Method and apparatus for the rapid delivery of heavy plates from a rolling mill

a technology of heavy plate and rolling mill, which is applied in the direction of metal rolling arrangement, tensioning/braking arrangement, manufacturing tools, etc., can solve the problems of uneconomical and/or impossible production of limited-width hot strips, and achieve the effects of short cycle time, high speed and reliable storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

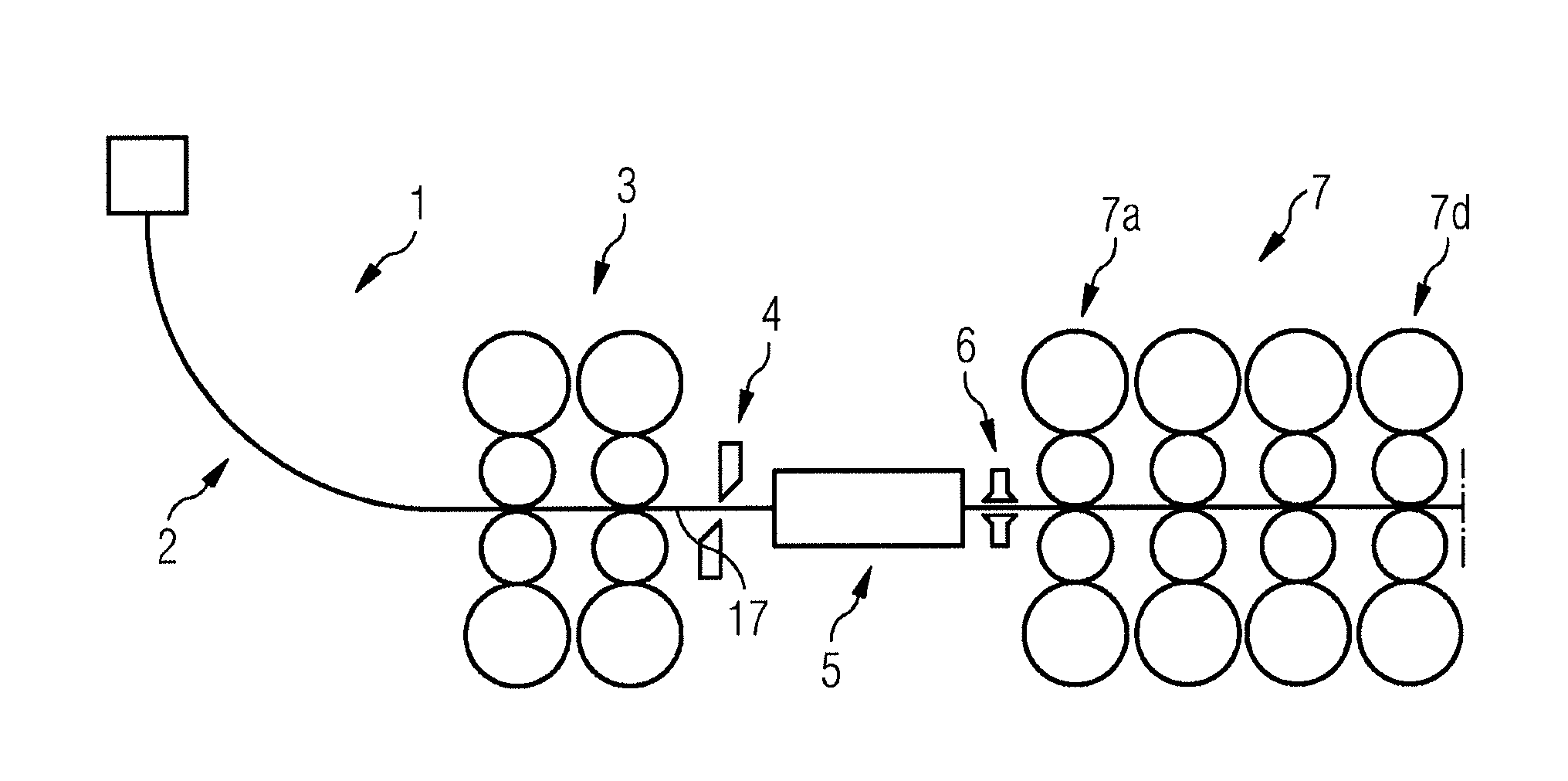

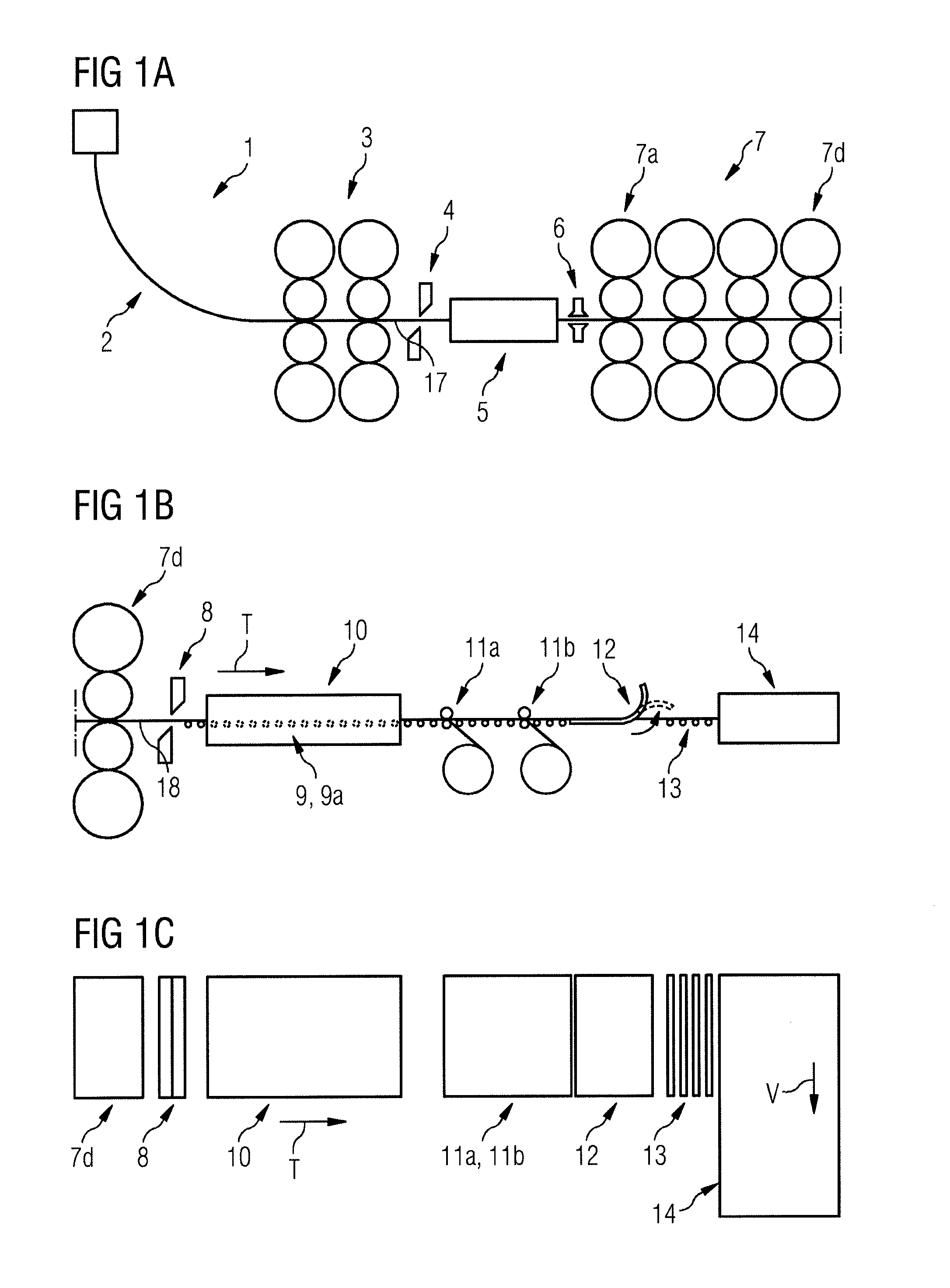

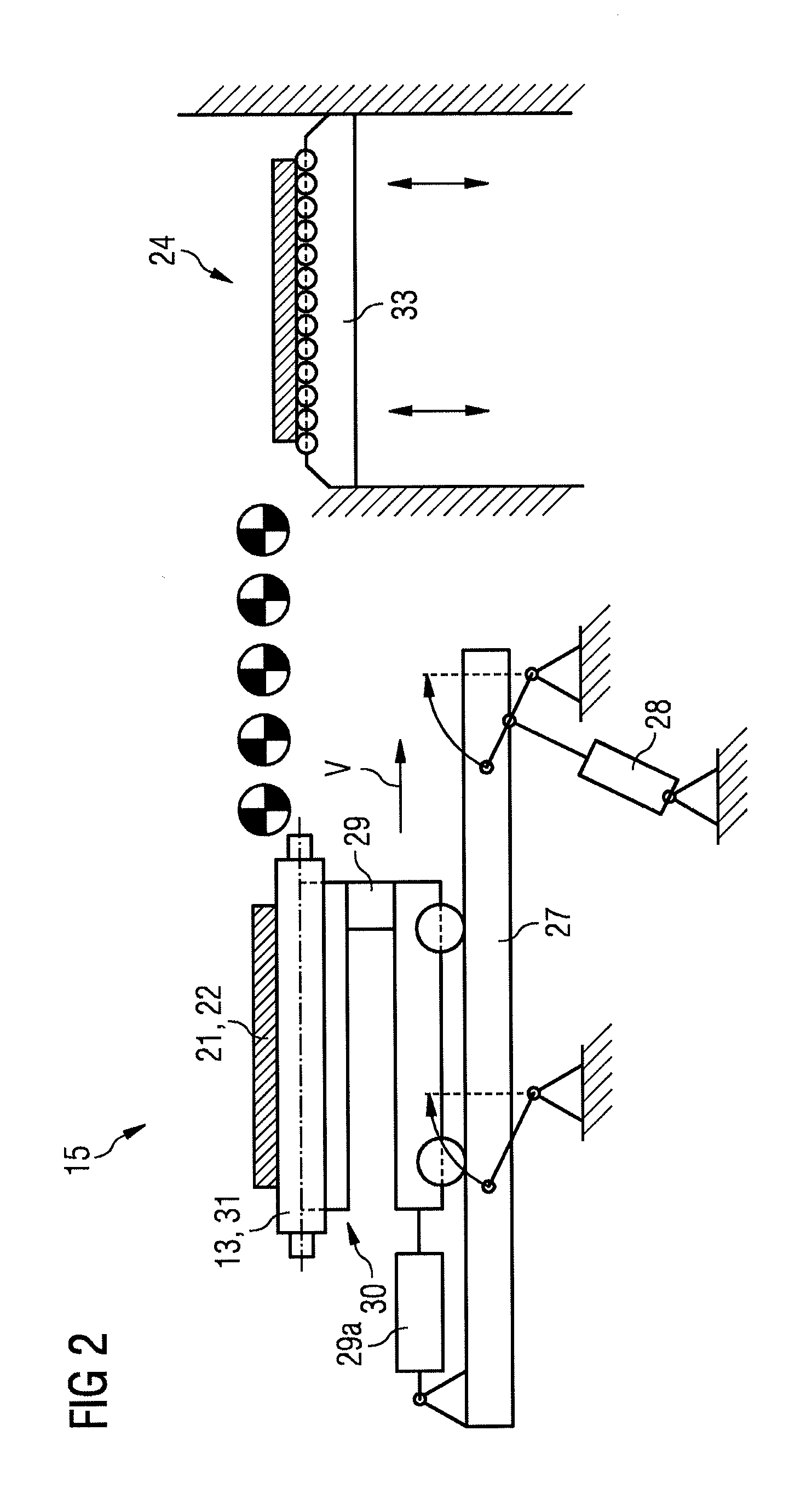

[0093]FIGS. 2 and 3 show a first embodiment variant of a delivery device 14 for the delivery of heavy steel plates from the ESP combined casting and rolling plant as per FIGS. 1A to 1C.

