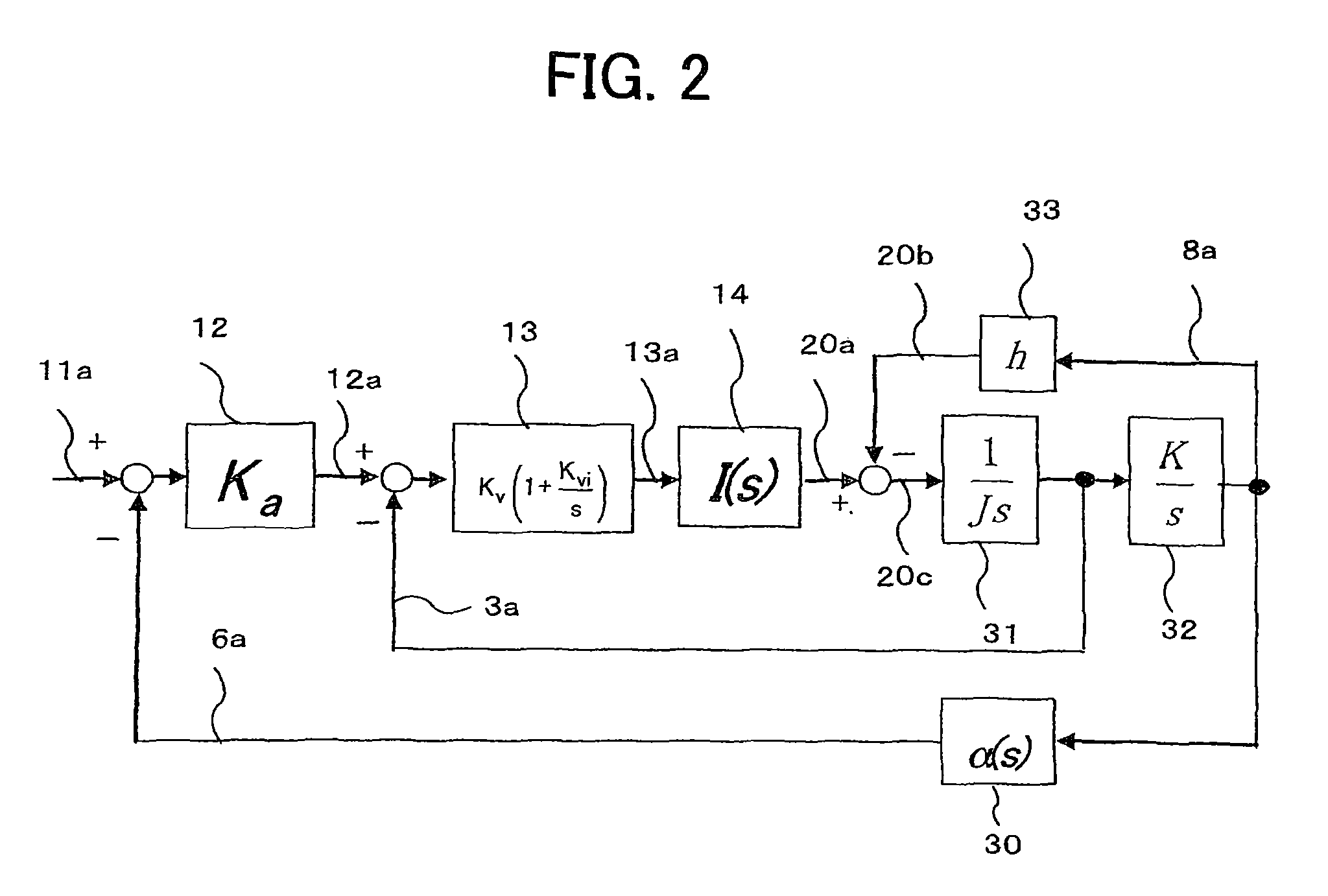

Motor control device

InactiveUS20130063068A1Improve controlEnsure stability of controlElectric motor controlSimulator controlMotor speedForce constant

A motor-control-device main unit includes a pressure-command-signal generating section, a pressure control section, a speed control section, a current control section, and a parameter-adjusting section. With respect to a parameter for a control computation by the pressure control section, the parameter-adjusting section includes an information-acquiring section and a parameter-calculating section. The information-acquiring section acquires, from an exterior, each of pieces of information including an elastic constant of a pressurized target, a reaction-force constant indicating information of a reaction force, a transfer characteristic from a motor torque to a motor speed, and parameters of the speed control section. The information-acquiring section previously acquires information of a control law of the speed control unit. The parameter-calculating section calculates a parameter for the pressure control section based on the information acquired by the information-acquiring section.

Owner:MITSUBISHI ELECTRIC CORP

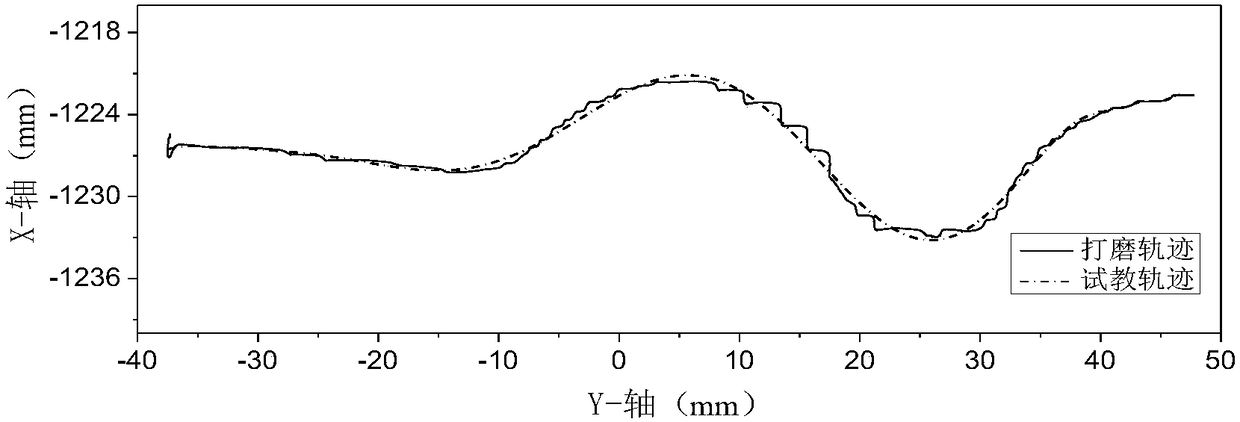

Force control-based robot polishing trajectory estimation method

InactiveCN108107842AAccurate estimateProgramme controlComputer controlForce constantEstimation methods

The invention discloses a force control-based robot polishing trajectory estimation method. The method comprises the steps of S1, acquiring a grinding initial point and obtaining the position of the grinding initial point; S2, carrying out the impedance position correction on the position of the grinding initial point and obtaining a reference position point; S3, judging whether a stop signal is received or not; if not, obtaining the approximate tangential vector of the reference position point, controlling a robot arm to feed a unit displacement in the tangential direction so as to obtain a next grinding initial point, and returning to the step S2; if yes, stopping obtaining the next grinding initial point, and connecting all reference position points according to the sequence obtained bythe reference position points to form a grinding track. According to the invention, the method disclosed by the invention is suitable for a complex workpiece to automatically generate a rough grinding track. By adopting the method, the estimation of a complex unknown outline is more accurate. The grinding initial point is corrected by keeping the machining process force constant, so that a more accurate track point is obtained.

