Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Short welding cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

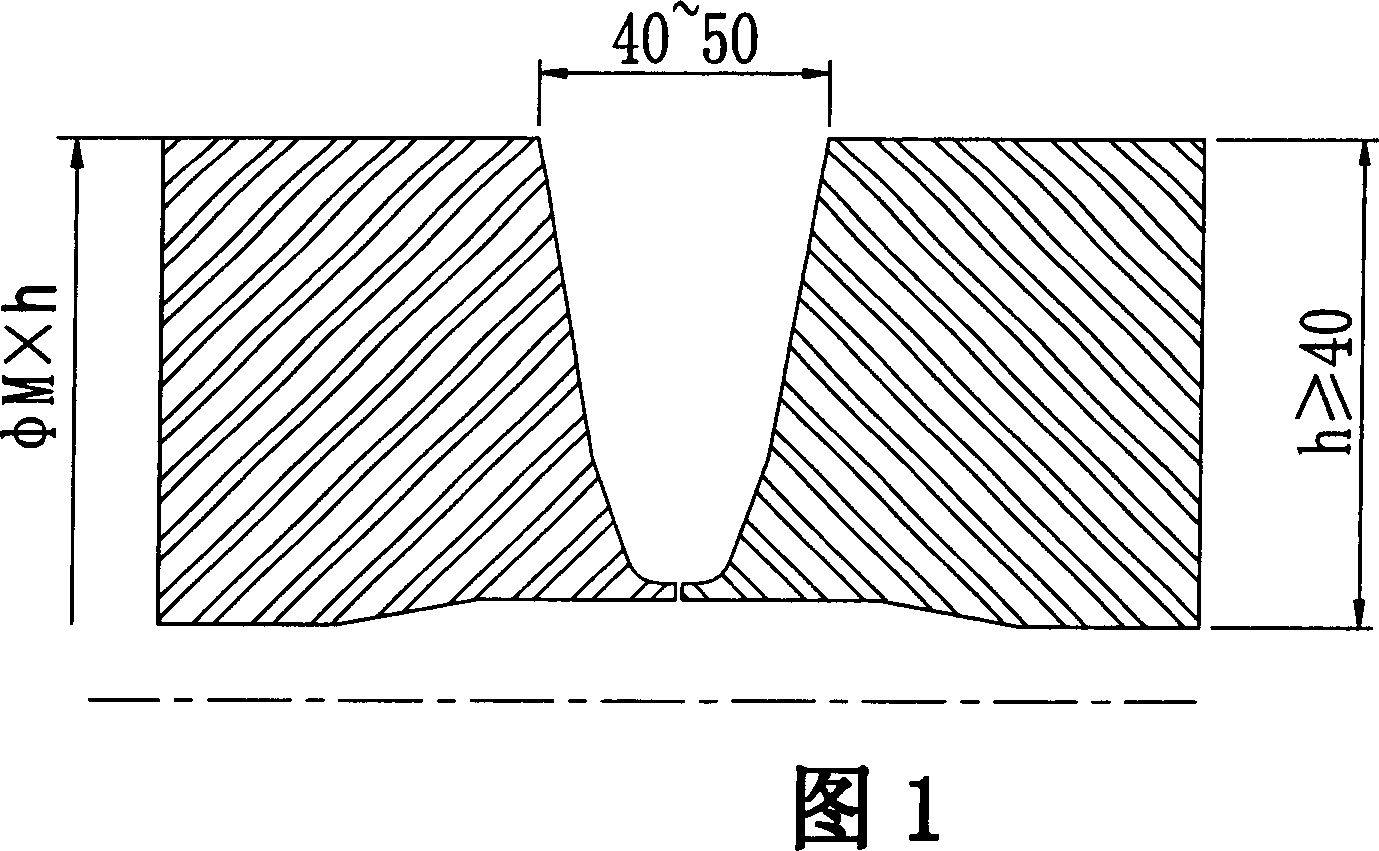

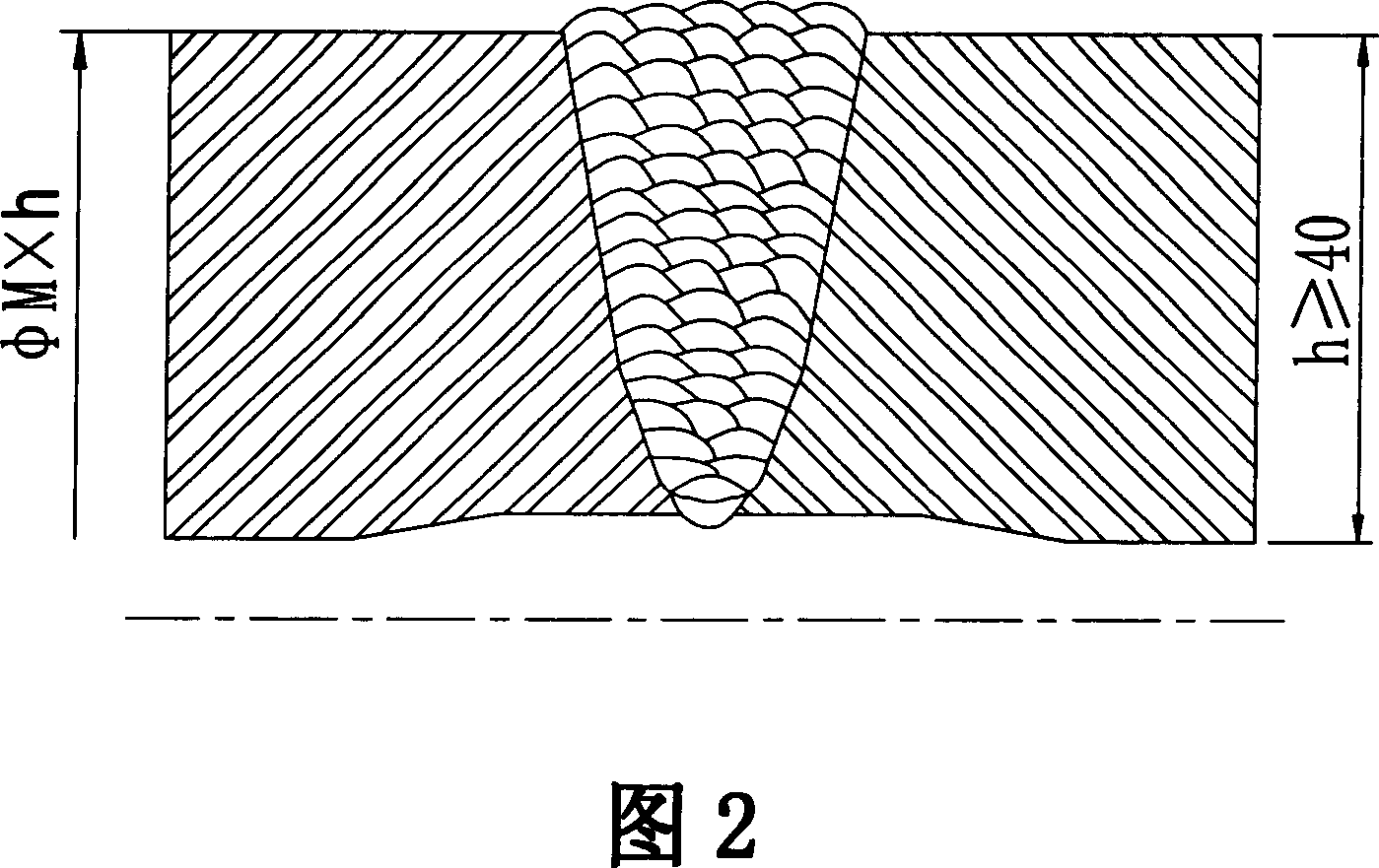

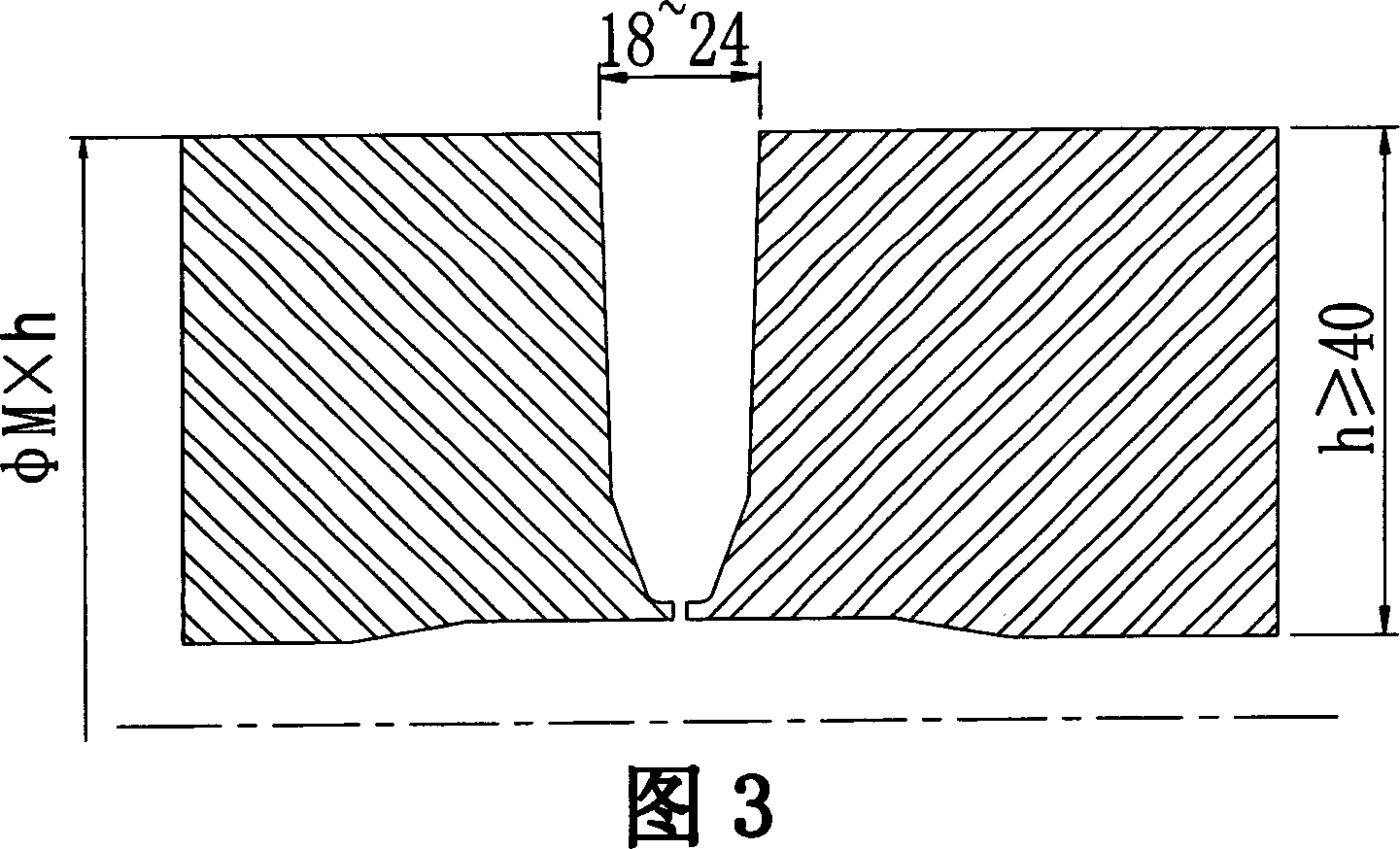

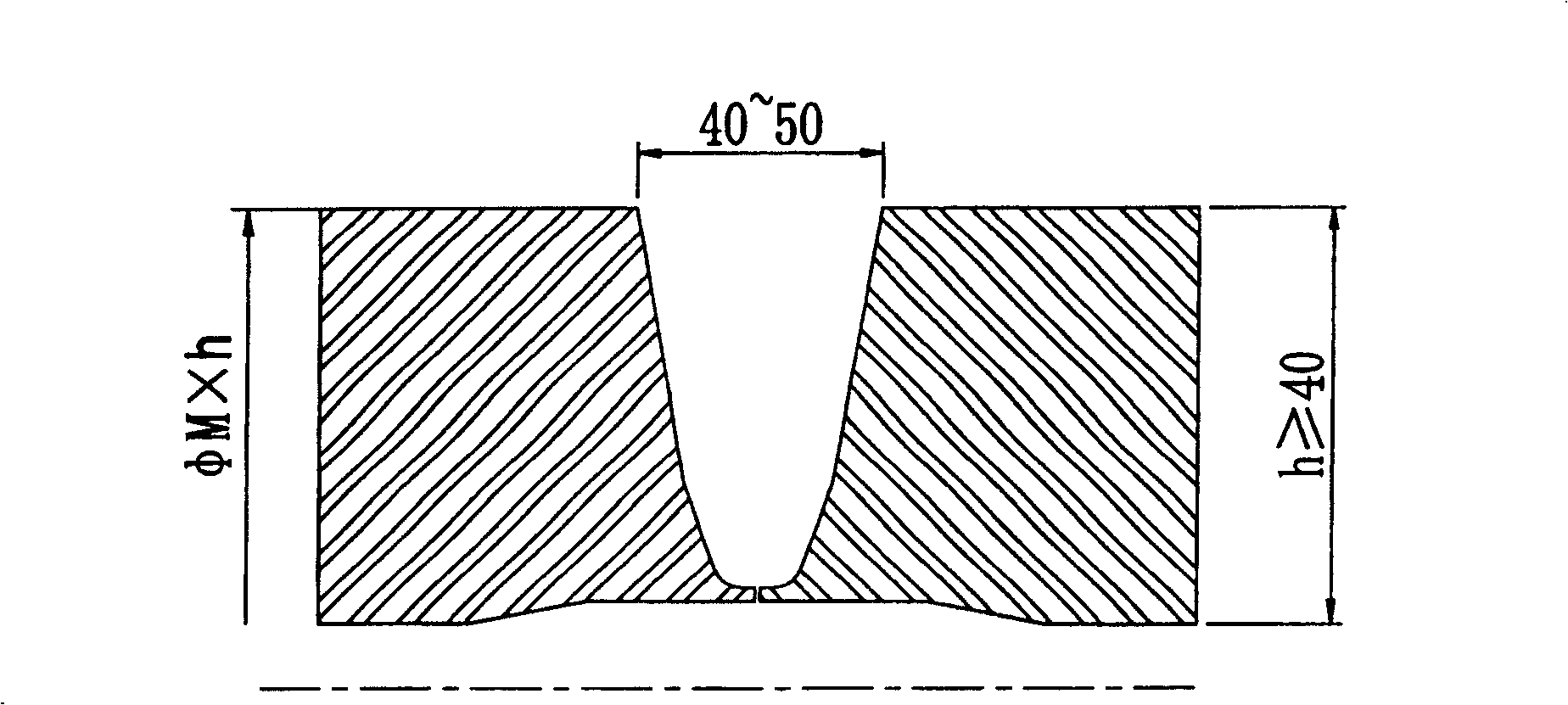

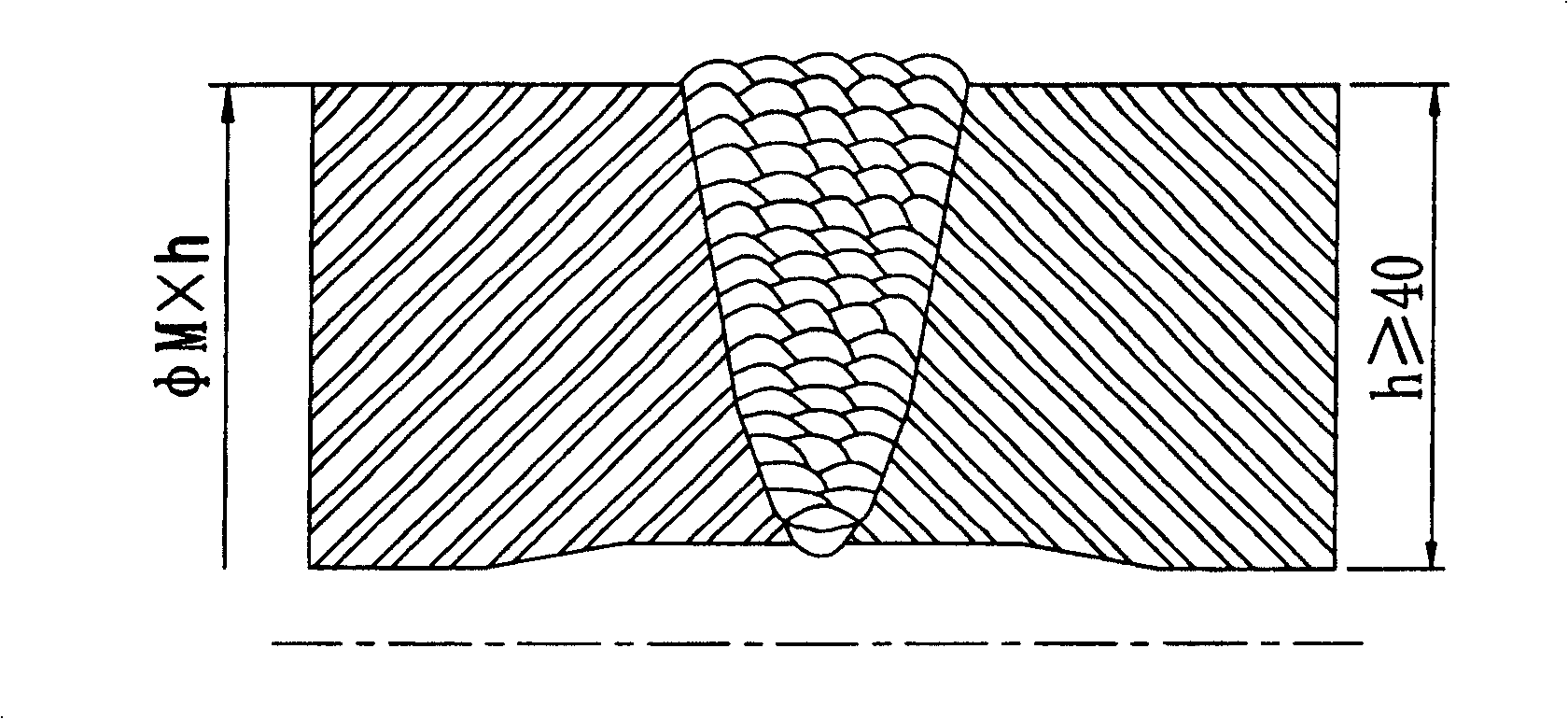

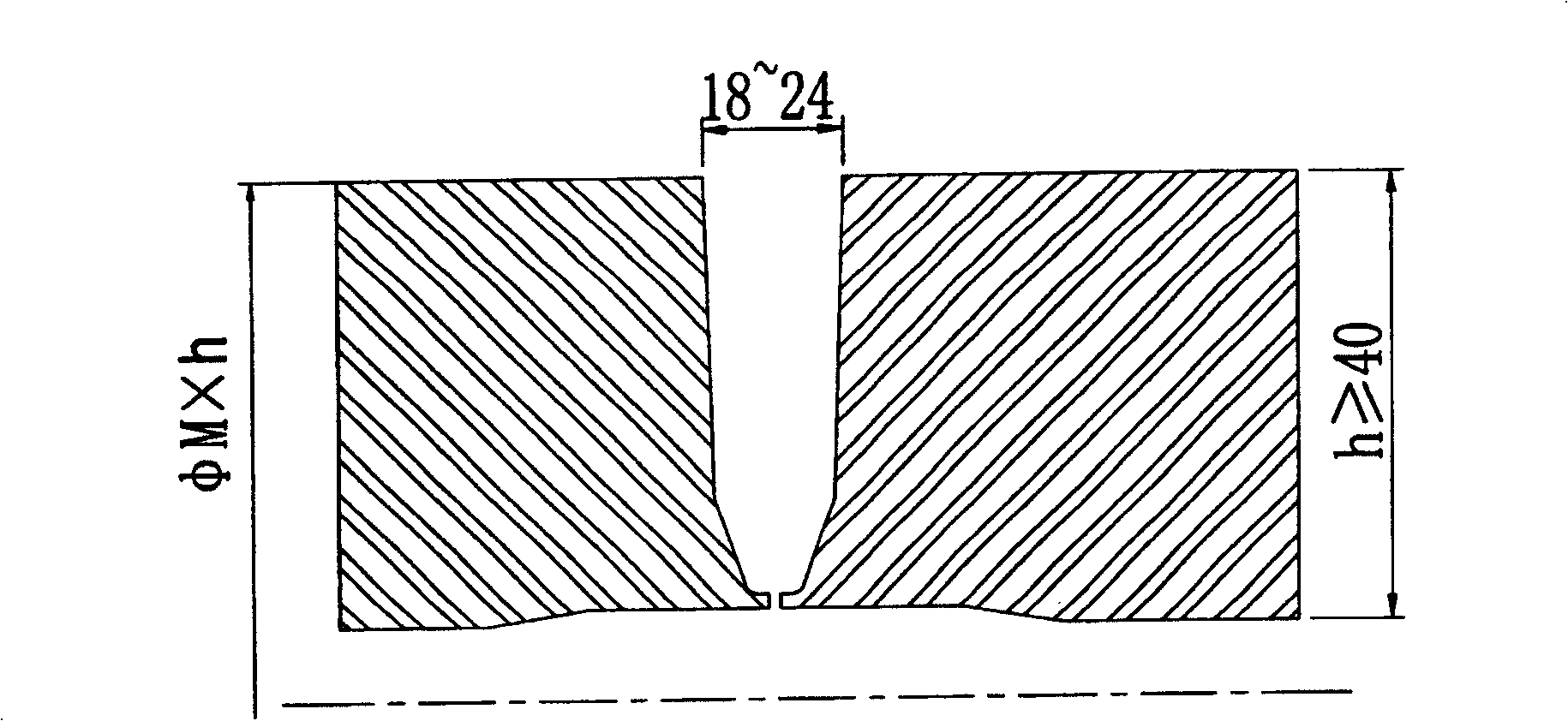

Large posted sides pipeline narrow gap tungsten electrode noble gas protecting all-position automatic soldering method

ActiveCN101077547AReduce fillingReduce welding costsArc welding apparatusWelding/cutting media/materialsNoble gasEngineering

The present invention relates to inert gas protected automatic narrow gap tungsten electrode welding process for large thick pipe with diameter over 325 mm and thickness over 40 mm. The automatic welding process includes forming combining chamfer in the opposite ends to be welded before welding, bottoming welding, single layer filling welding, and covering welding in linear or swinging weld pass. The process has less filled deposited metal, low welding cost, high welding efficiency and other advantages.

