Method and equipment for continuous production of rolled metal plate from molten metal

A technology of metal strips, molten metal, applied in the direction of metal rolling, metal rolling, metal rolling stands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

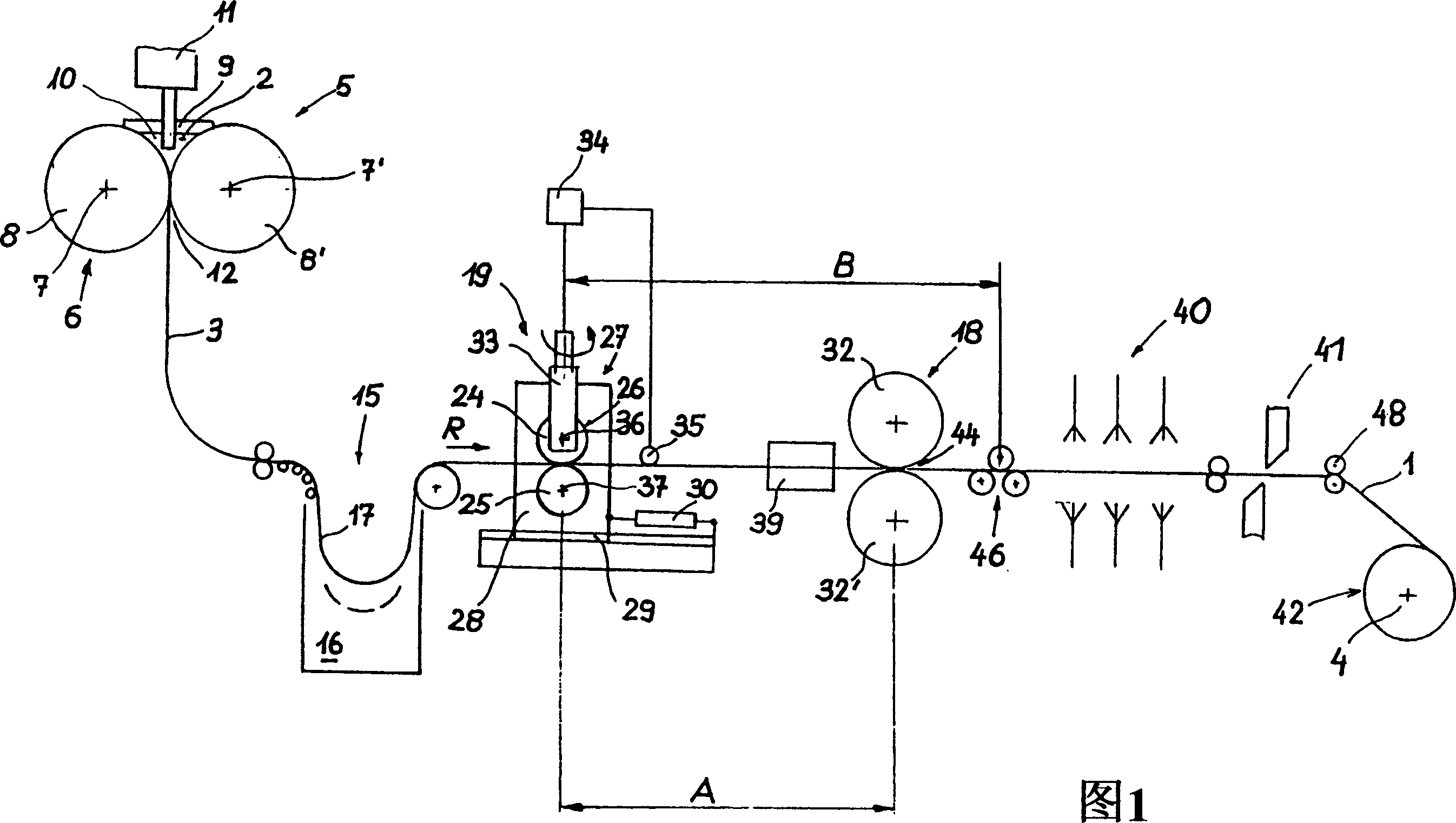

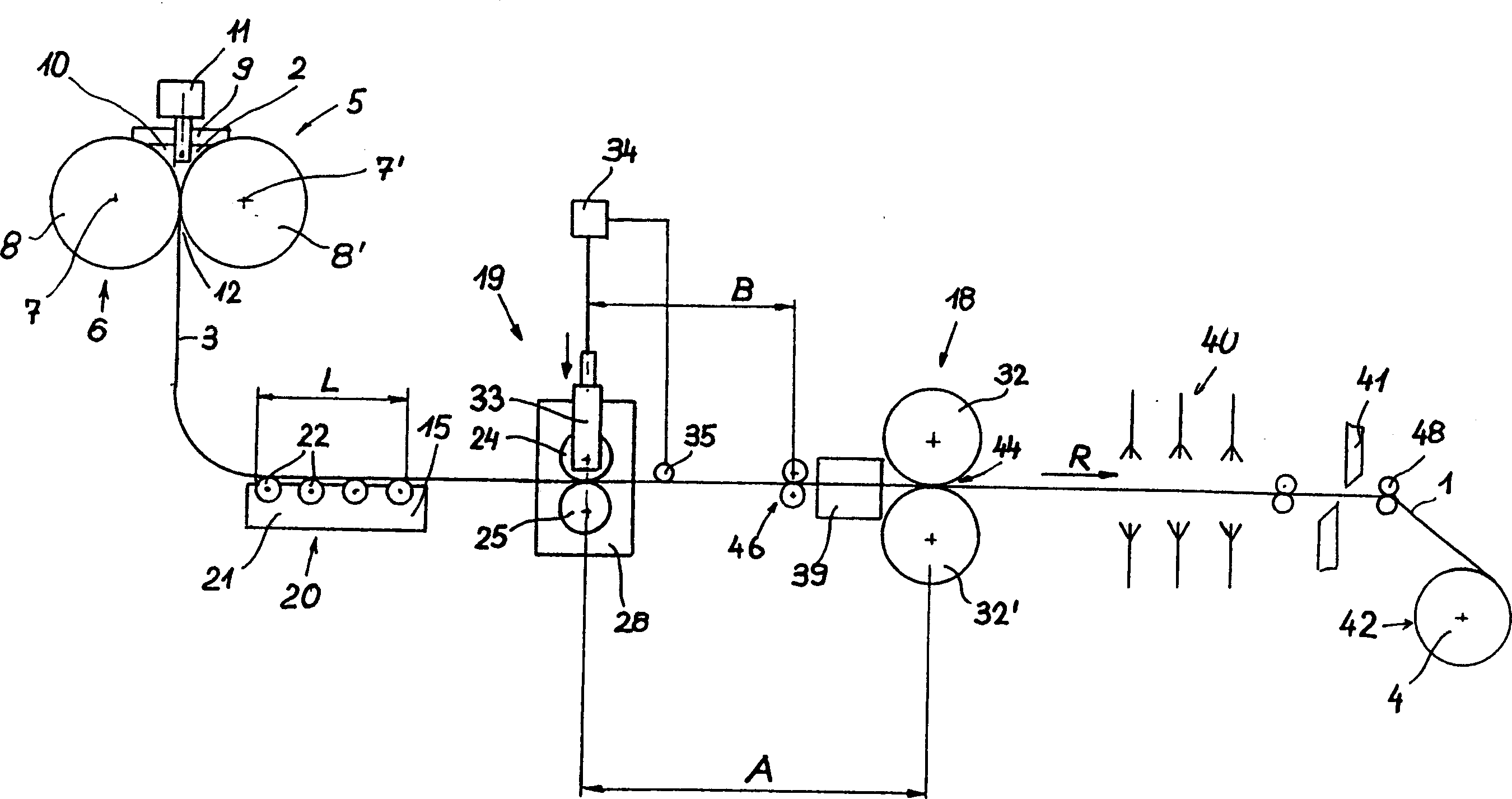

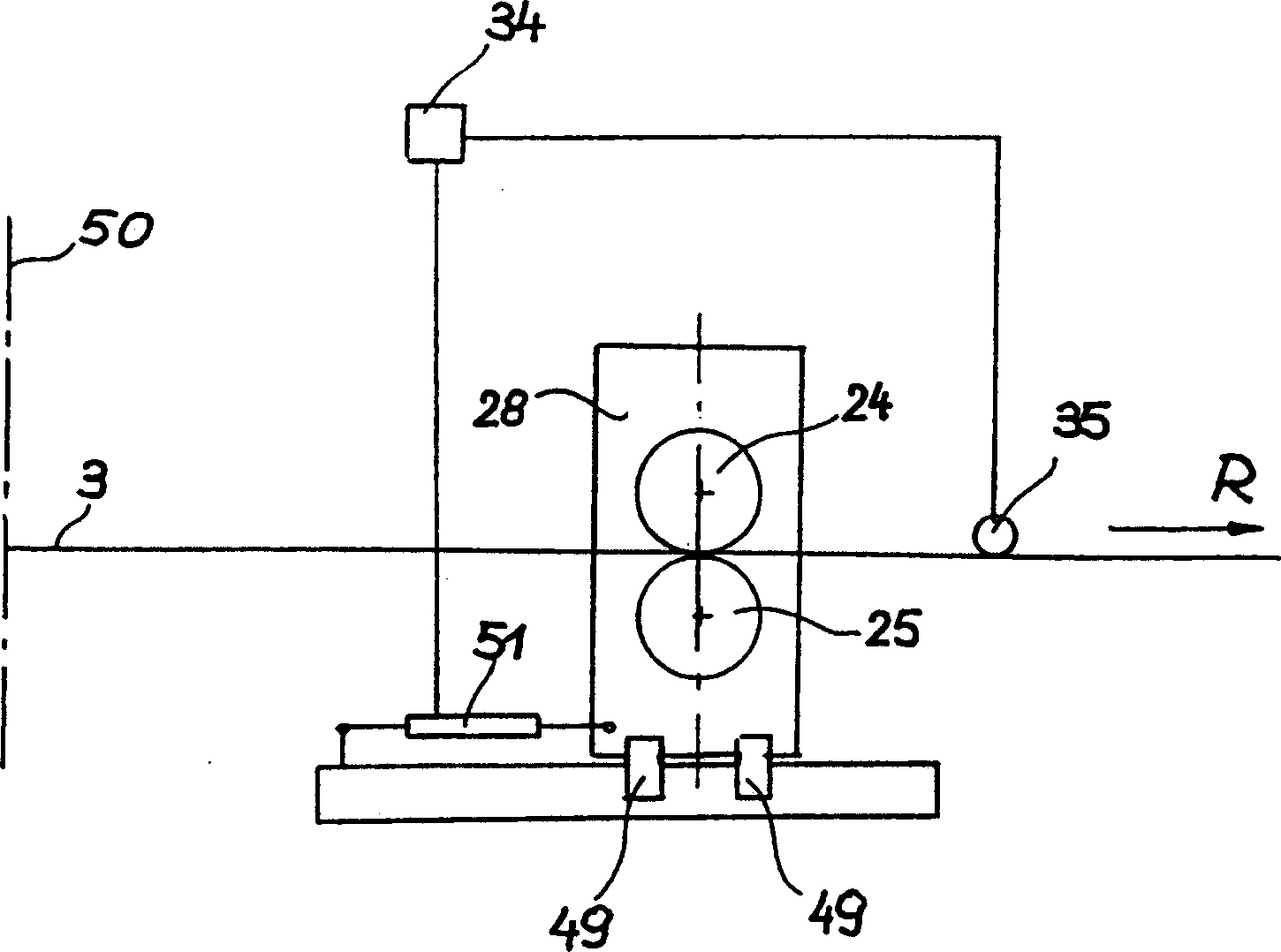

[0029]In the embodiment shown in Figures 1 to 3, which are described below, like reference numerals designate like elements. 1 and 2 show a plant according to the invention for the continuous production of rolled metal strip 1 with molten metal 2, wherein, in a first production step, cast metal strip 3 is produced from molten metal, and in the next In a second production step of one step, the cast metal strip 3 is thermally deformed during rolling. If appropriate, after a controlled cooling process, which is not explained further in the context of the present invention, the rolled metal strip 1 produced in this way is subsequently coiled into coils 4 of predetermined weight.

[0030] The strip casting device 5 is used to produce strip casting metal strips with a thickness between 1.0 mm and 20 mm. The stream forming core unit of the device is composed of a single belt moving horizontally on the lower side, or multiple turnover belts, caterpillars Or cast wall composition,. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com