Owner:WUHU HIT ROBOT TECH RES INST

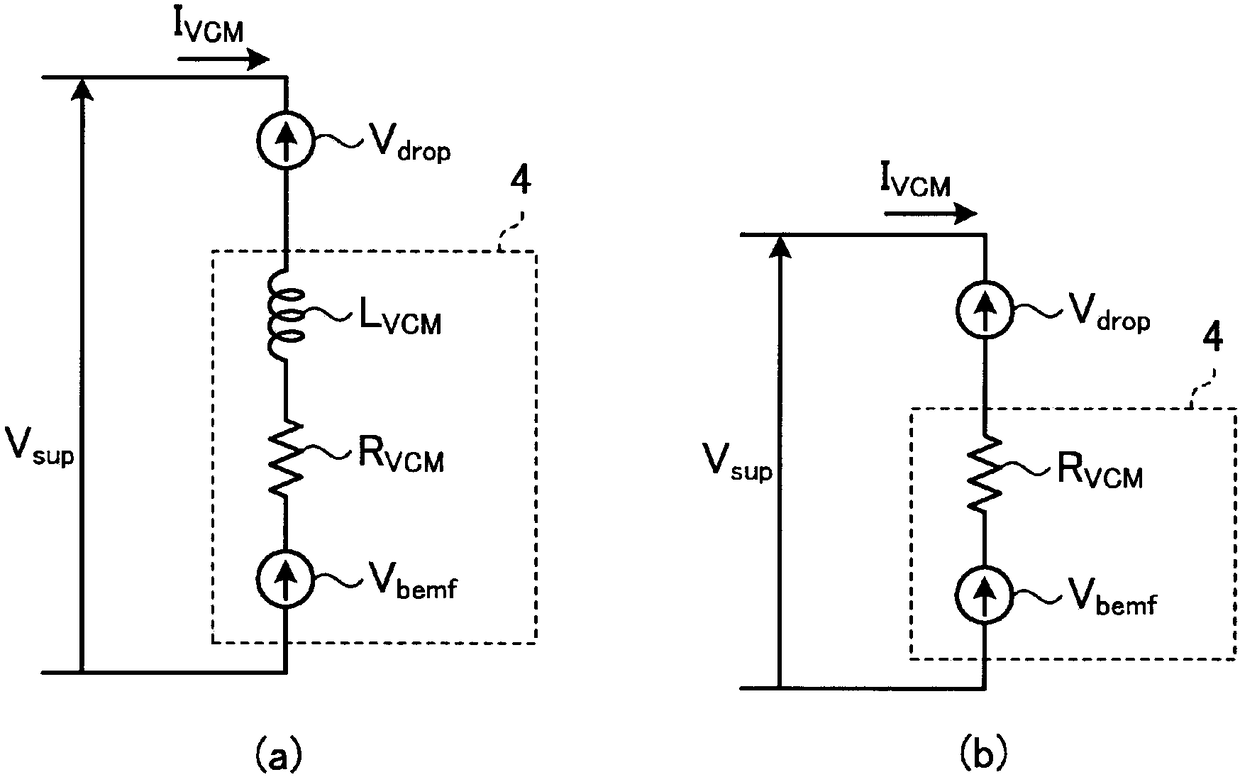

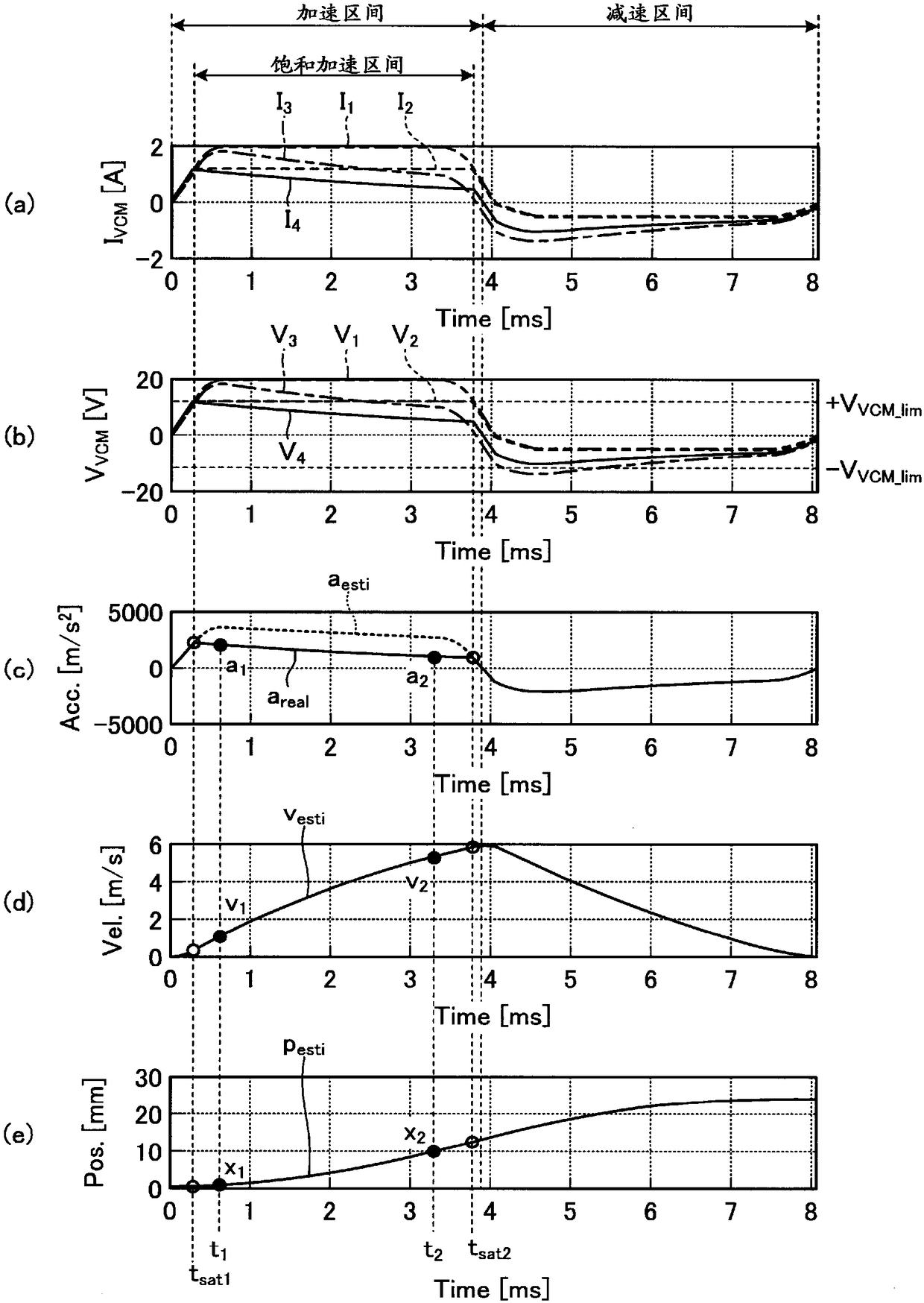

Magnetic disk apparatus

ActiveCN108630237ADisposition/mounting of recording headsRecord information storageElectrical resistance and conductanceForce constant

The invention provides a magnetic disk apparatus capable of stabilizing seek control. A VCM resistance estimation unit (9A) estimates a VCM resistance in a voice coil motor (4) based on an acceleration and a velocity of a magnetic head with a VCM voltage saturated, and an equivalent current force constant estimation unit (9B) estimates an equivalent current force constant of the voice coil motor (4) based on the acceleration and the velocity of the magnetic head with the VCM voltage saturated. A seek control unit (9C) performs a seek control based on the VCM resistance and the equivalent current force constant of the voice coil motor (4).

Owner:KK TOSHIBA +1

Clamping fixation seat for welding of plate-shaped workpieces

InactiveCN105414854AEasy to weldConstant clamping forceWelding/cutting auxillary devicesAuxillary welding devicesForce constantMechanical engineering

The invention provides a clamping fixation seat for welding of plate-shaped workpieces. The clamping fixation seat comprises a base plate, wherein two opposite movable baffles are arranged on the base plate and connected with a driving mechanism, the driving mechanism can drive the two movable baffles to move horizontally in same or opposite directions, and at least one jacking head is arranged on the inner side surface of each mobile baffle and connected with a jacking head cylinder. The two opposite movable baffles are arranged on the base plate of the clamping fixation seat, so that to-be-welded workpieces can be clamped between the two movable baffles. Most end surfaces of the to-be-welded workpieces are uneven possibly, so that the at least one jacking head is arranged on each movable baffle and connected with the corresponding jacking head cylinder, and the workpieces with the uneven end surfaces can also be fixedly clamped. The clamping fixation seat is applicable to various plate-shaped to-be-welded workpieces and can clamp the to-be-welded workpieces very conveniently and keep the clamping force constant, so that the welding quality can be effectively improved.