Owner:CHINA NUCLEAR IND 23 CONSTR

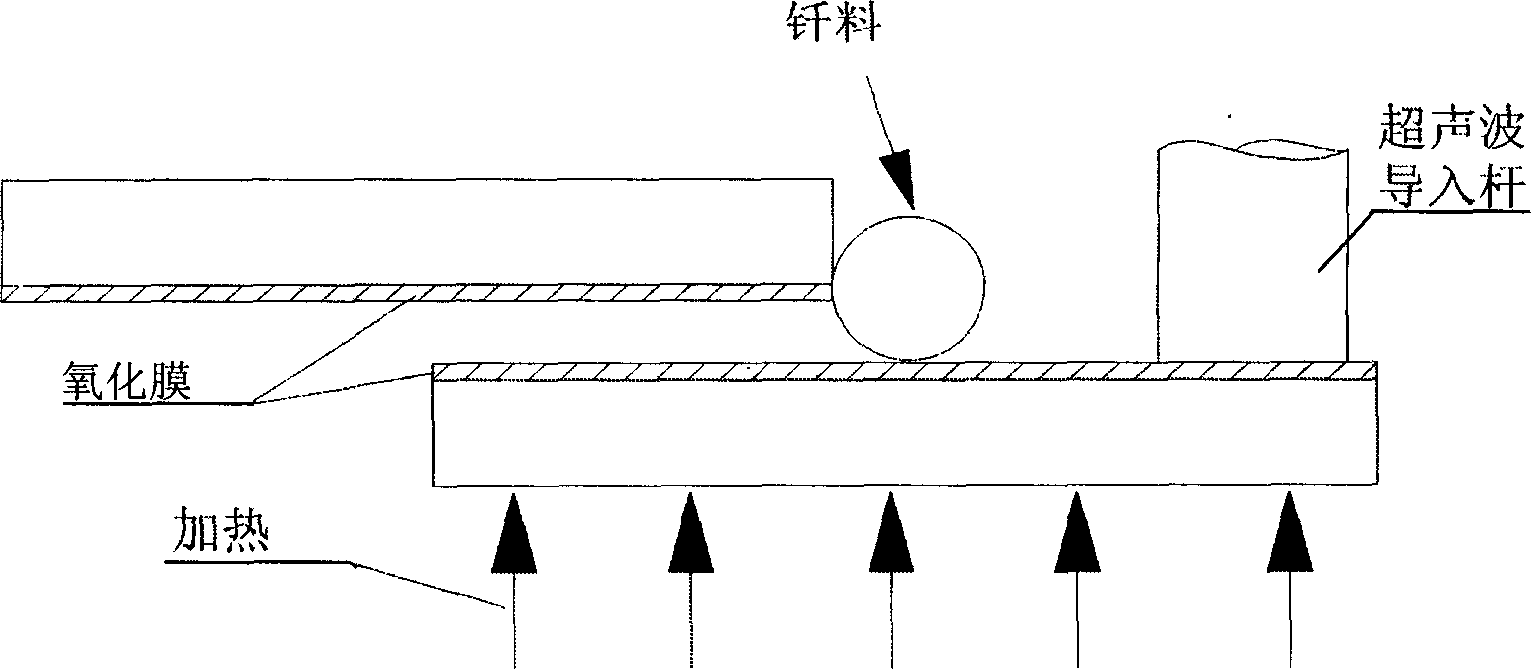

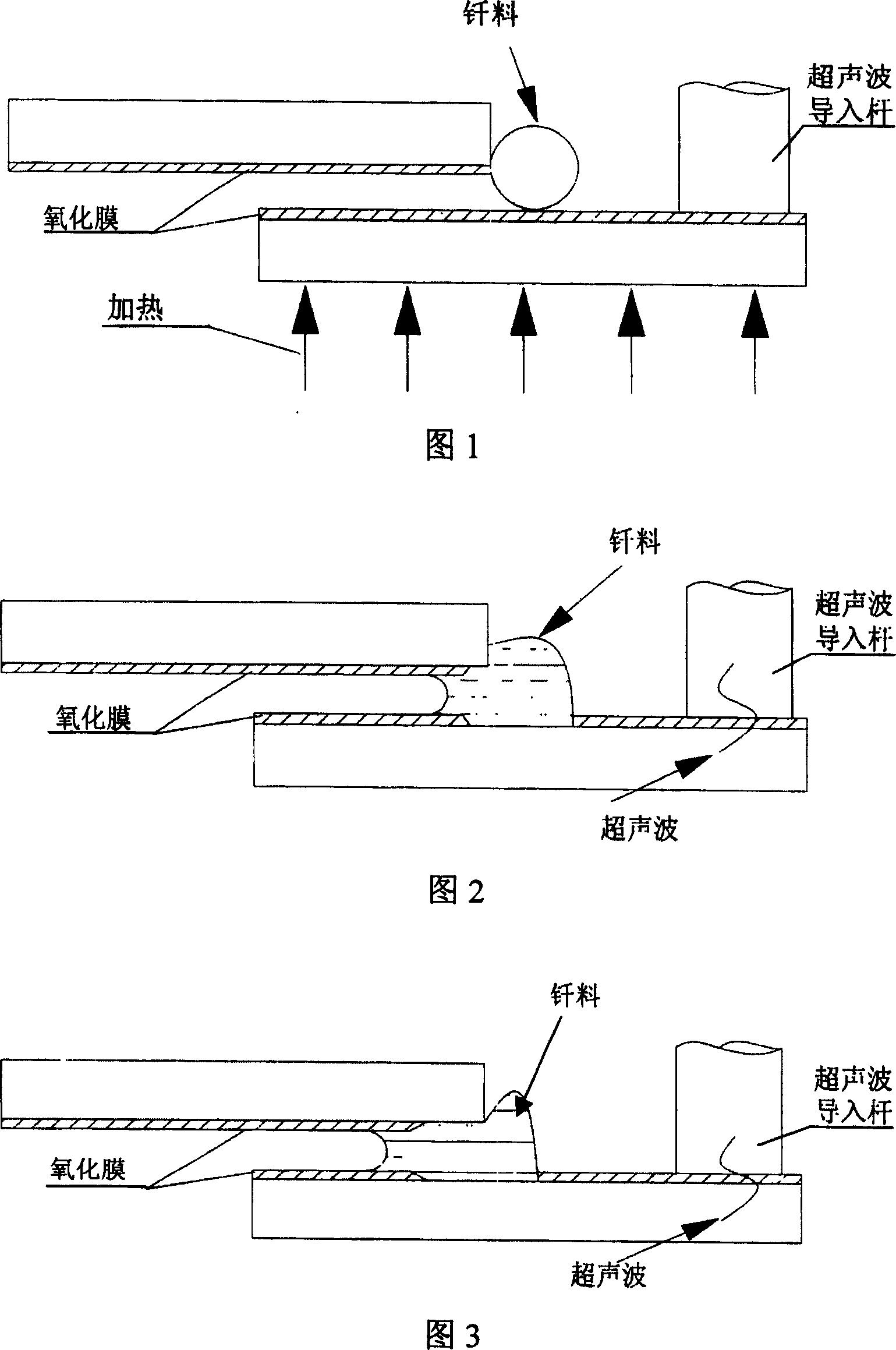

Aluminium base composite material ultrasonic wave fine welding method

InactiveCN1644291AAvoid WeldingEfficient weldingNon-electric welding apparatusUltrasonic vibrationMaterials science

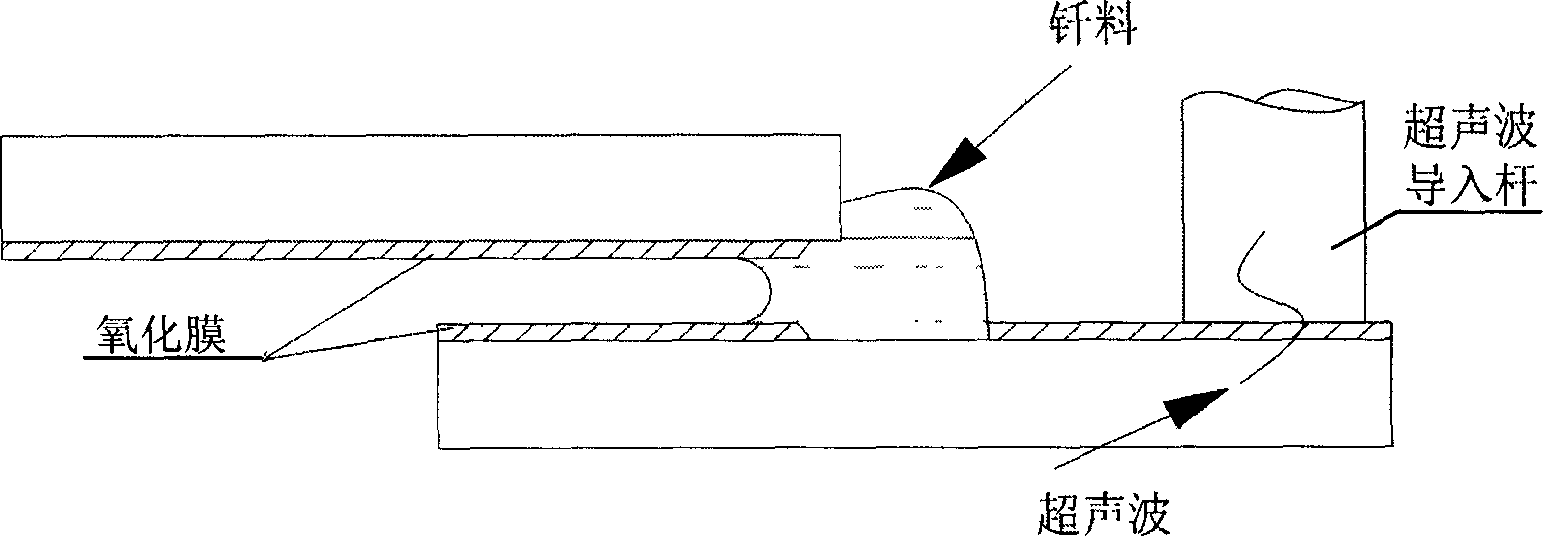

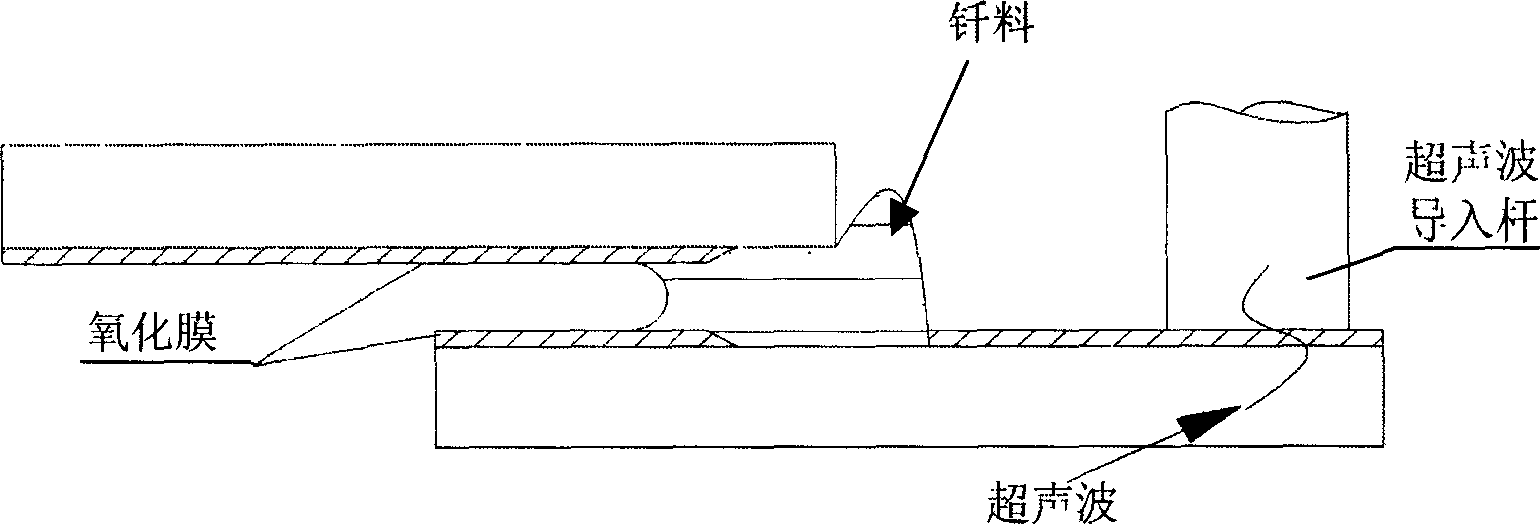

An ultrasonic capillary welding method for the Al-base composite material includes such steps as arranging upper and lower parts to be welded in such manner that the gap between them is 10-300 microns, putting the flux close to lap end, heating to smelt the flux, holding the temp, pressing the ultrasonic head onto surface of the part to be welded, and applying ultrasonic vibration for 0.5-15 S. Its advantages are high welding quality, low welding temp, and high speed.