[0094]The delivery device 14 comprises a roller table 13 on which plates 21, 22 can be transported in the direction of transport T, means in the form of the rear limit stop 26a for storing a first plate 21 and means in the form of the forward limit stop 26b for storing a second plate 22 on the roller table 13, and a lateral conveyor 15 for the concurrent delivery of two plates 21, 22 transversely relative to the direction of transport T onto a storage location 24. The roller table 13 has a plurality of driven 9a table rollers 31; non-driven table rollers may also be present. According to the illustration in FIG. 3, two plates 21 and 22 are situated one behind the other on the roller table 13 before the delivery.

[0095]Before the actual delivery of the plates 21, 22 in the delivery device 14, the endles...

second embodiment

[0109]FIG. 5 shows a second embodiment variant of the lateral conveyor 15. The lateral conveyor 15 comprises a gripper 25 which is arranged to the left and right of the plates 21, 22 for the purpose of clamping the plates, and a swiveling unit 32 for swiveling the plates about an axis of rotation D which is oriented parallel to the direction of transport T.

[0110]Once the plates 21, 22 have been clamped by the gripper 25, the swiveling unit 32 is swiveled through approximately 180°, thereby moving the plates from the position illustrated on the left to that illustrated on the right. The plates 21,22 are then released by the gripper 25 and stored on the storage table 33. After storage of the plates, the swiveling unit 32 is swiveled back to the starting position, such that a plurality of plates can be delivered again.

[0111]Parts A) to F) of FIG. 6 show a schematic illustration of a delivery device 14 comprising two lateral conveyors 15, 15′, which are arranged one behind the other, du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com