Owner:SUZHOU RECEN PRECISION MACHINERY CO LTD

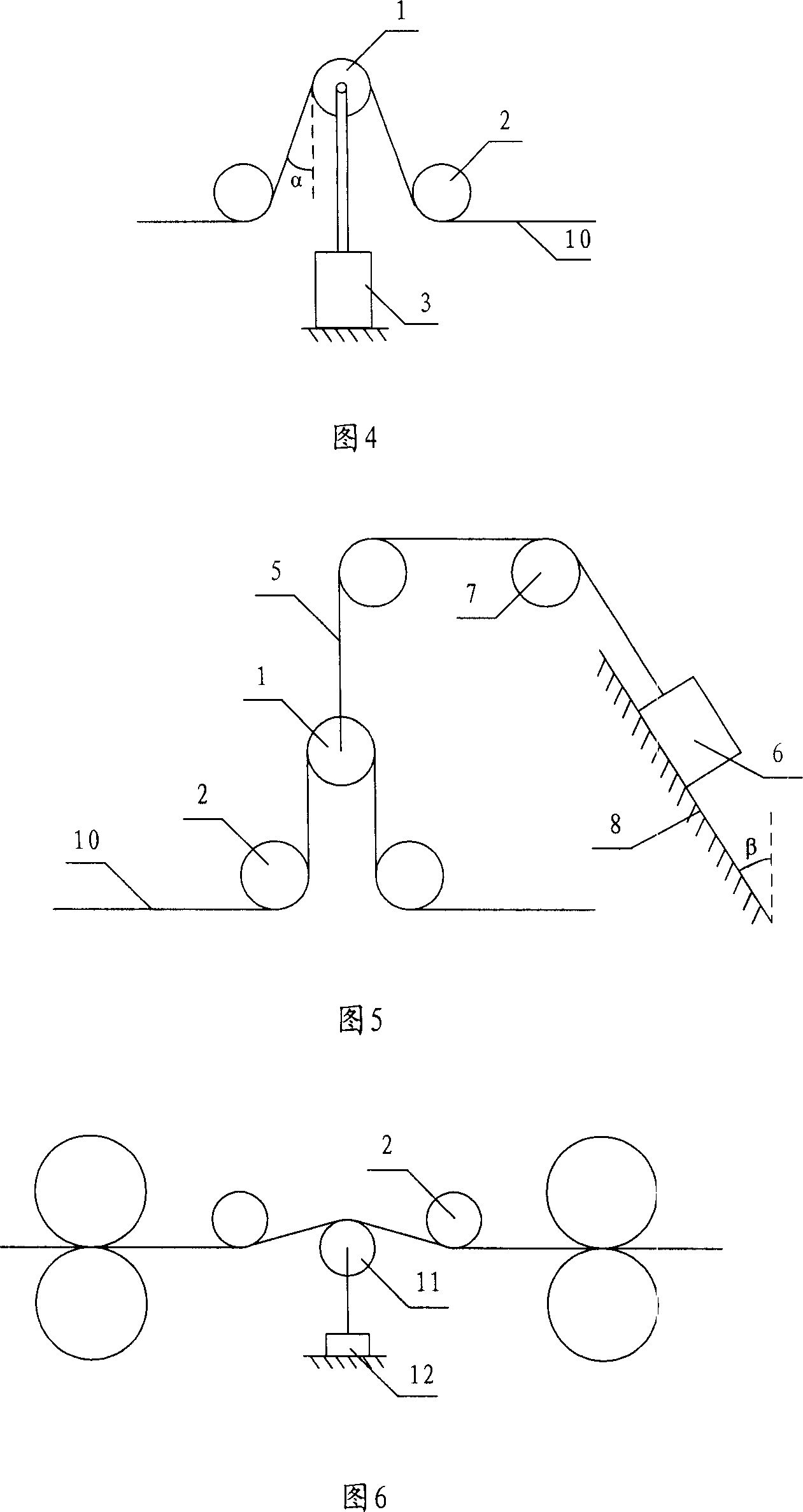

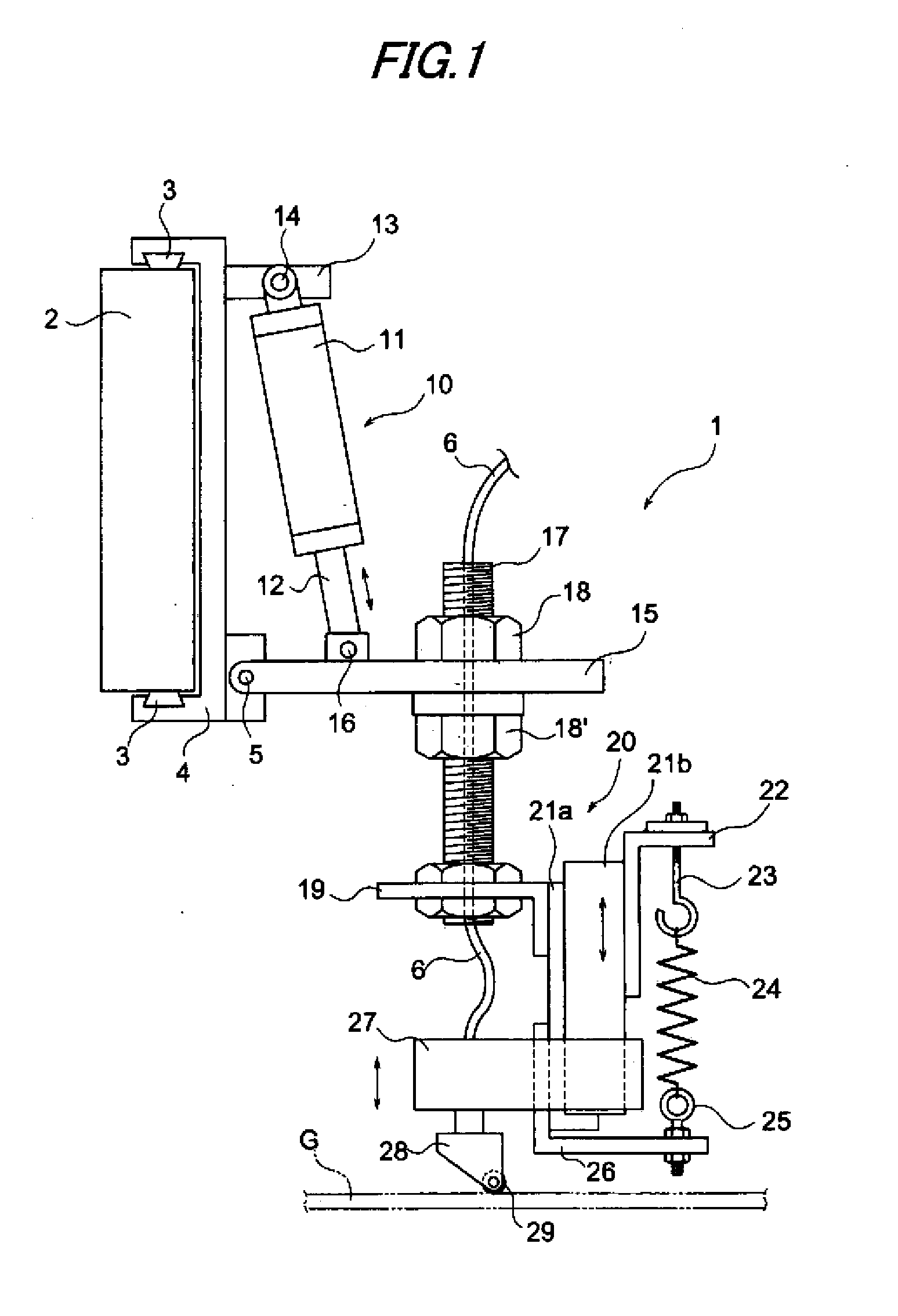

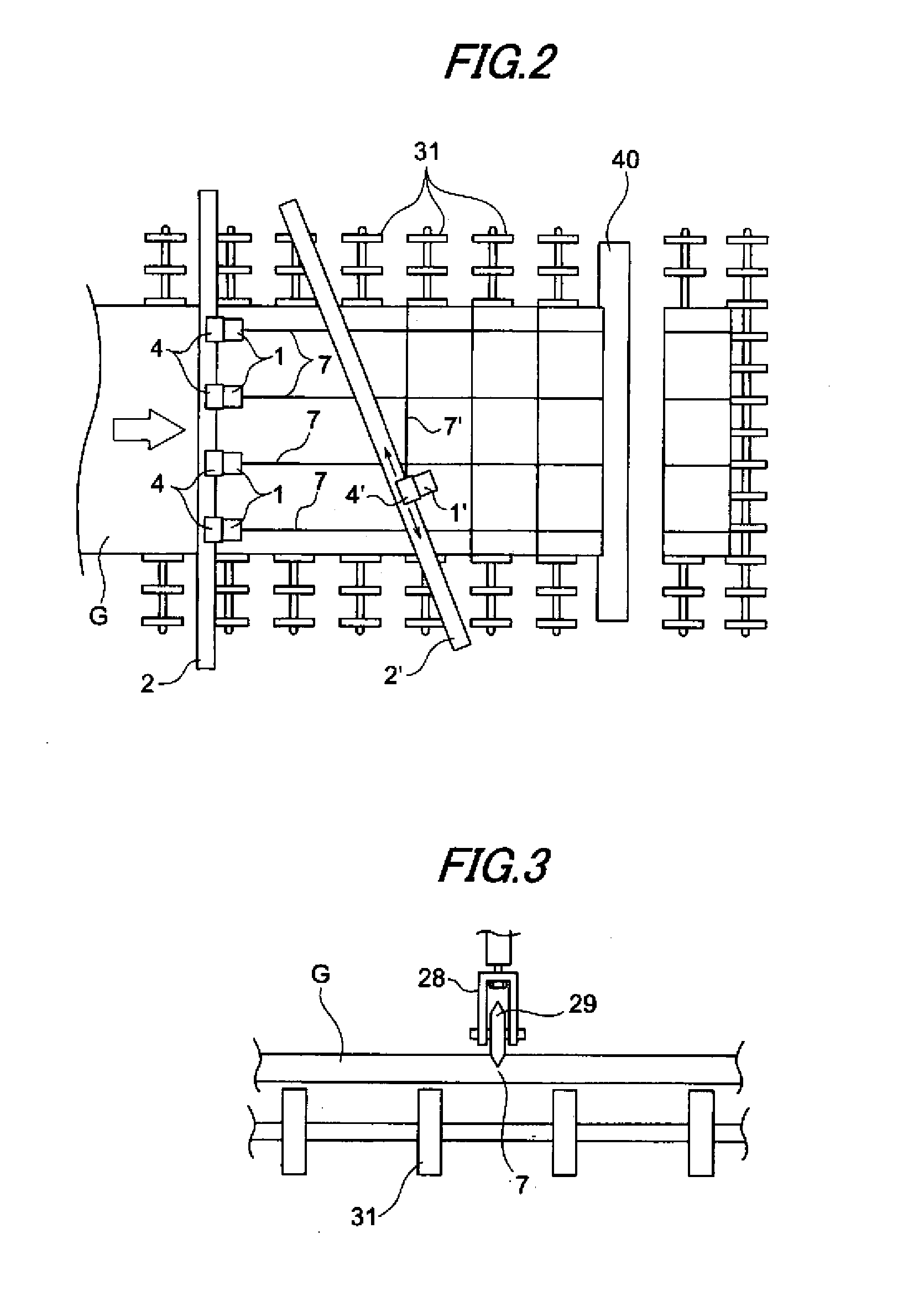

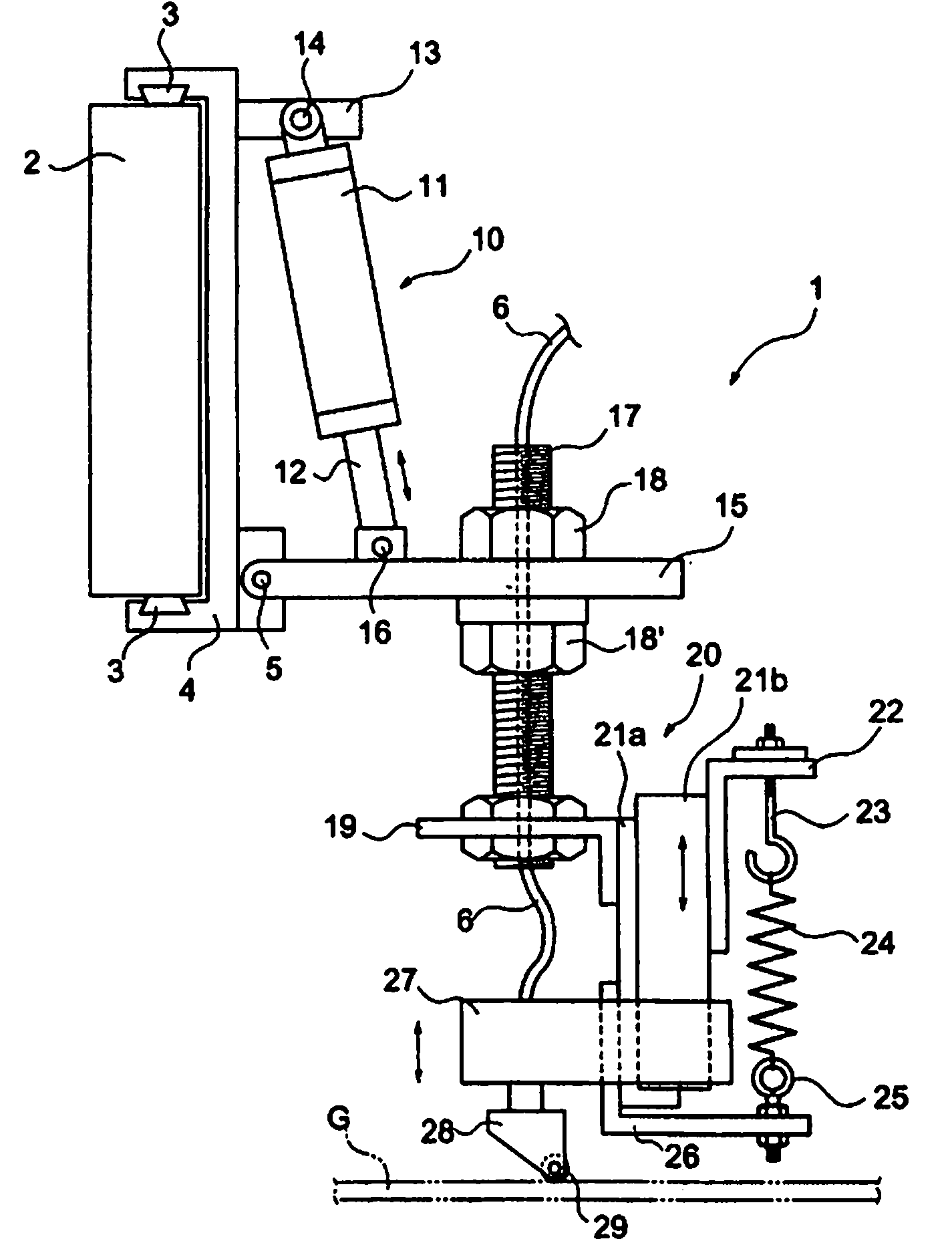

Cutting line on glass sheet providing apparatus

InactiveUS20100242702A1Avoid damageSmoothly moved up and downGlass severing apparatusMetal working apparatusForce constantEngineering

An apparatus for providing a cutting line on a glass sheet, in which the cutting line for bend-cutting the glass sheet is provided on the glass sheet conveyed on a carrying roller, is provided with: a cutter configured to provide the cutting line on the glass sheet; a ball slide device configured to freely move the cutter up and down in accordance with an up-down movement of the conveyed glass sheet, and to absorb an excessive pressing force of the cutter onto a glass sheet surface so as to keep the pressing force constant; a spring configured to apply an appropriate cutter pressure to the glass sheet surface; an arm configured to support the ball slide device, the spring, and the cutter; and a pressing device configured to press the arm toward the glass sheet surface.

