Hot rolling thin strip

A steel strip, thin steel technology, used in metal rolling, metal rolling, metal rolling stands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

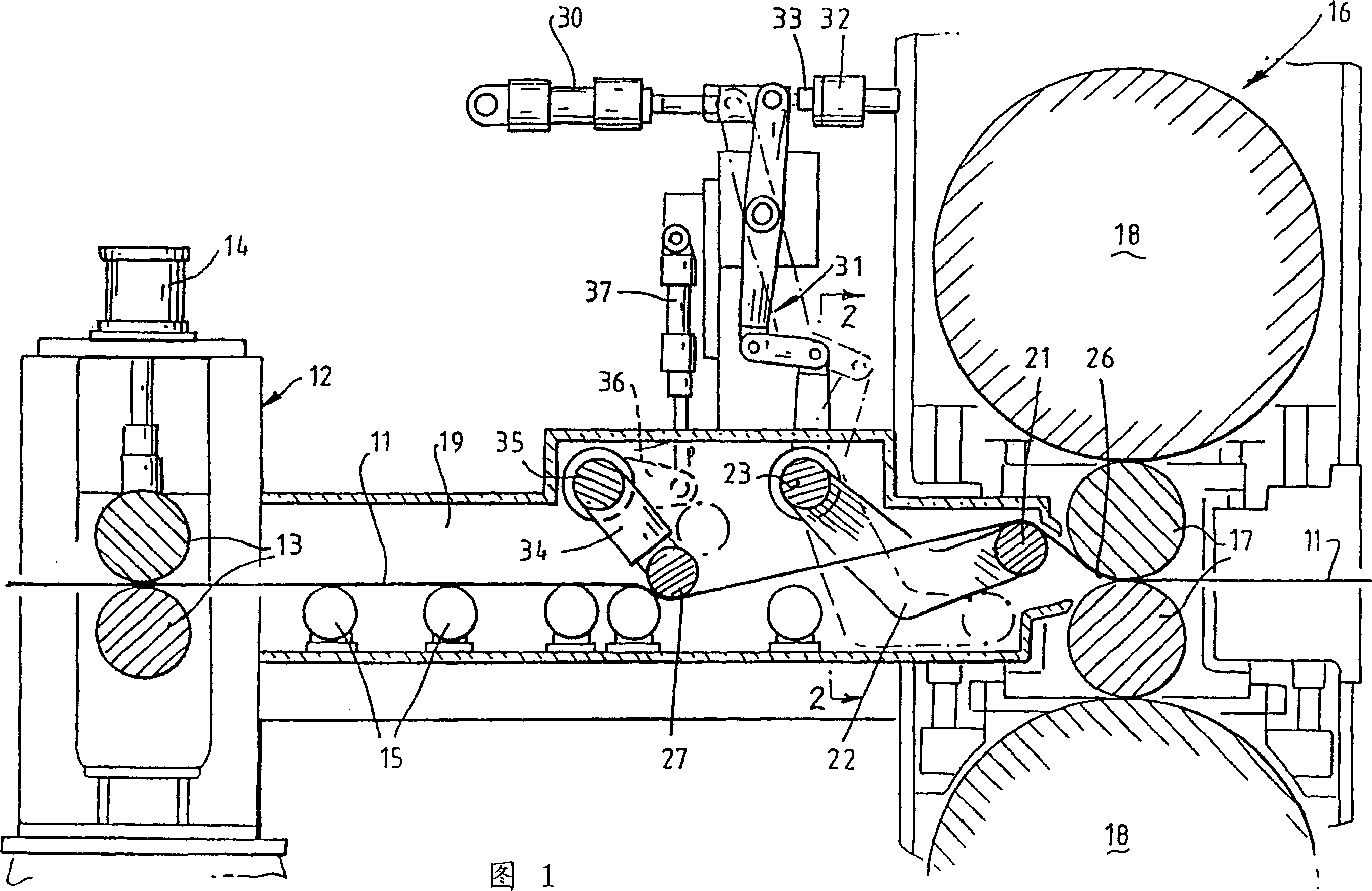

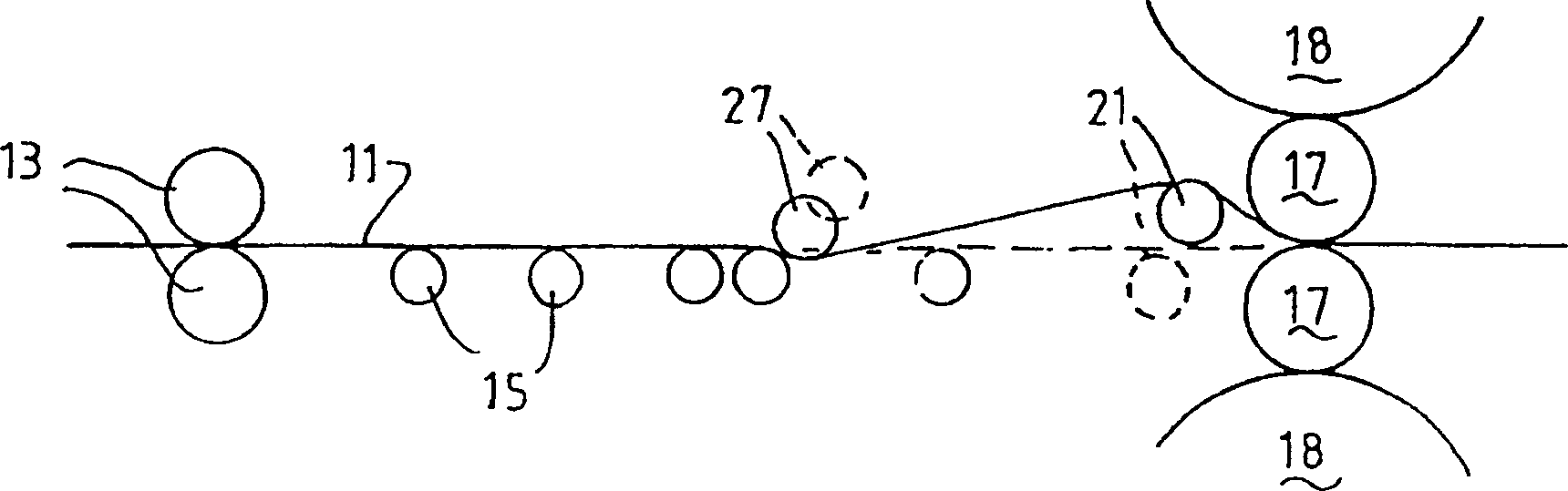

[0017] In the shown rolling mill arrangement, a thin steel strip 11 passes through a pinch roll stand 12 comprising a pair of pinch rolls 13 to which a strip clamping force is applied by a pair of hydraulic cylinder units 14 , a hydraulic cylinder unit 14 is provided on each side of the pinch roll frame.

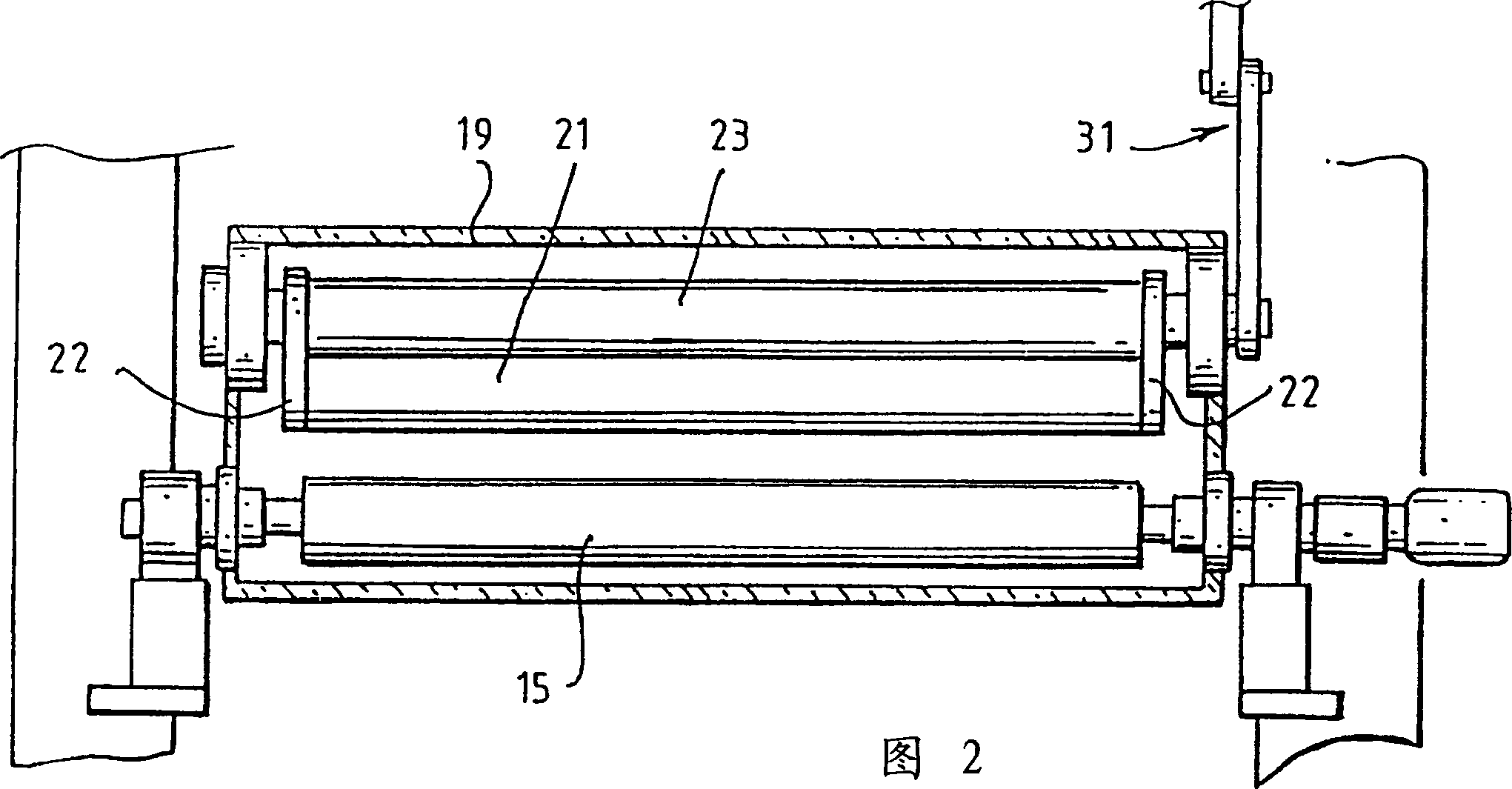

[0018] After passing through the pinch roll stand 12, the strip 11 is supported on a table formed by a series of rollers 15, through which the strip is conveyed to a rolling mill 16 comprising a pair of rollers arranged one above the other. One upper work roll 17 and a pair of upper and lower backup rolls 18 . The strip thinning force is applied between the work rolls 17 through hydraulic cylinder units (not shown), which are arranged on both sides of the rolling mill and act through the upper pressure roll 18 . Between the pinch roll stand 12 and the rolling mill stand 16 the steel strip is held in a sealed casing 19 .

[0019] According to the invention, the apparatus co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com