Compact, flexible CSP facility for continuous, semi-continuous and batch operation

A compact and semi-continuous technology, applied in the direction of metal processing equipment, workpiece surface treatment equipment, braking/tensioning devices, etc., can solve the problems of long extension length, quality reduction, unfavorable production operations of steel types, etc., and achieve good roll heat insulation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

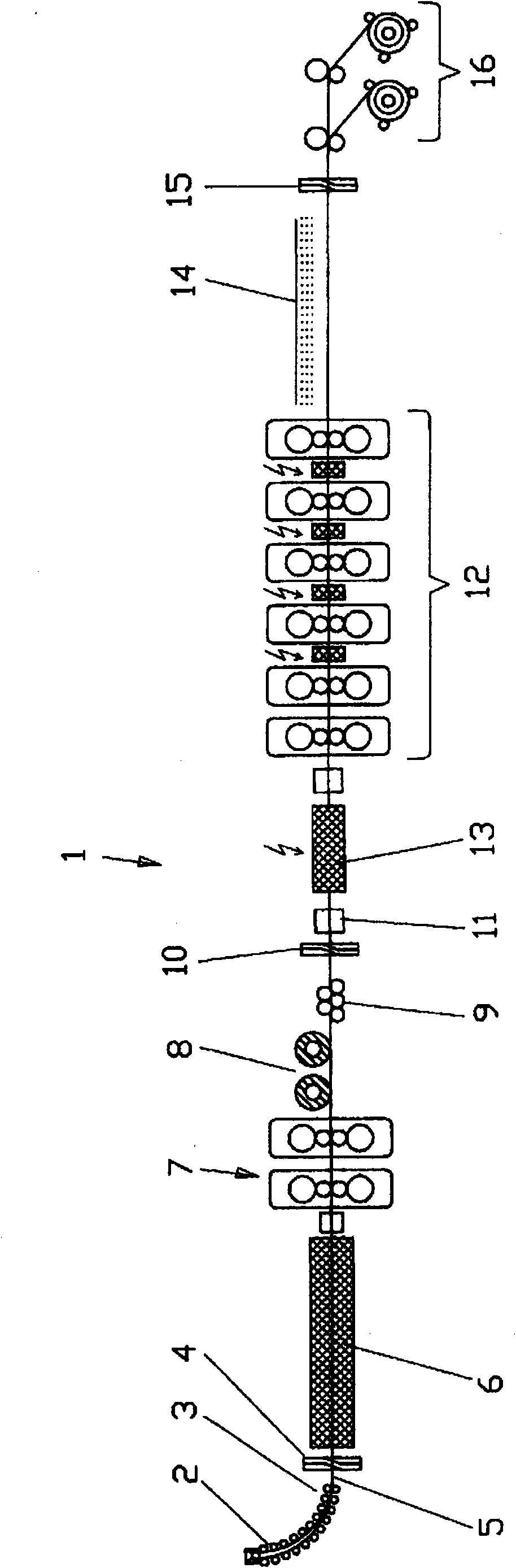

[0029] figure 1 A schematic diagram showing a flexible and compact CSP plant 1 for continuous operation, semi-continuous operation and intermittent operation. The plant 1 here has a continuous casting machine 2 with a continuous casting machine outlet 3 . After the continuous casting machine outlet 3, a shearing machine 4 is arranged, so that the cast strand 5 coming out of the continuous casting machine outlet 3 can be sheared. A furnace 6 , for example preferably a tunnel furnace, is located downstream of the shear 4 , which heats the strand 5 to the desired temperature. The furnace 6 is therefore located between the caster outlet 3 and the shear 4 on the one hand and the subsequent roughing train 7 on the other hand. exist figure 1 In the embodiment, the roughing group 7 includes double roughing stands. According to another inventive concept, however, the roughing train 7 can also have a single roughing stand or three roughing stands. In this exemplary embodiment, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com