Owner:CENT GLASS CO LTD +1

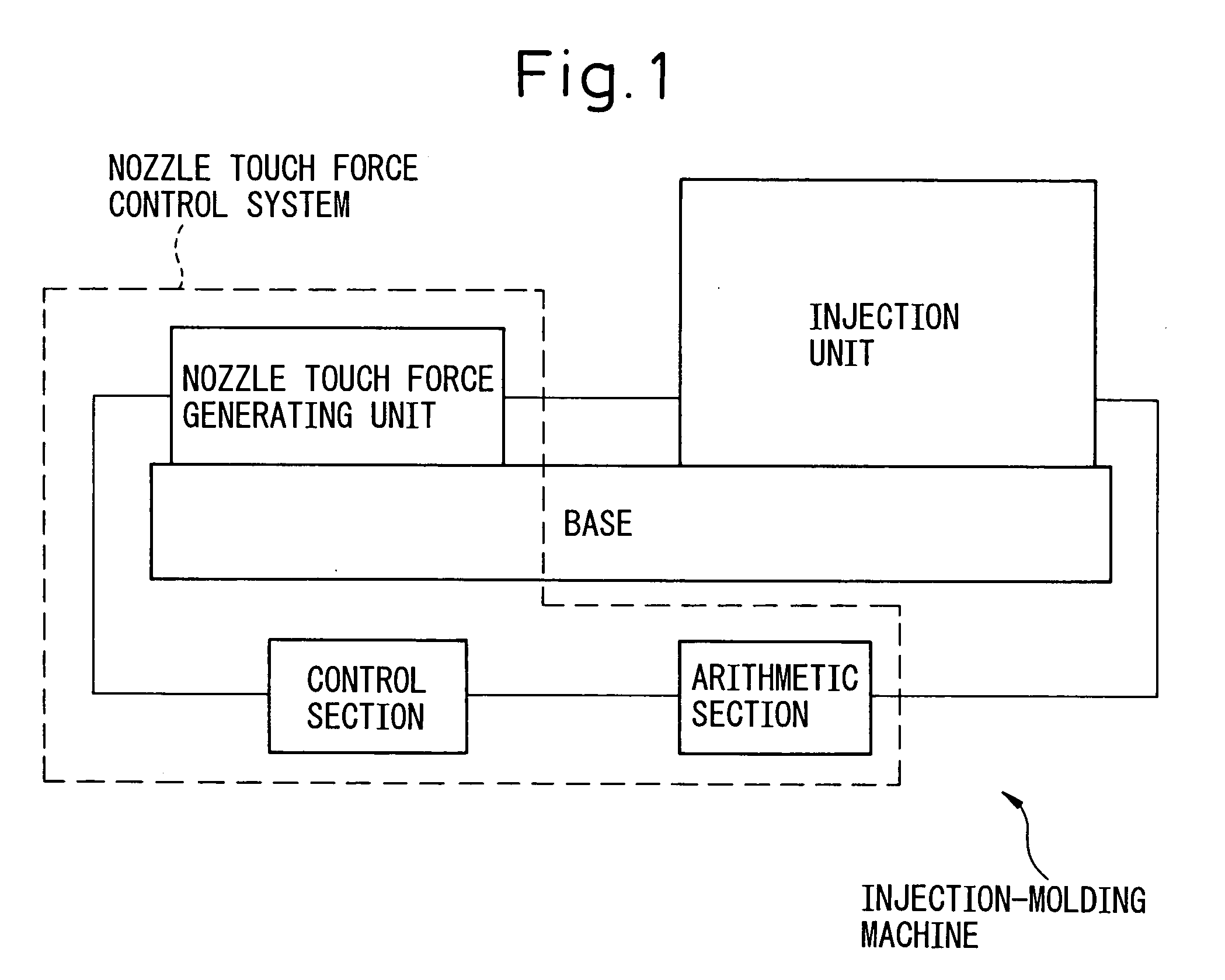

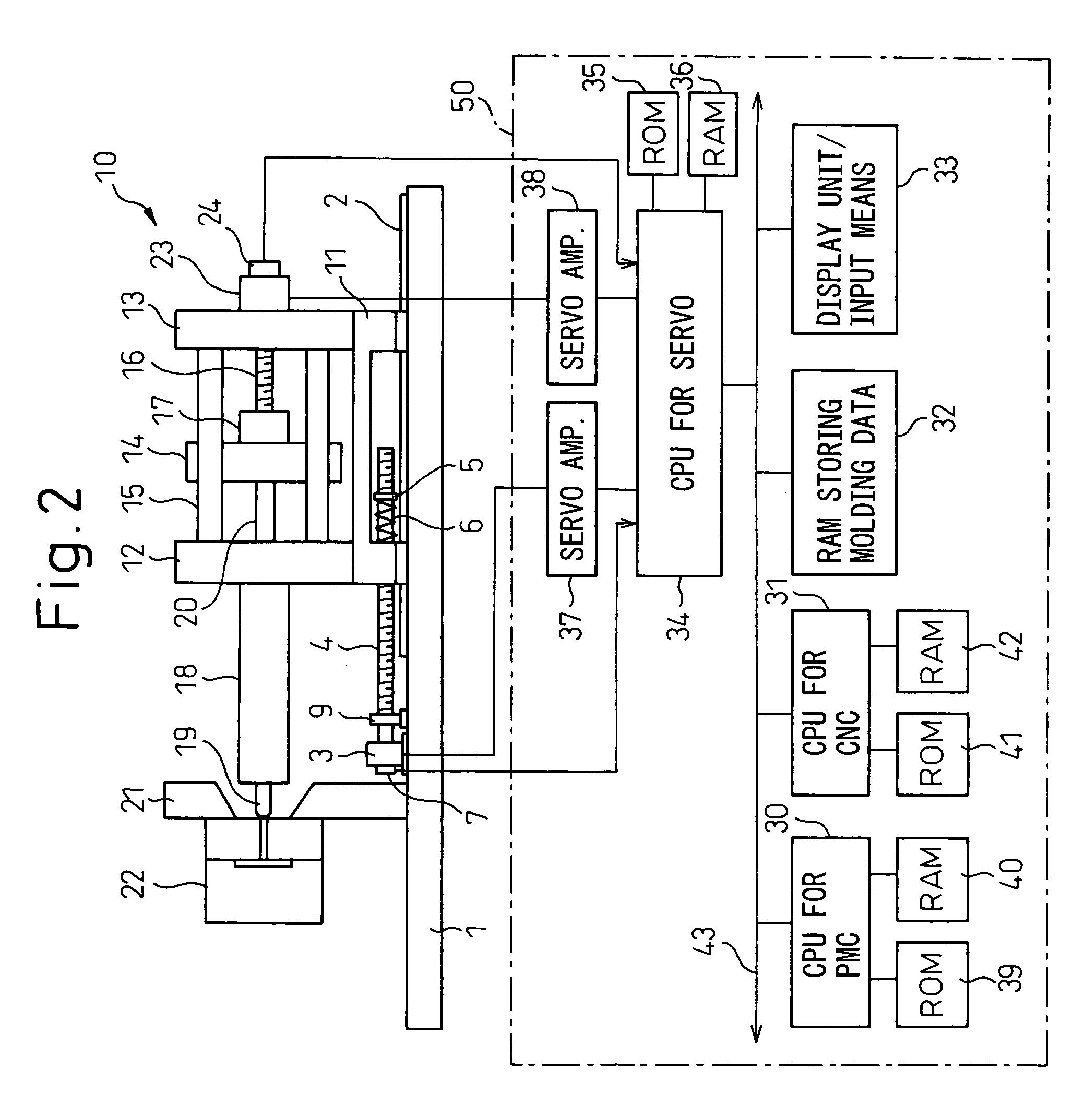

System for controlling nozzle touch force

ActiveUS20050053685A1Simple structureEasy maintenanceAuxillary shaping apparatusFood shapingForce constantEngineering

A system for controlling nozzle touch force, which is capable of maintaining the touch force relying upon a simple constitution. An electric motor moves the injection unit forward via a spring to bring a nozzle into contact with a metal mold. Further, the spring is compressed to impart a preset nozzle touch force. In the injection / pressure-maintaining step, the screw is driven, and a position / speed detector provided on a servo motor for injecting the resin detects the injection speed at regular intervals. A force produced by the force of inertia of the moving portions such as the injection screw and the pusher plate that move due to the injection operation, is found from the acceleration that is found from the injection speed. The amount of compression of the spring is controlled by varying the rotational position of the motor by an amount corresponding to the force that is found to maintain the nozzle touch force constant. Since the nozzle touch force is maintained constant, no resin leaks and an excess of nozzle touch force is not produced, either.

Owner:FANUC LTD

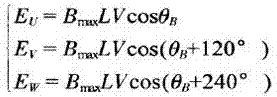

Rapid testing method of linear motor force constant

The invention relates to the technical field of an electronic industry, and particularly relates to a rapid testing method of a linear motor force constant. The rapid testing method of the linear motor force constant includes steps of (1), connecting a reference ground; (2), measuring phase voltages of U, V and W phases of a coil by three channels of an oscilloscope; manually pushing the motor tomove at constant speed, and capturing the wave form of the oscilloscope; recording the voltage peark values Epk-pk in uniform waveform and the time tp of the whole waveform cycle; repeating continuously until finding out the wave form with the most uniform speed and recording; (3), calculating the motor force constant KF and measuring an electrodynamic potential and the linear voltage. The methodfor measuring the linear motor force constant by a reverse electrodynamic potential is a rapid method and has the advantages of rapidly acquiring the motor force constant in the absence of special devices.