Owner:HARBIN INST OF TECH

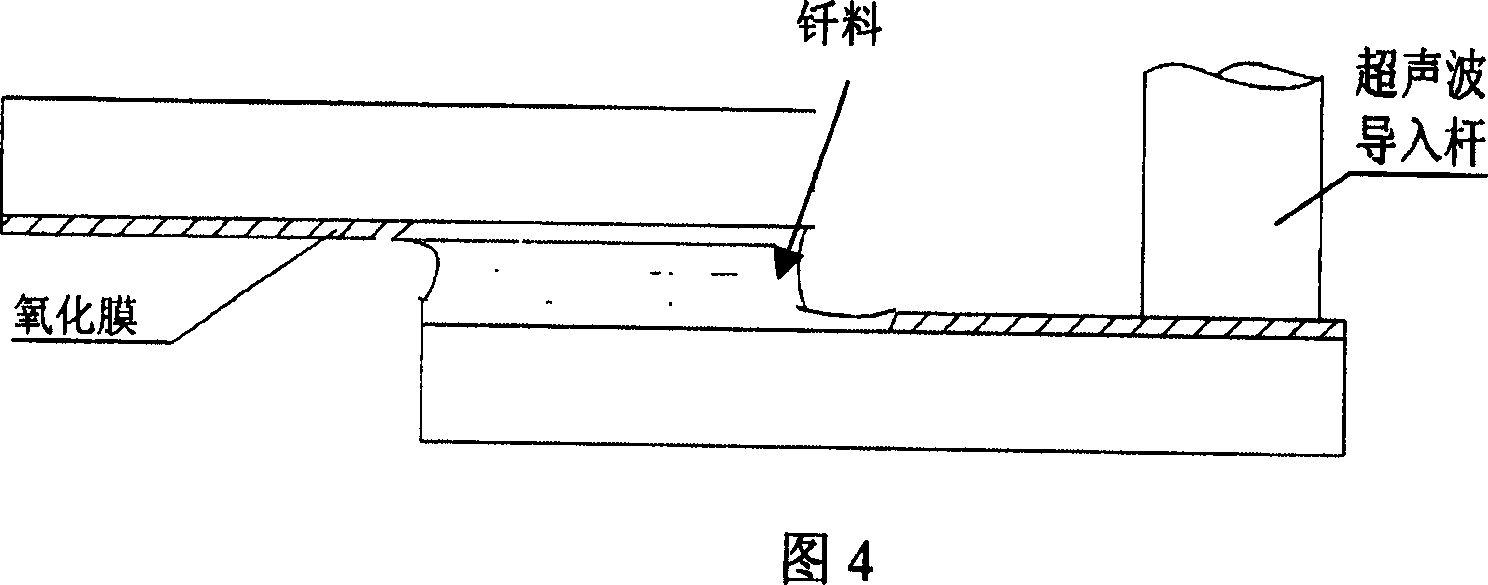

Process of obtaining composite brazed seam with ultrasonic brazed aluminium-base composite material

InactiveCN101088691ARealize weld compoundingRealize the structureWelding/cutting media/materialsWelding/soldering/cutting articlesBraze alloyUltrasonic vibration

The present invention relates to relates to welding method, and is especially ultrasonic brazing process of obtain composite brazed seam in aluminum-base composite material. The process includes the following steps: 1. filling brazing alloy; 2. primary brazing; and 3. ultrasonic vibration treatment to obtain composite brazed seam in aluminum-base composite material. The said brazing process can obtain brazed joint with greatly improved mechanical performance and heat expansion performance, low heat expansion coefficient, and high strength near that of the mother material.

Owner:HARBIN INST OF TECH

Non-metallic material and metal material brazing method capable of forming interpenetrating network structure brazing seams

ActiveCN103990880AReduce residual stressHigh strengthSoldering apparatusNetwork structureMetallic materials

The invention relates to a brazing method for a non-metallic material and a metal material, in particular to a non-metallic material and metal material brazing method capable of forming interpenetrating network structure brazing seams. The problem that large residual stress exists on a joint welded through the brazing method for the non-metallic material and the metal material is solved. The method comprises the steps that grinding is carried out through abrasive paper; acetone is used for cleaning; the materials are overlapped according to a certain sequence; welding is carried out, and the materials are placed in a vacuum brazing furnace to be welded. The brazing method is used for brazing of the non-metallic material and the metal material.

Owner:HARBIN INST OF TECH

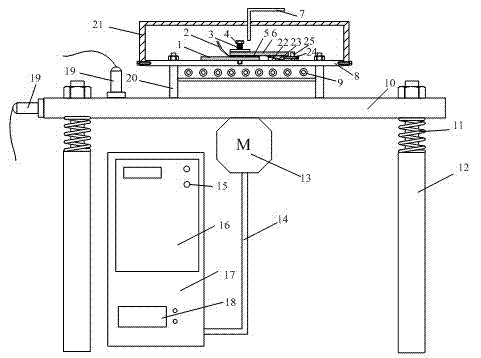

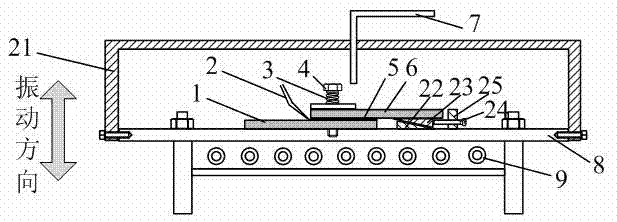

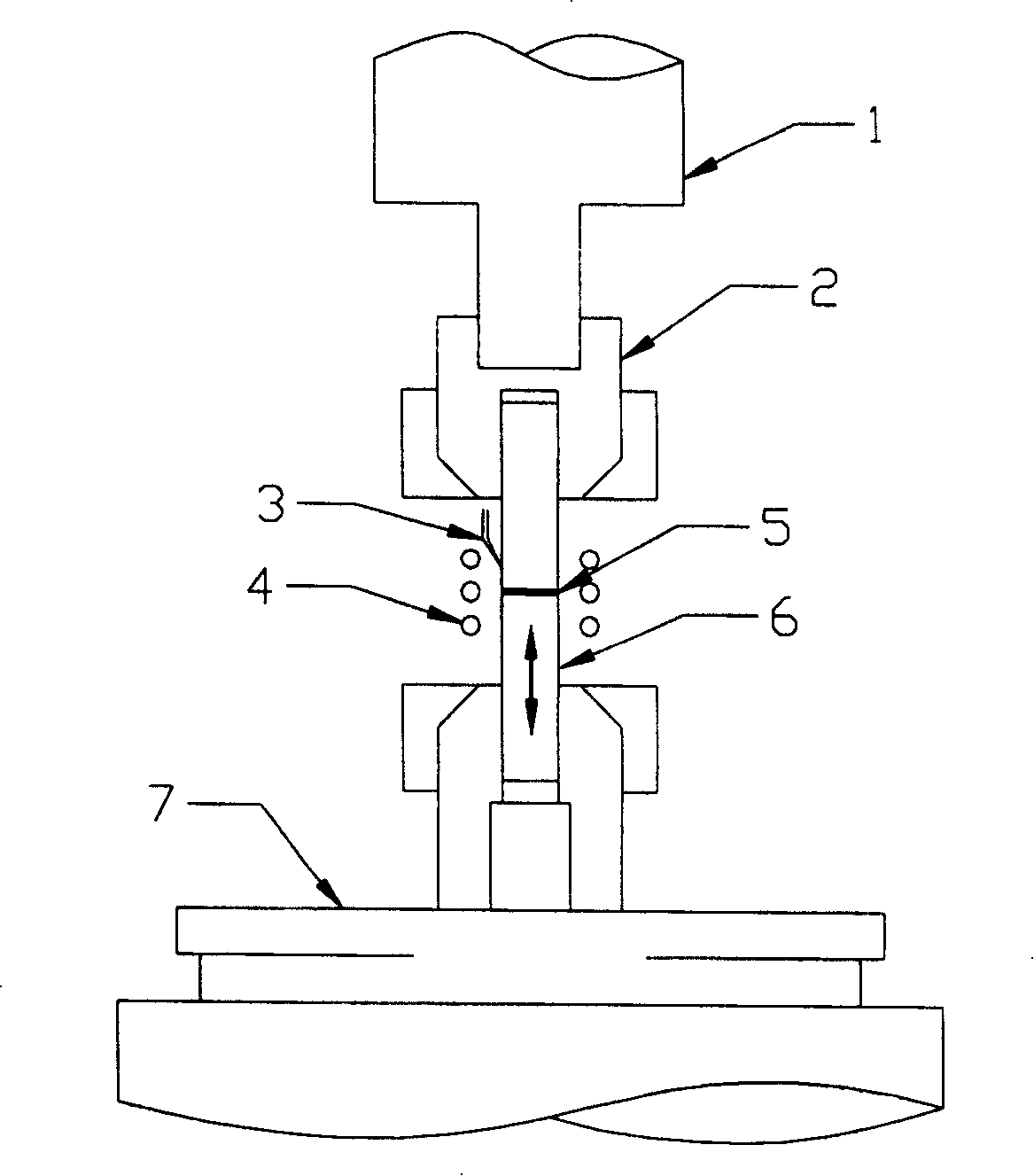

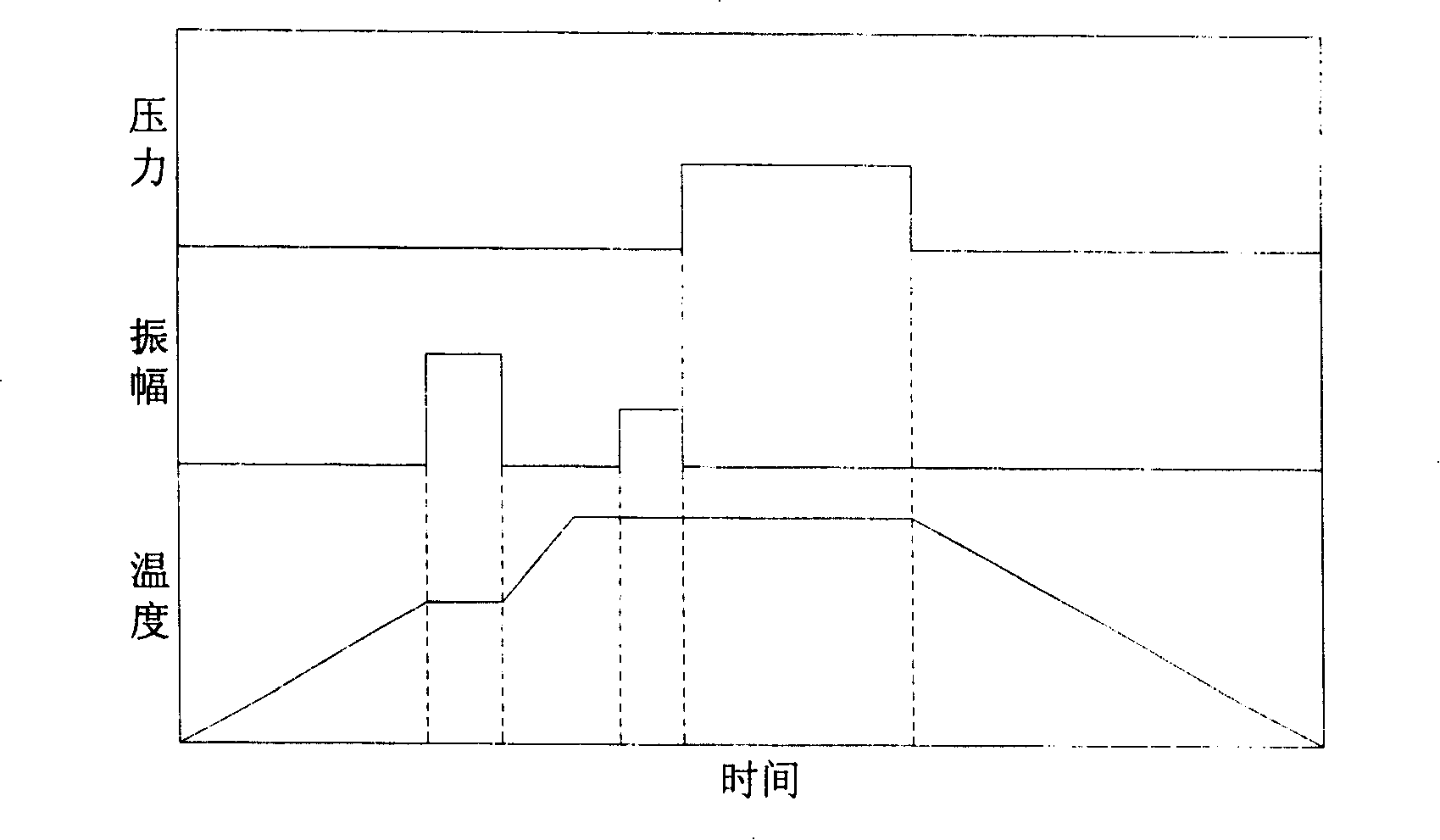

Heterogeneous semi-solid brazing method of aluminum alloy and magnesium alloy assisted by external vibration energy

InactiveCN102266994AAvoid serializationEfficient weldingSoldering apparatusRoom temperatureSemi solid

The invention provides a heterogeneous semi-solid brazing method for an aluminum alloy and a magnesium alloy under assistance of external vibration energy. According to the invention, the method comprises the following steps of: clamping an aluminum alloy weld member and a magnesium alloy weld member on a fixture and placing medium-temperature brazing filler metals of a Zn-Al or Al-Si series on two surfaces to be welded, wherein the brazing filler metals can be of flaky shapes or foil shapes, can be plating layers or can be sprayed on the surfaces to be welded in advance; heating the weld members so that the middle layer of brazing filler metal is in a semi-solid state; adjusting the pressure to be matched with the amplitude of the applied vibration; starting a vibrating device with amplitude of 0.01-2mm, wherein the brazing filler metals vibrate along with the two weld members, and the vibration time is 0.5-3 minutes according to actual requirements; stopping the vibration; and cooling the weld members to room temperature by air, wherein a certain pressure of 0.1-5 Mpa is always applied in the brazing process. According to the invention, high-efficiency, high-quality and economic connection between the aluminum alloy and the magnesium alloy can be realized.

Owner:CHONGQING UNIV OF TECH

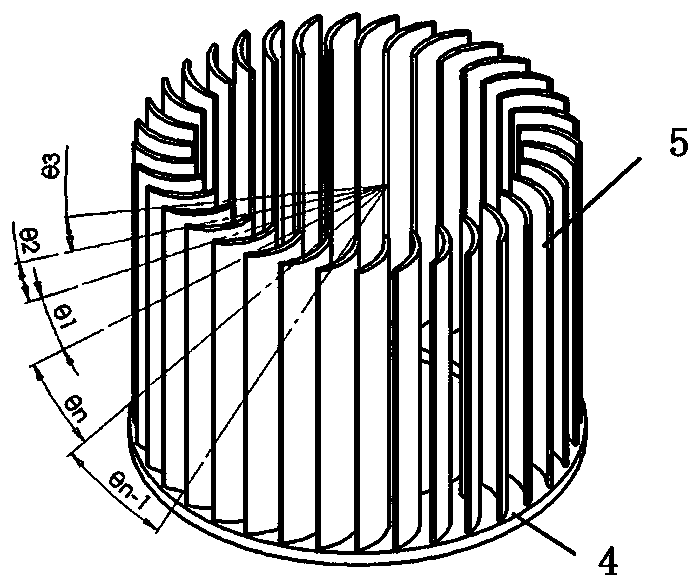

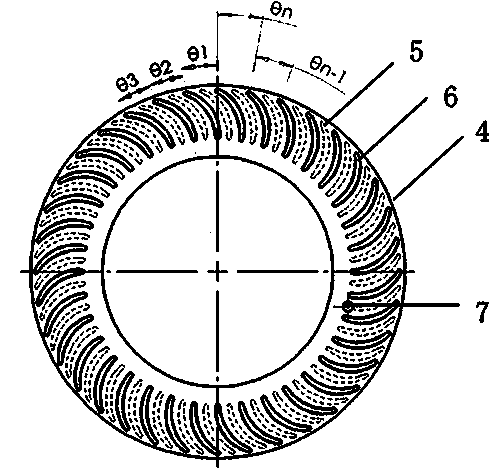

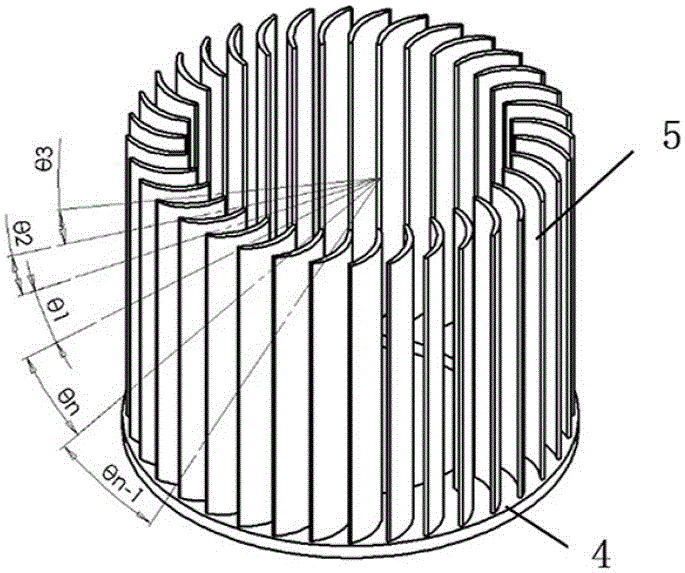

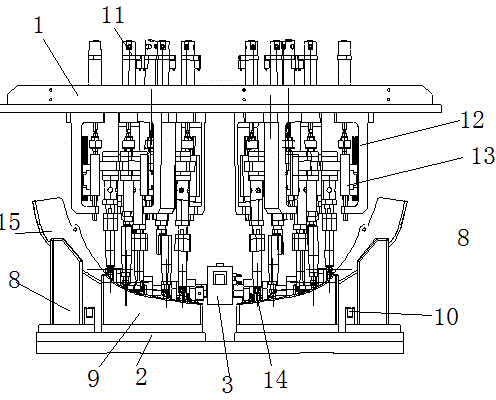

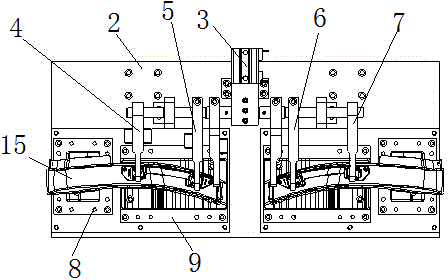

Cross-flow fan blade welding robot

The invention discloses a cross-flow fan blade welding robot. The cross-flow fan blade welding robot comprises a material distribution and conveying module, a material grabbing mechanical arm, a pre-positioning module, a feeding module, an ultrasonic welding machine and a material receiving module; the welding robot is used for conveying a workpiece to the material grabbing mechanical arm through the material distribution and conveying module and is primarily shaped and self-centered through being clamped by three clamping claws; then the workpiece is conveyed into the pre-positioning module to realize eight-clamping-claw clamped self-centering and rotary alignment of positioning marks; four-clamping-claw clamped self-centering, compensation of translation errors and rotary angle errors, and blade embedment of soft landing and rotary search are realized by the feeding module, and furthermore, the welding is finished in an ultrasonic welding machine through the clamping self-centering and the clamping force control of four guide rods, two-grade type welding head movement and a digital power supply driven ultrasonic transducer; then the material receiving module is used for taking out a welded finished product and conveying the welded finished product to a material storage belt line. The cross-flow fan blade welding robot has the advantages of rapid welding period, low noises, high yield, short line exchanging time, online real-time quality monitoring, stability and reliability in operation and the like.

