Tundish flow control device for slab casting machine, preparation method thereof and slagging method using tundish flow control device

A slab continuous casting machine and tundish technology, applied in casting equipment, mechanical cleaning, manufacturing tools, etc., can solve the problems of prolonging the residence time of molten steel, increasing the amount of tundish injection, and unable to discharge steel slag regularly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

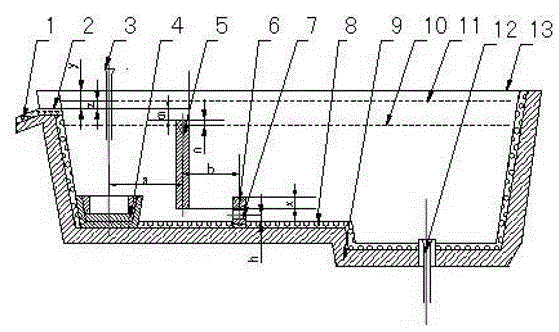

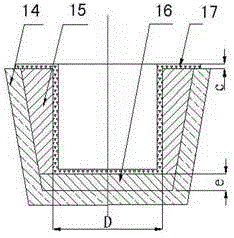

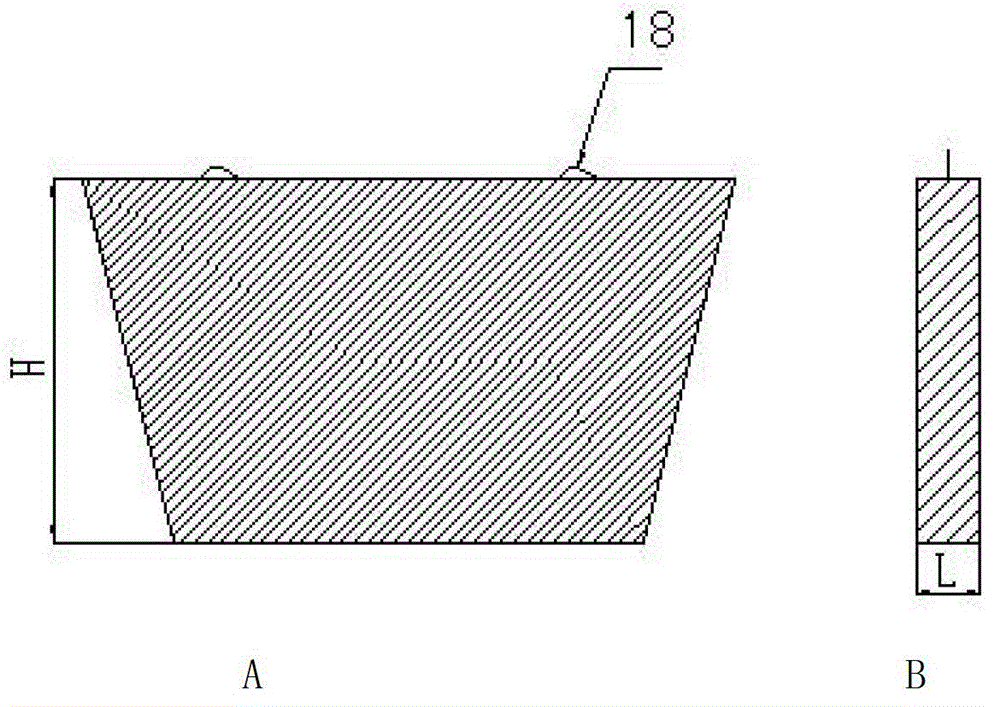

[0052] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a tundish flow control device for a slab continuous casting machine includes a turbulence controller 4, a slag retaining weir, and a slag retaining dam. Line coincides with the center line of the long nozzle of the ladle, the slag retaining weir is fixed on the working lining of the tundish wall, the slag retaining dam is fixed on the working lining of the tundish bottom, and the upper edge of the slag retaining weir 5 is higher than the normal pouring of the tundish The distance n of the highest liquid steel level 10 of the molten steel is 50 mm, and the distance m between the upper edge of the slag retaining weir 5 and the working surface of the smear material 1 of the tundish overflow port is 50 mm, and the slag retaining weir 5 and the slag retaining dam 6 are arranged alternately up and down The height x is 100mm, and there is a through hole at both ends of the slag retaining dam 6, the position of th...

Embodiment 2

[0063] A preparation method of the turbulence controller 4 as described in embodiment 1, comprising the following steps:

[0064] 1) Preparation of the turbulence controller housing 14. After weighing the constituent materials of the castable of the turbulence controller housing 14, add them into the mixer for dry mixing for 2 minutes, add 4.5% of the total weight of the materials in water, and wet mix for 6 minutes. After mixing, put it into the tire mold and vibrate it with a vibrating rod. When no large air bubbles emerge, the green body of the turbulence controller shell 14 is poured. Firing process: ①Raise the temperature from 0~135±15℃ at a heating rate of 10℃ / h to 135±15℃; ②keep at 135±15℃ for 12 hours; / h heating rate to 275±15℃; ④ heat preservation at 275±15℃, holding time 8h; 435±15°C heat preservation, heat preservation time 8h; ⑦ cease fire and natural cooling, cooling time 12h, the turbulence controller shell 14 is completed.

[0065] 2) Preparation of the turbu...

Embodiment 3

[0071] A slagging method utilizing the flow control device of the tundish of the slab continuous casting machine as described in embodiment 1, comprising the following steps:

[0072] 1) During normal production of continuous casting, the molten steel liquid level in the tundish is controlled below the maximum liquid steel level of the tundish normally poured by 10, and the upper edge of the slag retaining weir 5 is higher than the distance n of the maximum liquid steel level of the tundish normally poured by 10 50mm;

[0073] 2) When the tundish is discharging slag, raise the molten steel level in the tundish to the molten steel level 11 when the tundish is discharging slag, so that the distance z above the working surface of the coating material 1 at the overflow port of the tundish is 50mm. The steel slag in the ladle is discharged through the overflow port 2 of the tundish;

[0074] 3) After the tundish slag discharge is completed, lower the molten steel level in the tund...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lumen diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com