Owner:SHAANXI SHENGMAI PETROLEUM

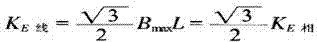

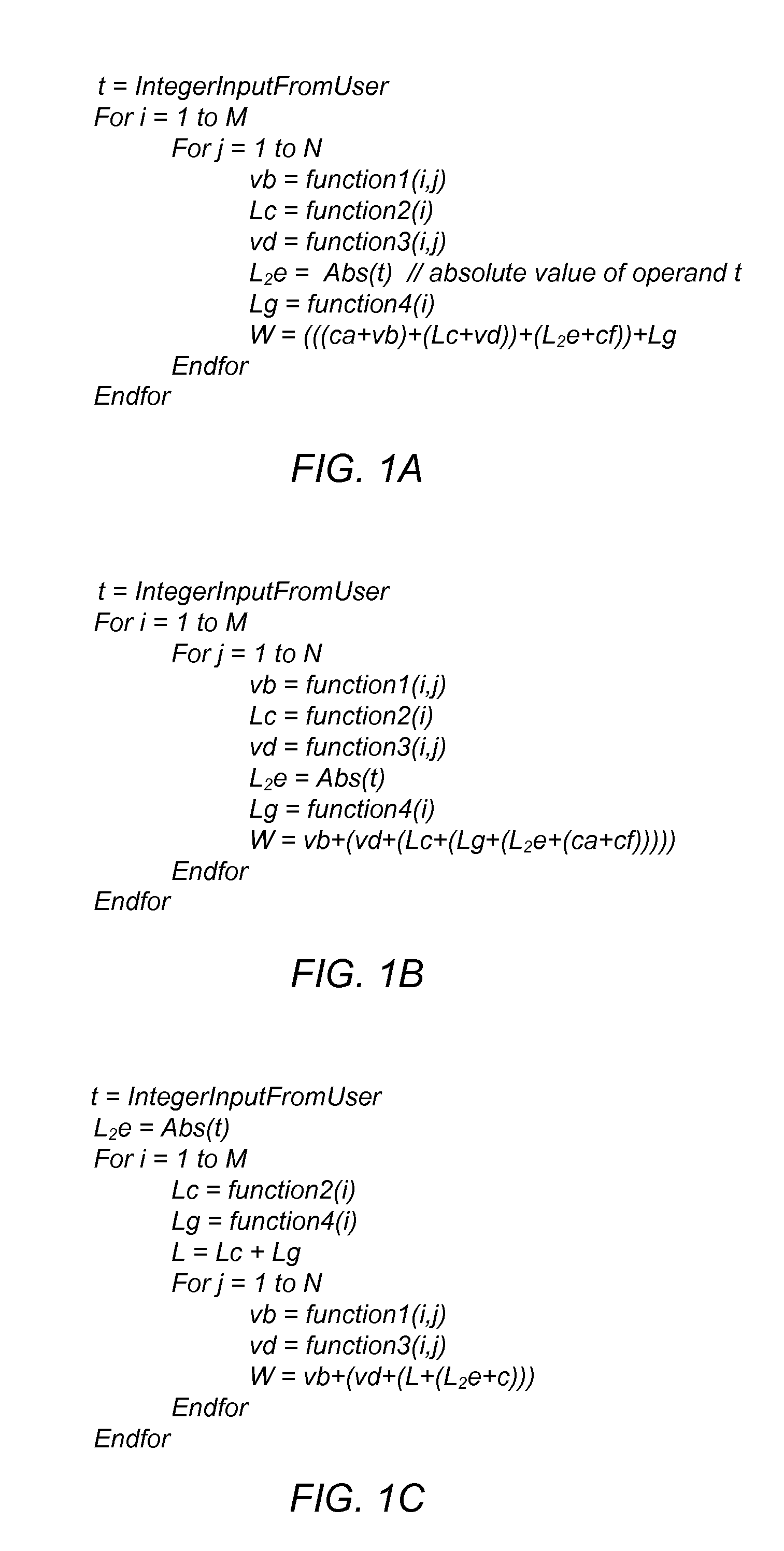

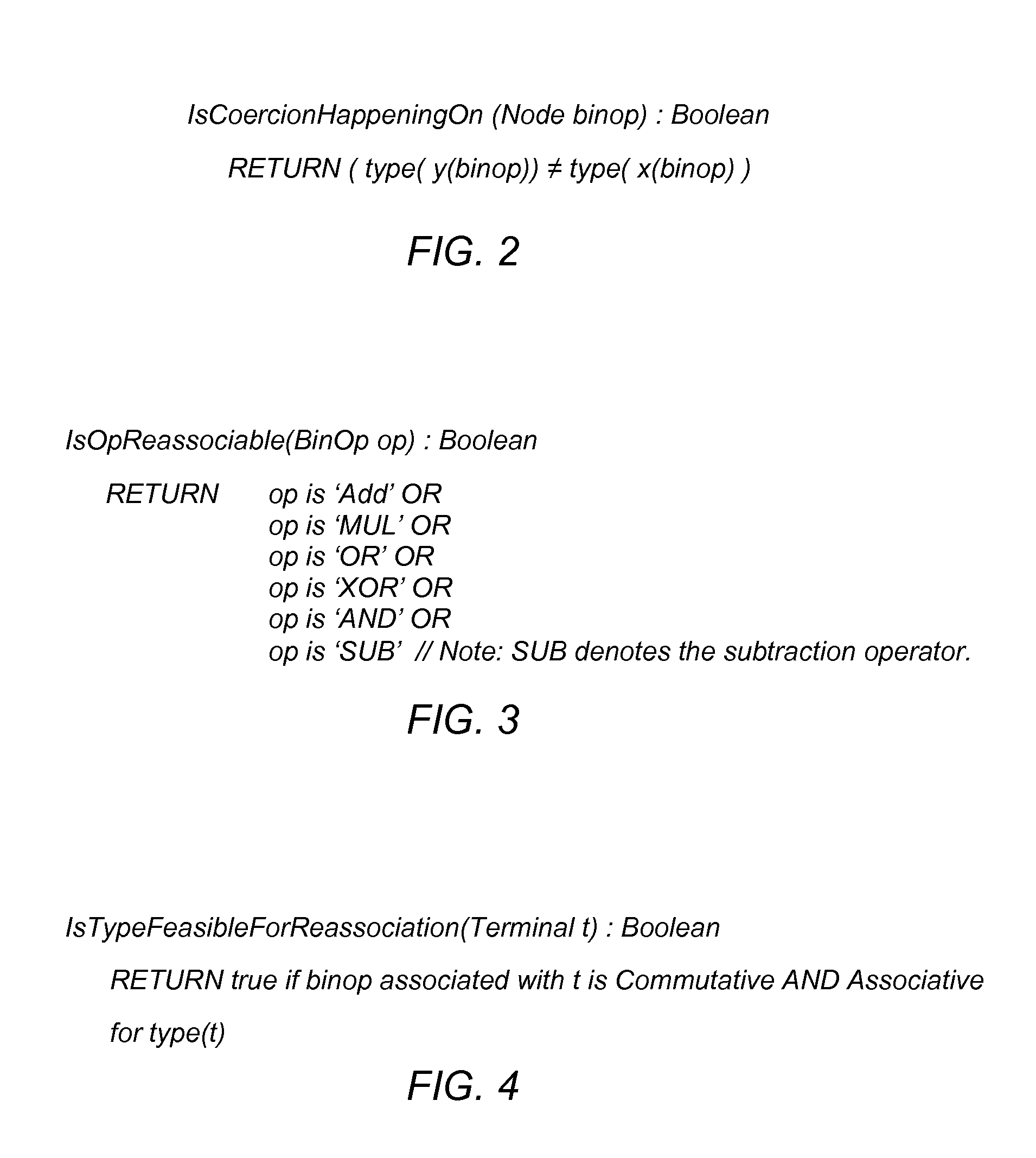

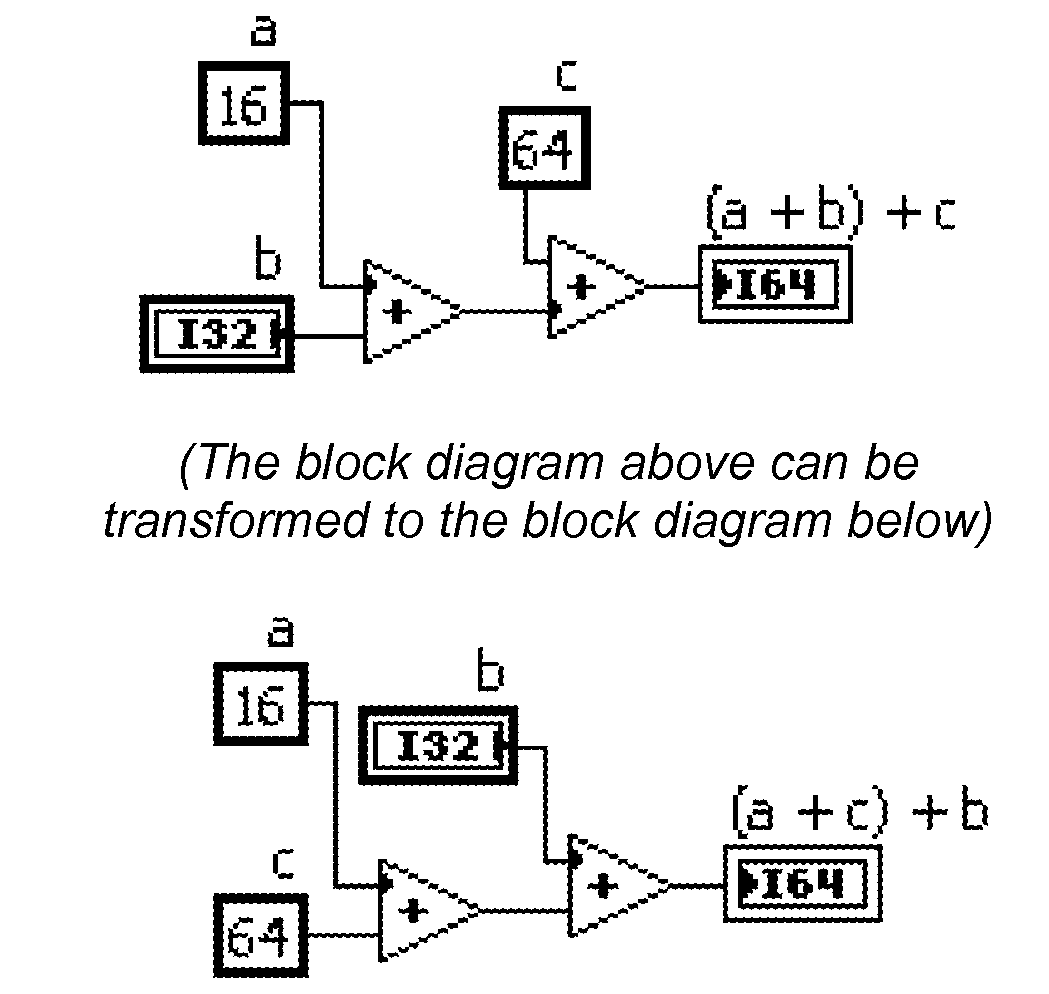

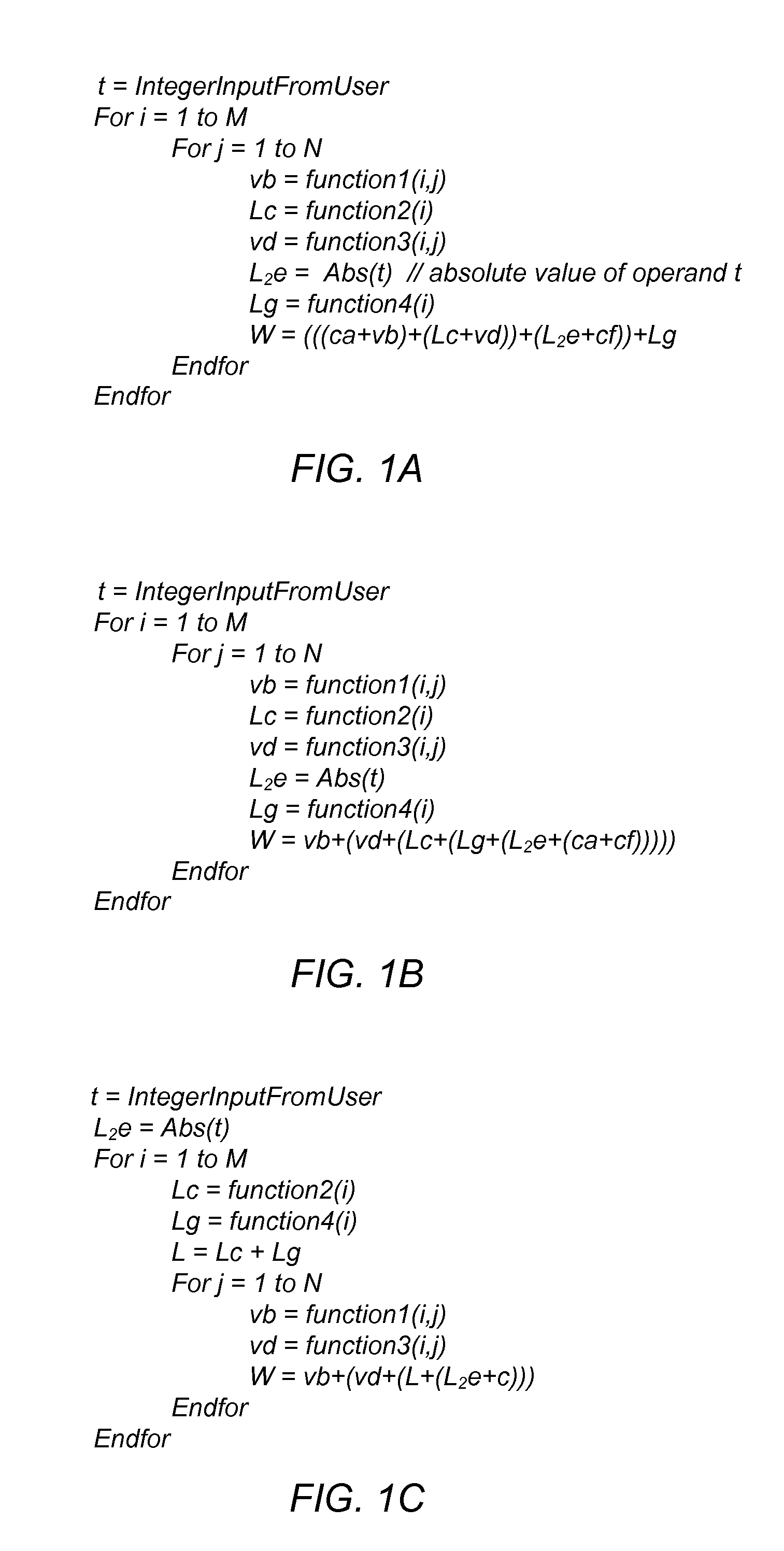

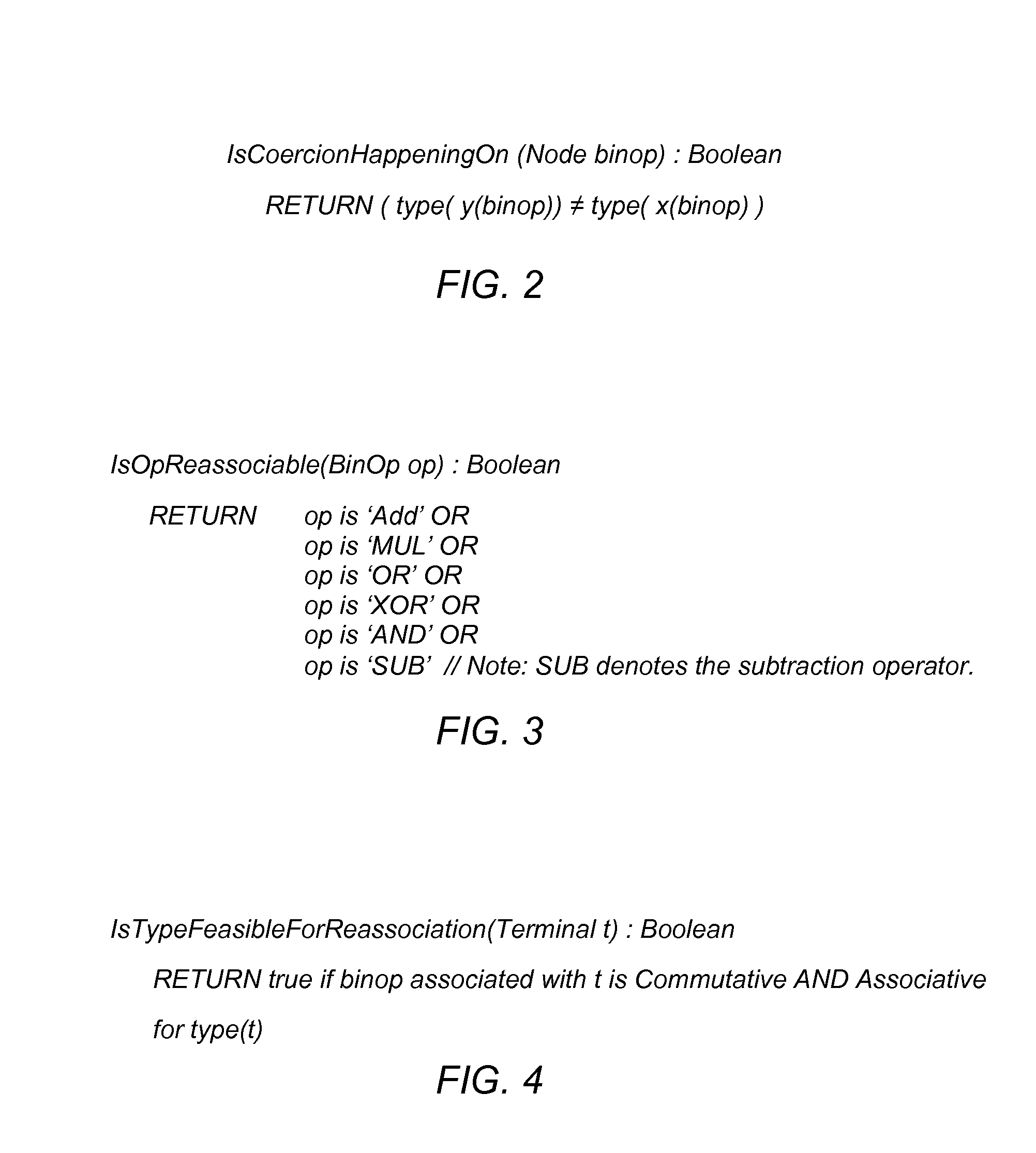

Rearrangement of algebraic expressions based on operand ranking schemes

ActiveUS9098307B2Software engineeringSpecific program execution arrangementsAlgebraic transformationsArray data structure

A system and method for rearranging algebraic expressions occurring in program code based on a scheme of ranking operands. The system scans program code to identify an algebraic expression specified by the program code. The expression includes binary operations, scalar operands and at least one array operand. The system operates on the algebraic expression to obtain a final expression by: computing a rank for each of the operands; and performing algebraic transformations on selected subexpressions of the algebraic expression so that in the final expression operands are combined in the order of their rank. The ranking scheme may be designed to force scalars to be combined before arrays, and / or, to force constants to be combined first, loop invariants second, and variants last. In some embodiments, the ranking scheme is a vector ranking scheme including two or more components (such as invariance rank, dimensional rank and data-size rank).

Owner:NATIONAL INSTRUMENTS

Rearrangement of Algebraic Expressions Based on Operand Ranking Schemes