Owner:SHENZHEN SIJIECHUANG TECH CO LTD

Method for low temperature brazing aluminium alloy to obtain brazed joint with high temperature use performance

ActiveCN101088690AHigh strengthSmall amount of deformationWelding/cutting media/materialsWelding/soldering/cutting articlesEtchingUltimate tensile strength

The method for low temperature brazed aluminum alloy to obtain brazed joint with high temperature use performance includes the following steps: 1. setting the brazing alloy inside the brazed gap; 2. primary brazing; and 3. ultrasonic treatment. The said brazing process has no any etching on the aluminum alloy workpiece, short brazing period, low brazing temperature, low operation cost, and capacity of obtaining brazed joint with high strength and high temperature use performance.

Owner:哈尔滨工大光电科技有限公司

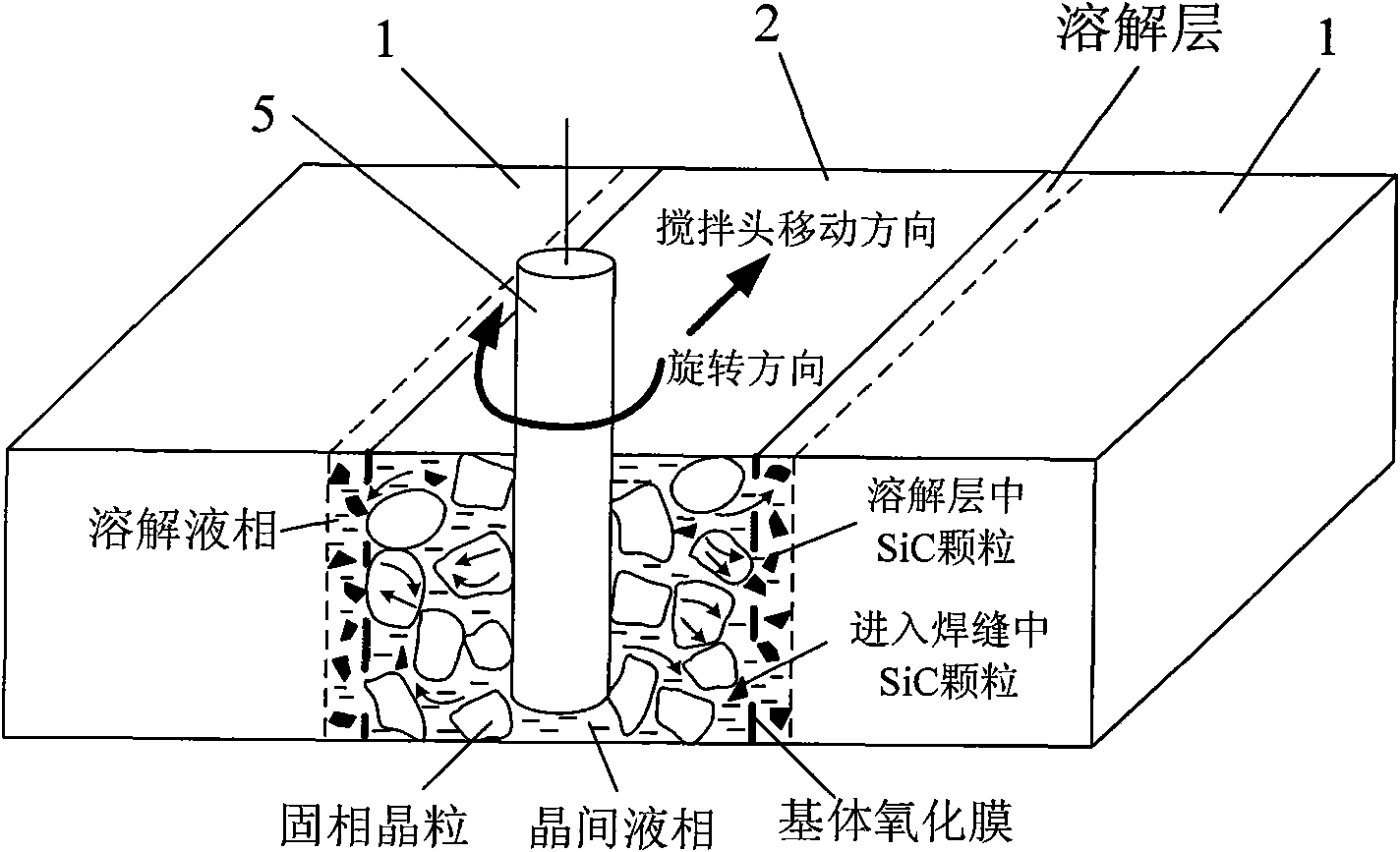

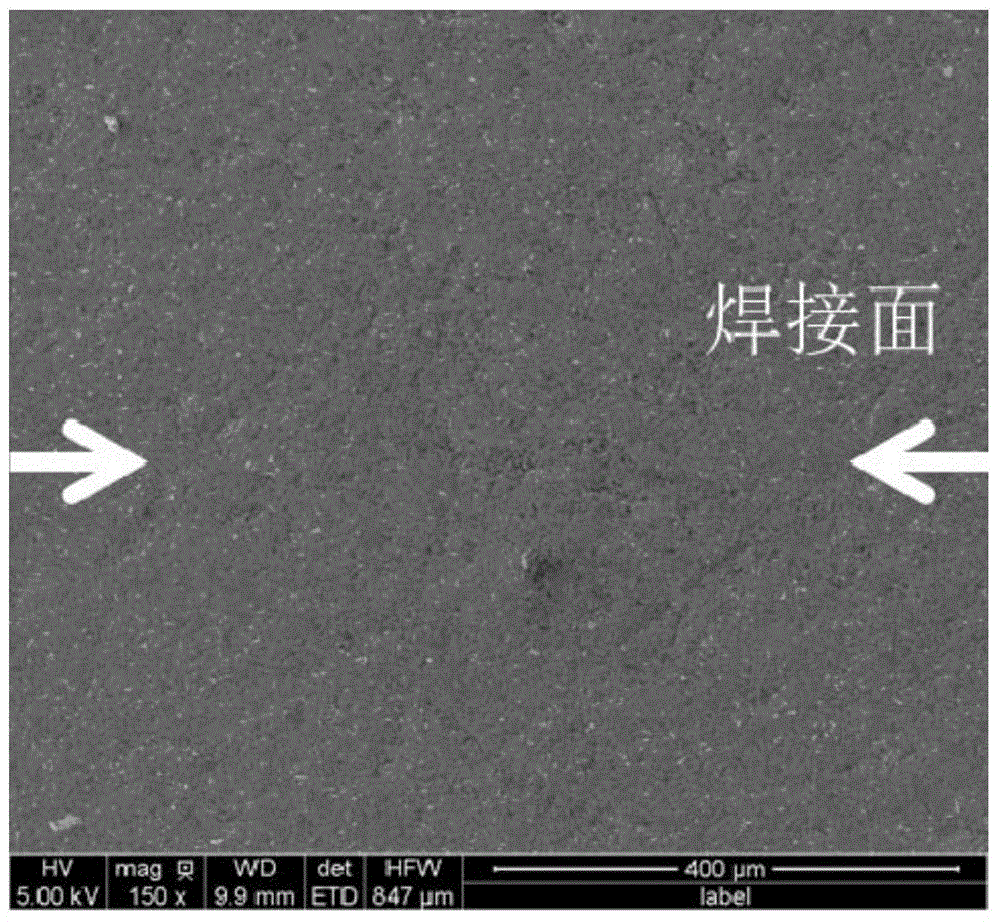

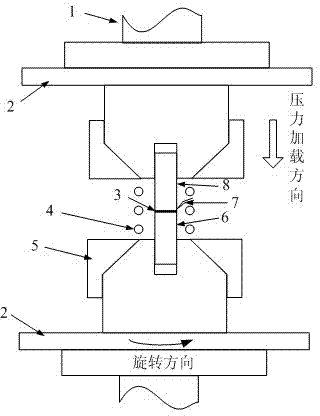

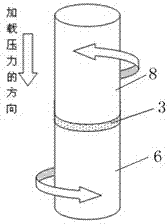

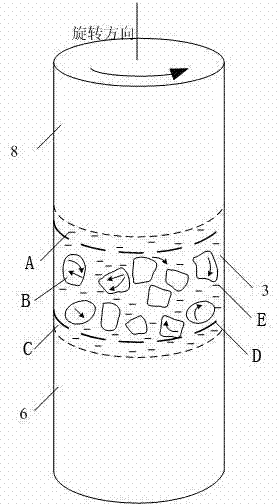

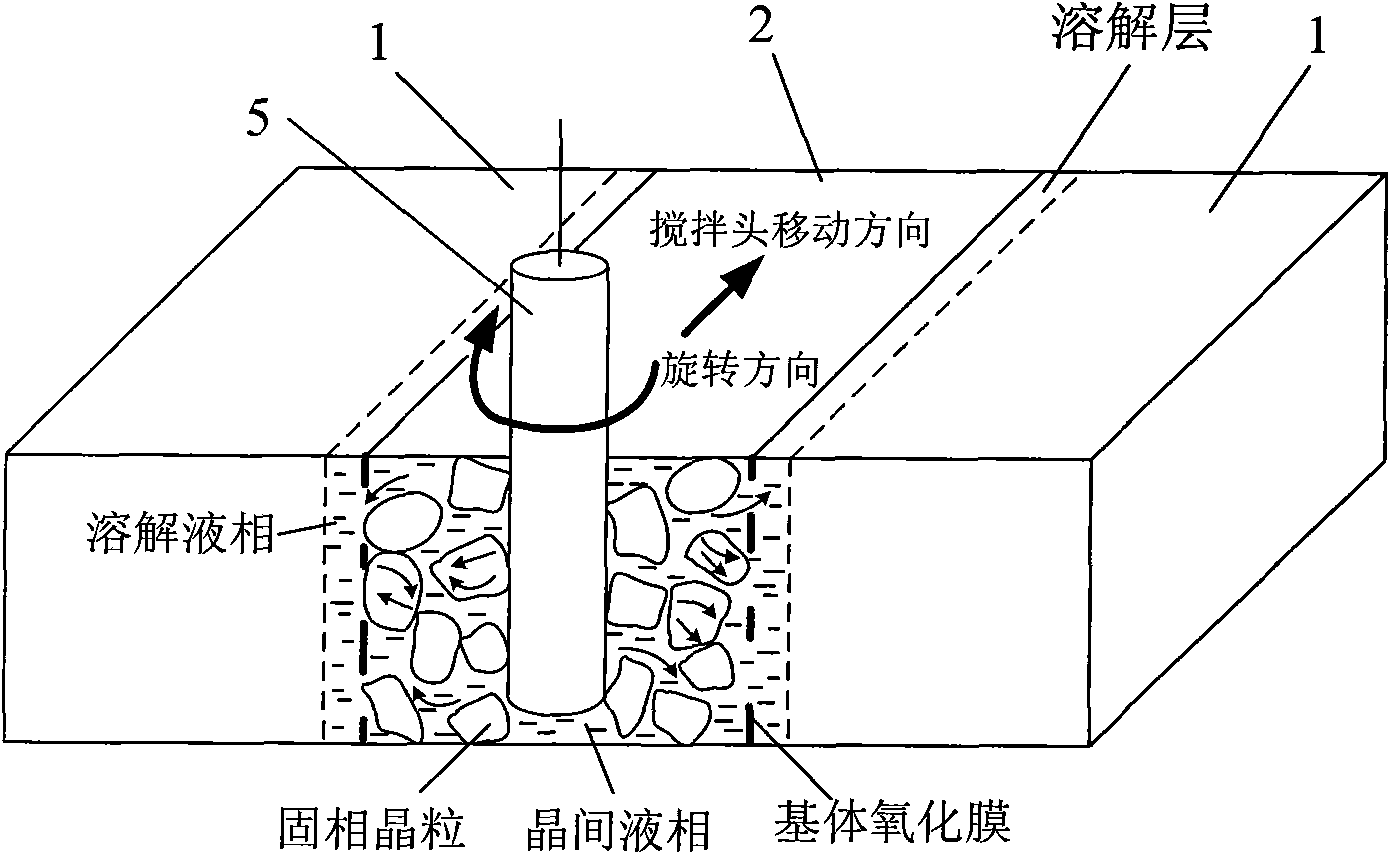

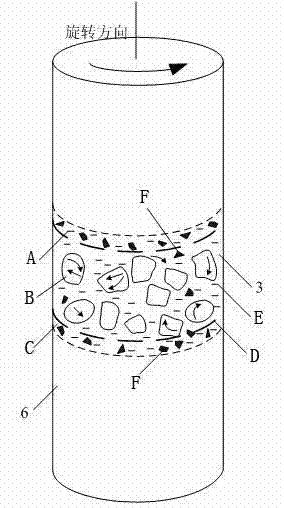

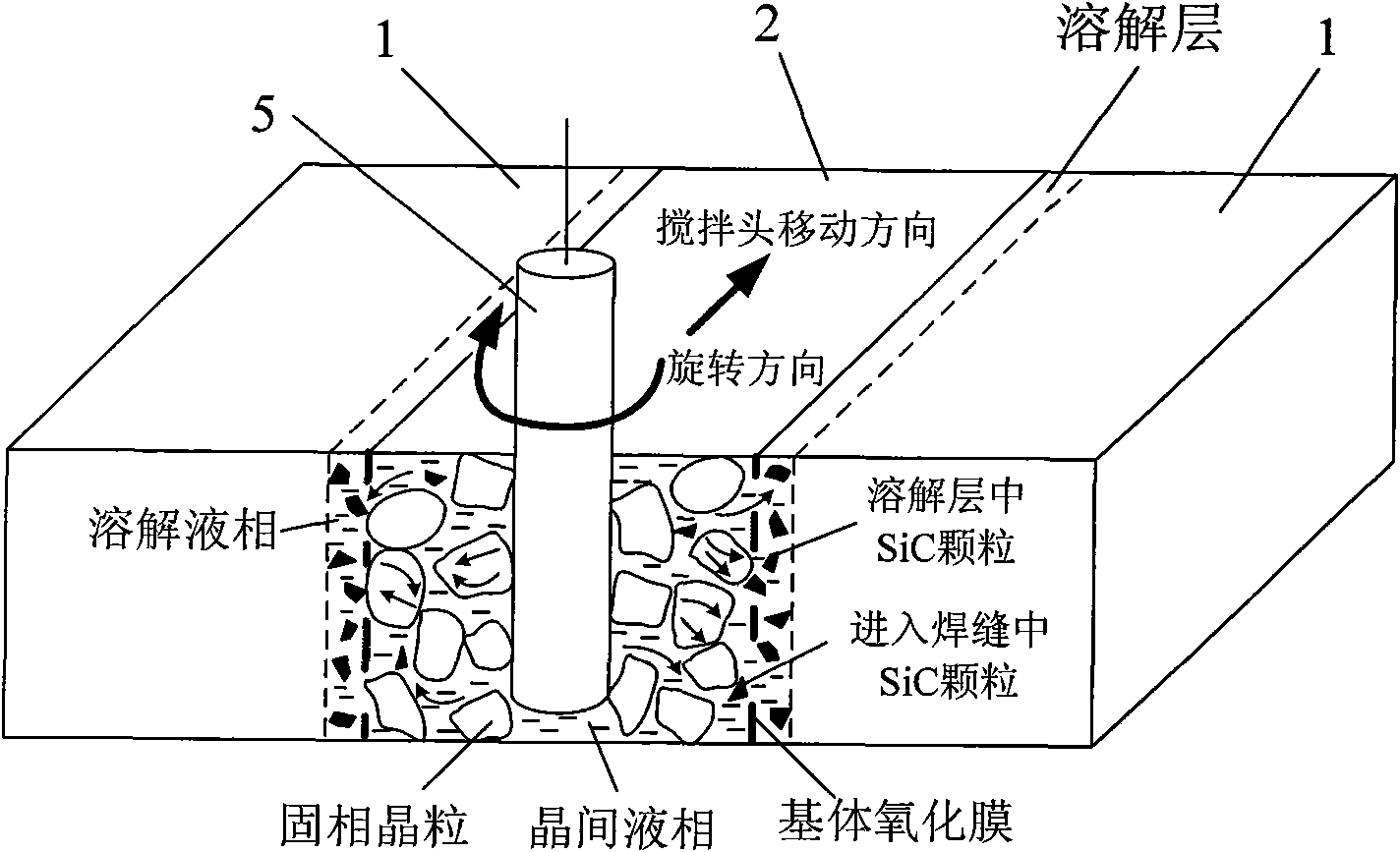

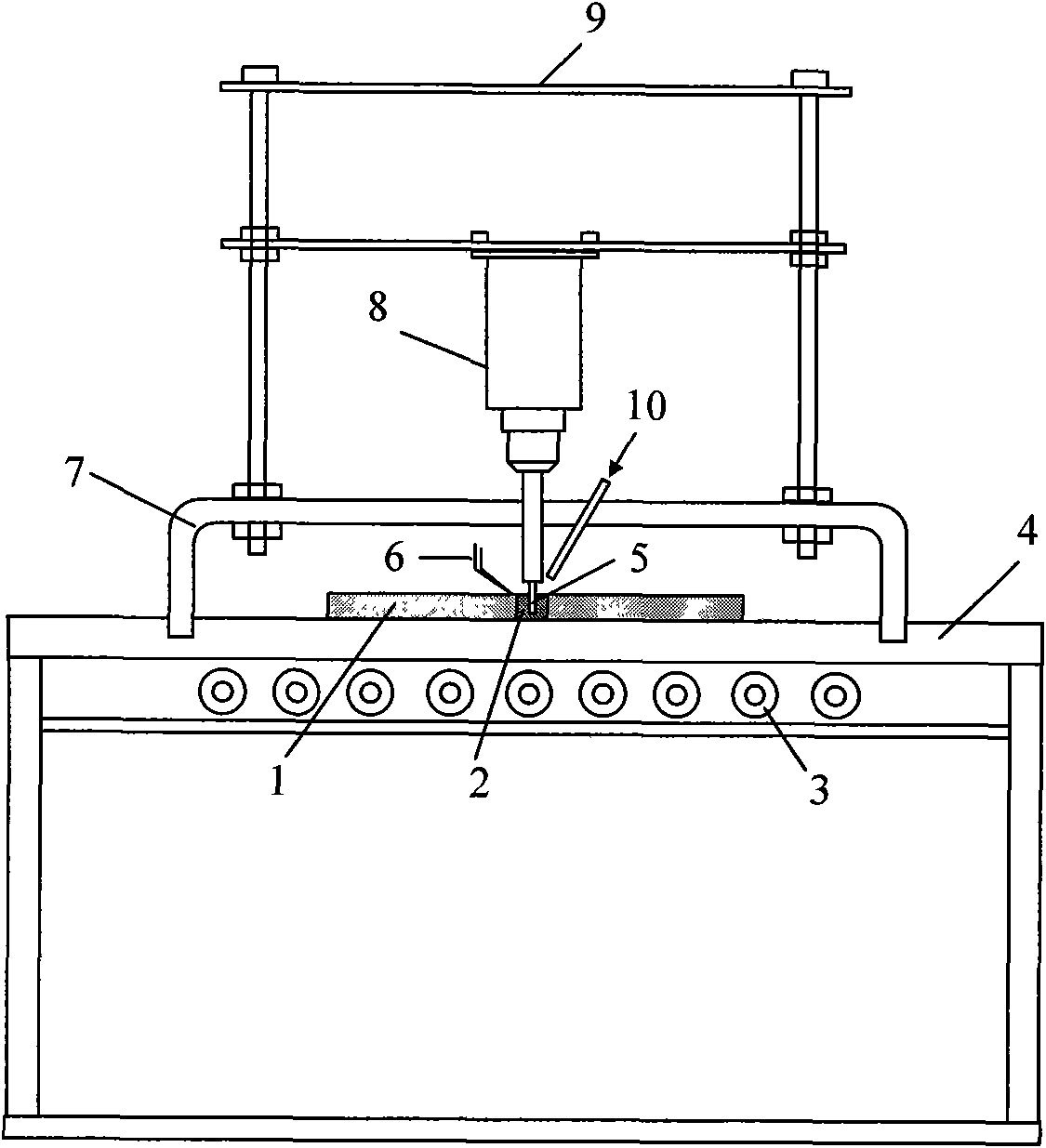

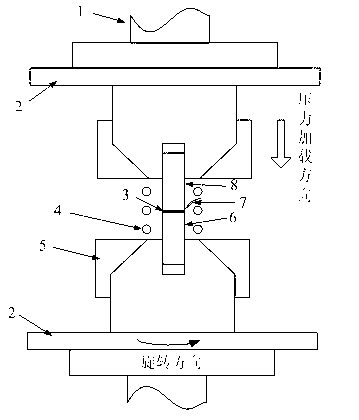

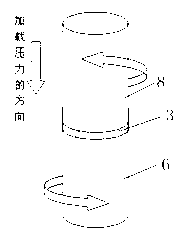

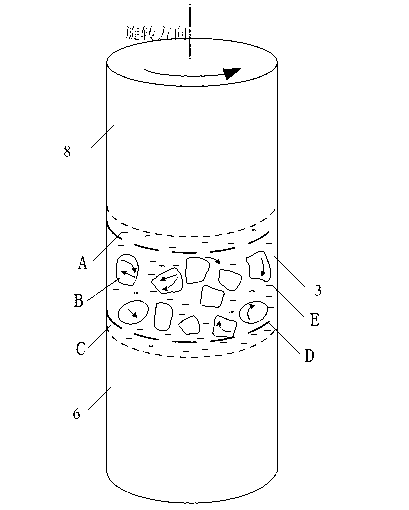

Non-vacuum semi-solid stirring brazing method for aluminum alloy and composite material thereof

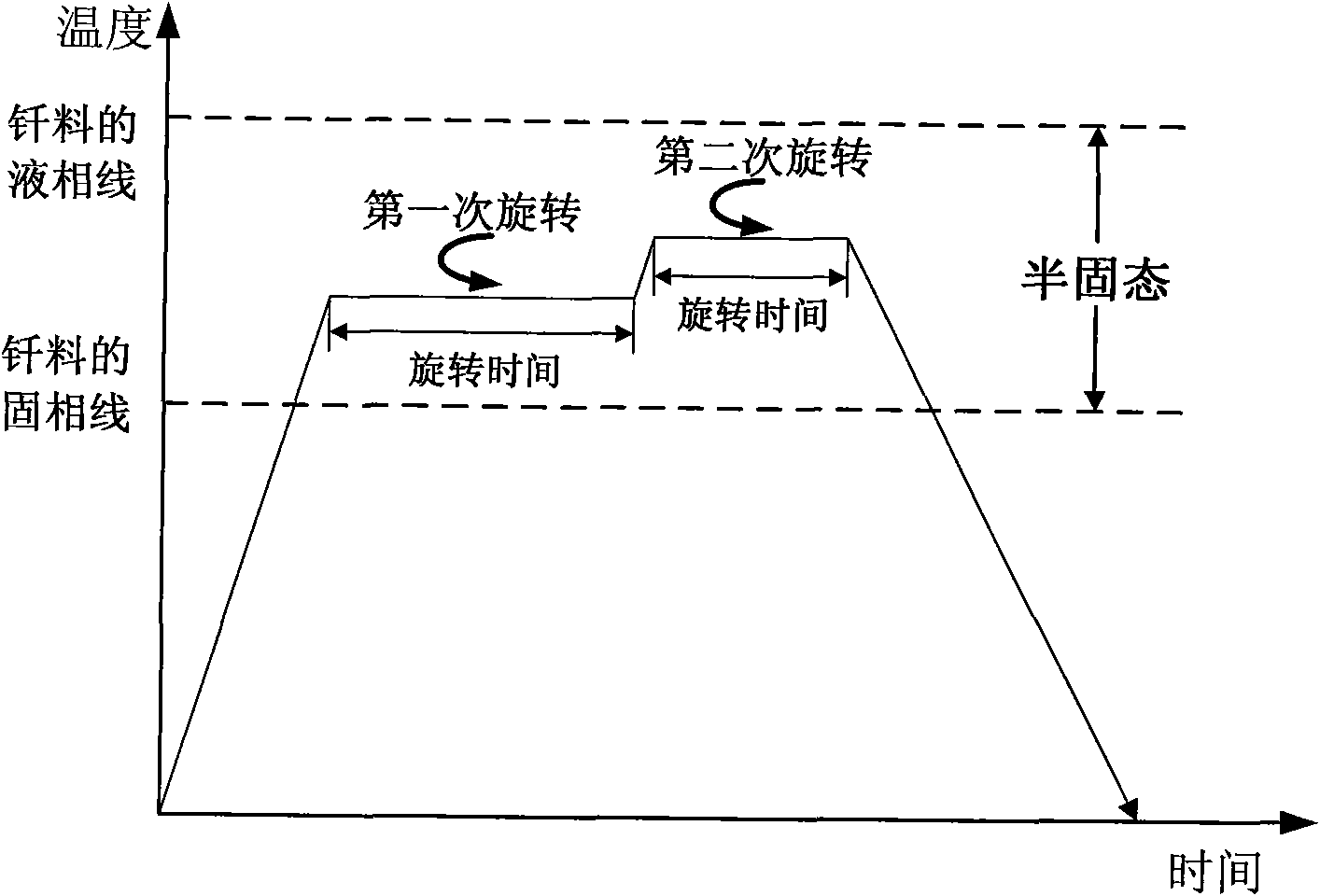

The invention provides a semi-solid brazing method for aluminum alloy and a composite material thereof under the assistance of non-vacuum mechanical stirring, which comprises the steps of: mounting a weldment taking the aluminum alloy or the composite material thereof as a base material on a welding platform first; placing intermediate-temperature solder on two surfaces to be welded, heating the weldment to between 390 and 420 DEG C, and ensuring that the solid fraction of the solder is between 50 and 80 percent; staring a rotary sliding device, wherein the rotating speed is between 150 and 300 r / m, the temperature is constant, and the longitudinal movement rate, which is parallel to a welding seam, of a stirring head is between 0.5 and 2 cm / min; stopping the rotary sliding when the stirring head moves to the terminal of the welding seam; increasing the temperature to between 430 and 450 DEG C, performing thermal insulation for 1 to 5 minutes, and ensuring