Nano-granules reinforced ultra-high molecular weight polyethylene artificial joint material and production method thereof

An ultra-high molecular weight, nanoparticle technology, applied in the field of materials for implanted devices, can solve the problems of difficulty in improving the wear resistance of UHMWPE and difficult long-term use, and achieve the effects of improving lubrication, wetting and reducing wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: select ultra-high molecular weight polyethylene powder for use, molecular weight is 3,000,000; Filling material is to use nanometer SiO 2 Powder (note: other nanoparticles with good biocompatibility are acceptable, such as metal and alloy particles), with a purity of 99% and an average particle size of 10nm.

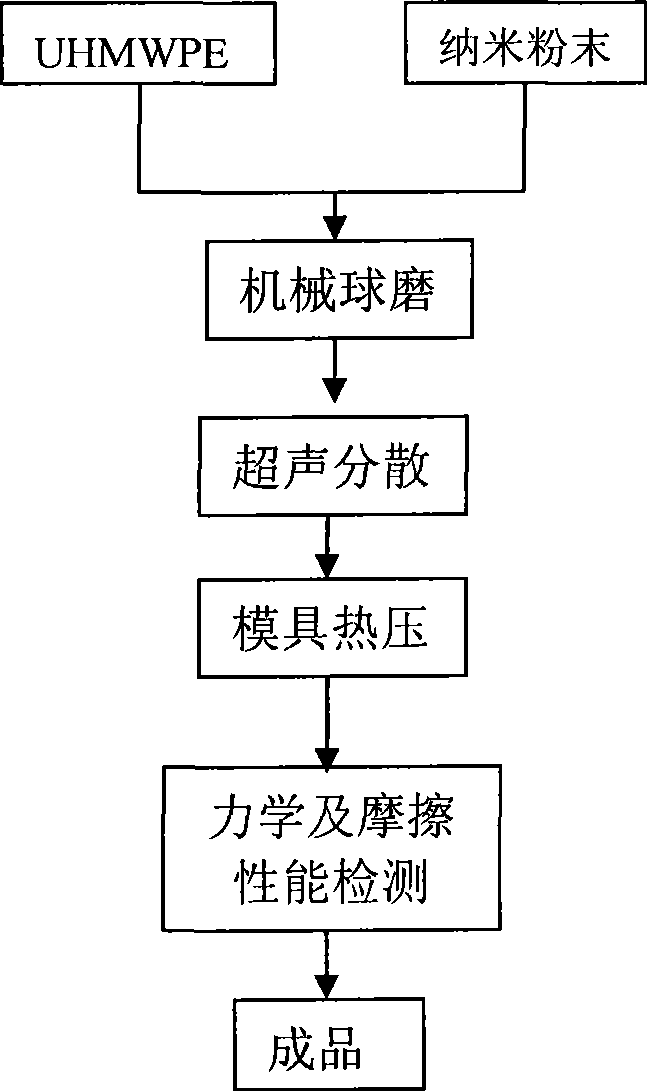

[0024] The preparation process of the composite material is as follows:

[0025] (1) be that 100m sieve is screened to high molecular weight polyethylene powder with aperture;

[0026] (2) Use 1% KH-570 coupling agent to nano-SiO 2 Particle surface modification;

[0027] (3) the mass fraction is respectively 1%, 3%, 6%, 10% nano-SiO 2 The powder and the UHMWPE powder are wet-mixed in an ethanol solution in a ball mill, the speed of the ball mill is 200 rpm, and each mixing process is clockwise and counterclockwise for 30 minutes;

[0028] (4) Ultrasonic dispersion is carried out for 10 minutes to the powder after wet mixing, and then dried in a d...

Embodiment 2

[0033] Embodiment 2: select ultra-high molecular weight polyethylene powder for use, and molecular weight is 5,000,000; Filling material is tetragonal nanometer ZrO 2 Powder with a purity of 99.9% and an average particle size of 40nm.

[0034] The preparation process of the composite material is as follows:

[0035] (1) be that 100m sieve is screened to high molecular weight polyethylene powder with aperture;

[0036] (2) Use 1.5% KH-570 coupling agent to nanometer ZrO 2 Particle surface modification;

[0037] (3) the mass fraction is respectively 1%, 2%, 3%, 5% nanometer ZrO 2 The powder and the UHMWPE powder are wet-mixed in an ethanol solution in a ball mill, the speed of the ball mill is 200 rpm, and each mixing process is clockwise and counterclockwise for 30 minutes;

[0038] (4) Ultrasonic dispersion is carried out for 10 minutes to the powder after wet mixing, and then dried in a drying oven;

[0039] (5) Add the dried mixed powder into the mold, hot-press molding...

Embodiment 3

[0043] Embodiment 3: Select ultra-high molecular weight polyethylene powder, molecular weight is 5,000,000; Filling material is α crystal form nanometer Al 2 o 3 Powder with a purity of 99.9% and an average particle size of 80nm.

[0044] The preparation process of the composite material is as follows:

[0045] (1) be that 100m sieve is screened to high molecular weight polyethylene powder with aperture;

[0046](2) Use 3% KH-570 coupling agent to nanometer Al 2 o 3 Particle surface modification;

[0047] (3) the mass fraction is respectively 1%, 2%, 3%, 5%, 10% nanometer Al 2 o 3 The powder and the UHMWPE powder are wet-mixed in an ethanol solution in a ball mill, the speed of the ball mill is 200 rpm, and each mixing process is clockwise and counterclockwise for 30 minutes;

[0048] (4) Ultrasonic disperse the powder after wet mixing for 10 minutes, and then dry in a drying oven;

[0049] (5) Add the dried mixed powder into the mold, hot-press molding at a pressure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com