Manufacturing apparatus for hot-rolled steel plate and manufacturing method for steel plate

A hot-rolled steel plate and manufacturing device technology, applied in the direction of braking/tensioning devices, metal rolling, manufacturing tools, etc., can solve problems such as hindering cooling water drainage, achieve excellent mechanical properties, increase cooling water volume, and promote rapid cooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

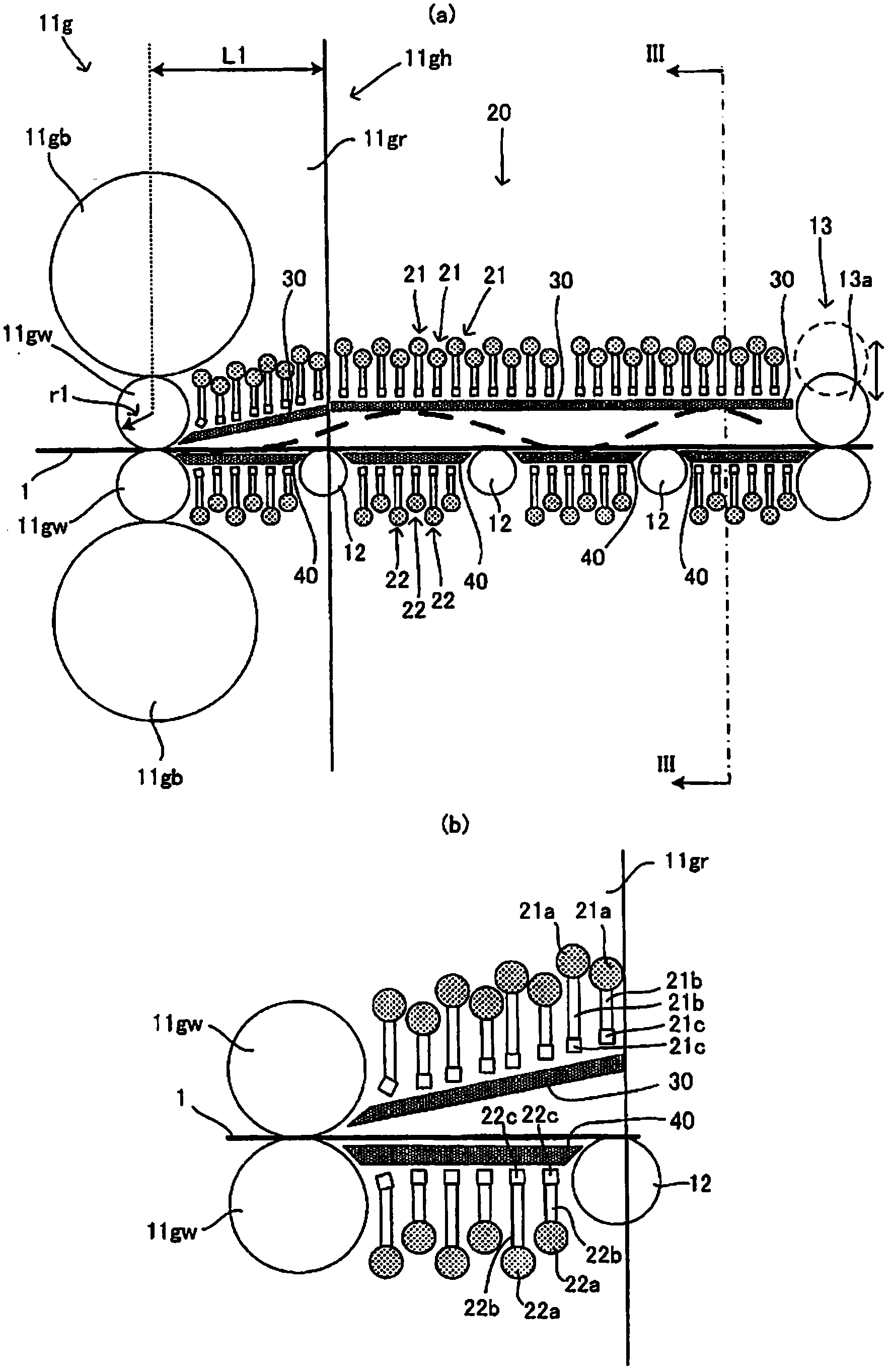

Method used

Image

Examples

Embodiment

[0123] Hereinafter, the present invention will be described in further detail based on examples. However, the present invention is not limited to these Examples.