A system and method for rearranging algebraic expressions occurring in program code based on a scheme of ranking operands. The system scans program code to identify an algebraic expression specified by the program code. The expression includes binary operations, scalar operands and at least one array operand. The system operates on the algebraic expression to obtain a final expression by: computing a rank for each of the operands; and performing algebraic transformations on selected subexpressions of the algebraic expression so that in the final expression operands are combined in the order of their rank. The ranking scheme may be designed to force scalars to be combined before arrays, and / or, to force constants to be combined first, loop invariants second, and variants last. In some embodiments, the ranking scheme is a vector ranking scheme including two or more components (such as invariance rank, dimensional rank and data-size rank).

Owner:NATIONAL INSTRUMENTS

Cutting line on glass sheet providing apparatus

InactiveCN101842326ASmooth liftFine working devicesGlass severing apparatusForce constantMechanical engineering

The invention provides a cutting line on glass sheet providing apparatus. A device for scoring a glass sheet applies a score line for cutting to the glass sheet conveyed on conveyance rollers. The device has a cutter for applying a score line to a glass sheet, ball slide means capable of lifting and lowering the cutter while following vertical movement of the glass sheet conveyed and, when the cutter is pressed against the surface of the glass sheet, maintaining pressing force constant by absorbing excessive pressing force, a spring for applying appropriate cutter pressure to the surface of the glass sheet, and pressing means for pressing an arm to a position on the surface of the glass sheet, the arm supporting the ball slide means, the spring, and the cutter.