that the solid fraction of the solder is between 10 and 40 percent; restarting the rotary device again, wherein the rotating speed is between 20 and 150 r / m; sliding the stirring head in a reverse direction, wherein the movement speed is between 1 and 2 cm / m; stopping the rotation, when the stirring head moves to the initial end of the welding seam, and lifting the stirring head; and cooling the solder along with a furnace after thermal insulation for 5 to 30 minutes. The method can realize the low-cost, high-efficiency and high-quality welding of the aluminum alloy or the composite material thereof.

Owner:CHONGQING UNIV OF TECH

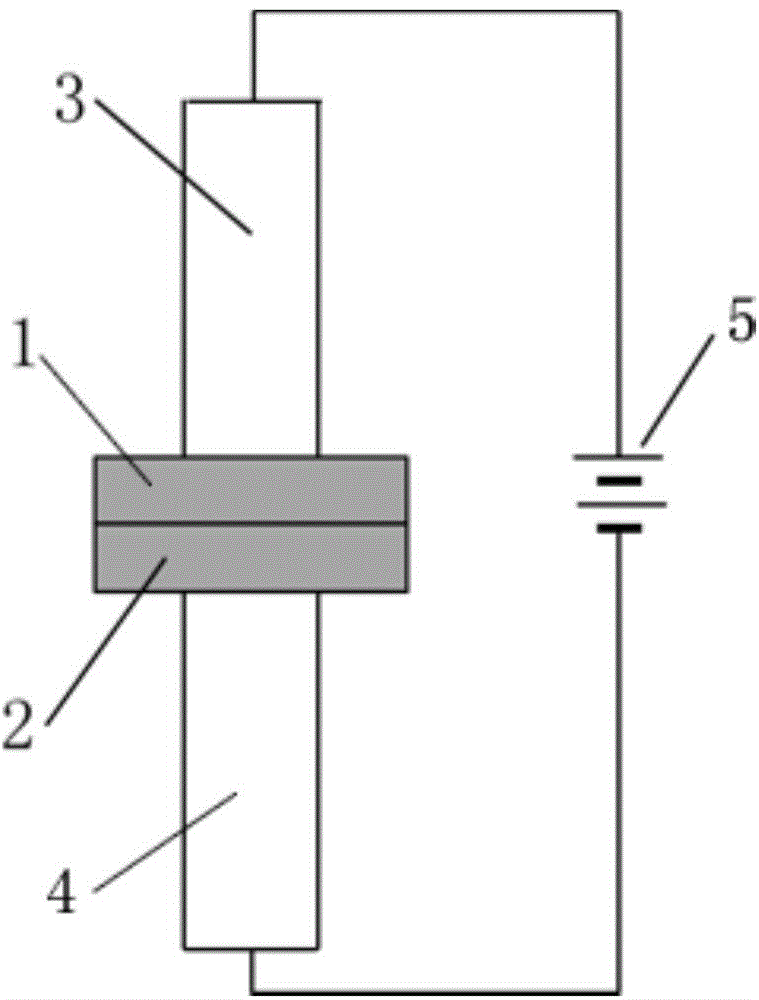

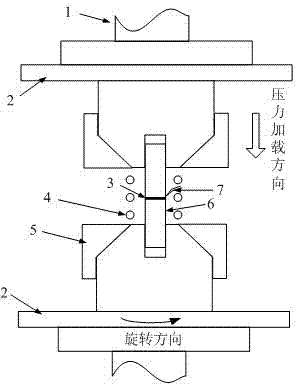

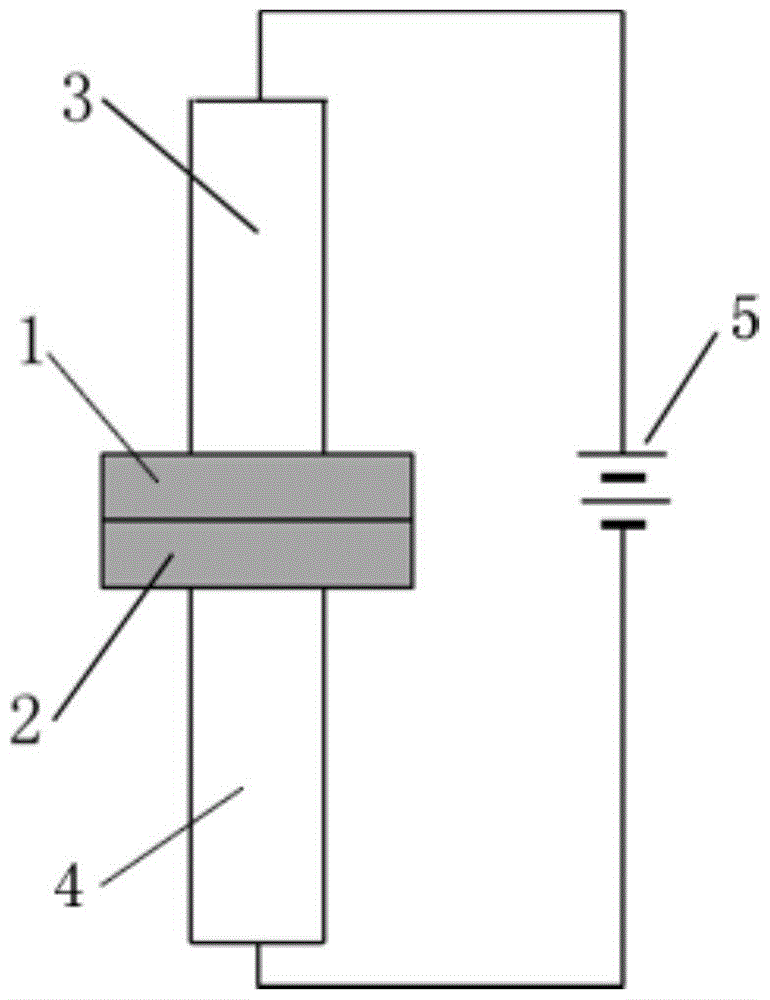

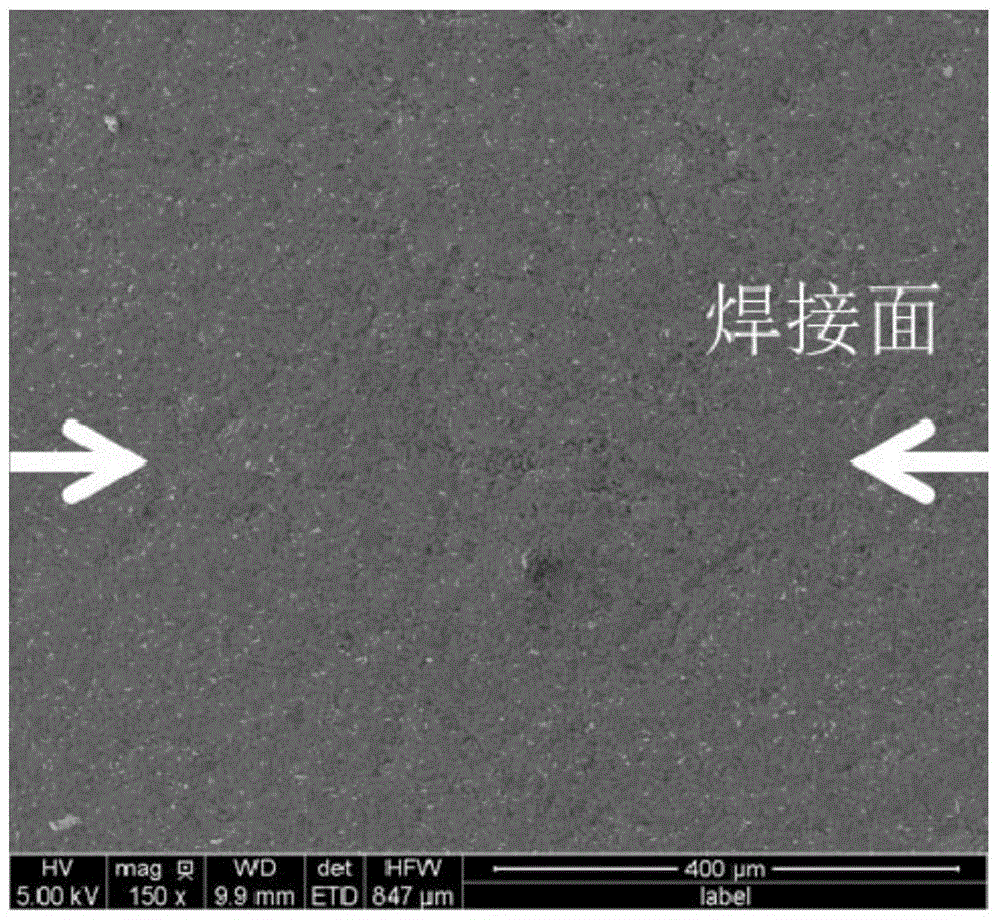

MAX phase ceramic material welding method

The invention provides an MAX phase ceramic material welding method. In the provided welding method, the ends of two MAX phase ceramic materials to be welded are respectively connected to an upper electrode and a lower electrode, the welding surfaces are processed and then contacted with each other, then the ceramic materials, electrodes, and a power supply form a closed loop, joule heat is generated by the current on the touch surfaces, the temperature of the touch surface is rapidly raised, thus the MAX phase ceramic material of the touch surface is activated and diffused, and the welding is achieved. In the conventional welding method, a middle transition layer is used, and the middle transition layer is diffused at a high temperature under the combined actions of temperature-pressure-temperature maintaining so as to achieve the welding. Compared with the conventional welding method, the provided welding method has the following advantages: (1) the method is simple and practical; (2) a middle transition layer is not needed; (3) the welding period is short; (4) no welding silt or interface on the surface of welded material, and the ceramic materials are perfectly integrated together; (5) the welding method has a very good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

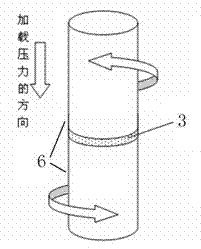

Magnesium alloy and aluminum alloy heterogeneous non-vacuum mechanical forced rotation semi-solid brazing method

InactiveCN102284758ALow costHigh quality weldingSoldering apparatusWelding/soldering/cutting articlesSemi solidMagnesium alloy

