Magnesium alloy and aluminum alloy heterogeneous non-vacuum machinery forced rotation semi-solid brazing method

A brazing method, aluminum alloy technology, applied in the direction of non-electric welding equipment, welding equipment, welding equipment, etc., to achieve the effects of avoiding softening, shortening time, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

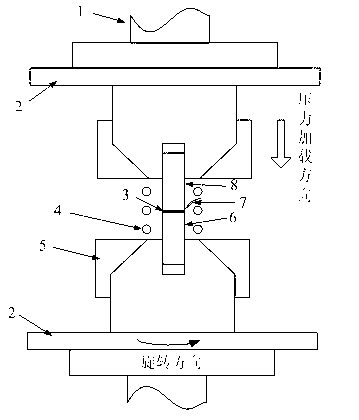

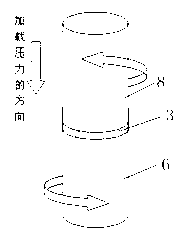

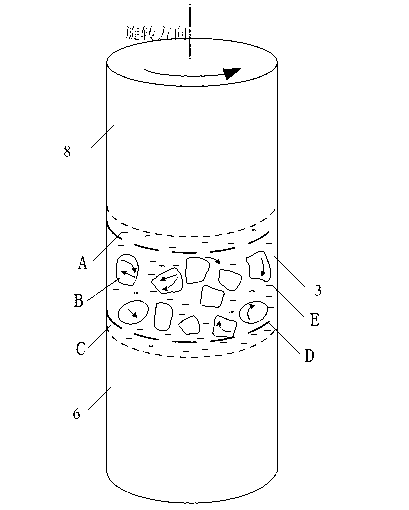

[0037] see figure 1 with Figure 2A , the AZ31B magnesium alloy to-be-welded piece 6 and the 2024 aluminum alloy to-be-welded piece 8 were clamped on the fixture 5, and the gap between the to-be-welded pieces was 500 μm. And place Zn-Al27 mid-temperature solder 3 on the welding surfaces of the two parts to be welded 6 and the welded part 8, the solder can be sheet, foil, coating or sprayed on the surface to be welded in advance. Use the cylinder 1 to apply pressure between the workpiece 6 and the weldment 8 and maintain a constant value. The loading pressure is 0.3 MPa. At the same time, the high-frequency coil 4 is used to heat the workpiece to be welded. melt. Start the rotary platform 2, the rotation mode is double weldment rotation, the rotation direction is opposite, the speed is 300r / min, the temperature is constant during the rotation, and the rotation time is 30 seconds. After the rotation stops, the temperature rises at a certain heating rate, the heating rate is 0...

Embodiment 2

[0039] see figure 1 with Figure 2B, the AZ91D magnesium alloy to-be-welded piece 6 and the 6061 aluminum alloy to-be-welded piece 8 were clamped on the fixture 5, and the gap between the welded pieces was 600 μm. And place Zn-Al12 mid-temperature solder 3 on the two surfaces to be welded. The solder can be in the form of flakes, foils, coatings or sprayed on the surfaces to be soldered in advance. Use the cylinder 1 to apply pressure between the weldments and maintain a constant value. The loading pressure is 0.2 MPa, and the weldment 6 and the workpiece 8 are heated at the same time. The heating temperature is 380 ° C, so that the middle layer solder 3 is semi-solid. Start the rotating platform 2 device, the rotation method is single weldment rotation, the speed is 300r / min, the temperature is constant during the rotation, and the rotation time is 40 seconds. After the rotation stops, the temperature rises at a certain heating rate, the heating rate is 1°C / s, and it is kep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com