Owner:CENT GLASS CO LTD +1

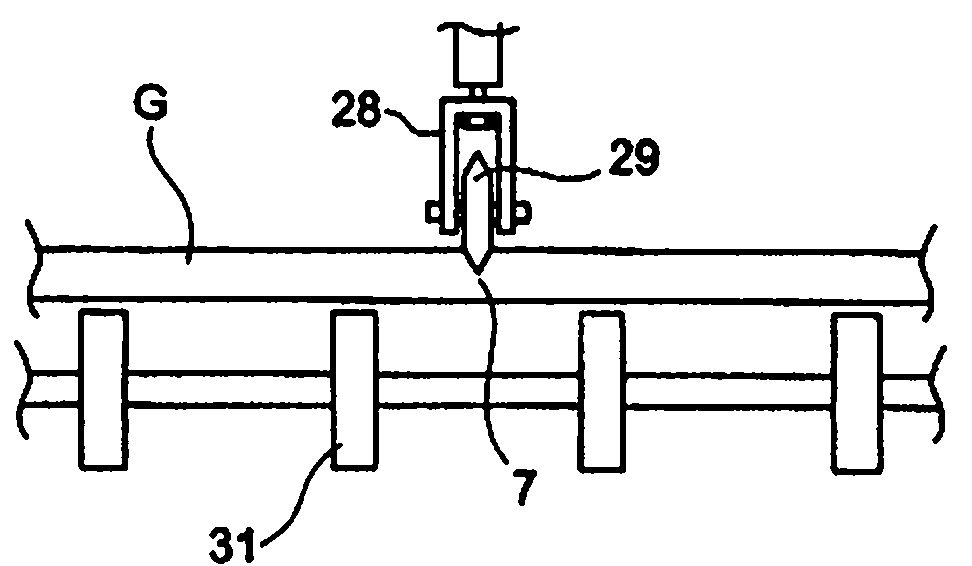

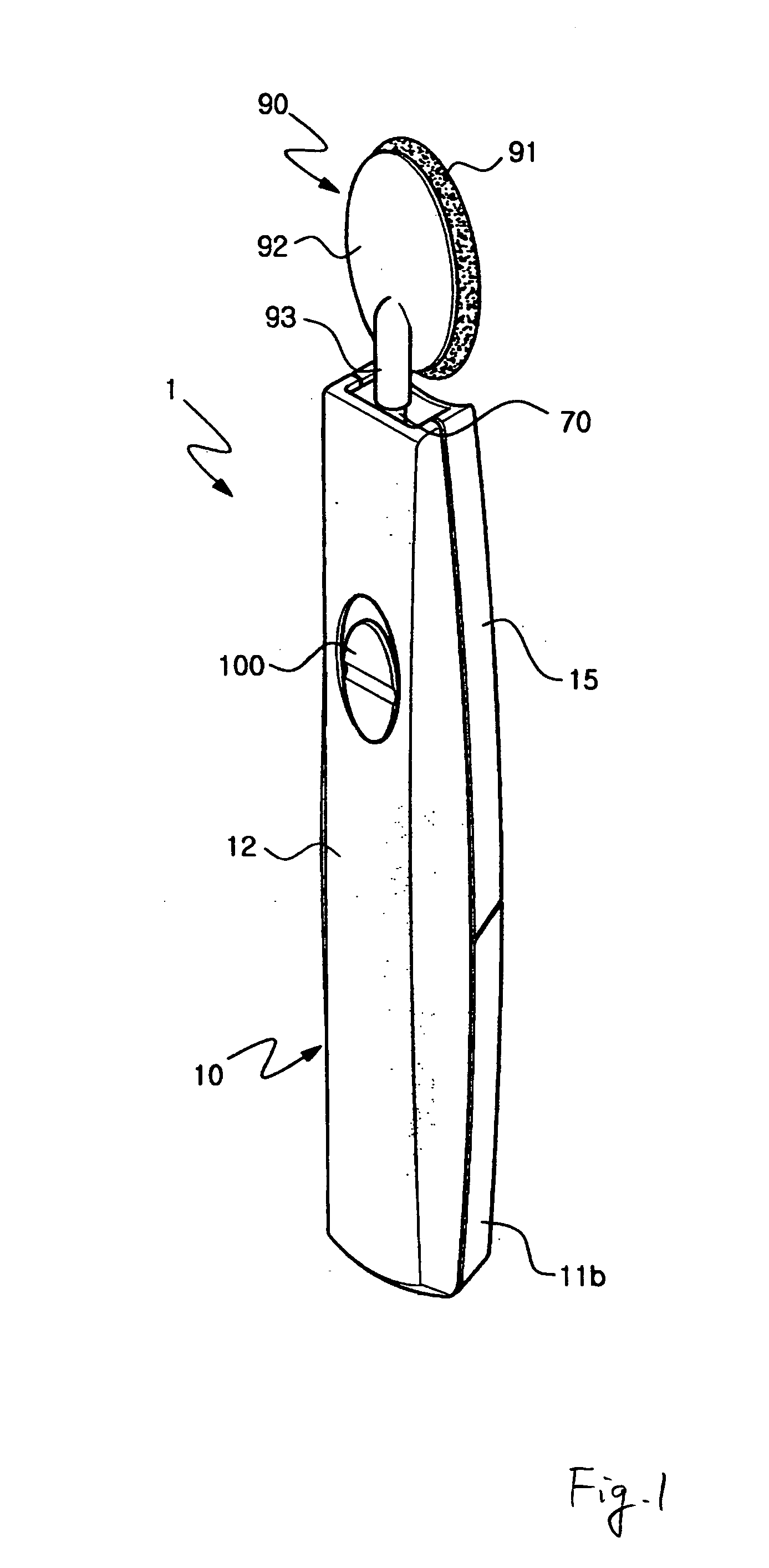

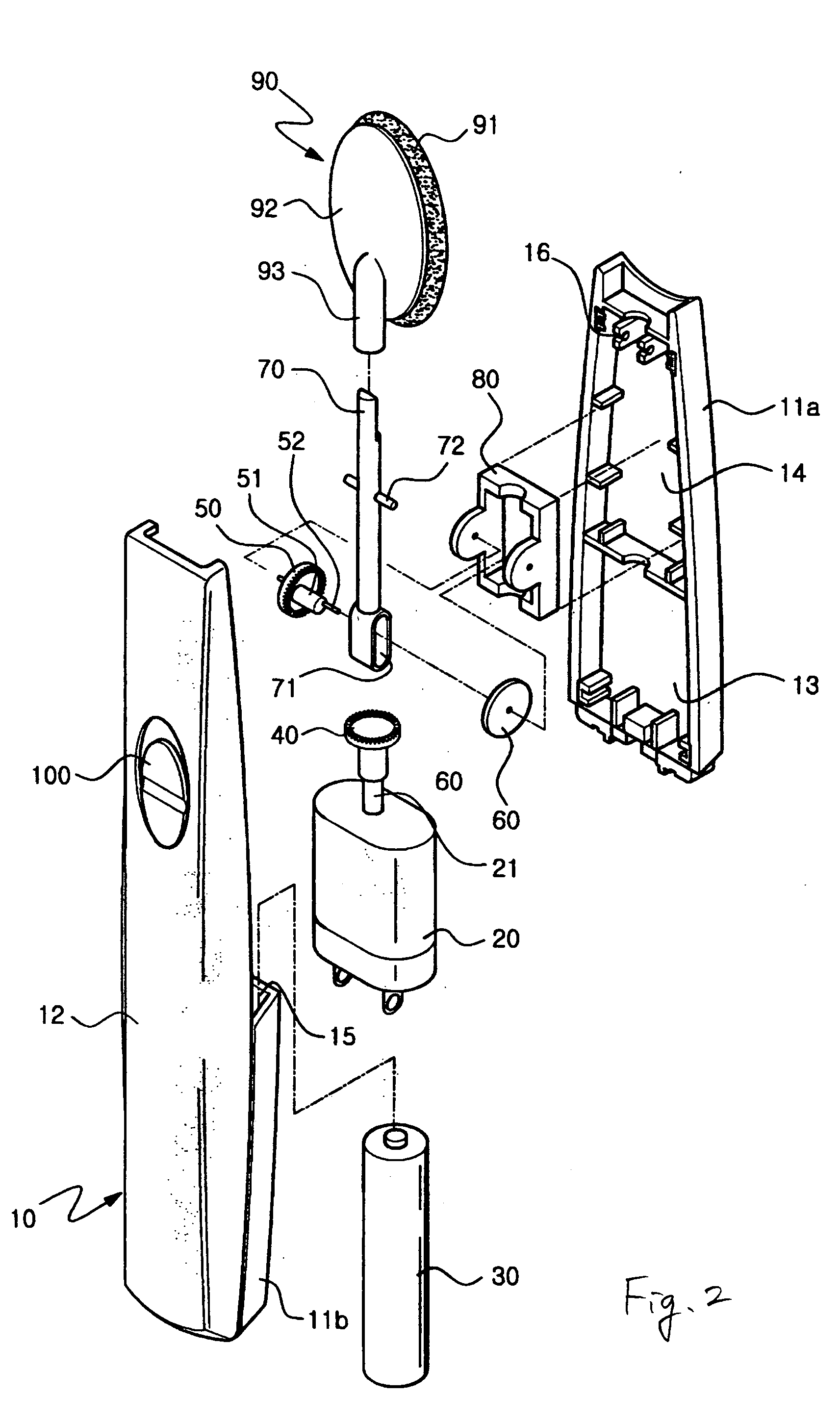

Electric puffs

InactiveUS20060021169A1Evenly and rapidly applyConstant forceLiquid processingCarpet cleanersConstant forceForce constant

Disclosed herein is an electric puff, intended to rapidly and easily apply various types of cosmetics to a desired body part. A conventional puff is problematic in that a user must dab a surface covered with a cosmetic on a desired body part by hand, so that it is very complicated to do a user's makeup, and besides, it is difficult to keep a user's force constant, so that the cosmetic may not be evenly applied to the desired body part. The electric puff of this invention is constructed so that an actuating shaft is swingably coupled to an electric motor installed in a handle-shaped casing via a drive gear and a conversion gear and a puff head is coupled to an upper end of the actuating shaft, thus allowing a cosmetic to be evenly applied to a desired body part with a constant force although a user does not reciprocate the puff by hand, therefore allowing the user to rapidly and easily put on makeup, and allowing the cosmetic to be effectively applied to the desired body part.