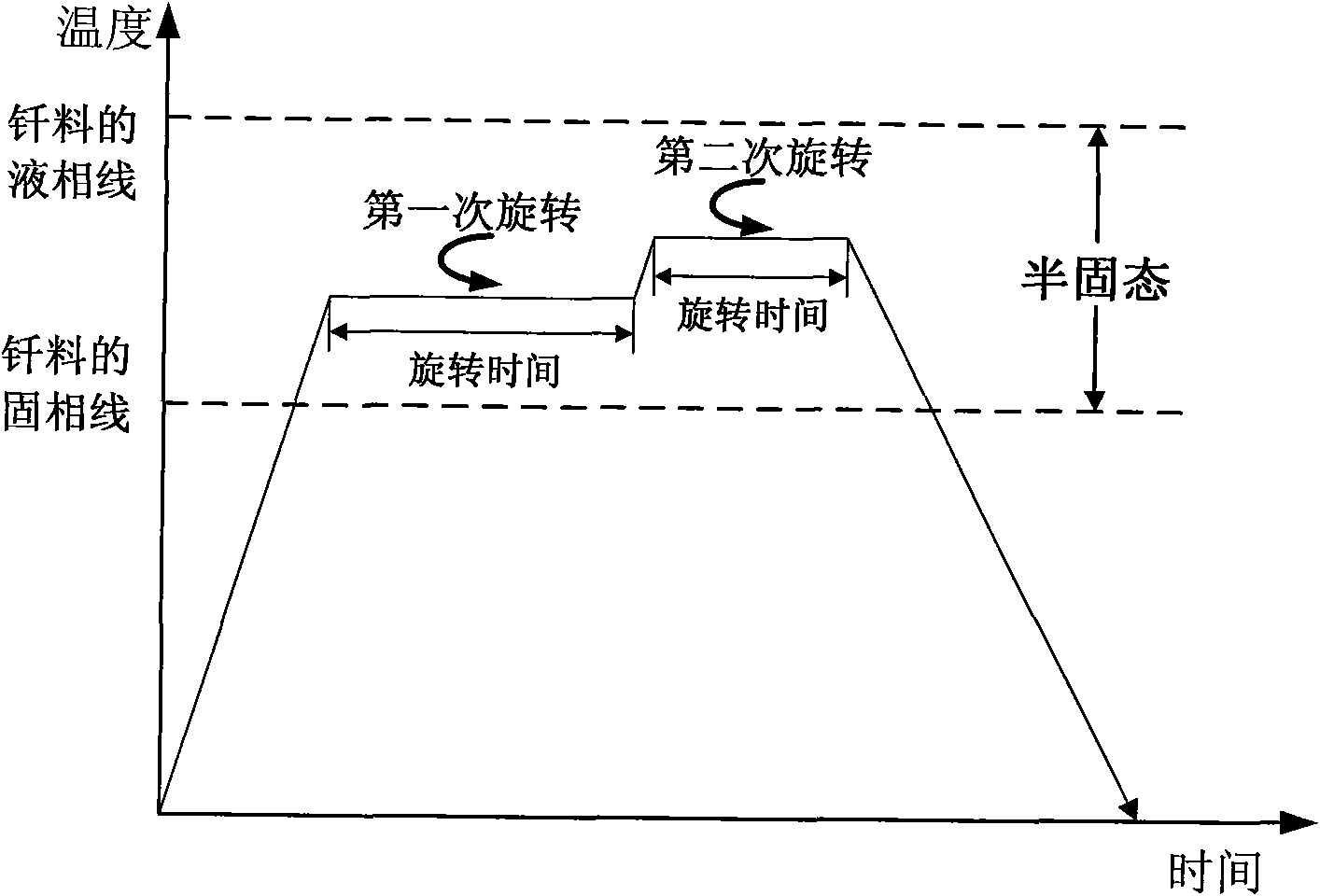

The invention relates to a magnesium alloy and aluminum alloy heterogeneous non-vacuum machinery forced rotation semi-solid brazing method; a magnesium alloy weldment and an aluminum alloy weldment are clamped on a clamp, Zn-Sn or Zn-Al-Sn system other brazing materials are arranged on two surfaces to be brazed, the weldments are heated, the heating temperature is between 350DEG C to 450DEG C, simultaneously pressure is increased, the pressure range is 0.1MPa to 1MPa, so that the brazing materials on a middle layer are in a semi-solid state, a rotary device is started, the rotating speed is 65r / min to 1500r / min, the temperature is constant during a rotation process, and the rotation time is 10s to 300s. After the rotation, the temperature rises by a certain rate, the heat is insulated at preset temperature, so that the brazing materials dissolve parent materials with a certain thicknesses, the heat insulating temperature is between 400DEG C to 480DEG C, and the heat insulating time is1min to 5min. Afterwards, pressure is increased, the pressure range is 0.1MPa to 1MPa, the rotary device is started again (secondary rotation), the rotating speed is 65r / min to 600r / min, rotation is stopped after 3s to 60s, and cooling is carried out with a furnace after the heat is insulated for 5 min to 30min. The magnesium alloy and aluminum alloy heterogeneous non-vacuum machinery forced rotation semi-solid brazing method can realize the high-efficiency, high-quality and economic connection of a magnesium alloy and an aluminum alloy.

Owner:CHONGQING UNIV OF TECH

Anti-vacuum semi-solid states stirring soldering method of magnesium alloy and composite material thereof

The invention provides an anti-vacuum semi-solid states stirring soldering method of magnesium alloy and composite material thereof, which comprises the following steps of: a weldment taking the magnesium alloy or the composite material thereof as a parent metal is arranged and blocked on a welding platform and medium temperature brazing filler metal is put on two surfaces to be welded; the weldment is heated in the temperature of 380 to 430 DEG C to cause that the solid phase ratio of the brazing filler metal is between 50 to 80%; hereupon, a rotational sliding device is started; the rotary speed is 150 to 300 r / m; the temperature is constant; a stirring head is parallel to the longitudinal movement speed of 0.5-2cm / min of a welding line; when the stirring head moves to the terminal of the welding line, the rotational sliding stops; the holding time is 1 to 5 minutes so that the weldment is further dissolved; the rotational device is started again; the rotary speed is 20 to 150 r / m; the stirring head slides in a negative direction; the movement speed is 1 to 2 cm / min. When the stirring head moves to the initial end of the welding line, the rotary stops; the stirring head is lifted; the holding temperature is 5-30 minutes, and a furnace cools. The method can realize the low cost, high efficient, high quality welding of the magnesium alloy and the composite material thereof.

Owner:CHONGQING UNIV OF TECH

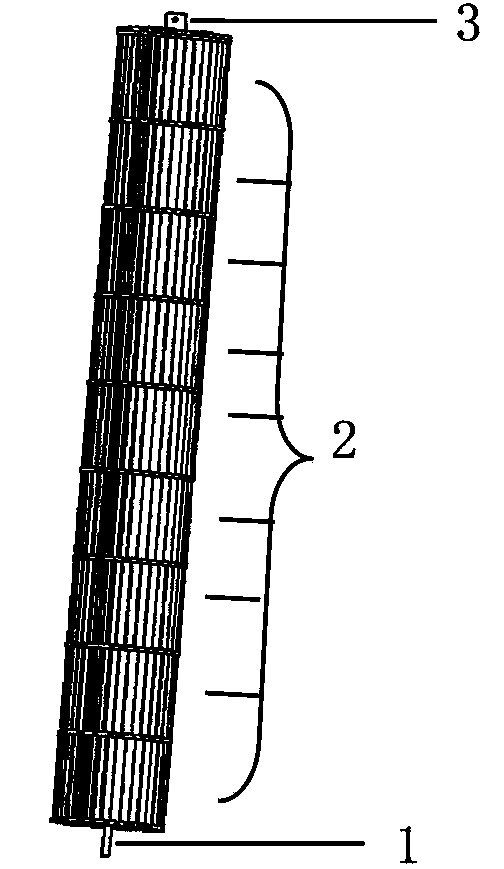

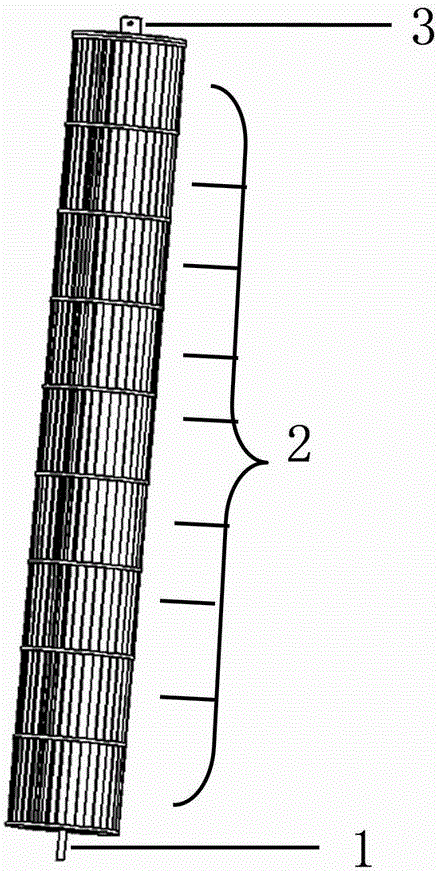

Brazing method for cable shielding layer and shell

InactiveCN102350552ARealize one-time moldingUniform and stable shapeSoldering apparatusEngineeringConductor Coil

The invention discloses a brazing method for a cable shielding layer and a shell, wherein wire branching holes are formed in two ends of the shell; a cable passes through the wire branching holes; and the brazing method comprises the following steps of: winding, namely winding brazing wires on parts, opposite to the wire branching holes, of the cable shielding layer; fixing, namely fixing the cable, the shell and the brazing wires by a clamp; heating, namely, putting a brazing part into an induction coil and heating the brazing part by induction heating equipment; and cooling, namely stopping heating until the brazing part is cooled. By the brazing method, one-time molding of joints at two ends of the shell can be realized, the shape of the shell is uniform and stable, the brazing quality is easy to guarantee, and efficient and automatic production requirements can be met.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

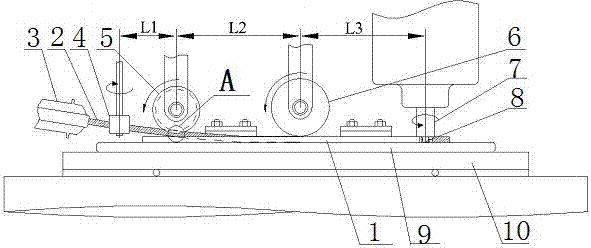

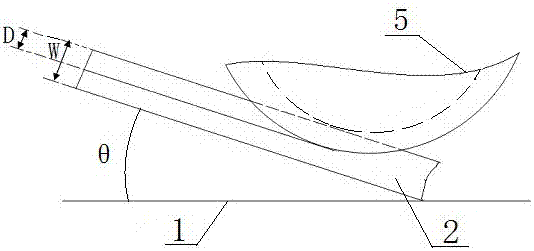

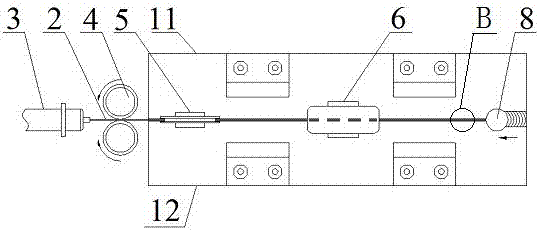

Automatic wire-feeding friction stir welding method for butt joint of dissimilar metal materials

ActiveCN107414283AReduce frictional heatReduce thicknessWelding/soldering/cutting articlesNon-electric welding apparatusButt jointChemical compound

The invention discloses an automatic wire-feeding friction stir welding method for butt joint of dissimilar metal materials. The automatic wire-feeding friction stir welding method comprises the following steps that 1, welding pieces are in butt joint with each other and are clamped, an interval is formed between the welding pieces, strip-shaped welding wires are led out from a wire-feeding gun, a straightening wheel set, a pre-buried wheel and a leveling wheel are sequentially placed on the interval, the strip-shaped welding wires are straightened through the straightening wheel set, then obliquely downwards fed into the interval through the pre-buried wheel and later leveled through the leveling wheel, and the ends of the strip-shaped welding wires are arranged under a stirring head; 2, a welding machine is started, the stirring head starts vertical downwards feeding, later a stirring needle is pressed into the interval where the strip-shaped welding wires are stored, welding is started, and in the welding process, the wire-feeding speed keeps consistent with the welding speed; and 3, the stirring head is lifted, then wire feeding is stopped, and the strip-shaped welding wires are cut off. According to the automatic wire-feeding friction stir welding method for butt joint of the dissimilar metal materials, generation of chemical compounds between metal can be reduced, the interface temperature is decreased, the residual stress is reduced, a welding joint is prevented from generating holes, and the mechanical property and the welding efficiency of welding connectors are improved.

Owner:CHONGQING UNIV OF TECH

Non-vacuum semi-solid mechanically assisted rotary brazing method for magnesium alloy and its composite materials

InactiveCN102284760ALow costHigh quality weldingSoldering apparatusNon-electric welding apparatusVacuum assistedSemi solid

The invention relates to a non-vacuum semi-solid machine-assisted rotary soldering method for a magnesium alloy and a composite material thereof, which comprises the following steps of: clamping the magnesium alloy and a composite material weldment thereof on a fixture, putting Zn-Sn or Zn-Al-Sn solders and the like on two surfaces to be welded, heating the weldment at the temperature of between 350 and 450 DEG C, and applying pressure of 0.1 to 1MPa to make the solder in an intermediate layer positioned in a semi-solid state; starting a rotating device, rotating at a speed of 65 to 1,500r / min for 10 to 300 seconds, and keeping the temperature constant in the rotating process; raising the temperature at a certain heating rate after rotation is stopped, and preserving heat at the predetermined temperature of between 400 and 480 DEG C for 1 to 5 minutes to make the solder dissolve parent metal with certain thickness; and applying pressure of 0.1 to 1MPa, starting the rotating device again, rotating for the second time at a speed of 65 to 600r / min for 3 to 60 seconds, stopping rotation, preserving heat for 5 to 30 minutes, and cooling with a furnace. By the method, the magnesium alloy and the composite material thereof can be efficiently and economically connected at high quality.

Owner:CHONGQING UNIV OF TECH

Non-vacuum semi-solid stirring brazing method for aluminum alloy and composite material thereof

InactiveCN101596630BAchieve weldingShort welding cycleSoldering apparatusThermal insulationSemi solid

The invention provides a semi-solid brazing method for aluminum alloy and a composite material thereof under the assistance of non-vacuum mechanical stirring, which comprises the steps of: mounting a weldment taking the aluminum alloy or the composite material thereof as a base material on a welding platform first; placing intermediate-temperature solder on two surfaces to be welded, heating the weldment to between 390 and 420 DEG C, and ensuring that the solid fraction of the solder is between 50 and 80 percent; staring a rotary sliding device, wherein the rotating speed is between 150 and 300 r / m, the temperature is constant, and the longitudinal movement rate, which is parallel to a welding seam, of a stirring head is between 0.5 and 2 cm / min; stopping the rotary sliding when the stirring head moves to the terminal of the welding seam; increasing the temperature to between 430 and 450 DEG C, performing thermal insulation for 1 to 5 minutes, and ensuring that the solid fraction of the solder is between 10 and 40 percent; restarting the rotary device again, wherein the rotating speed is between 20 and 150 r / m; sliding the stirring head in a reverse direction, wherein the movementspeed is between 1 and 2 cm / m; stopping the rotation, when the stirring head moves to the initial end of the welding seam, and lifting the stirring head; and cooling the solder along with a furnace after thermal insulation for 5 to 30 minutes. The method can realize the low-cost, high-efficiency and high-quality welding of the aluminum alloy or the composite material thereof.

