Flow control device for tundish of slab continuous caster and deslagging method thereof

A slab continuous casting machine and tundish technology, which is applied to casting equipment, casting melt containers, metal processing equipment, etc., can solve the problems of resistance to molten steel erosion, low service life, and poor scouring performance of impact pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

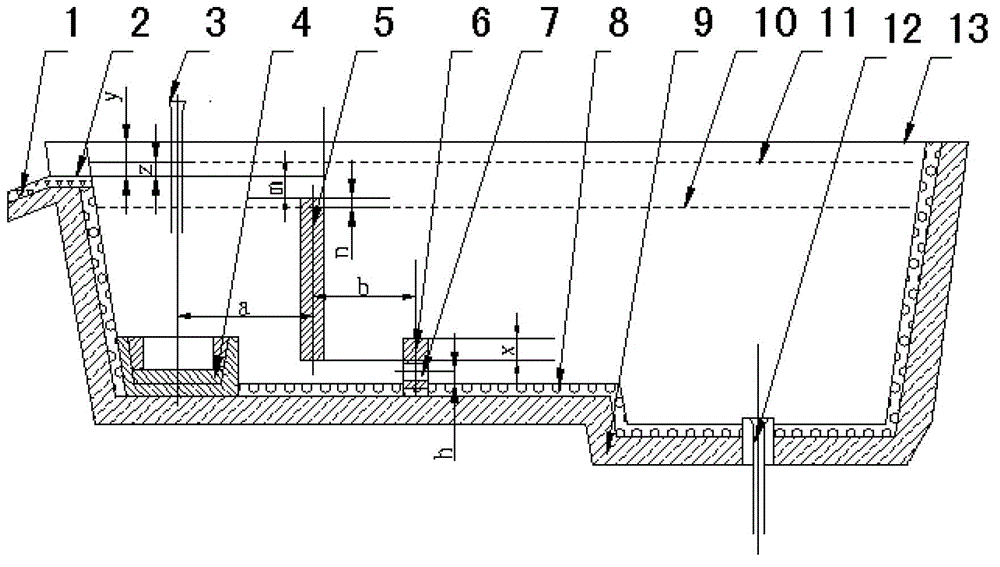

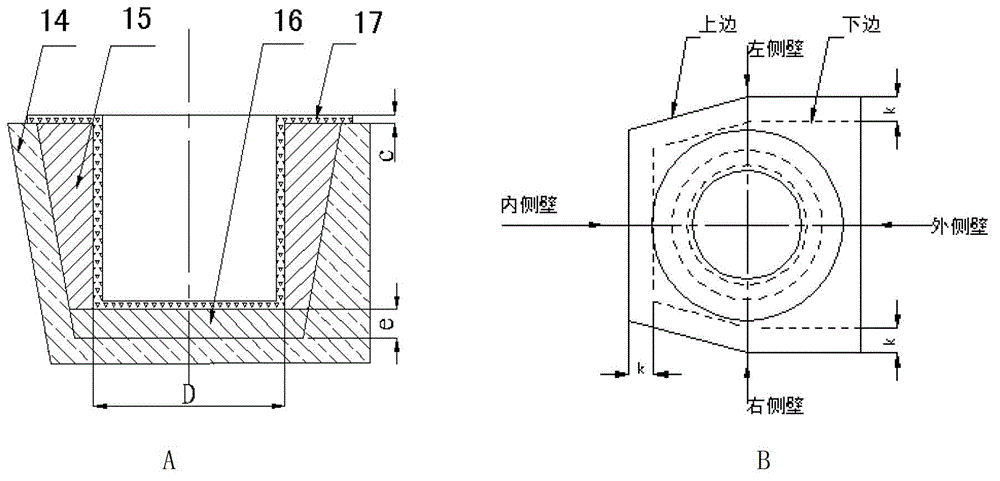

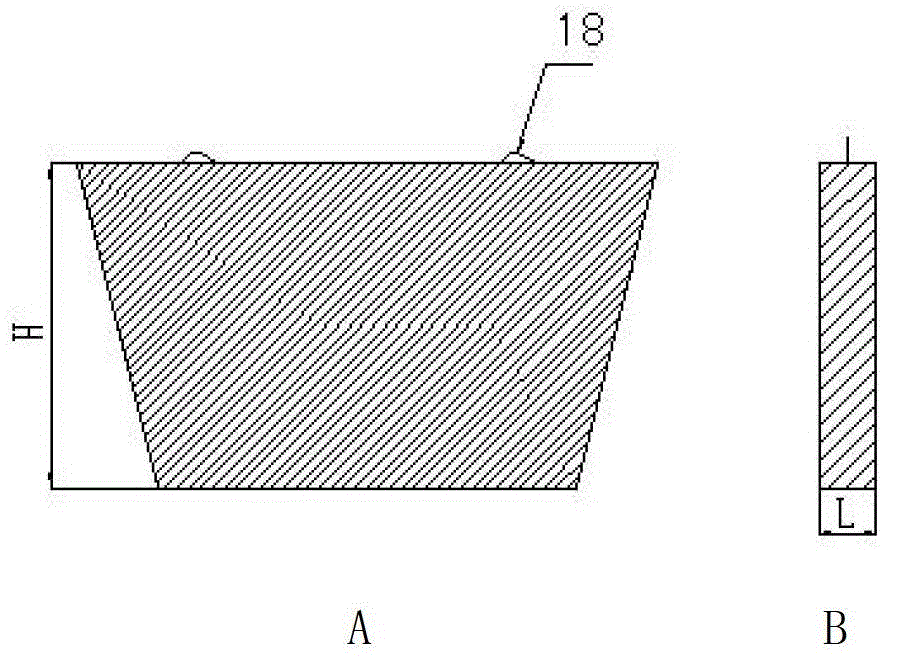

[0052] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a tundish flow control device for a slab continuous casting machine includes a turbulent flow controller 4, a slag retaining weir 5, and a slag retaining dam 6, and the turbulent flow controller 4 is installed on the working lining 8 of the tundish injection impact area. On the inner side, its center line coincides with the center line of the long nozzle 3 of the ladle, the slag retaining weir 5 is fixed on the working lining 8 of the tundish wall, and the slag retaining dam 6 is fixed on the working lining 8 of the tundish bottom. The distance n between the upper edge of the slag weir 5 and the maximum liquid steel level 10 of the tundish normally poured is 50 mm, and the distance m between the upper edge of the slag weir 5 and the working surface of the smear material 1 at the overflow port of the tundish is 50 mm . The staggered height x of the slag retaining weir 5 and the slag retaining dam 6 is 100 ...

Embodiment 2

[0075] Others are the same as embodiment 1, the difference is:

[0076] The distance n of the upper edge of the slag retaining weir 5 higher than the maximum liquid steel level 10 of the tundish normally poured is 20 mm, and the distance m of the upper edge of the slag retaining weir 5 lower than the working surface of the smear 1 of the tundish overflow port is 100 mm . The staggered height x of the slag retaining weir 5 and the slag retaining dam 6 is 200 mm. The through holes at both ends of the slag retaining dam 6 are located at 1 / 4 of the slag retaining dam, the diameter d is 50 mm, and the distance h between the center line of the through hole 7 and the working lining 8 at the bottom of the tundish is 40 mm. The center distance a between the slag retaining weir 5 and the turbulence controller 4 is 400 mm; the center distance b between the slag retaining dam 6 and the slag retaining weir 5 is 300 mm. The distance y between the working surface of the tundish overflow po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com