Owner:CHOO YOON JEONG

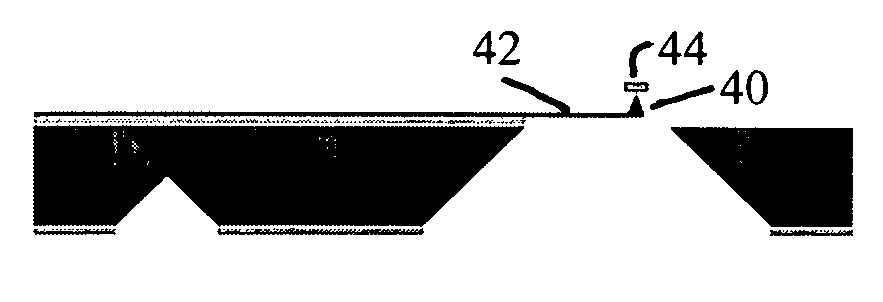

Short and thin silicon cantilever with tip and fabrication thereof

ActiveUS7637960B2Low force constantRaise the resonance frequencyNanotechSemiconductor/solid-state device manufacturingManufacturing technologyForce constant

Thin and short cantilevers possess both a low force constant and a high resonance frequency, thus are highly desirable for atomic force microscope (AFM) imaging and force measurement. According to some embodiments, the invention provides small silicon (Si) cantilevers integrated with a Si tip, for example fabricated from SOI wafers that are used for reducing the variation of thickness of the cantilevers. In one example, the fabrication process provided SOI chips containing 40 silicon cantilevers integrating with an ultra-sharp Si tip. The resolution of images obtained with these tips was much higher than those obtained with the commercial tips, while the force constants were much less, that is, more suitable for imaging soft samples. The availability of such SOI chips greatly facilitates large scale modification of the surfaces of the silicon cantilever tips with a monolayer of oligo(ethylene glycol) derivatives that resist the non-specific interactions with proteins, rendering them most suitable for imaging and measurement of biological samples.

Owner:UNIV HOUSTON SYST

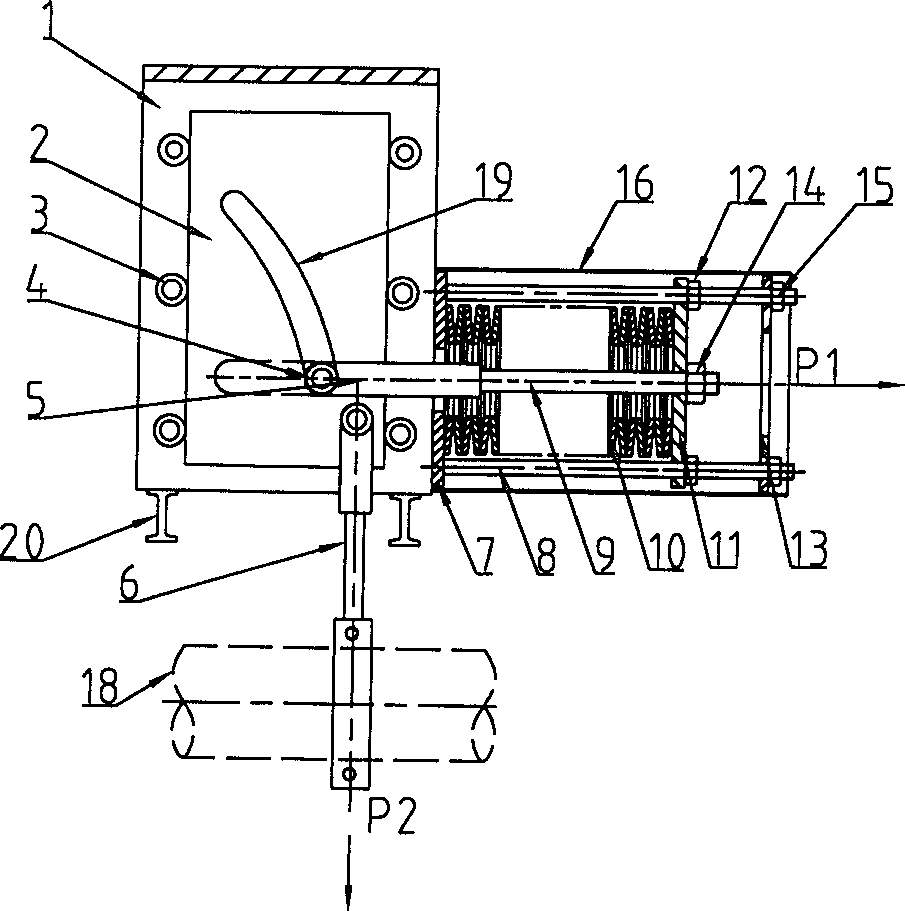

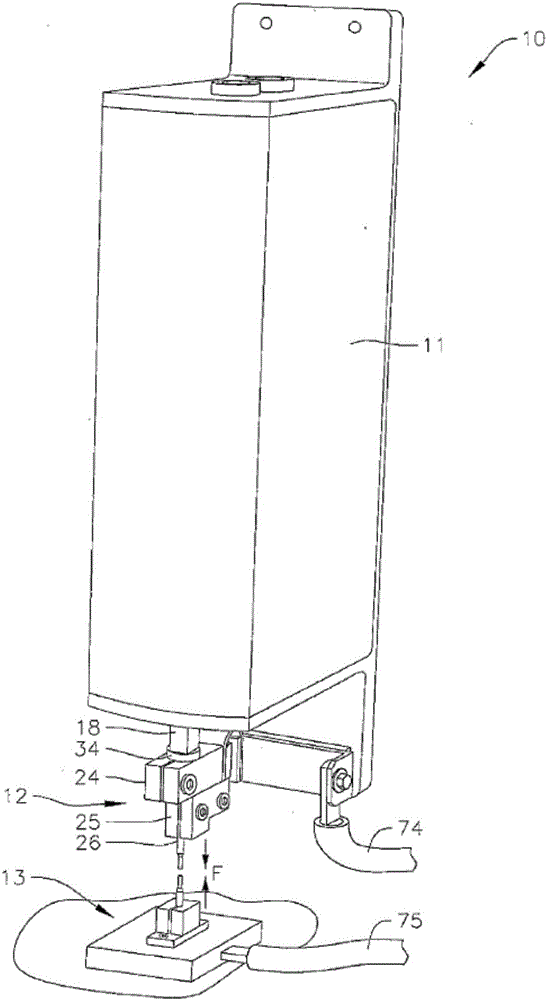

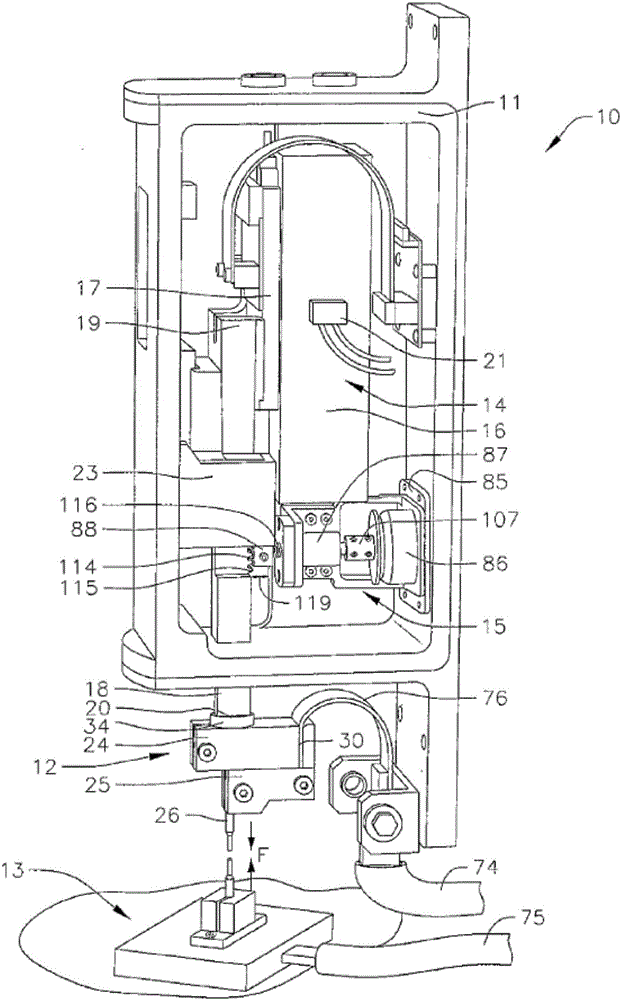

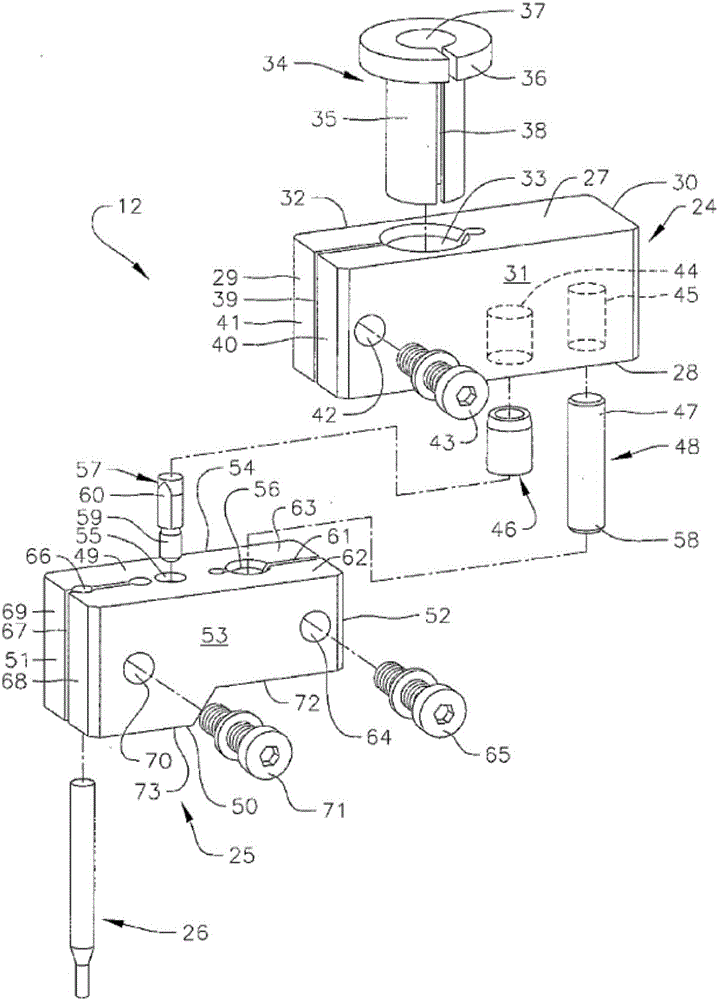

Weld head

A weld head for spot welding two or more components together. The weld head includes first and second electrode assemblies and a linear actuator motor to drive the first electrode assembly into a desired position and apply a desired clamping force. The weld head may include a sensor configured to measure a temperature of the motor and a controller configured to monitor the temperature and adjust the current supplied to the motor to maintain the desired clamping force. The weld head may include linear encoder to measure the position of the linear actuator motor and an algorithm that correlates the position of the motor with a force constant of the motor. Based on the position of the motor and the corresponding force constant of the motor, the controller is configured to adjust the current supplied to the motor to maintain the desired clamping force.

Owner:MIYACHI AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com