Owner:CHONGQING UNIV OF TECH

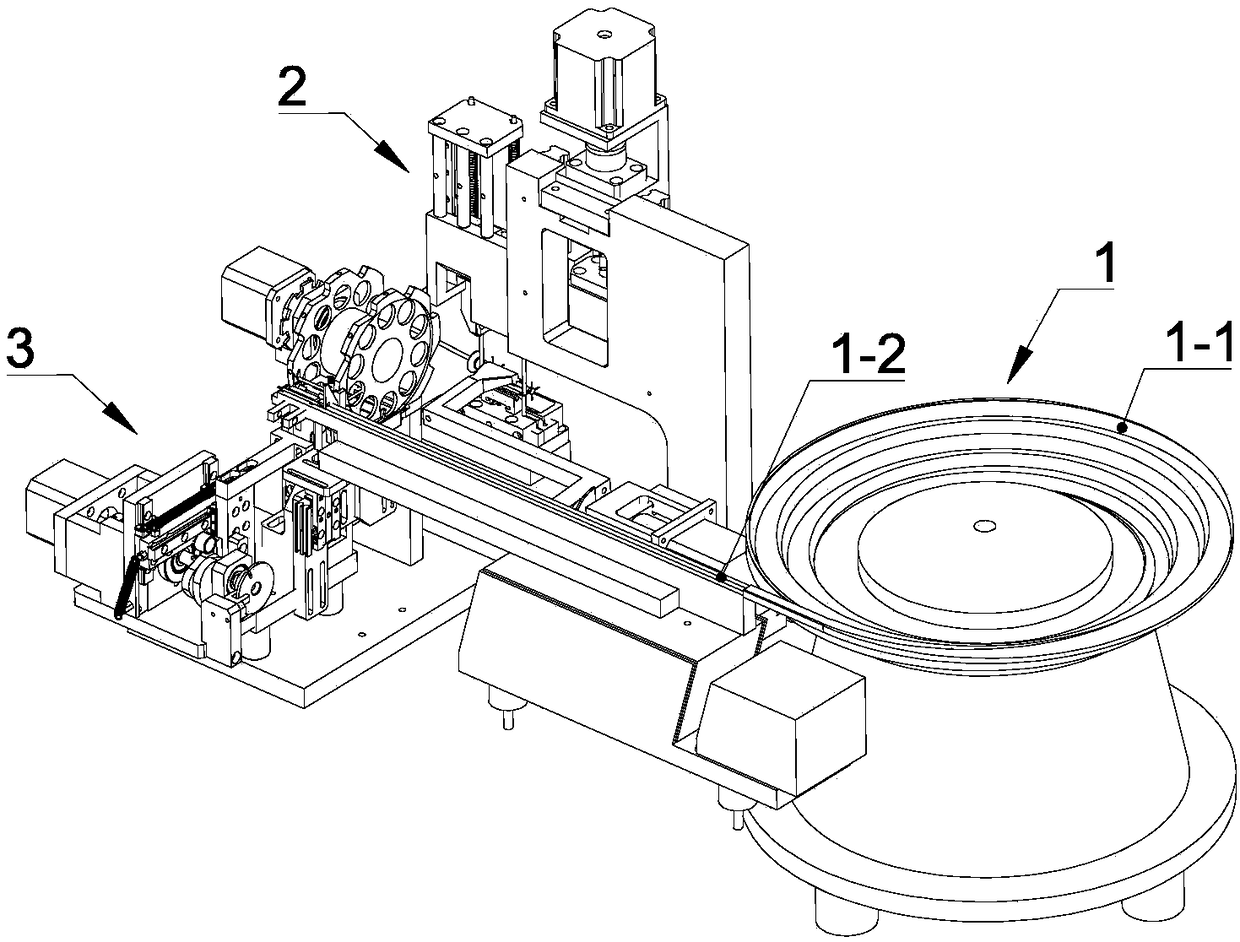

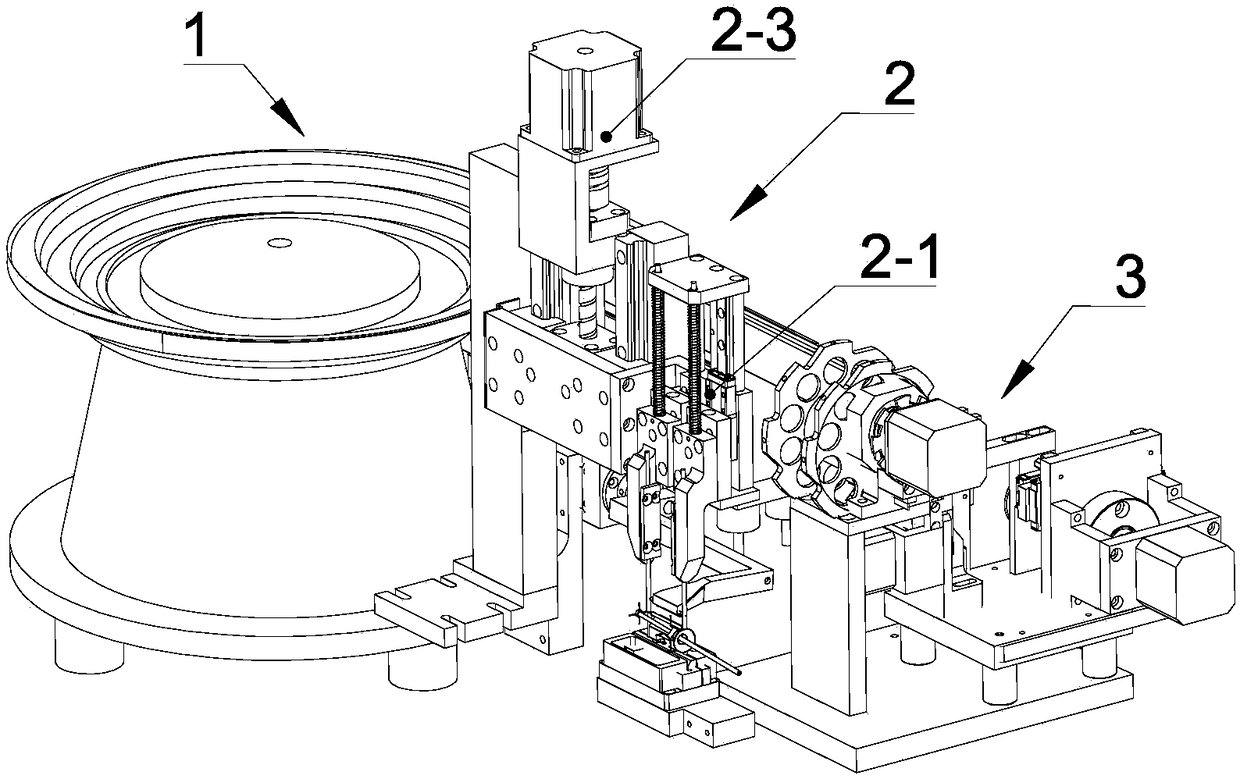

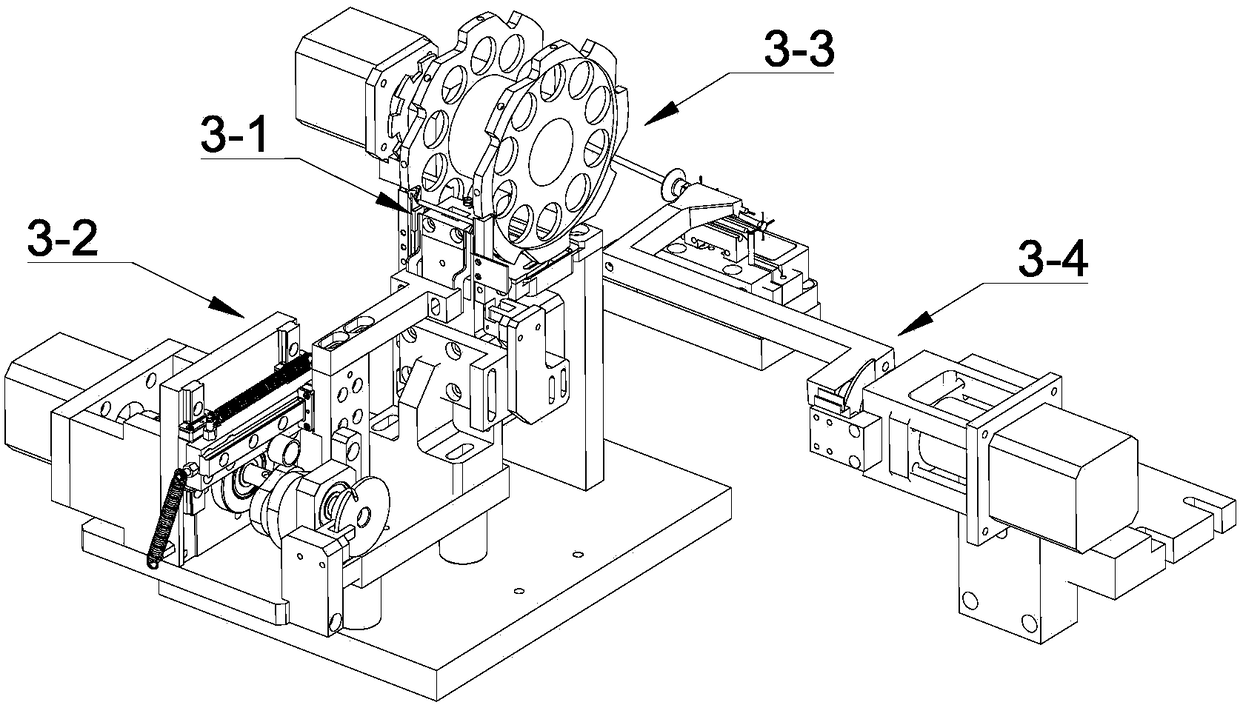

LED lamp filament column welding equipment

PendingCN108356402AHigh degree of automationSolve troublesome problemsResistance welding apparatusEngineeringSpot welding

The invention discloses LED lamp filament column welding equipment. The LED lamp filament column welding equipment comprises a feeding module, a welding module and a material carrying module used fortransferring LED lamp filament columns to the welding module from the feeding module. The feeding module comprises a vibration disc and a vibration guide rail connected with a discharging port of thevibration disc. The welding module is provided with a welding executing device. The welding executing device comprises a pot welding machine, two electrode columns and a spot welding machine lifting driving mechanism for driving a spot welding needle to move up and down. The material carrying module comprises a supporting positioning mechanism, a first material carrying device for carrying the LEDlamp filament columns to the supporting positioning mechanism from the vibration guide rail, a material taking carrying device for carrying the LED lamp filament columns away from the supporting positioning mechanism, and a discharging carrying device used for carrying the LED lamp filament columns to the two electrode columns from the material taking carrying device. According to the equipment,LED lamp filament column carrying and positioning work and welding work in the welding process can be automatically finished, and the beneficial effects that the welding effect is good, and the welding efficiency is high are achieved.

Owner:GUANGZHOU MINGSEN TECH CO LTD

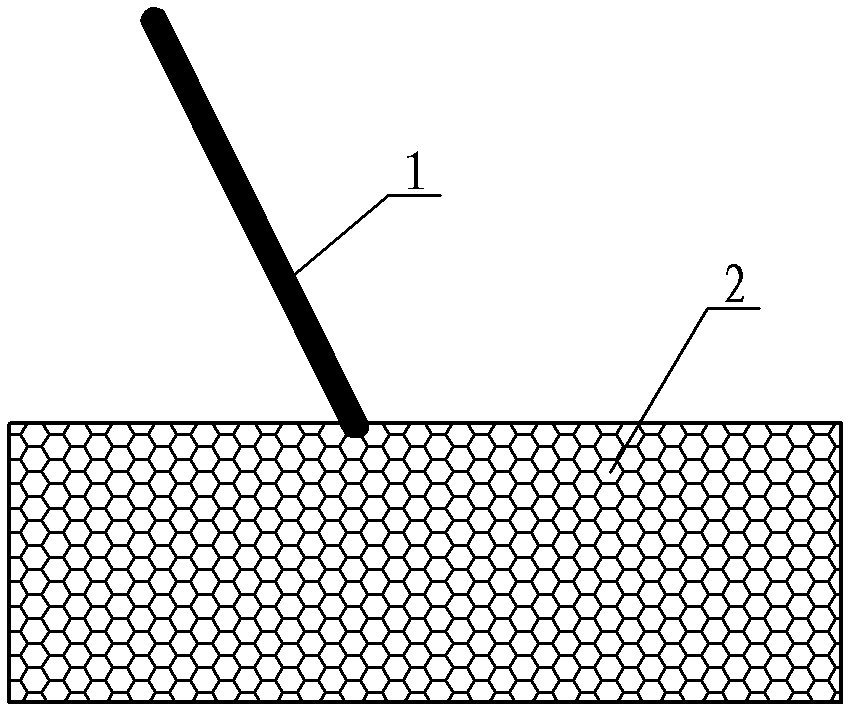

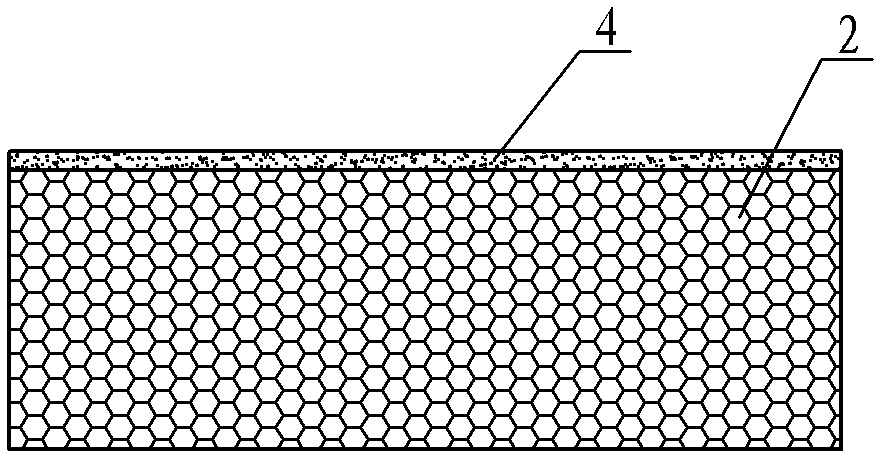

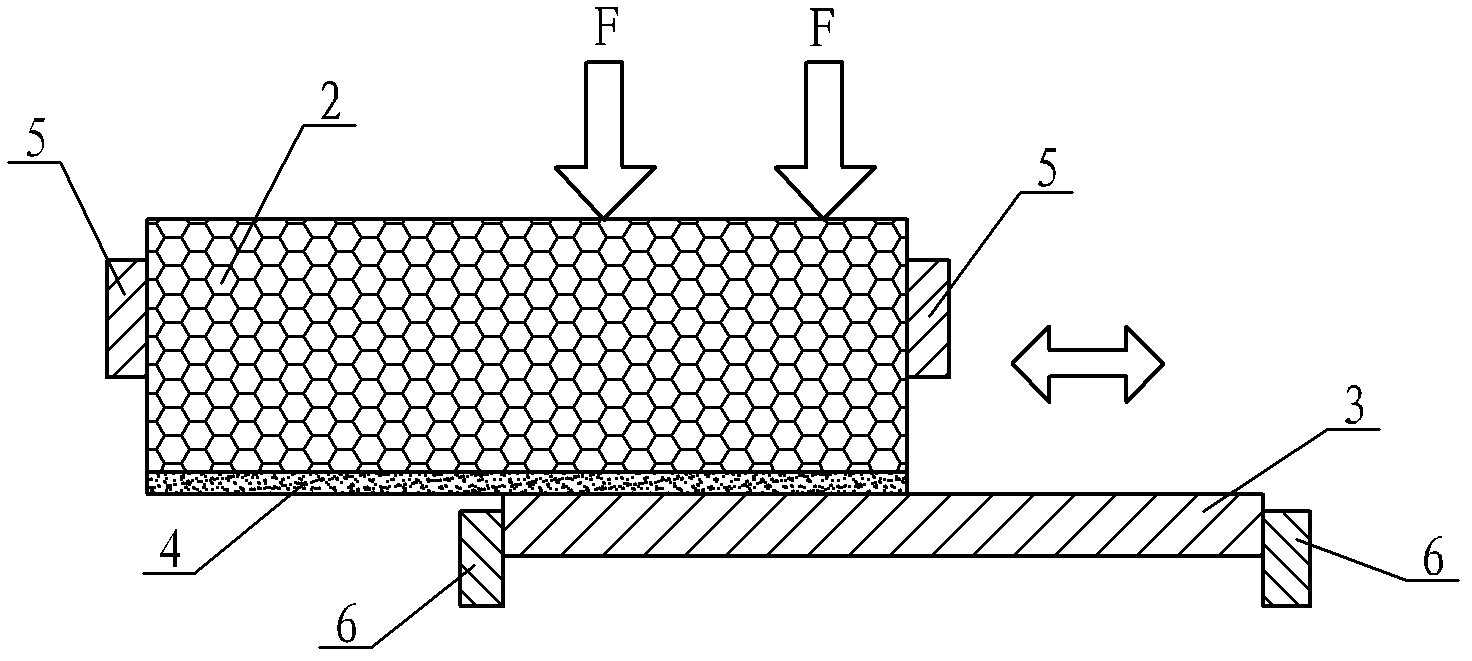

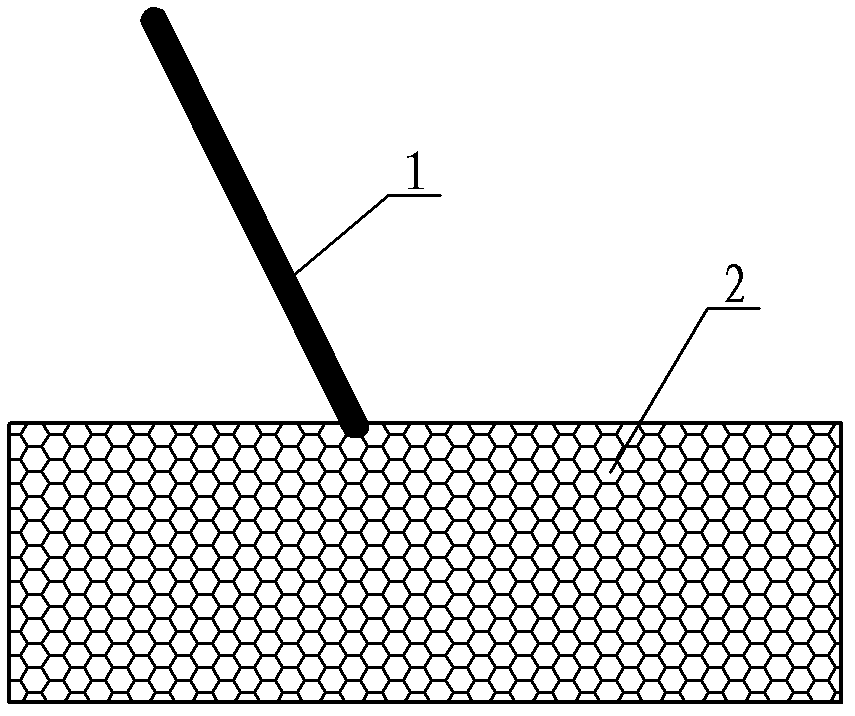

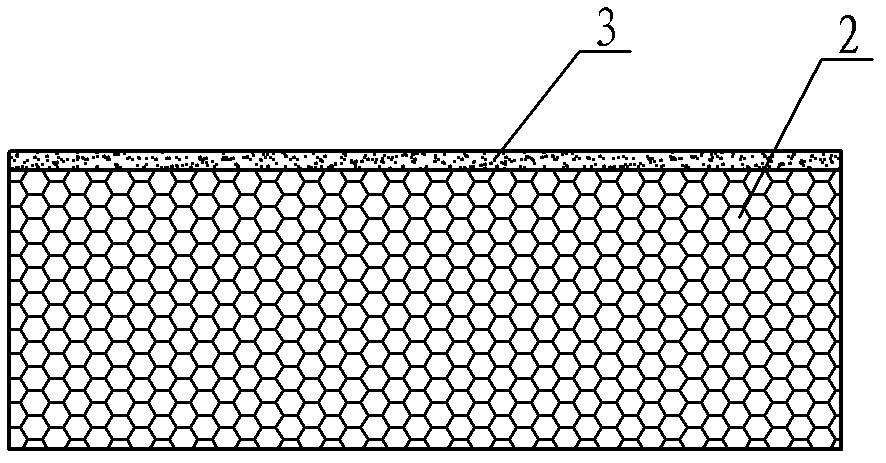

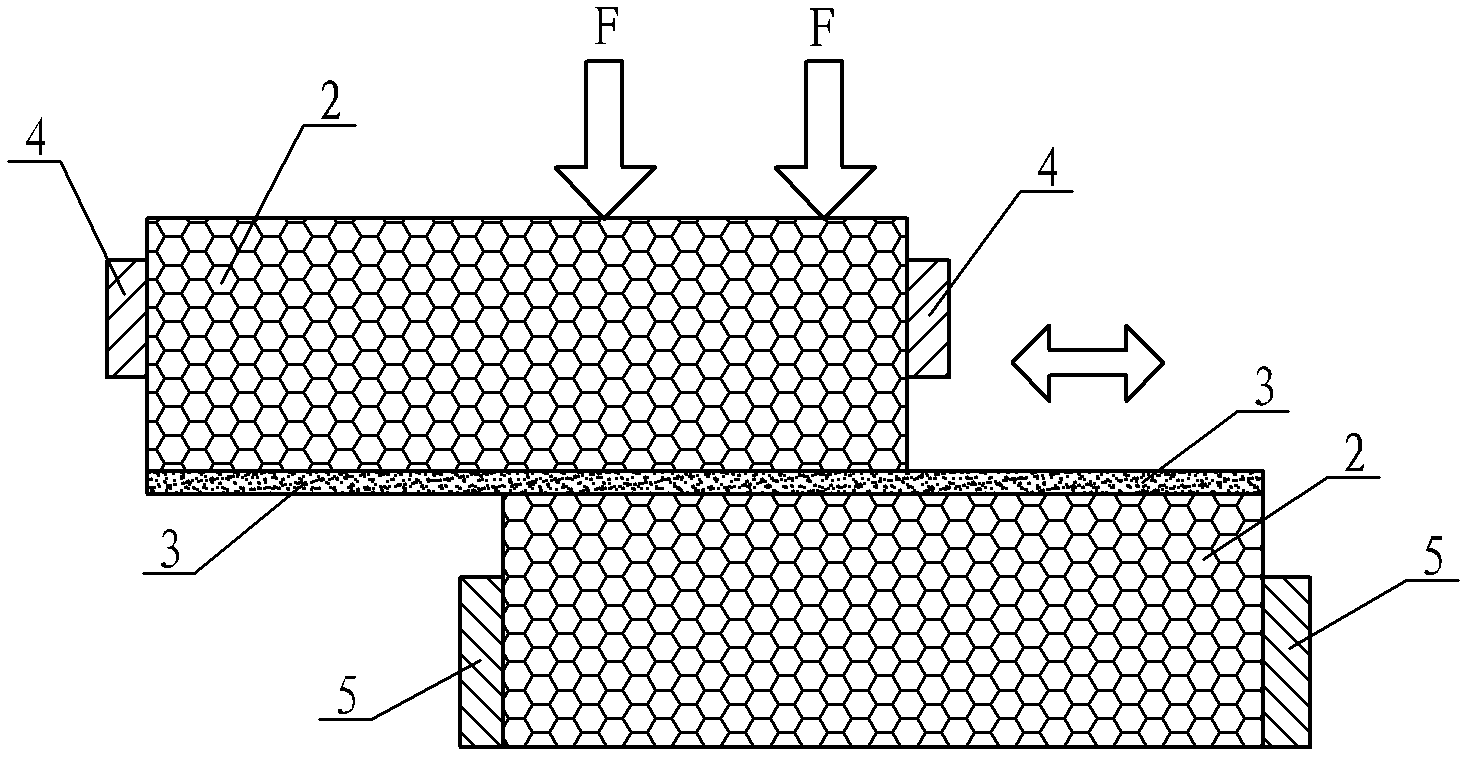

Method for brazing foamed aluminum plate and aluminum plate by removing interfacial oxide films through bubble wall friction