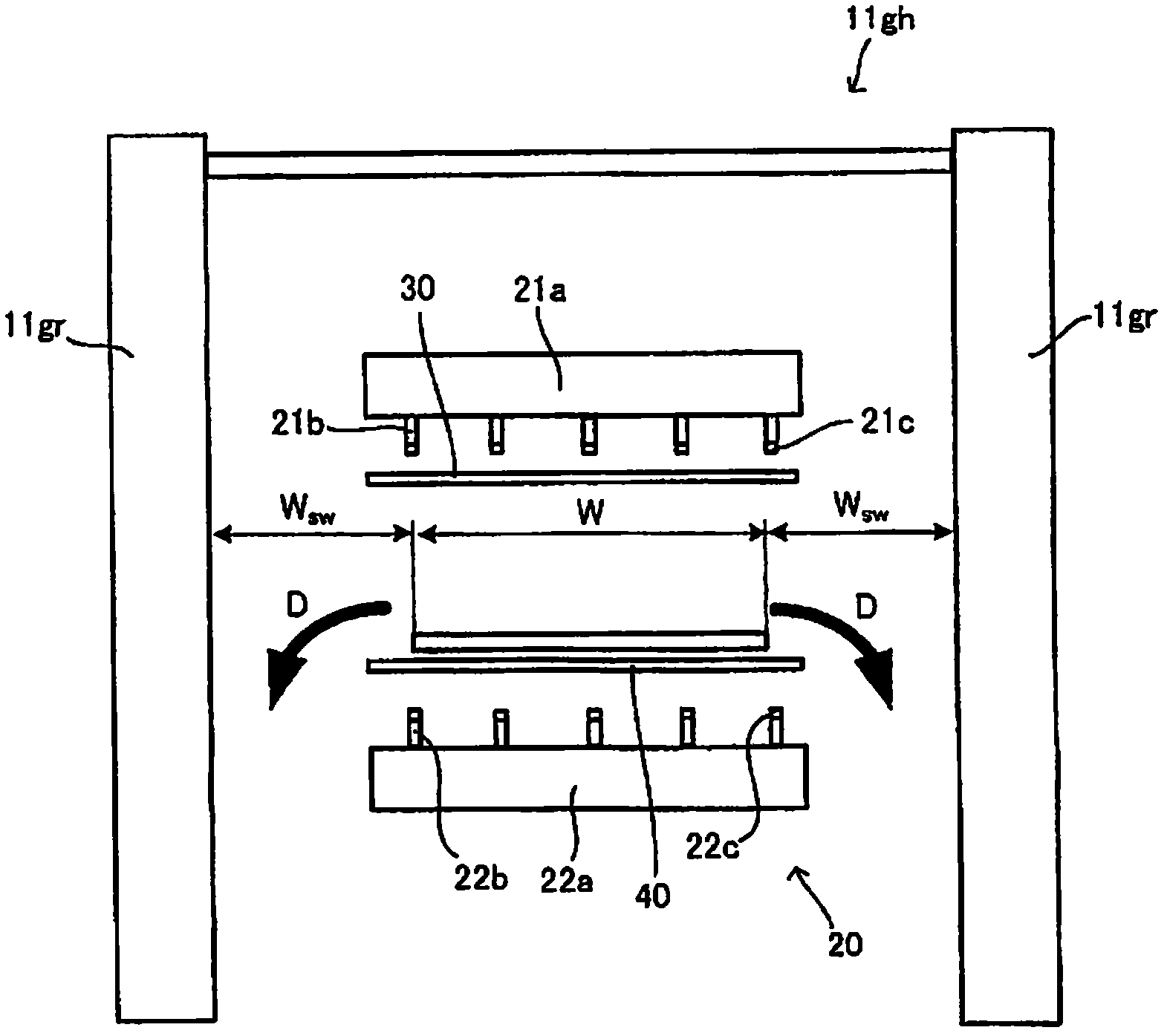

[0124] In the example, let Q q 0.33[m 3 / (m 2 ·s)], h is 0.35[m], observed Figure 12 The gap distance W between the end portion of the uniform cooling width as shown and the housing erected portion 11gr sw Changes in case of stagnant water on the steel plate. The results are shown in Table 1. Here, when the tip of the cooling nozzle was not submerged in water and drainage was possible, it was evaluated by ○, and when the tip of the cooling nozzle was submerged in water, it was evaluated by ×. In addition, in each case, the left side of calculated formula (1) is shown together.

[0125] [Table 1]

[0126] W sw (m)

[0127] It can be seen from Table 1 that the gap distance W sw In the case of 0.44 [m], 0.32 [m], and 0.20 [m], the cooling water supplied from the header is smoothly discharged downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com