Large posted sides pipeline narrow gap tungsten electrode noble gas protecting all-position automatic soldering method

A tungsten inert gas, automatic welding technology, used in welding media, welding equipment, welding equipment and other directions, can solve the problems of large welding deposit metal filling, wide groove, long welding cycle, etc., to achieve high welding efficiency, The effect of small filling amount and short welding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

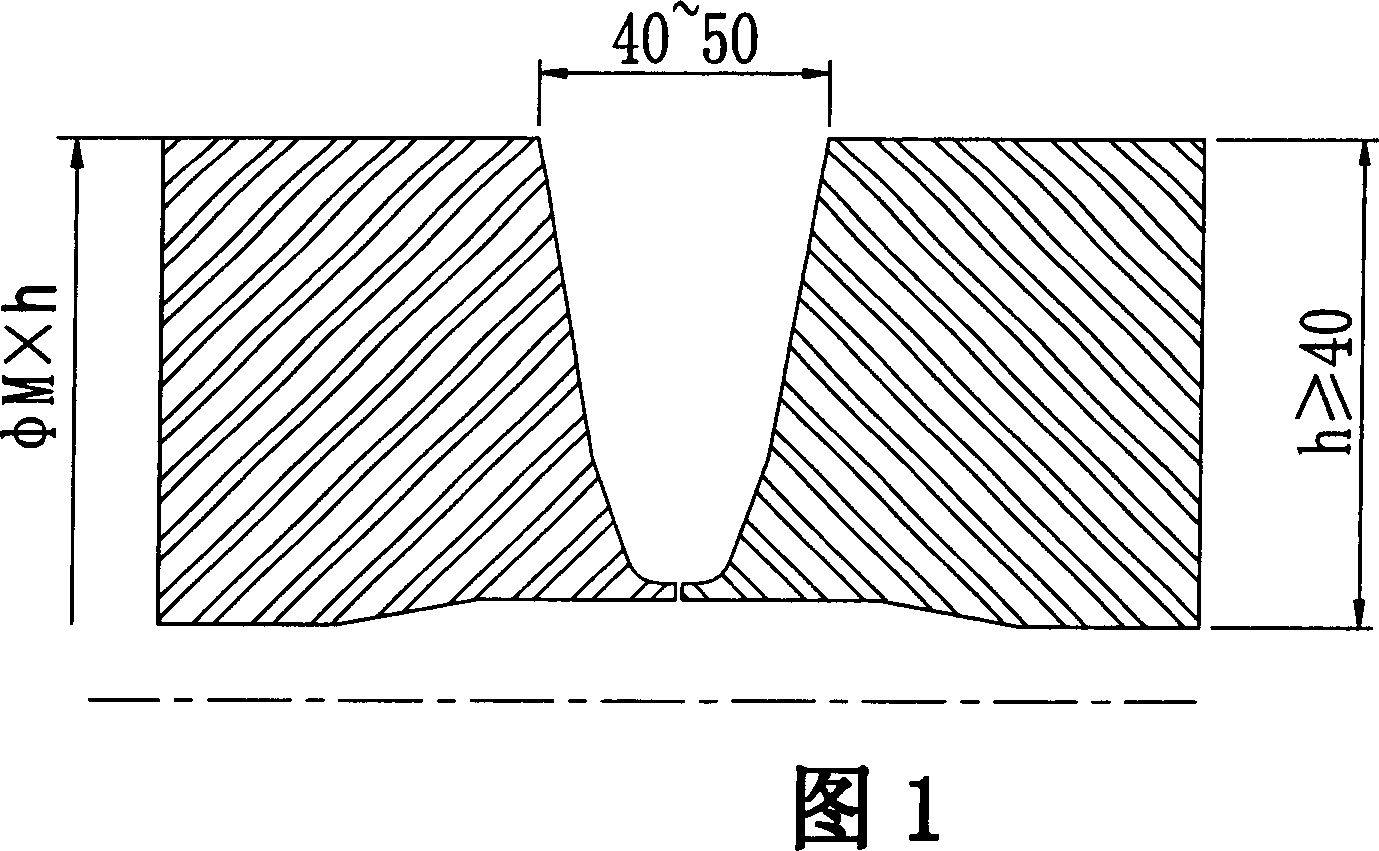

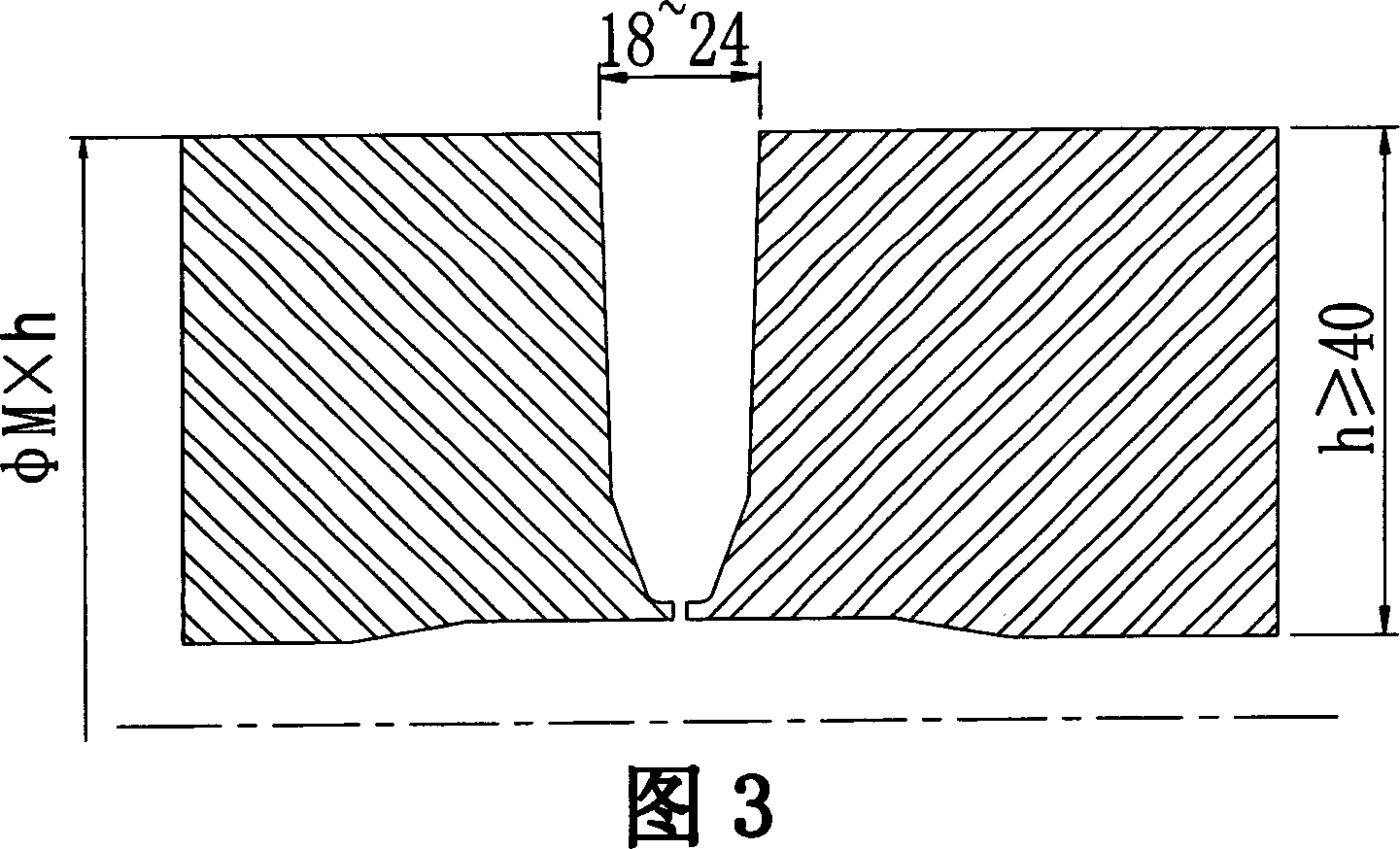

[0030] For all-position automatic welding of narrow gaps in large-diameter thick-walled pipes with a wall thickness h above 40mm, the present invention is based on the traditional argon-electric combined welding process for welding the bevel of large thick-walled pipes, through repeated tests and improvements, The groove type and size suitable for the narrow gap automatic welding process of large thick-walled pipes are obtained, as shown in Figure 3. Compared with the groove of large thick-walled pipes welded by the traditional argon-electric combined welding process shown in Figure 1, this paper The width of the groove proposed by the invention is obviously narrowed, the maximum width of the groove is reduced to 18-24 mm, and the structural shape of the groove is also obviously changed.

[0031] Fig. 4 shows a schematic diagram of the speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com