Tool used for track welding

A track welding and tooling technology, which is applied to tracks, welding equipment, auxiliary welding equipment, etc., to achieve the effects of high welding efficiency, convenient production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

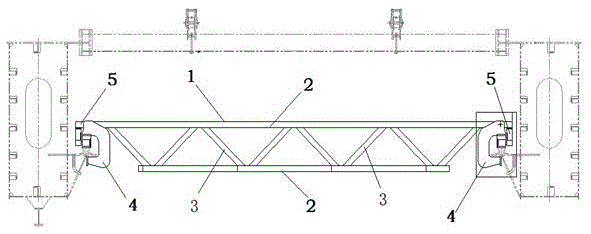

[0019] see figure 1 , a tooling for rail welding, including an inverted trapezoidal main hanger 1, a number of reinforcing ribs 3 are arranged between the upper and lower horizontal supports 2 of the main hanger 1, and the two ends of the main hanger 1 are horizontal along the upper The lower edge of the support 2 is provided with a jack base 4 and a running mechanism 5 in sequence. The connection between the reinforcing rib 3 and the horizontal support 2 is a 45-degree fillet weld, and the height of the welding angle is 0.7 times the thickness of the thin plate connected between the reinforcing rib 3 and the horizontal support 2 . An angle of 90 degrees is formed between two adjacent reinforcing ribs 3 . The upper and lower horizontal supports 2 and reinforcing ribs 3 of the main hang frame 1 are square tubes, the distance between two adjacent reinforcing ribs 3 is 60mm, and the main hang frame 1 adopts a square tube of 80×80mm. The main hang frame 1 is connected with the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com