InactiveCN102581415APromote wettingEasy to spreadSoldering apparatusWelding/soldering/cutting articlesInterfacial oxideUltimate tensile strength

A method for brazing a foamed aluminum plate and an aluminum plate by removing interfacial oxide films through bubble wall friction relates to a welding method in the field of brazing, and solves the problem that an existing foamed aluminum plate and an existing aluminum plate are low in joint strength as the existing foamed aluminum plate and the existing aluminum plate are directly brazed, brazing filler metal is non-wetted and oxide films are difficult to remove. The method includes the steps: firstly, cleaning and drying the foamed aluminum plate and the compact aluminum plate; secondly, heating the foamed aluminum plate, sliding rod-like brazing filler metal on a surface to be welded of the foamed aluminum plate in a reciprocating manner, and coating the brazing filler metal on the surface of the foamed aluminum plate to be welded; thirdly, butting end surfaces to be welded of the foamed aluminum plate and the compact aluminum plate, and heating butt joint surfaces to melt the brazing filler metal on the butt joint surfaces; fourthly, sliding the foamed aluminum plate on an interface to be welded in a reciprocating manner for 5-15 times, and exerting pressure in a direction perpendicular to the surface to be welded; and fifthly, stopping sliding friction, exerting pressure again, cooling the plates after heat preservation, and connecting brazing interfaces of the foamed aluminum plate and the compact aluminum plate. The method is used for welding the foamed aluminum plate and the aluminum plate.

Owner:HARBIN INST OF TECH

Method for removing oxidation film and brazing foamed aluminum through self-friction of foam walls

InactiveCN102601475AGive full play to the advantages of light weightPromote fragmentationSoldering apparatusNon wettingMolten state

The invention discloses a method for removing an oxidation film and brazing foamed aluminum through self-friction of foam walls, which relates to a welding method in the brazing field and solves the problem that the joint strength is reduced as brazing filler metal is non-wetting and the oxidation film is removed difficultly in the brazing process of the foamed aluminum. The method for removing the oxidation film and brazing the foamed aluminum comprises the following steps that: 1. two foamed aluminum plates are heated, and the rodlike brazing filler metal can slide on to-be-welded surfaces of the two foamed aluminum plates in a reciprocating way respectively, so that the brazing filler metal can be coated on the to-be-welded surfaces; 2. the end surfaces of the two foamed aluminum plates, which are coated with the brazing filler metal, are butted, and the brazing filler metal on the contact surfaces of the two foamed aluminum plates can be in a molten state after heating; 3. the foamed aluminum plates clamped by slidable fixtures can slide at the to-be-welded interfaces in a reciprocating way, and the pressure is exerted in the direction vertical to the welding surfaces at the same time; and 4. the sliding of the foamed aluminum plates can be stopped, the to-be-welded surfaces of the two foamed aluminum plates are aligned with each other and are pressurized again, heat preservation is carried out on the to-be-welded surfaces of the two foamed aluminum plates for 1-3 minutes, and then the to-be-welded surfaces of the two foamed aluminum plates can be cooled naturally to the room temperature, so as to realize a metallurgical-bonding brazing interface between the two foamed aluminum plates. The method for removing the oxidation film and brazing the foamed aluminum can be used for welding the foamed aluminum.

Owner:HARBIN INST OF TECH

Process of obtaining composite brazed seam with ultrasonic brazed aluminium-base composite material

InactiveCN100493795CRealize weld compoundingRealize the structureWelding/cutting media/materialsWelding/soldering/cutting articlesBraze alloyUltrasonic vibration

The present invention relates to relates to welding method, and is especially ultrasonic brazing process of obtain composite brazed seam in aluminum-base composite material. The process includes the following steps: 1. filling brazing alloy; 2. primary brazing; and 3. ultrasonic vibration treatment to obtain composite brazed seam in aluminum-base composite material. The said brazing process can obtain brazed joint with greatly improved mechanical performance and heat expansion performance, low heat expansion coefficient, and high strength near that of the mother material.

Owner:HARBIN INST OF TECH

A cross-flow fan blade welding robot

The invention discloses a cross-flow fan blade welding robot, which includes a material distribution module, a material grabbing manipulator, a pre-positioning module, a material feeding module, an ultrasonic welding machine and a material receiving module; the welding robot sends workpieces to the material grabbing manipulator through the material distribution module Preliminary shaping and self-centering by three-jaw clamping, and then sent to the pre-positioning module to realize eight-jaw clamping self-centering and positioning mark rotation alignment, and then through the feeding module to realize four-jaw clamping self-centering, Compensation of translation errors and rotational angle errors as well as blade interpolation for soft landing and rotational search, in turn clamping self-centering and clamping force control with four guide rods in ultrasonic welding machines, two-stage welding head movement and digital power supply The driven ultrasonic transducer completes the welding, and then the receiving module takes out the finished product after welding and sends it to the storage belt line. The invention has the advantages of fast welding cycle, low noise, high yield rate, short line change time, online real-time quality monitoring, stable and reliable operation, and the like.

Owner:SHENZHEN SIJIECHUANG TECH CO LTD

Heterogeneous semi-solid brazing method for aluminum alloy and magnesium alloy under assistance of external vibration energy

InactiveCN102266994BAvoid serializationEfficient weldingSoldering apparatusRoom temperatureSemi solid

Owner:CHONGQING UNIV OF TECH

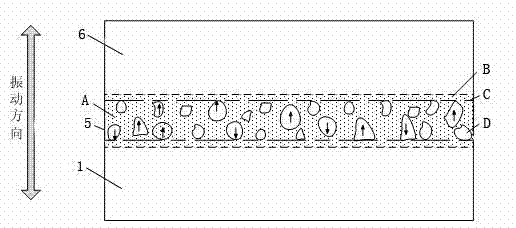

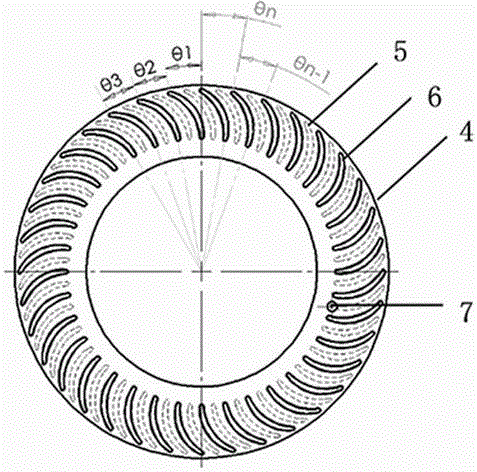

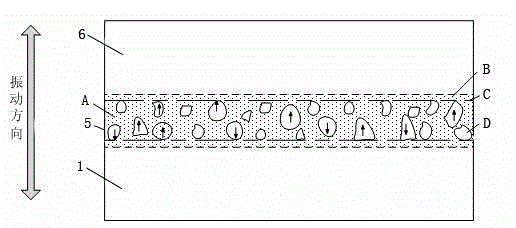

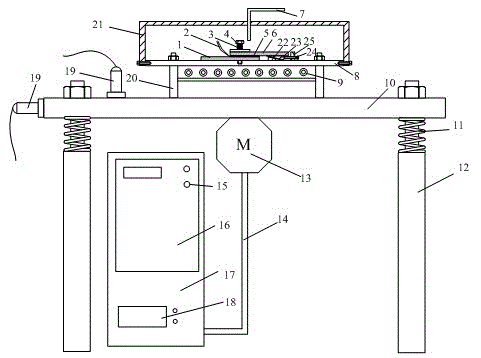

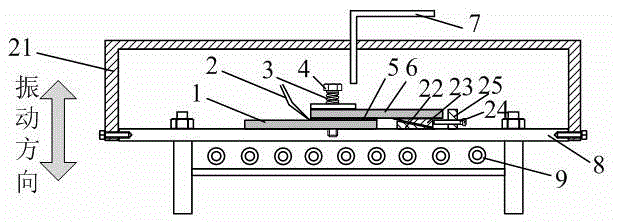

Aluminum alloy and its composite material non-vacuum semi-solid state vibration-rheological connection method

InactiveCN100408243CAchieve weldingShort welding cycleSoldering apparatusNon-electric welding apparatusForce constantSemi solid

The invention provides a method for anti-vacuum vibrating theological connecting aluminum alloy and its complex material. The invention is characterized in that: clamping aluminum alloy or complex material weldment on chucking appliance and placing medium temperature welding material on two pre-welding surface, heating weldment with temperature being 380-400 Deg. C, starting vibrating device after welding material fusion, the amplitude is 0.1-0.5 mm. The temperature during vibrating process is the same, and the vibrating time is 10-300 seconds. The temperature is increased to 450-520 Deg. C after vibration, and it is kept for 1-5 minutes. Then starting vibrating device again, the amplitude is 0.1-1 mm, stopping after 3-60 seconds, forcing constant pressure with pressure range being between 0.1-2 Mpa, keeping temperature for 5-30 minutes, and cooling. The invention is characterized by low cost, high efficiency and quality.

Owner:HARBIN INST OF TECH

Method for making integral electric contact

InactiveCN1188879CImprove electrical performanceIncrease productivityElectric switchesNon-electric welding apparatusMaterials scienceHeat treating

The invention discloses the method for manufacturing the solid type electric contact belonging to the sintering technique. The technique of the friction welding makes the two kinds of metals composed of the electric contact weld together. Then the proper heart treatment for removing the internal stress and the whole form processing are carried out so as to obtain the solid type electric contact with better tensils strength and rigidity. Comparing with the liquid phase sintering, the friction welding technique provides the advantages of 5% higher yield, productivity raised 7.3 times, saving copper product more than 36%, eliminating the procedure for treating the solidified liquid.

Owner:BEIJING SHANGHUAYANG ELECTRONICS TECH DEV

A kind of welding method of max phase ceramic material

The invention provides an MAX phase ceramic material welding method. In the provided welding method, the ends of two MAX phase ceramic materials to be welded are respectively connected to an upper electrode and a lower electrode, the welding surfaces are processed and then contacted with each other, then the ceramic materials, electrodes, and a power supply form a closed loop, joule heat is generated by the current on the touch surfaces, the temperature of the touch surface is rapidly raised, thus the MAX phase ceramic material of the touch surface is activated and diffused, and the welding is achieved. In the conventional welding method, a middle transition layer is used, and the middle transition layer is diffused at a high temperature under the combined actions of temperature-pressure-temperature maintaining so as to achieve the welding. Compared with the conventional welding method, the provided welding method has the following advantages: (1) the method is simple and practical; (2) a middle transition layer is not needed; (3) the welding period is short; (4) no welding silt or interface on the surface of welded material, and the ceramic materials are perfectly integrated together; (5) the welding method has a very good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

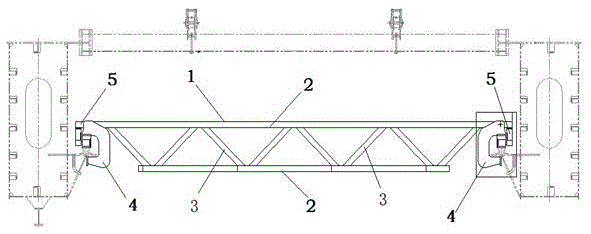

Tool used for track welding

PendingCN105458590AEasy assembly and disassemblyStrong site adaptabilityRailsWelding/cutting auxillary devicesEngineeringBolt connection

The invention discloses a tool used for track welding, comprising a main cross frame, wherein the main cross frame is connected with a jack base by a bolt and is welded with a travelling mechanism, and pressed welding of the track can be achieved by a jack on the jack base. The tool is mainly used for welding of main trolley tracks of harbor machinery, and has the characteristics of being simple to produce, convenient to assembled, strong in field adaptability and low in cost. The tool is quick, high in efficiency and good in quality when being used for carrying out trolley track welding,

Owner:WISON NANTONG HEAVY IND

Large posted sides pipeline narrow gap tungsten electrode noble gas protecting all-position automatic soldering method

ActiveCN100450692CReduce fillingReduce welding costsArc welding apparatusWelding/cutting media/materialsNoble gasSoldering

Owner:CHINA NUCLEAR IND 23 CONSTR

Aluminium base composite material ultrasonic wave fine welding method

InactiveCN1326658CAvoid WeldingEfficient weldingNon-electric welding apparatusUltrasonic vibrationMaterials science

Owner:HARBIN INST OF TECH

Method for low temperature brazing aluminium alloy to obtain brazed joint with high temperature use performance

ActiveCN100519032CHigh strengthSmall amount of deformationWelding/cutting media/materialsWelding/soldering/cutting articlesBraze alloySoldering

Owner:哈尔滨工大光电科技有限公司

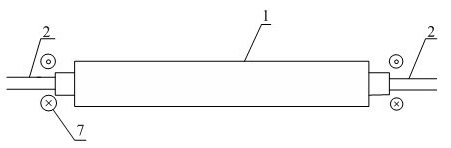

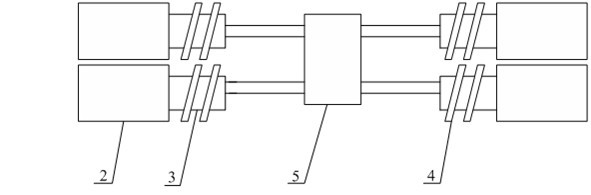

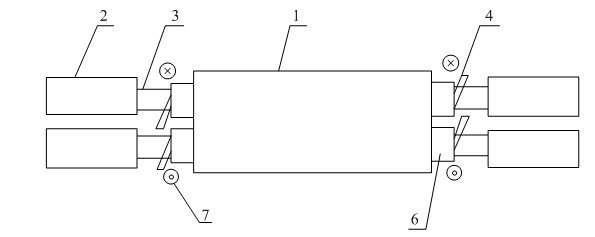

Rapid hot riveting welding equipment for ultrathin sheet rib

The invention relates to rapid hot riveting welding equipment for an ultrathin sheet rib. The equipment includes a hot riveting fixation plate, a hot riveting welding structure arranged on the hot riveting fixation plate, a workpiece fixation station and a workpiece clamping structure arranged on the workpiece fixation station. And a workpiece fixation die is disposed on the workpiece fixation station. The equipment is characterized in that: the hot riveting welding structure includes multiple independent hot riveting units, the workpiece clamping structure includes a clamping air cylinder arranged on the workpiece fixation station and a holddown connecting the clamping air cylinder, and the holddown comprises a first compression plate, a second compression plate, a third compression plate and a fourth compression plate. The equipment provided by the invention adopts the independent hot riveting welding structure to weld the wing plate of the ultrathin sheet rib. Independent welding and independent hot riveting are needed by each welding spot to start welding. The welding mechanism has no need for integral lifting, each independent hot riveting mechanism can be welded together, and the welding cycle is short.

Owner:WUHU XINBAO ULTRASONIC EQUIP

Magnesium alloy and aluminum alloy heterogeneous non-vacuum machinery forced rotation semi-solid brazing method

InactiveCN102284758BLow costHigh quality weldingSoldering apparatusWelding/soldering/cutting articlesSemi solidMagnesium alloy

The invention relates to a magnesium alloy and aluminum alloy heterogeneous non-vacuum machinery forced rotation semi-solid brazing method; a magnesium alloy weldment and an aluminum alloy weldment are clamped on a clamp, Zn-Sn or Zn-Al-Sn system other brazing materials are arranged on two surfaces to be brazed, the weldments are heated, the heating temperature is between 350DEG C to 450DEG C, simultaneously pressure is increased, the pressure range is 0.1MPa to 1MPa, so that the brazing materials on a middle layer are in a semi-solid state, a rotary device is started, the rotating speed is 65r / min to 1500r / min, the temperature is constant during a rotation process, and the rotation time is 10s to 300s. After the rotation, the temperature rises by a certain rate, the heat is insulated at preset temperature, so that the brazing materials dissolve parent materials with a certain thicknesses, the heat insulating temperature is between 400DEG C to 480DEG C, and the heat insulating time is1min to 5min. Afterwards, pressure is increased, the pressure range is 0.1MPa to 1MPa, the rotary device is started again (secondary rotation), the rotating speed is 65r / min to 600r / min, rotation is stopped after 3s to 60s, and cooling is carried out with a furnace after the heat is insulated for 5 min to 30min. The magnesium alloy and aluminum alloy heterogeneous non-vacuum machinery forced rotation semi-solid brazing method can realize the high-efficiency, high-quality and economic connection of a magnesium alloy and an aluminum alloy.

Owner:CHONGQING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com